A production process of advanced coated white paperboard

A production process and technology of white paperboard, which is applied in the field of preparation of coated white paperboard, can solve problems such as unstable surface strength, influence of paper quality and energy consumption, and impact on visual effects, so as to improve the first pass rate and improve papermaking Quality, strengthen the effect of information management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

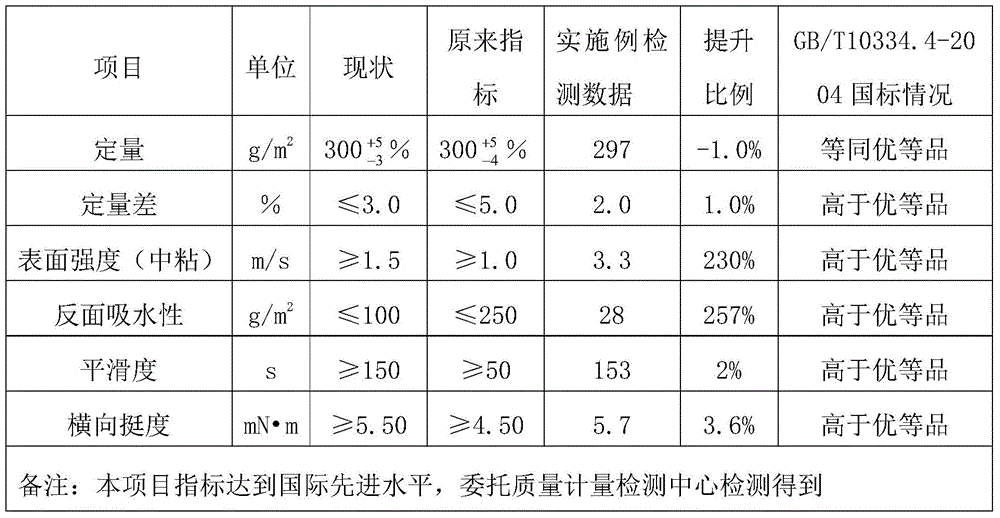

Examples

Embodiment Construction

[0034] In this embodiment, high-grade coated white paperboard is manufactured, and the raw materials are selected as follows:

[0035] Surface layer: The main components are chemically bleached wood pulp and a small amount of white paper edge.

[0036] Liner: The main components are imported daily waste and a small amount of 8# or 10# waste paper.

[0037] Core layer: the main component is imported 3# waste paper and 11# waste paper mixed waste paper

[0038] Bottom layer: The main components are imported 8# waste paper and a small amount of domestic newspapers

[0039] Chemical coatings: The main ingredients are auxiliary additives such as china clay, calcium carbonate, latex, etc. The coating amount is about 25-45g / ㎡, and the amount per ton of finished paper accounts for about 8.5-15% of the total weight.

[0040] Auxiliary chemical raw materials: the main ingredients are starch, rosin, aluminum sulfate, retention aids, water-resistant agents, fungicides, etc., with a cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com