A functional filler additive used in the field of papermaking

A technology of functional fillers and filler additives, which is applied in the field of functional filler additives in the field of papermaking, and can solve the problem of not being able to meet the requirements of technological progress in the papermaking industry for product replacement, professional production has not yet been formed, and there are not many varieties, etc. problems, to achieve the effect of saving drying steam, alleviating processing burden and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

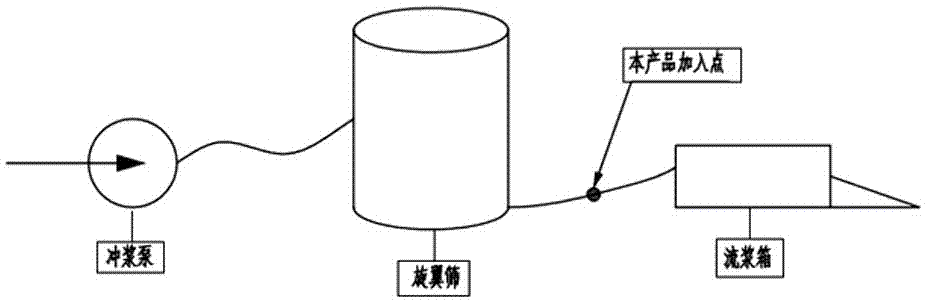

Image

Examples

Embodiment Construction

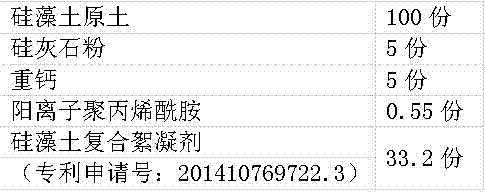

[0027] Put 100 parts of diatomite raw soil (water content 50%) produced in Ma'anshan Village, Changbai County, 5 parts of wollastonite powder, 5 parts of heavy calcium, and 0.55 parts of cationic polyacrylamide into a kneader, and use a speed of less than 1000r / min Stir at a rotating speed of less than 1 hour to fully mix the materials; put the mixed materials into the dryer, and dry them at a temperature of 50°C~80°C for 2 hours to dry the materials, and put the dried materials into the pulverizer In the process, pulverize at a speed of 10000r / min or less for 5s, then add diatomite composite flocculant (patent application number: 201410769722.3) in the above ratio after pulverization, put it into a kneader and stir at a speed of 1000r / min or less for 1 hour or less, Mix the materials evenly, weigh them, and pack them to get the finished product.

[0028] The preparation method of the above-mentioned diatomite composite flocculant (patent application number: 201410769722.3) is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com