Preparation method of Mg-contained hydrogen storage alloy

A technology for hydrogen storage alloy and preparation process, which is applied to the preparation field of Mg-containing hydrogen storage alloy, can solve problems such as unfavorable large-scale production, increased raw material loss and oxidation, unstable electrode alloy composition, etc., and achieves high controllability of the production process. , the batch stability is improved, and the effect of large-scale production is realized.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

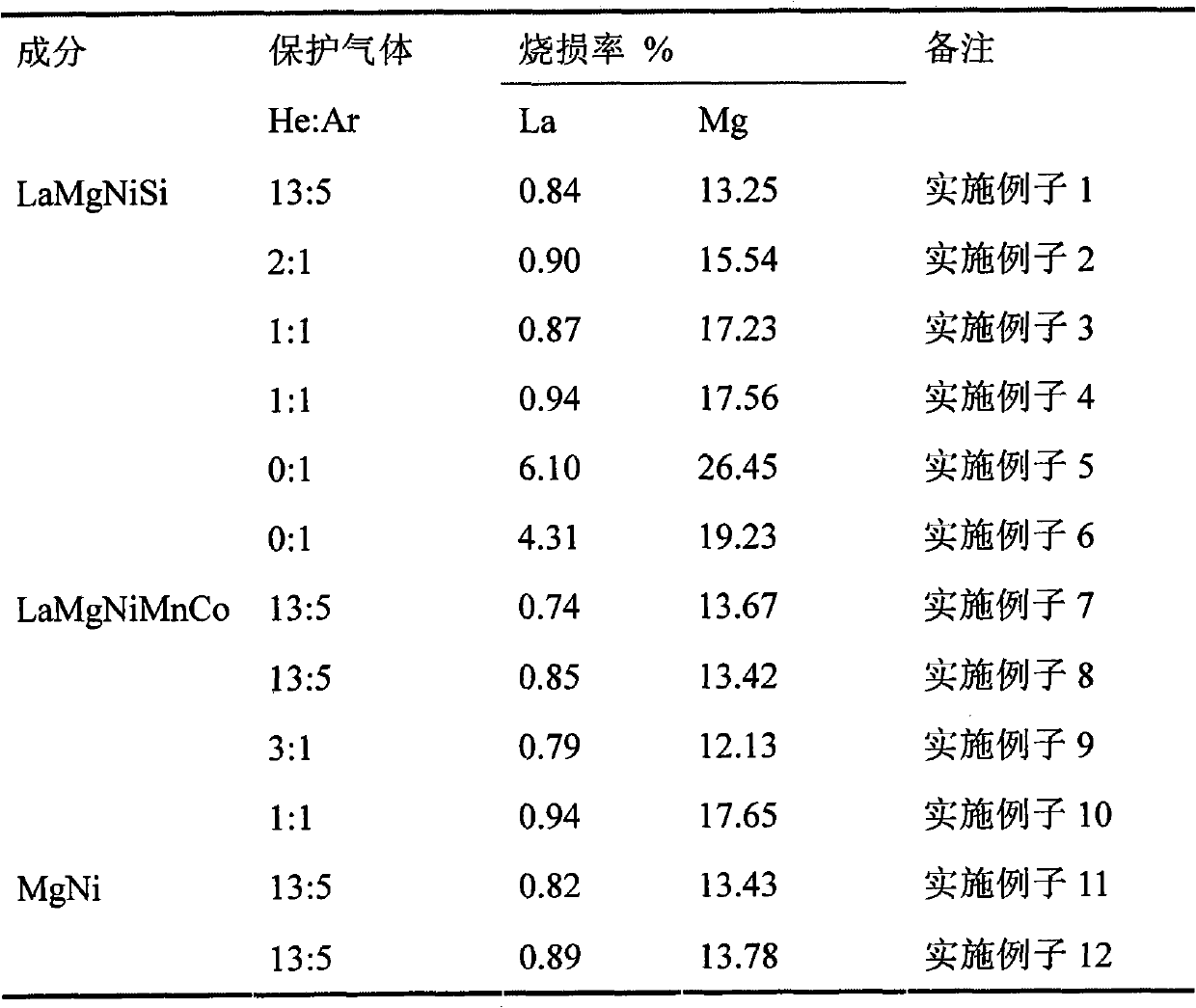

Embodiment 1

[0015] carry out La 0.73 Mg 0.27 Ni 3.43 Si 0.07 For the smelting of hydrogen storage alloys, raw metals with a purity of 99.9% are selected, weighed according to the stoichiometric ratio, and the bulk raw materials of La, Mg, Ni, and Si with a mass of 325.0g, 21.4g, 647.5g, and 6.9g are smelted . First place the Mg block on the furnace feeding device, put other metals into the furnace crucible; vacuumize to a vacuum degree of 10 -2 After Pa, fill the protective gas with the ratio of He:Ar=13:5 to 0.04MPa; adjust the power of the intermediate frequency induction melting furnace to 25kW, and control the temperature at about 1050°C. After the metal in the crucible is completely melted, stop the power supply for 2 minutes , Put the Mg block into the molten metal, continue to energize, control the power at 20kW, control the temperature at about 1000°C, smelt for 1.5min, stop energizing, and cast. After cooling for 15 minutes, take out the ingot. Put the cast ingot into a hea...

Embodiment 2

[0018] carry out La 0.73 Mg 0.27 Ni 3.4 Si 0.1 For the smelting of hydrogen storage alloys, raw metals with a purity of 99.9% are selected, weighed according to the stoichiometric ratio, and smelted in blocks of La, Mg, Ni, and Si with masses of 329.0g, 21.5g, 648.0g, and 9.4g, respectively. First put the Mg block on the charging device in the furnace, and put other metals into the crucible in the furnace. Vacuum down to a vacuum of 10 -2 After Pa, fill the protective gas with the ratio of He:Ar=2:1 to 0.01MPa; adjust the power of the intermediate frequency induction melting furnace to 15kW, and control the temperature at 600°C. After the metal in the crucible is completely melted, stop the power supply for 1min. Put the Mg block into the molten metal, continue to energize, control the power at 15kW, control the temperature at 600°C, smelt for 1min, stop energizing, and cast. After cooling for 15 minutes, take out the ingot. Put the cast ingot into a heat treatment furna...

Embodiment 3

[0021] carry out La 0.73 Mg 0.27 Ni 3.9 Si 0.1 For the smelting of hydrogen storage alloys, raw metals with a purity of 99.9% are selected, weighed according to the stoichiometric ratio, and the bulk raw materials of La, Mg, Ni, and Si with masses of 328g, 21.7g, 745g, and 8.6g are smelted. First put the Mg block on the charging device in the furnace, and put other metals into the crucible in the furnace. Vacuum down to a vacuum of 10 -2 After Pa, fill the protective gas with the ratio of He:Ar=1:1 to 0.02MPa; adjust the power of the intermediate frequency induction melting furnace to 20kW, and control the temperature at 700°C. After the metal in the crucible is completely melted, stop the power supply for 3min. Put the Mg block into the molten metal, continue to energize, control the power at 20kW, control the temperature at 700°C, smelt for 2min, stop energizing, and cast. After cooling for 15 minutes, take out the ingot. Put the cast ingot into a heat treatment furnac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com