Near ultraviolet excited charge compensation type infrared light borophosphate luminescence material and preparation method thereof

A technology of charge compensation and borophosphate, applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of insufficient efficiency, wide application limitations, harsh synthesis conditions, etc., and achieve full reaction, high brightness, and low synthesis temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] A method for preparing a near-ultraviolet-excited charge-compensated red-light borophosphate luminescent material, comprising the following steps:

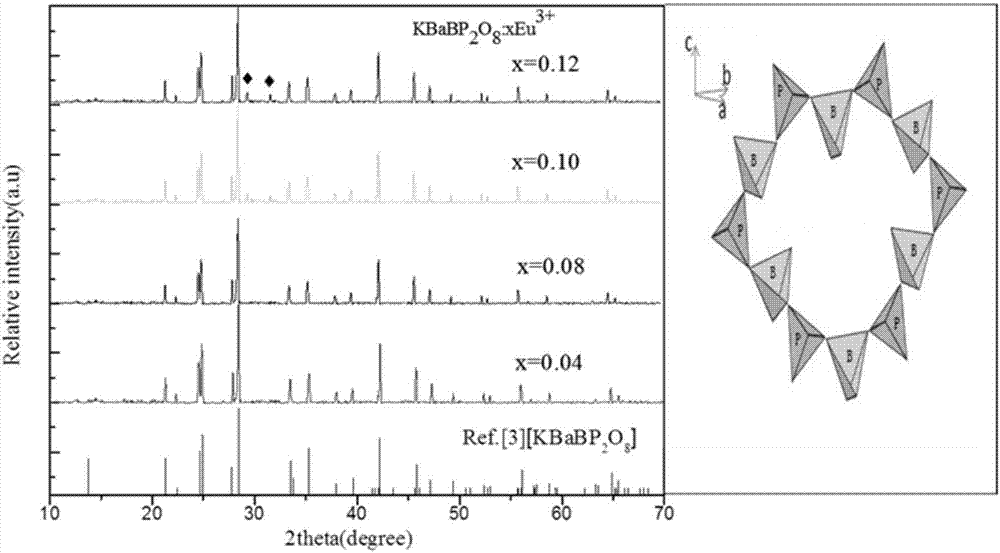

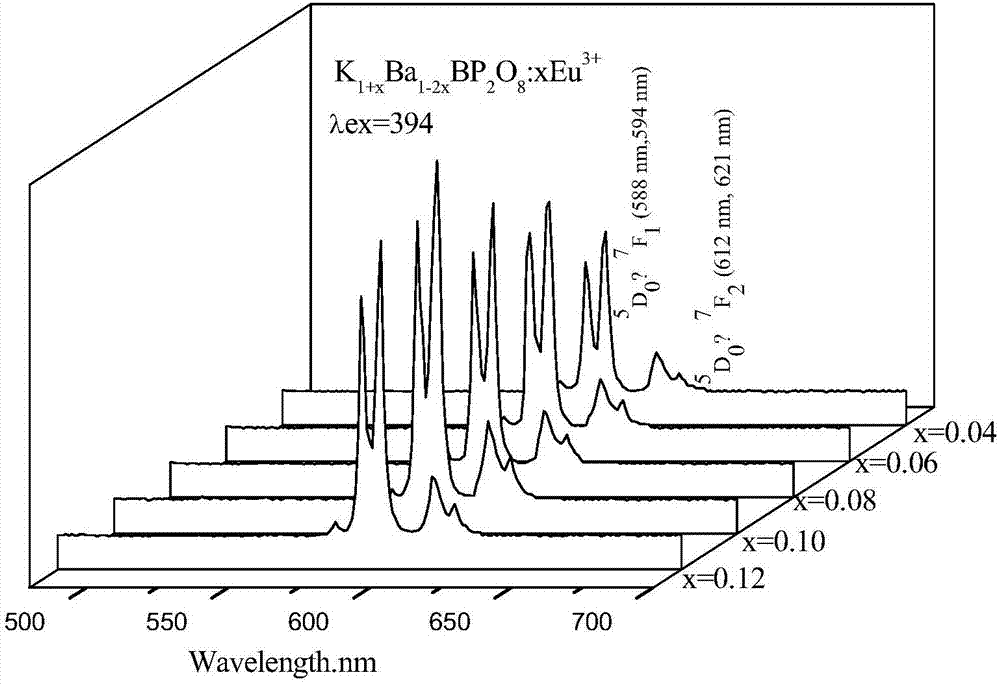

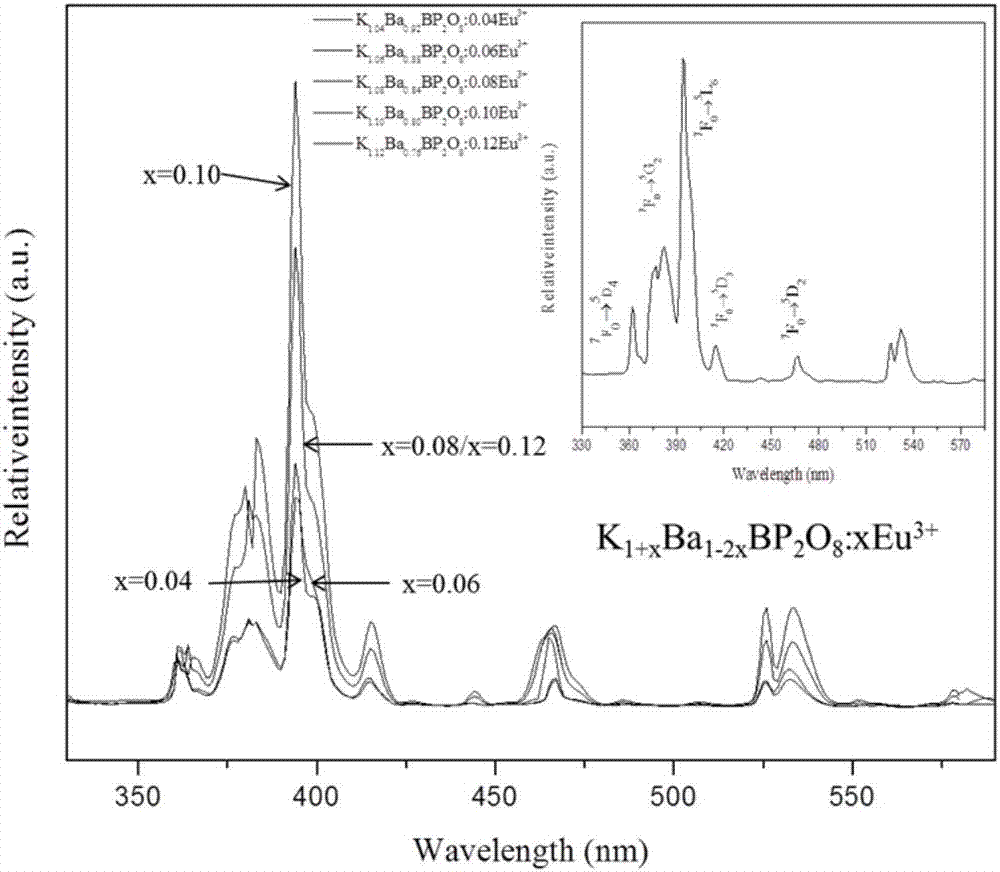

[0035] 1) According to the chemical composition K 1+x Ba 1-2x BP 2 o 8 :xEu 3+ , where Eu 3+ is the luminescence center, x=0.04~0.12. Weigh the raw material as K 2 CO 3 , BaCO 3 、H 3 BO 3 , NH 4 h 2 PO 4 、Eu 2 o 3 , and grind evenly to obtain a mixture;

[0036] 2) Heat the mixture to 600°C and hold it for 2 hours, then raise the temperature to 900°C at the same heating rate and hold it for 4 hours, then grind to obtain a near-ultraviolet-excited charge-compensated red-light borophosphate luminescent material.

[0037] or

[0038] 1) According to the chemical composition K 1+x Ba 1-2x BP 2 o 8 :xEu 3+ ,F - , where Eu 3+ is the luminescence center, x=0.04~0.12, the raw material is weighed as K 2 CO 3 、BaCO 3 、H 3 BO 3 , NH 4 h 2 PO 4 、Eu 2 o 3 and KF, and grind evenly to obtain the mixture; ...

Embodiment 1

[0045] 1) According to the chemical composition K 1+x Ba 1-2x BP 2 o 8 :xEu 3+ (x=0.04); accurately weigh K 2 CO 3 0.3657g, BaCO 3 0.8668g, (NH 4 ) 2 HPO 4 0.5745g, H 3 BO 3 0.3090g, Eu 2 o 3 0.0704g, and placed in an agate mortar, ground for 1h to make it uniform;

[0046] 2) Using a high-temperature solid-phase method, place the above-mentioned pretreated mixed solid powder in a corundum crucible, raise the temperature to 600° C. in an air atmosphere, and keep it warm for 2 hours. Then, the temperature was raised to 900° C. for 4 hours at the same heating rate. The system is naturally cooled to room temperature with the temperature of the furnace, and the final product is obtained through further grinding.

Embodiment 2

[0048] 1) According to the chemical composition K 1+x Ba 1-2x BP 2 o 8 :xEu 3+ (x=0.06); accurately weigh K 2 CO 3 0.3726g, BaCO 3 0.8274g, (NH 4 ) 2 HPO 4 0.5745g, H 3 BO 3 0.3090g, Eu 2 o 3 0.1056g, and placed in an agate mortar, ground for 1h to make it uniform;

[0049] 2) Using a high-temperature solid-phase method, place the pretreated mixed solid powder in a corundum crucible, raise the temperature to 600° C. in an air atmosphere, and keep it warm for 2 hours. Then, the temperature was raised to 900° C. for 4 hours at the same heating rate. The system is naturally cooled to room temperature with the temperature of the furnace, and the final product is obtained through further grinding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com