Molybdenum-vanadium based composite oxide catalyst and preparation and application thereof

A technology of composite oxides and catalysts, applied in the direction of metal/metal oxide/metal hydroxide catalysts, preparation of organic compounds, physical/chemical process catalysts, etc., can solve the problems of difficult handling, low atom economy, and cost Low potential and other problems, to achieve low cost, improved atom economy, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

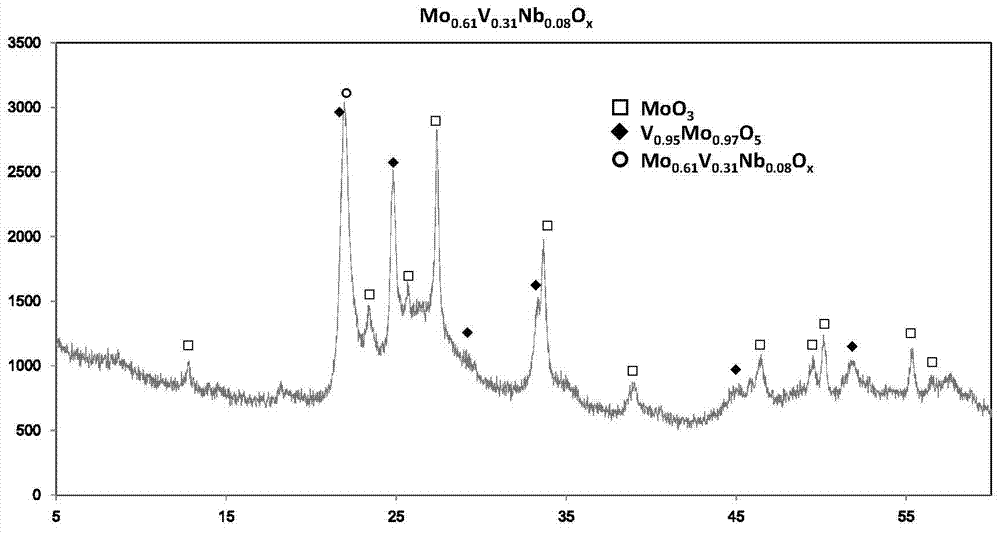

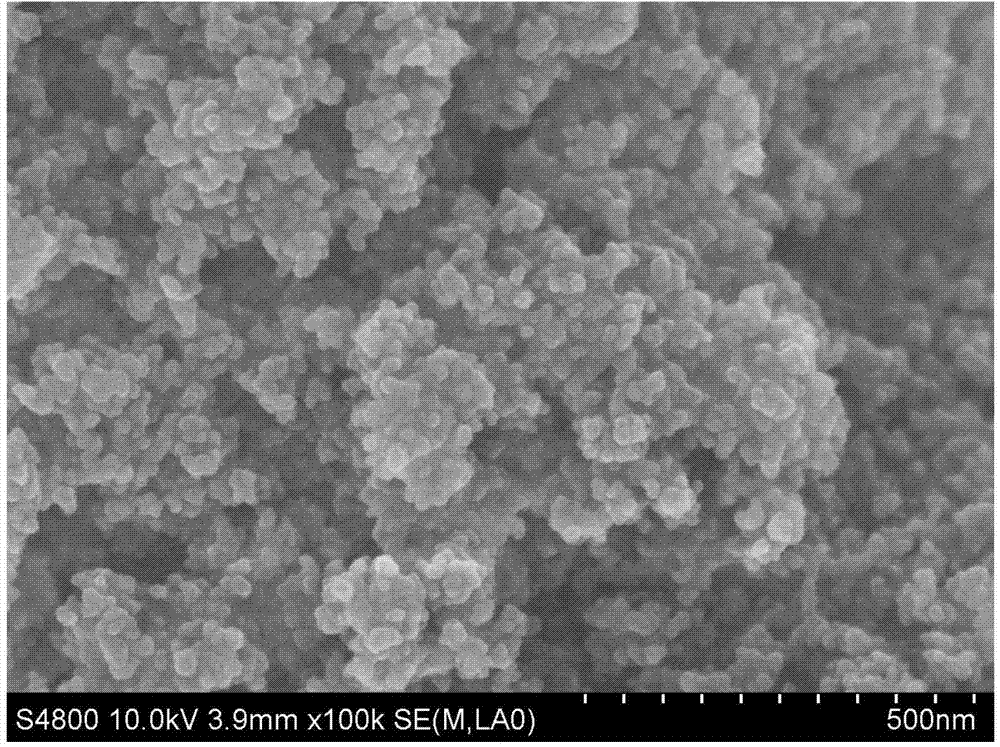

[0032] Preparation of molybdenum vanadium niobium catalyst: Dissolve 3.63g ammonium metavanadate and 7.2g oxalic acid in 25ml ultrapure water, take 10.77g ammonium paramolybdate and dissolve it in 25ml ultrapure water. Mix the solution dissolved in ultrapure water evenly, and heat it to 50°C, take 2.42g of ammonium niobate oxalate hydrate and dissolve it in 25ml of ultrapure water, add it dropwise to the mixed solution, and stir under vacuum at 80°C until the solvent evaporated completely. Dry overnight at 120°C, followed by calcination at 400°C for 4 hours in a dry air atmosphere with an air flow rate set at 100 ml / min. The obtained solid powder is Mo 1 V 0.51 Nb 0.13 o x catalyst.

[0033] The process of synthesizing pyruvic acid: In the fixed bed reactor, load the above 0.5g molybdenum vanadium niobium composite oxide catalyst, use 0.5g quartz sand to dilute, reactants are fed continuously, and the mass space velocity is 2.4h -1 , the air flow rate is 150ml / min, the m...

Embodiment 2

[0035] Preparation of molybdenum vanadium niobium catalyst: Dissolve 3.63g ammonium metavanadate and 7.2g oxalic acid in 25ml ultrapure water, take 10.77g ammonium paramolybdate and dissolve it in 25ml ultrapure water. The solution dissolved in ultrapure water was mixed evenly, and heated to 50°C, 0.89g of antimony oxide was dispersed in 50ml of oxalic acid aqueous solution, added dropwise to the mixed solution, and stirred in vacuum at 80°C until the solvent evaporated completely. Dry overnight at 120°C, followed by calcination at 400°C for 4 hours in a dry air atmosphere with an air flow rate set at 100 ml / min. The obtained solid powder is Mo 1 V 0.51 Sb 0.1 o x catalyst.

[0036] The process of synthesizing pyruvic acid: In the fixed bed reactor, load the above 0.5g molybdenum vanadium niobium composite oxide catalyst, use 0.5g quartz sand to dilute, reactants are fed continuously, and the mass space velocity is 2.4h -1 , the air flow rate is 150ml / min, the molar ratio...

Embodiment 3

[0038]Preparation of molybdenum vanadium niobium catalyst: Dissolve 2.42g ammonium metavanadate and 5g oxalic acid in 25ml ultrapure water, and dissolve 10.77g ammonium paramolybdate in 25ml ultrapure water. Mix the solution in ultrapure water evenly, and heat it to 50°C, dissolve 2.42g of ammonium niobate oxalate hydrate in 25ml of ultrapure water, add it dropwise to the mixed solution, and stir in vacuum at 80°C until The solvent evaporated completely. Dry overnight at 120°C, followed by calcination at 400°C for 4 hours in a dry air atmosphere with an air flow rate set at 100 ml / min. The obtained solid powder is Mo 1 V 0.34 Nb 0.13 o x catalyst.

[0039] The process of synthesizing pyruvic acid: In the fixed bed reactor, load the above-mentioned 0.5g molybdenum vanadium niobium composite oxide catalyst, use 0.5g quartz sand to dilute, reactants are fed continuously, and the mass space velocity is 2.4h -1 , the air flow rate is 150ml / min, the molar ratio of oxygen in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com