Method for forming full pulp by processing bobbin paper waste pulp residues and producing protoplasm by using formed full pulp

A bobbin paper and pulping technology, which is applied in the field of pulp manufacturing, can solve the problems affecting the quality of the bobbin paper finished product, cannot be better cleaned, and the fiber binding force is reduced, and achieves high circumferential pressure, easy control, and layering. The effect of strong bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Example 1 A method of treating bobbin paper waste into pulp

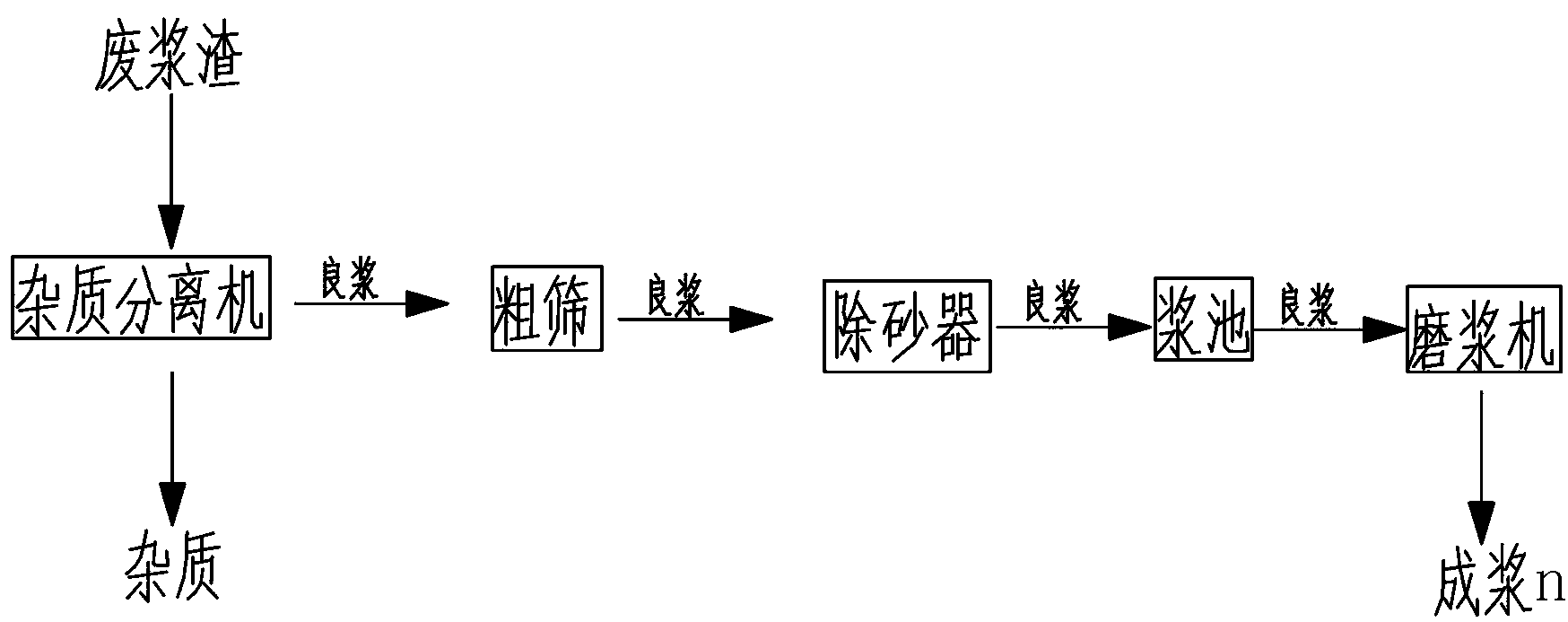

[0057] like figure 1 As shown, the preparation method of slurry n1 in this embodiment is carried out in sequence according to the following steps:

[0058] (n11) removal of impurities

[0059] Pass the waste slurry through the impurity separator to remove foam, plastic and other light impurity components to obtain A1;

[0060] Send A1 into a coarse sieve with a sieve width of 0.22mm, remove impurities and send it into a desander, after removing sand, the slurry enters the slurry tank to obtain B1;

[0061] (n12) heating up

[0062] Raise the temperature of B1 to 90°C and keep it warm for 4 minutes to obtain C1;

[0063] (n13) Refining

[0064] C is sent to the refiner for beating. The disc speed of the refiner is 750rpm. The material of the disc is high chromium alloy steel. Then get into slurry n1.

[0065] After the waste pulp slag in this embodiment goes through the heating process, the lignin con...

Embodiment 2-4

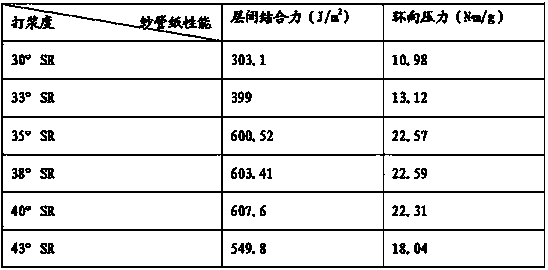

[0067] Embodiment 2-4 The method for processing bobbin paper waste pulp slag into pulp

[0068] Embodiments 2-4 respectively provide a method for treating bobbin paper waste slag into sizing n2-n4, and their steps are the same as in embodiment 1, the only difference is that the corresponding technologies involved in each method The parameters are different, see the table below for details.

[0069]

[0070] The fibers in the pulping n2-n4 provided by the above examples have high specific surface area, good brooming performance, and strong bonding force between fibers. The preparation method is simple, easy to control, less equipment investment, and short production cycle. The pulp slag turns waste into treasure, saves resources, can prepare raw pulp for bobbin paper production, and can reduce the production cost of bobbin paper raw pulp.

Embodiment 5

[0071] Example 5 A method of producing bobbin paper raw pulp by using bobbin paper waste slag to sizing

[0072] This embodiment is a method for producing bobbin paper raw pulp by using pulp n1-n4 treated with waste pulp residue of bobbin paper. The pulp m5 is mixed according to the weight ratio of 1:4. in:

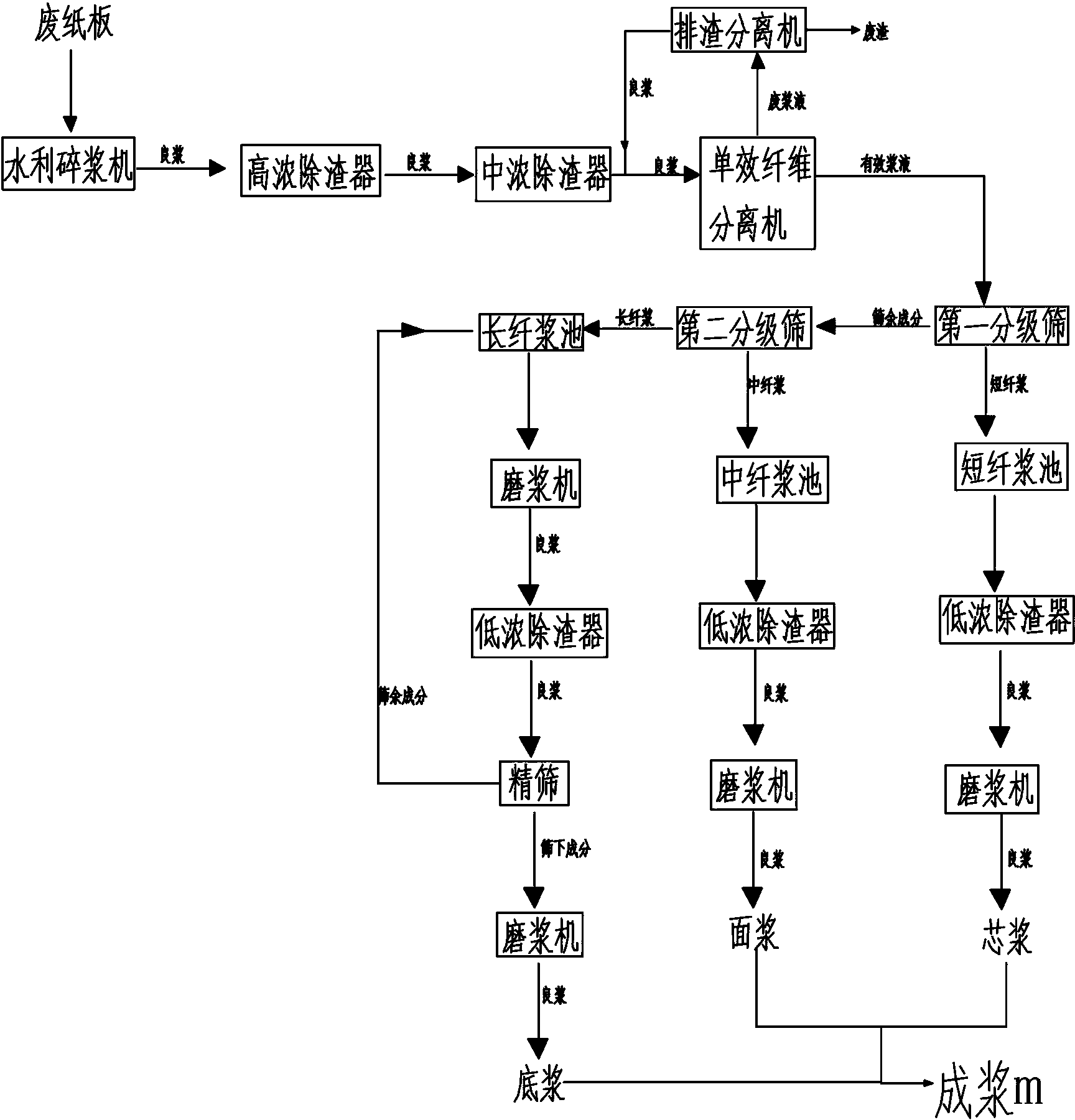

[0073] like figure 2 As shown, the preparation method of slurry m5 is carried out according to the following steps:

[0074] (m51) Pulping

[0075] After the waste cardboard is pulped by a hydraulic pulper, D5 is obtained;

[0076] (m52) removal of impurities

[0077] D5 passes through the high-concentration slag remover and the medium-concentration slag remover to remove the pulp slag in the slurry to obtain E5;

[0078] (m53) Fiber Separation

[0079] E5 is sent to the single-effect fiber separator for fiber separation, and the effective slurry F5 is separated. After the effective slurry, E5, enters the fiber separator, the fiber is crushed by the blade and de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com