Method for preparing organic montmorillonite/polyurethane self-repair coating

A technology of organic montmorillonite and polyurethane, applied in polyurea/polyurethane coatings, anti-corrosion coatings, dyed low-molecular organic compound treatment, etc., to achieve good penetration of corrosive media, reduce coating defects, and hinder the penetration of corrosive media Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

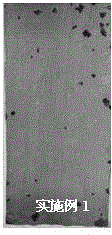

Embodiment 1

[0027] (2) Take 60 parts of hydroxyl resin, 0.5 parts of organic montmorillonite, 37.5 parts of mixed solvent, and 2 parts of additives, put them into a high-speed ball mill and mix them evenly to obtain organic montmorillonite / hydroxy resin, and then mix the modified hydroxyl resin with curing agent The organic montmorillonite / polyurethane coating is prepared by mixing according to the mass ratio of 100:36, and the organic montmorillonite / polyurethane coating is formed after drying and curing.

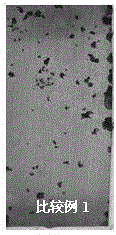

[0028] Comparative example 2

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com