Isopropanolamine producing method

A technology of isopropanolamine and its production method, which is applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve problems such as side reactions, high energy consumption, and high energy consumption for evaporation and dehydration, and achieve reduction of by-products , Reduce equipment, save energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

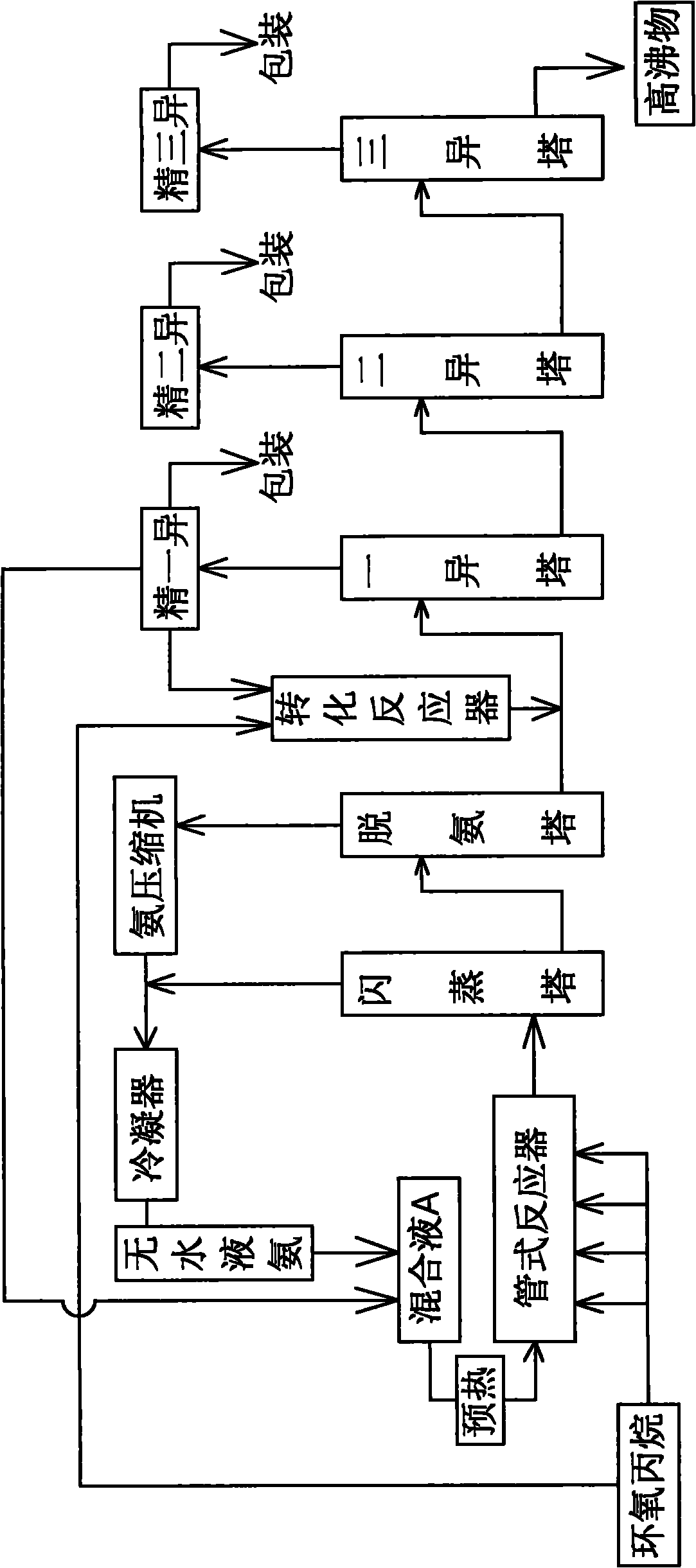

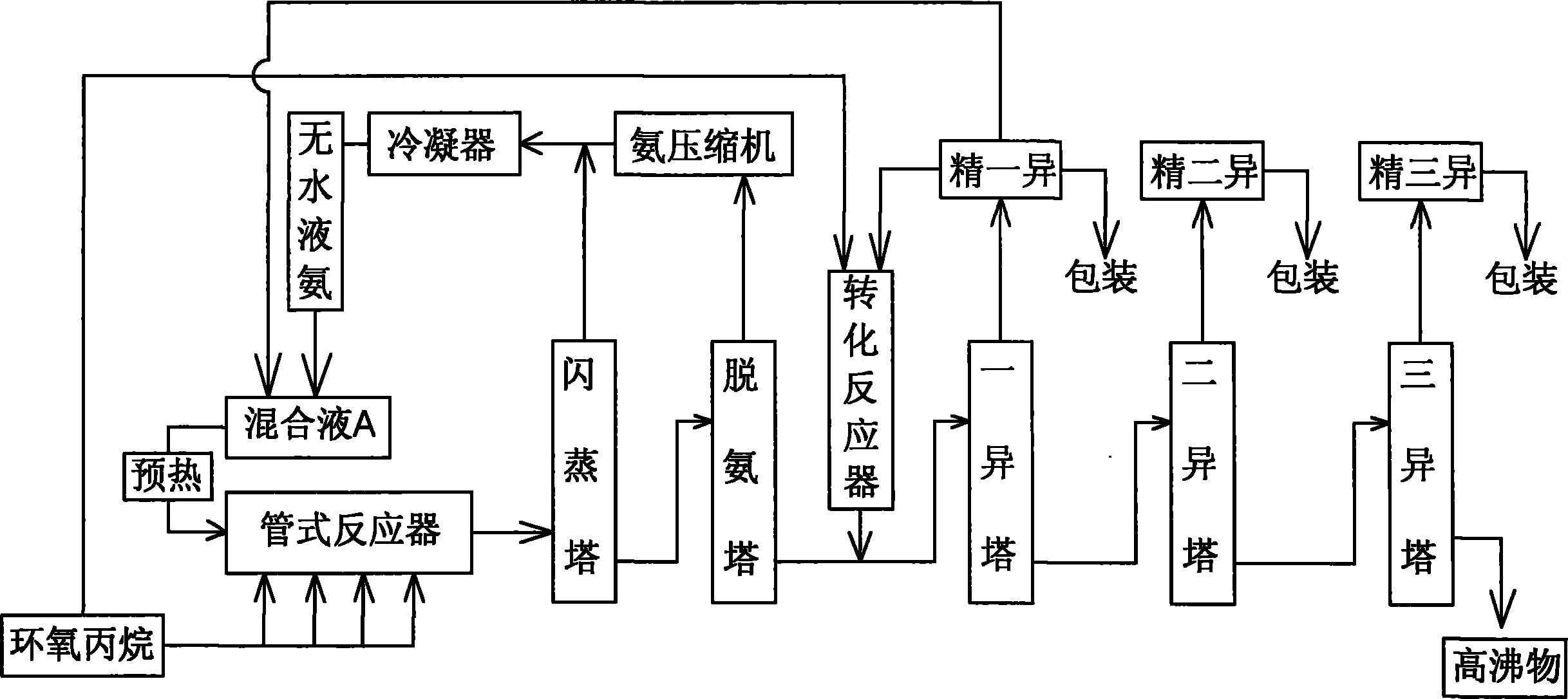

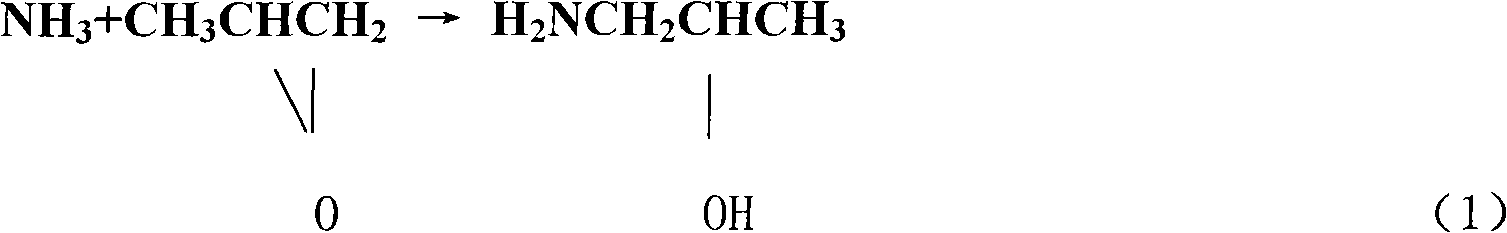

[0032] Embodiment 1: as figure 1 Shown, utilize aforementioned catalyst to produce the method for isopropanolamine, comprise tubular reaction, flash deamination and rectification, wherein tubular reaction is catalyzer with monoisopropanolamine, with anhydrous liquid ammonia and propylene oxide as Raw materials, with the multi-section tubular reactor as the production equipment, according to the speed of the mixed liquid A1 feed rate = 85kg / h, the total feed rate of propylene oxide = 58kg / h, to the tubular reactor under 11.0-20.0Mpa Feeding, wherein propylene oxide enters the tubular reactor in four sections, and the feed rate of each section of propylene oxide is 14.5kg / h; the mixed solution A1 is all pumped from the first section of the tubular reactor, and in the first After mixing with propylene oxide in the first-stage mixer, preheat to 100-130°C, and then enter each stage of reaction in turn. The reaction temperature of the four stages is controlled between 140-170°C, and...

Embodiment 2

[0039] Embodiment 2: Substitute A1 with A2, repeat above-mentioned embodiment 1, the obtained result has no substantial difference, omitted.

Embodiment 3

[0040] Embodiment 3: Substitute A1 with A3, repeat above-mentioned embodiment 1, the obtained result has no substantial difference, omitted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com