Corrugated paper board production line

A corrugated cardboard and production line technology, applied in the direction of mechanical processing/deformation, etc., can solve the problems of increasing production costs, back pressure interference, resource waste, etc., and achieve the effect of improving physical indicators, good edge pressure and burst resistance data, and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

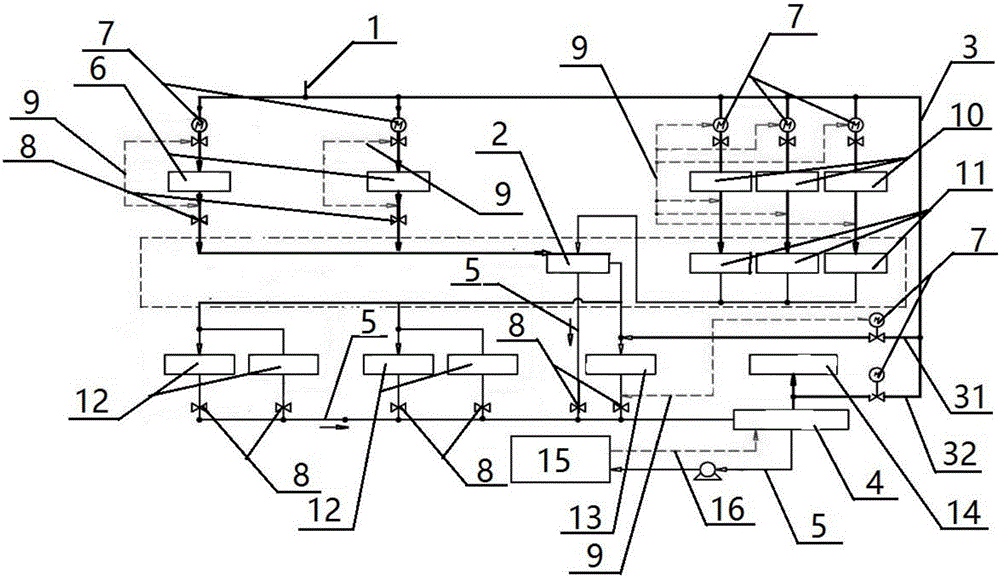

[0037] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

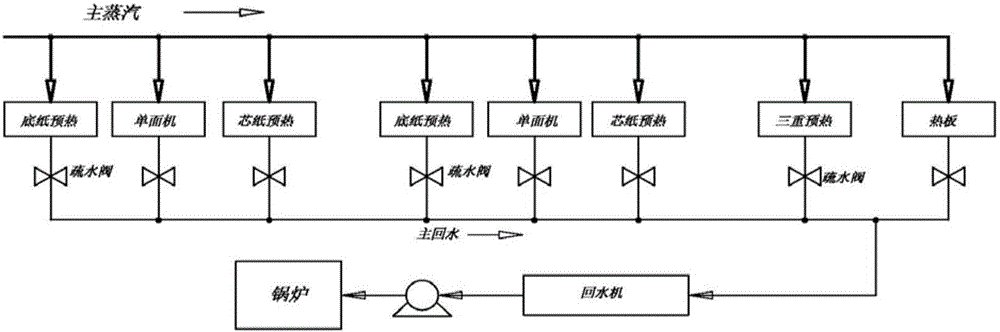

[0038] Such as figure 1 As shown, it is a corrugated cardboard production line proposed by the present invention. The main steam port 1 inputs steam into the entire pipeline, and the steam input in the main steam port 1 is called main steam. Between the main steam port 1 and the water vapor separation equipment 2, there are single-face machine system, multi-face machine system and regulating pipeline 3 arranged in parallel, and most of the steam in the main steam enters the water-vapor separation equipment through the single-face machine system and the multi-face machine system respectively 2 for water vapor separation. A small part of the main steam enters the regulating pipeline 3, and the steam in the regulating pipeline 3 is adjusted according to the steam volume required by the single-face mac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com