Elastic wick gray fabric weaving and dyeing-finishing process

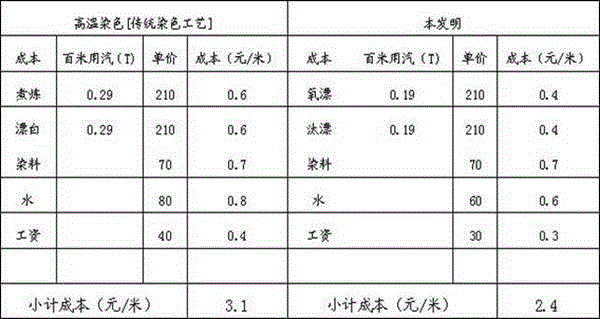

A grey fabric, dyeing and finishing technology, used in textiles and papermaking, dyeing, fiber processing and other directions, can solve the problems of high cost, wide width of the machine, improve physical indicators, reduce the width of the machine, and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The following knots and examples further describe the present invention.

[0013] Taking the weaving, dyeing and finishing process of 21 stretch corduroy grey fabrics as an example, the process flow is as follows:

[0014] 1) Grey cloth weaving:

[0015] Select raw materials → sizing → weaving on the machine → grey cloth maintenance;

[0016] The machine specification for grey cloth is: C16S×(C21S+C21S+C21S / 40D)×52×134×75″.

[0017] 2) Processing of burnt blanks:

[0018] Open the bristles → singe.

[0019] 3) Cold reactor → oxygen bleaching → cold reactor dyeing:

[0020] ① The cold pile is to immerse the burnt grey cloth with desizing enzyme and stack it for 24 hours. The desizing enzyme concentration in the desizing enzyme solution is 15g / L, and its auxiliary agents include penetrant 10g / L and refining agent 10g / L and caustic soda 50g / L. After the grey fabric is soaked in the desizing enzyme and stacked at room temperature for 24 hours, it undergoes a water removal process. Be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com