Water mist spraying device of air splicer

A technology of water mist spraying and water storage devices, which is applied in jointing devices, spinning machines, textiles and papermaking, etc., can solve the problems of poor evenness and poor physical indexes, and achieve the goal of improving strength, improving physical indexes, and improving atomization effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

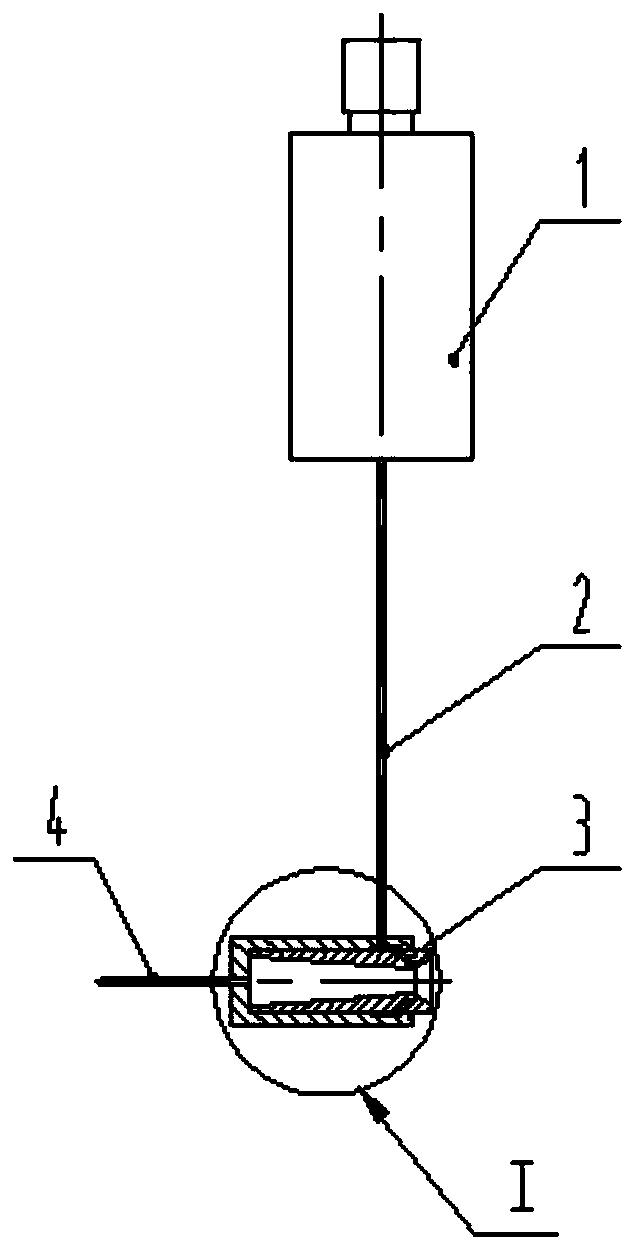

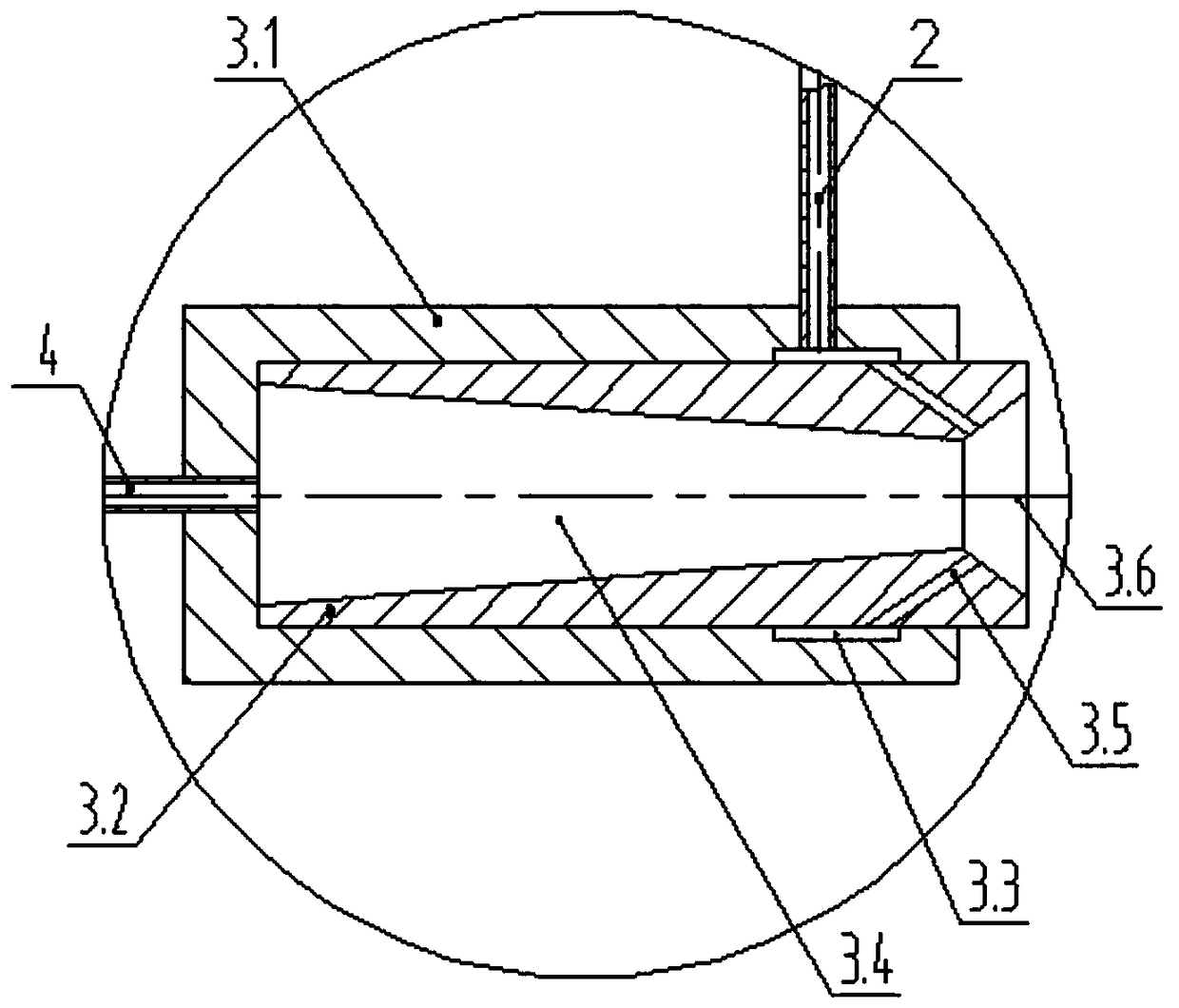

[0013] The water mist injection device of the air splicing machine shown in the accompanying drawings includes a water storage device 1, a water delivery pipe 2, an air delivery pipe 4, and a nozzle 3. In this embodiment, the water storage device 1 is a bucket; the nozzle 3 includes an outer jacket 3.1, an inner sleeve 3.2; the central axis of the inner sleeve 3.2 is placed flat, and a through hole 3.4 is provided with the central axis. In this embodiment, the through hole 3.4 is a tapered hole with a large left and a small right (in other embodiments, the through hole 3.4 is a cylindrical through hole hole), the right end of the through hole 3.4 expands to the right end surface of the inner sleeve 3.2 to form the right horn hole 3.6; the central axis of the outer sleeve 3.1 is flat, and there is a blind hole with the central axis flat a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com