Preparation method of moisture-regaining-resistant anti-layering high-strength environment-friendly kraft liner cardboard paper

A high-strength technology of liner board paper, applied in the field of papermaking, can solve problems such as poor printing, no products, easy water absorption strength of the board paper, etc., and achieve the effect of reducing porosity, simple preparation method, and good hydrophobic function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

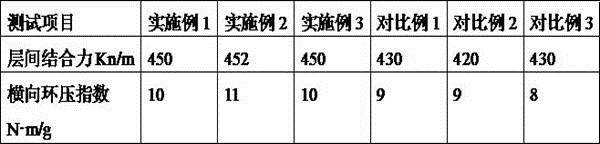

Examples

Embodiment 1

[0028] A method for preparing moisture-recovery and delamination-resistant high-strength environmentally friendly kraft liner liner paper, comprising the following steps:

[0029] (1) Beating: beat waste paper and then mix it with wood pulp at a weight ratio of 4:1, add cellulase to the mixed pulp under stirring conditions, and the amount added is 0.4% of the dry pulp weight of the pulp ;

[0030] (2) Classification: collect the pulp according to the long fiber pulp, medium fiber pulp and short fiber pulp, and mix the short fiber pulp, medium fiber pulp and long fiber pulp according to the ratio of 30:20:50 to obtain the surface layer pulp. Mix short fiber pulp, medium fiber pulp and long fiber pulp in a ratio of 10:40:50 to obtain the core layer pulp, and mix short fiber pulp, medium fiber pulp and long fiber pulp in a ratio of 20:30:50 to obtain the bottom layer Slurry; after adding retention aids to the surface layer slurry, core layer slurry and bottom layer slurry, proce...

Embodiment 2

[0038] A method for preparing moisture-recovery and delamination-resistant high-strength environmentally friendly kraft liner liner paper, comprising the following steps:

[0039] (1) Beating: beat the waste paper and then mix it with wood pulp at a weight ratio of 5:1, add cellulase to the mixed pulp under stirring conditions, and the amount added is 0.5% of the weight of the dry pulp of the pulp ;

[0040] (2) Classification: collect the pulp according to the long fiber pulp, medium fiber pulp and short fiber pulp, and mix the short fiber pulp, medium fiber pulp and long fiber pulp according to the ratio of 30:20:50 to obtain the surface layer pulp. Mix short fiber pulp, medium fiber pulp and long fiber pulp in a ratio of 10:40:50 to obtain the core layer pulp, and mix short fiber pulp, medium fiber pulp and long fiber pulp in a ratio of 20:30:50 to obtain the bottom layer Slurry; after adding retention aids to the surface layer slurry, core layer slurry and bottom layer sl...

Embodiment 3

[0048] A method for preparing moisture-recovery and delamination-resistant high-strength environmentally friendly kraft liner liner paper, comprising the following steps:

[0049] (1) Beating: beat waste paper and then mix it with wood pulp at a weight ratio of 4-5:1, add cellulase to the mixed pulp under stirring conditions, and the amount added is 1% of the dry pulp weight of the pulp 0.4-0.5%;

[0050] (2) Classification: collect the pulp according to the long fiber pulp, medium fiber pulp and short fiber pulp, and mix the short fiber pulp, medium fiber pulp and long fiber pulp according to the ratio of 30:20:50 to obtain the surface layer pulp. Mix short fiber pulp, medium fiber pulp and long fiber pulp in a ratio of 10:40:50 to obtain the core layer pulp, and mix short fiber pulp, medium fiber pulp and long fiber pulp in a ratio of 20:30:50 to obtain the bottom layer Slurry; after adding retention aids to the surface layer slurry, core layer slurry and bottom layer slurr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com