Medium-temperature coal economizer system and method thereof for recovering smoke afterheat

A flue gas waste heat and economizer technology, applied in preheating, feed water heaters, lighting and heating equipment, etc., can solve problems such as blockage of heat exchange surfaces, reduce flue gas temperature, improve operating economy, and improve dust removal efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

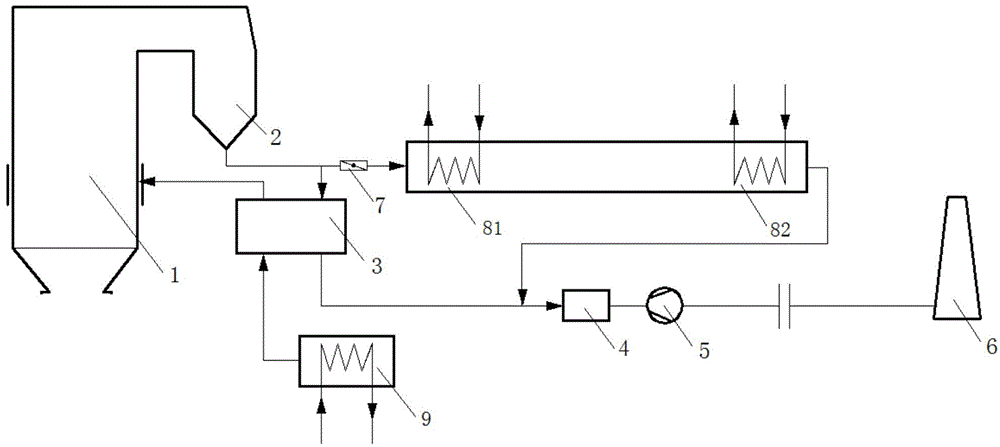

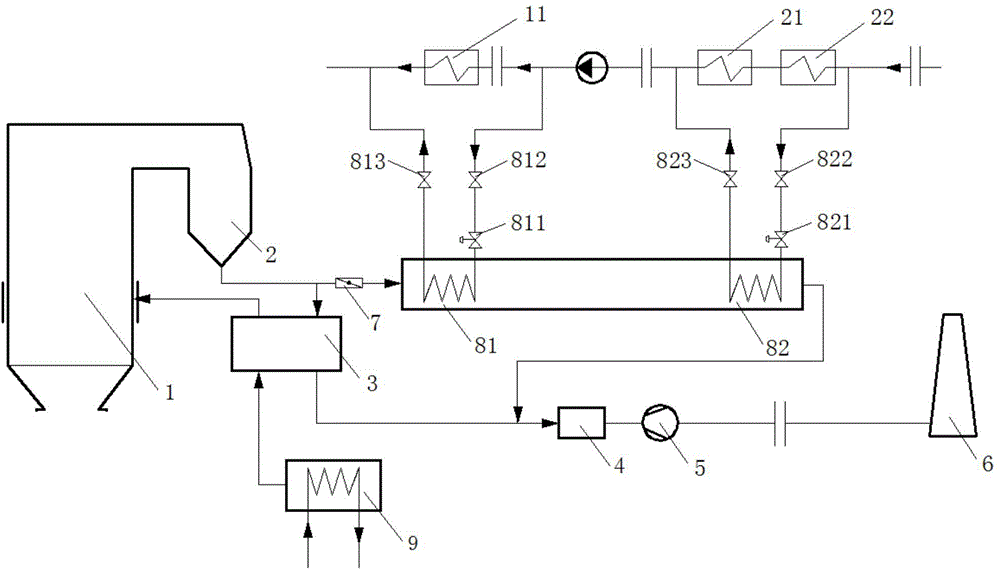

[0066] figure 1 It is a schematic diagram of a medium temperature economizer system according to an embodiment of the present invention, such as figure 1 As shown, the unit includes boiler 1, denitrification device 2, air preheater 3, dust collector 4, suction fan 5 and chimney 6, and the medium temperature economizer system includes inlet flue gas baffle 7, 'smoke-water' heat exchange device 81, 82 and heat exchange device 9.

[0067] The medium temperature economizer system in this embodiment includes two 'flue-water' heat exchange devices 81, 82, the smoke inlet of the 'flue-water' heat exchange device 81 passes through the flue at the inlet of the air preheater 3 The first flue is connected, the smoke outlet of the 'smoke-water' heat exchange device 81 is connected to the smoke inlet of the 'smoke-water' heat exchange device 82 through the flue, and the smoke outlet of the water heat exchange device 82 is connected to the air preheater The flue at the outlet of the heate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com