Feeding device and method of stepping beam heating furnace transmission

A feeding device and heating furnace technology, applied in the field of mechanical processing, can solve the problems of increasing maintenance workload and increasing equipment maintenance costs, and achieve the effects of low production cost, convenient maintenance and strong reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

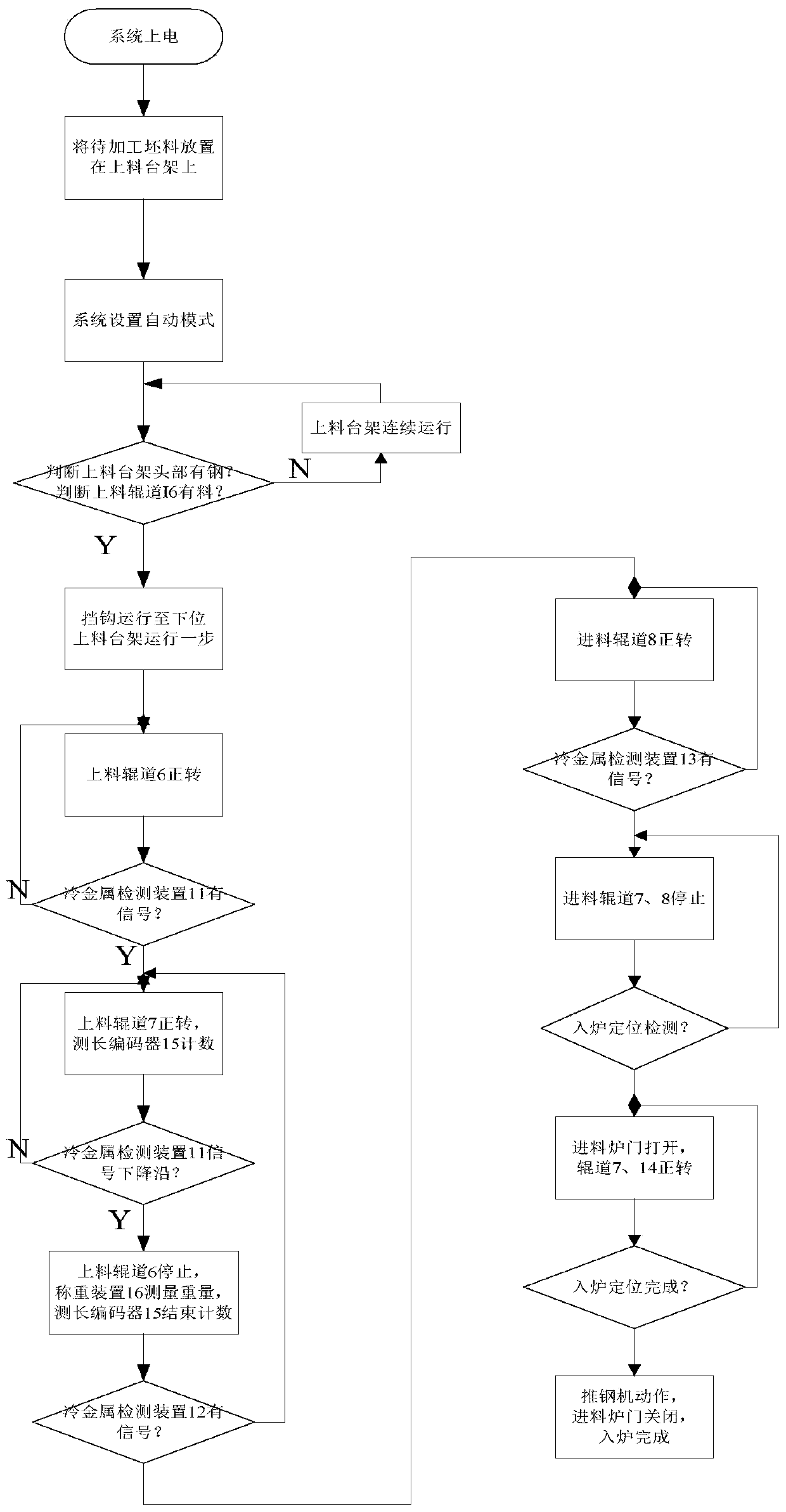

[0035] The present invention will be further described below in conjunction with accompanying drawing.

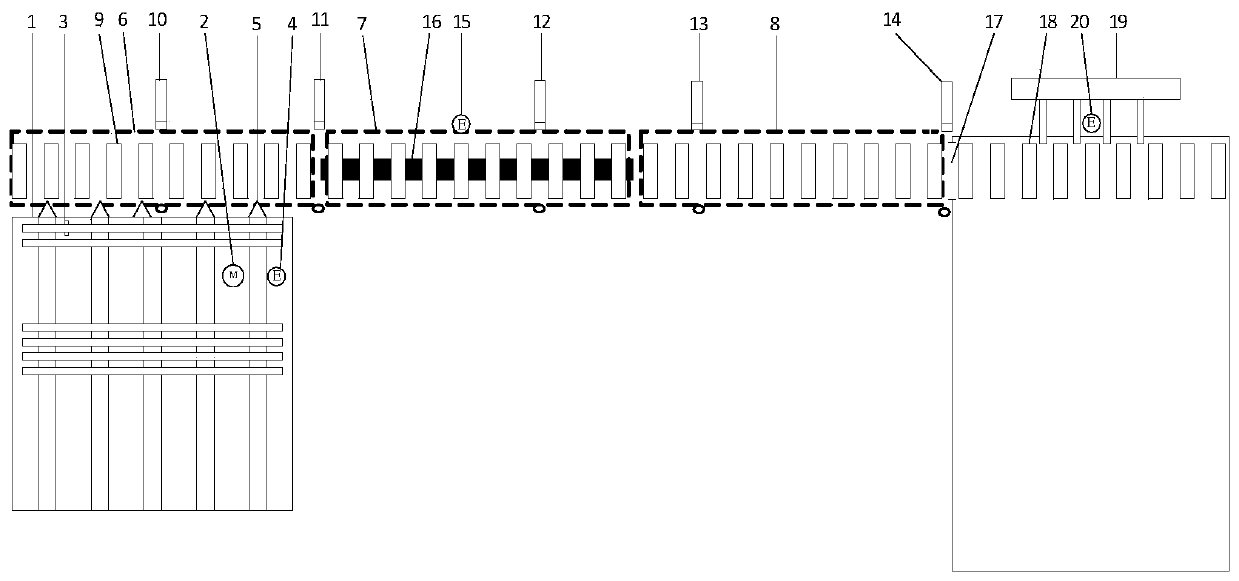

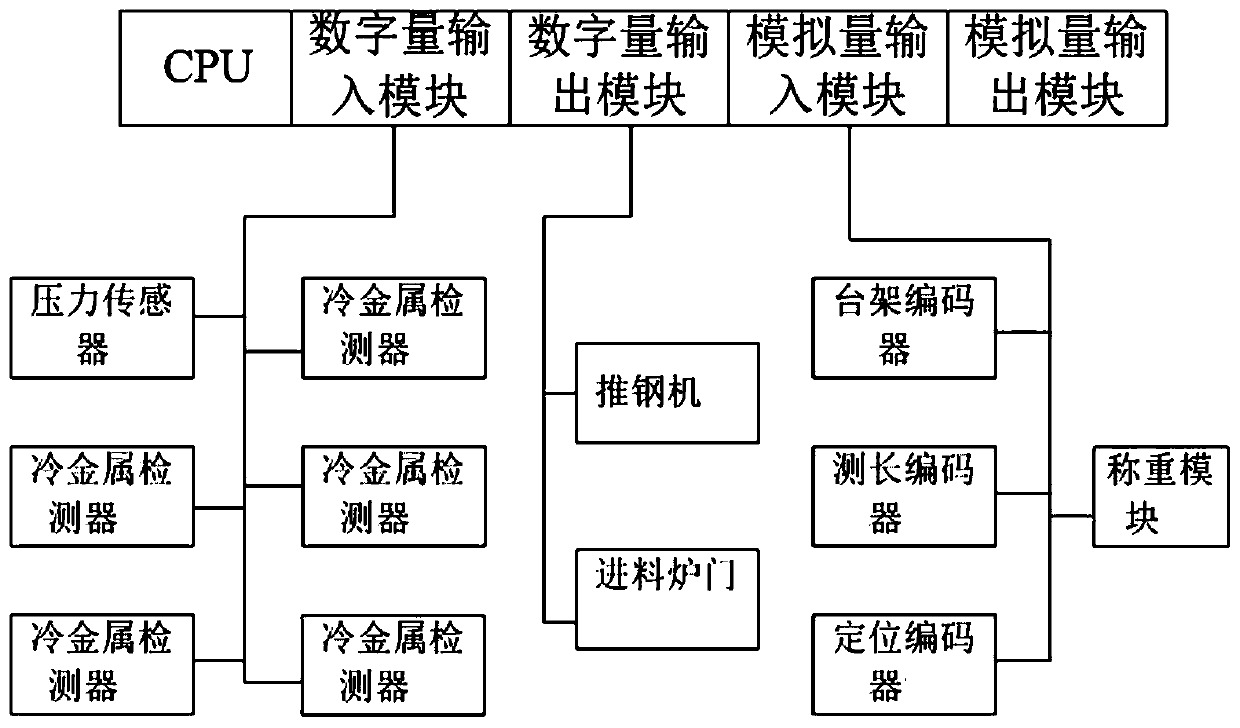

[0036] Such as figure 1 As shown, a kind of walking beam heating furnace transmission feeding device proposed by the present invention includes a feeding platform mechanism, a feeding roller table device, a furnace entering device and a PLC control unit;

[0037] The feeding platform mechanism includes a main body part 1 of the loading platform, a motor 2 of the loading platform, a pressure sensor 3, an encoder 4 of the loading platform, and a retaining hook 5; the main part of the loading platform 1 includes The movable mechanical arm and the fixed steel structure, the movable mechanical arm is driven by the motor 2 of the loading platform, and performs reciprocating motion, and the fixed steel structure supports the blank; the pressure sensor 3 is located at the end of the main part 1 of the loading platform to detect the position of the blank; the loading table The fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com