No-brush temperature measuring method and device with CVD system substrate

A temperature measuring device and brushless technology, which is applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of inconvenient measurement of substrate temperature and inability to measure dynamically, so as to prolong the trouble-free working cycle , Measurement can be monitored in real time to improve the effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following structural drawings and embodiments further illustrate the present invention.

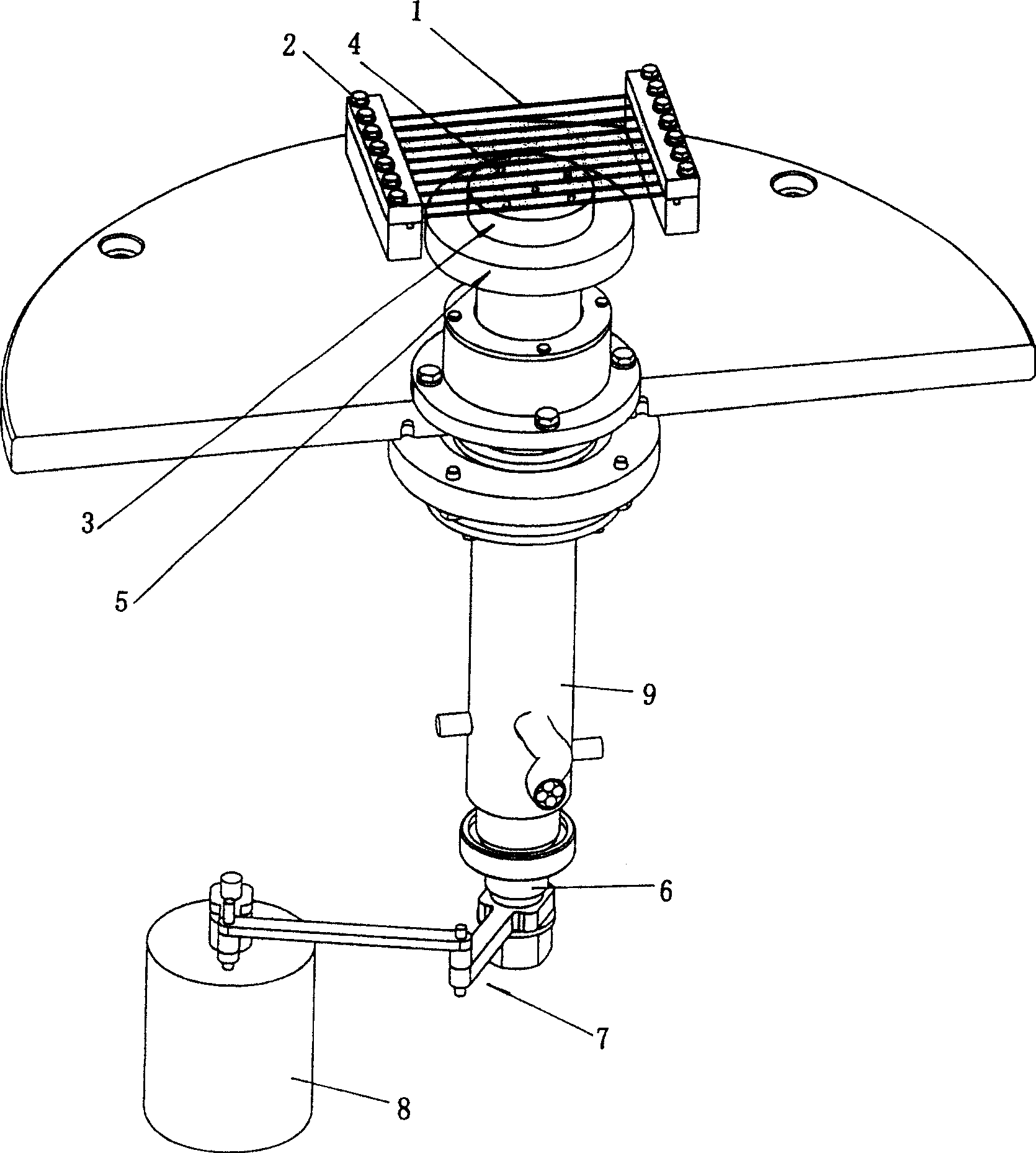

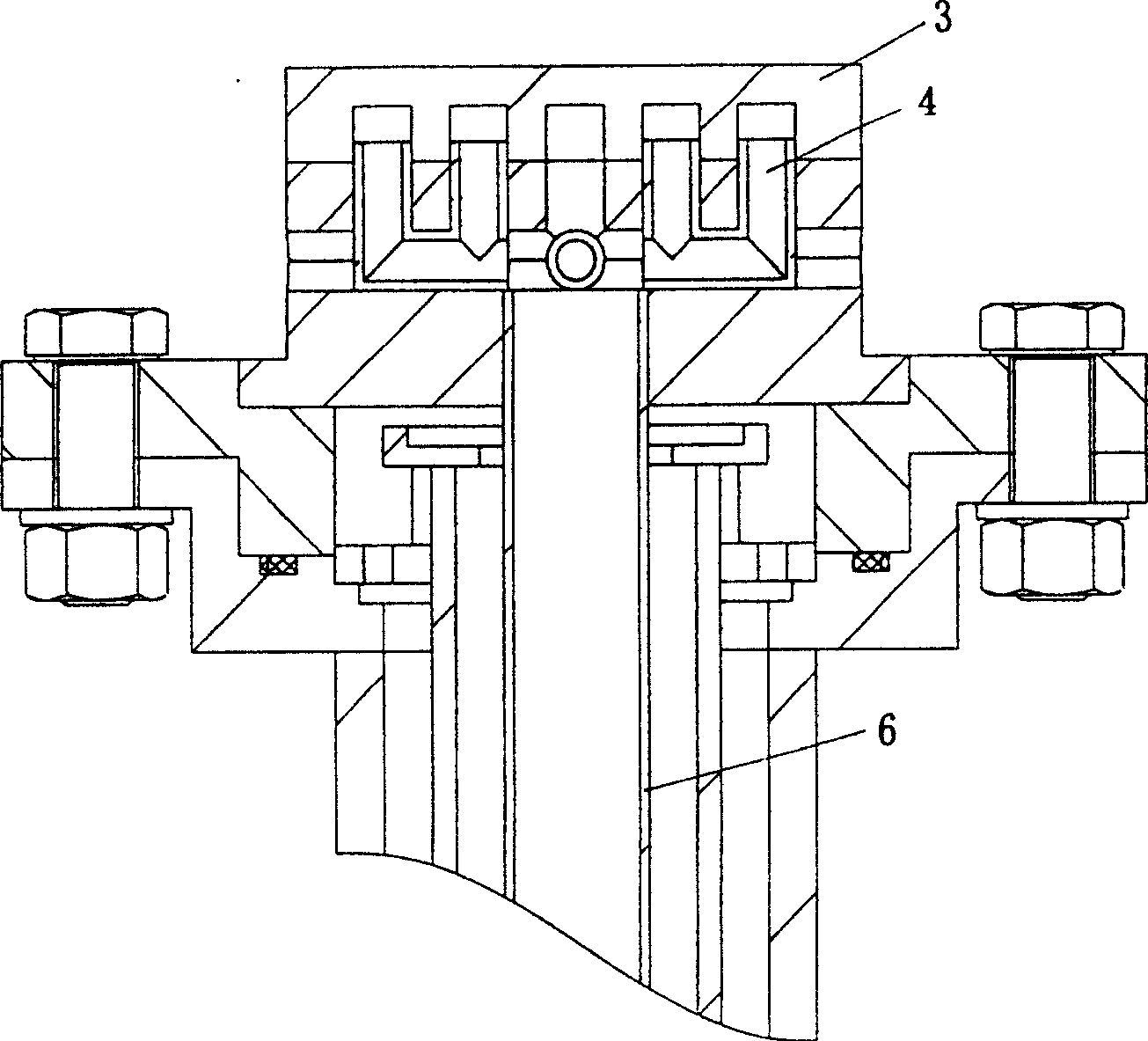

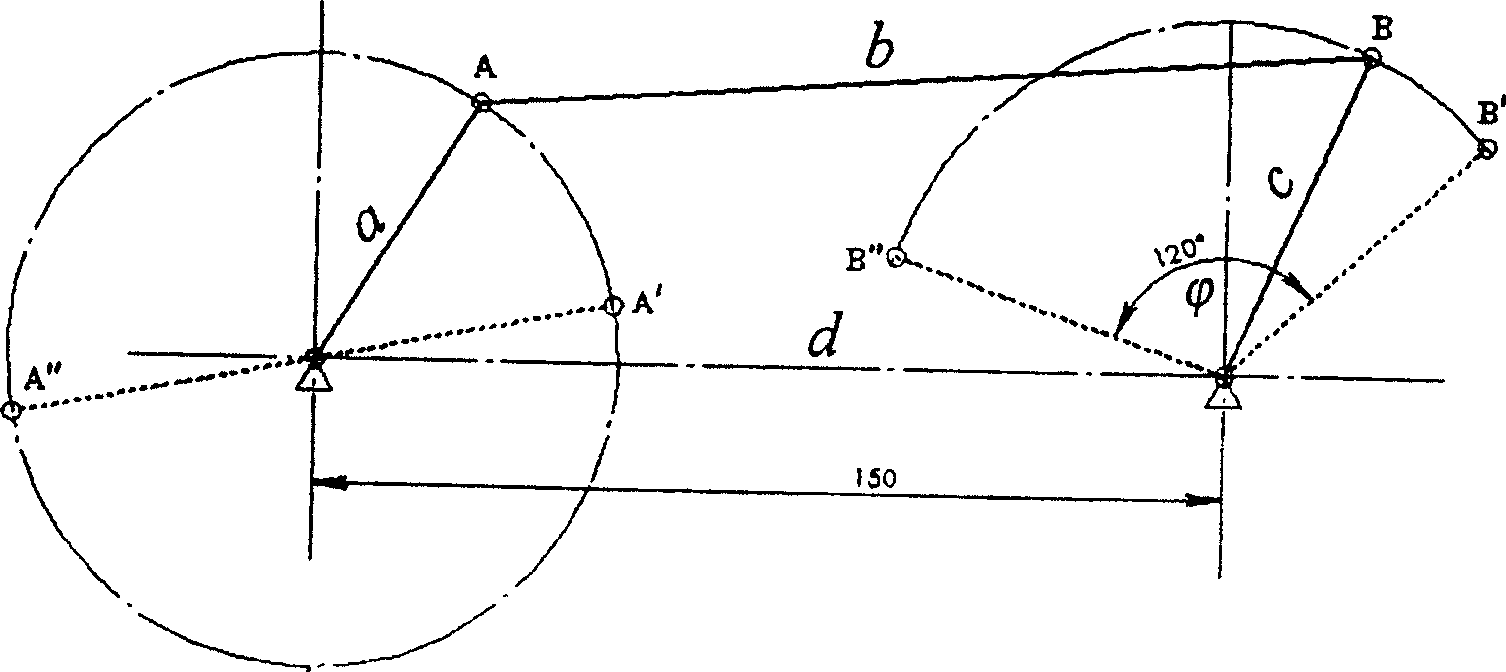

[0031] Such as figure 1 , 2 , 3 shown.

[0032] A brushless temperature measurement method for a CVD system substrate, comprising the following steps:

[0033] First, several thermoelectric sides are arranged radially and / or axially along the substrate table;

[0034] Secondly, the electrical signal measured by the thermocouple is led out of the vacuum chamber with the wire connected to it and sent to the electric control system for processing;

[0035] Third, connect the substrate workbench with a crank-link mechanism, and make it swing 90°-180°, 5-8 times per minute, driven by the crank-link mechanism to keep the temperature on the substrate workbench The field is in a uniform state, and the best diamond film deposition effect is obtained.

[0036] The specific device matched with the above method can be:

[0037] A brushless temperature measuring device for a CVD syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com