Semi-conductive paper and its preparation method and overall shielding structure of multi-winding current transformer

A semi-conductive, integral technology, applied in inductors, preventing/reducing unwanted electromagnetic/magnetic effects, paper, etc., can solve problems such as decreased physical strength of paper, increased oil resistance of paper, affecting paper forming, etc. Improved physical index, good mechanical strength, overcoming the effect of difficult forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1, the preparation of modified anionic starch of the present invention

[0040] Described modified anionic starch is made by following steps:

[0041] S1. Acid hydrolysis: Mix cornstarch and 8% hydrochloric acid solution at a ratio of 1:2, stir to obtain a starch polysaccharide solution, place the above starch polysaccharide solution in a constant temperature water bath at 45°C for 2 hours, and continue stirring during the reaction process. Stirring speed is 2000rpm;

[0042] S2. Cross-linking: Add soybean oil, sodium hydroxide solution, Span-80 and epichlorohydrin to the starch polysaccharide solution after the above-mentioned acid hydrolysis treatment, stir and mix, wherein, soybean oil, sodium hydroxide solution, Span-80 The weight ratio of 80 and epichlorohydrin is 1:1:0.5:0.8;

[0043] S3. Anionization: Add ethanol solution, monochloroacetic acid, sodium hydroxide solution, and starch polysaccharide solution treated in the above S2 step into the reacto...

Embodiment 2

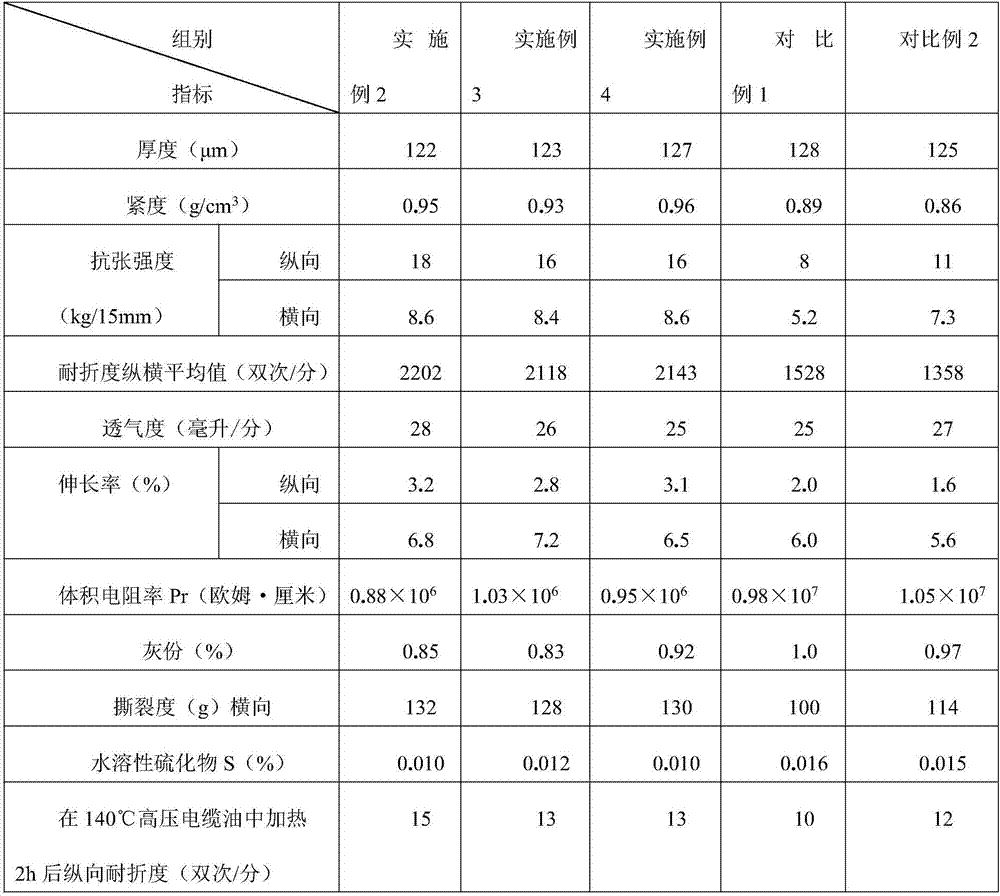

[0045] Embodiment 2, a kind of semiconductive paper

[0046] The semiconductive paper described in Example 2 of the present invention consists of the following components in parts by weight: 85 parts of unbleached kraft softwood pulp, 20 parts of acetylene black, 3 parts of magnesium borate whiskers, the improved 2 parts of anionic starch and 25 parts of 5% ethanol solution.

[0047] Preparation:

[0048] Soak acetylene black in 5% ethanol solution and set aside; add purified water to the unbleached kraft softwood pulp and soak for 20 minutes, move it into a beater for thawing, add the above-mentioned acetylene black, and beat; beat until the pulp is knocked down to 26 degrees Add magnesium borate whiskers, continue beating until the slurry has a beating degree of 38 degrees, add modified anionic starch, and use a double-cylinder double-drum paper machine to make paper.

Embodiment 3

[0049] Embodiment 3, a kind of semiconductive paper

[0050] The semiconductive paper described in Example 3 of the present invention is composed of the following components in parts by weight: 65 parts of unbleached kraft softwood pulp, 15 parts of acetylene black, 2 parts of magnesium borate whiskers, the improved 1 part of permanent anionic starch and 20 parts of 3% ethanol solution.

[0051] The preparation method is as in Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com