Patents

Literature

35results about How to "Avoid direct heating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

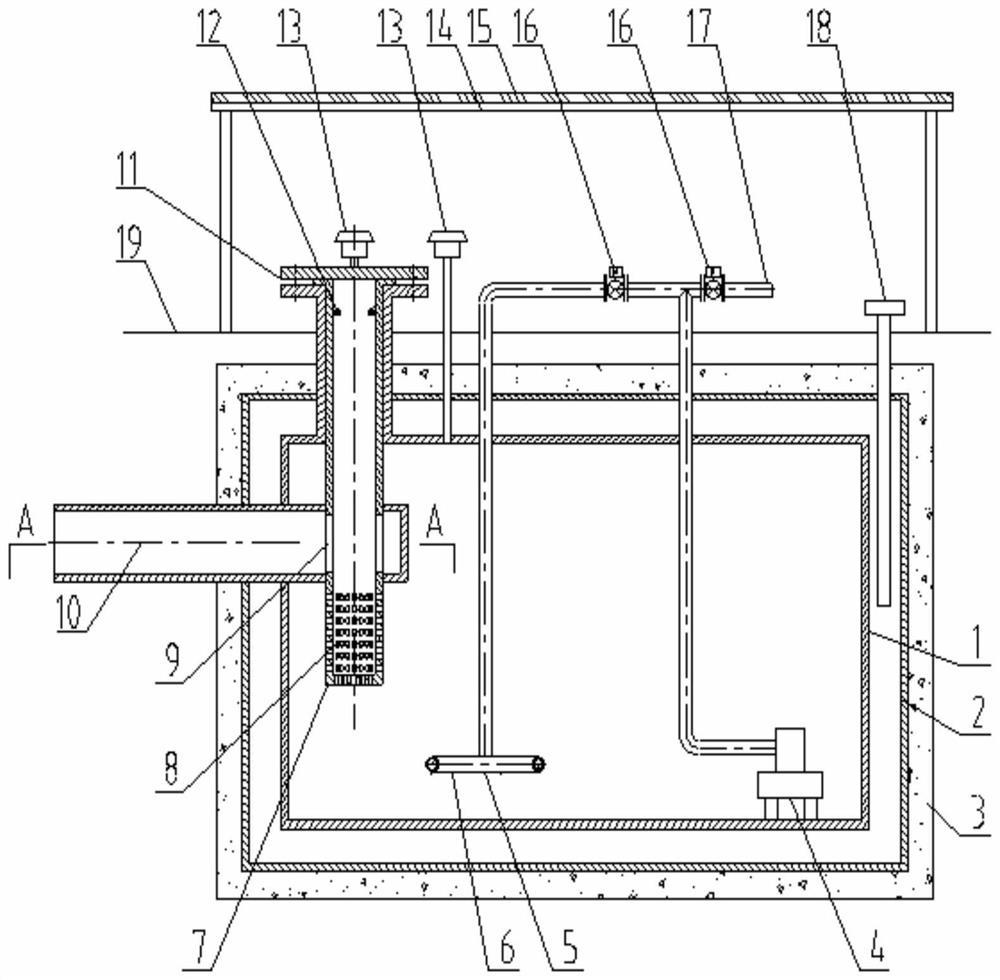

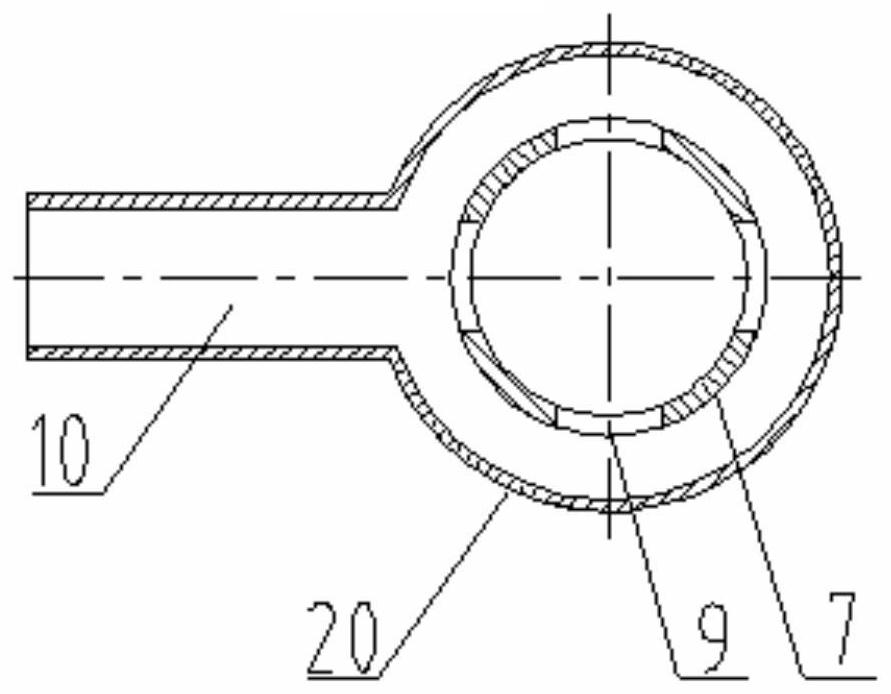

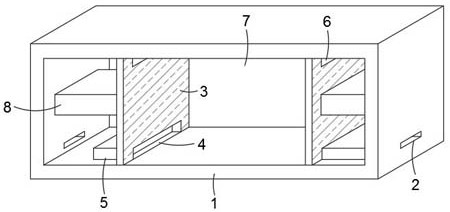

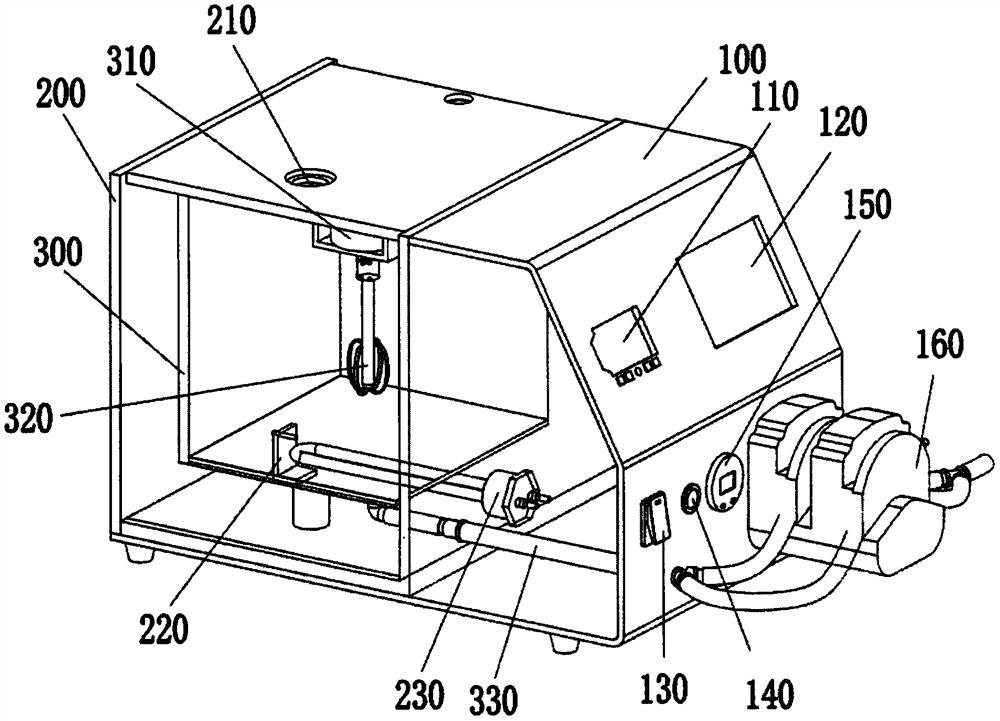

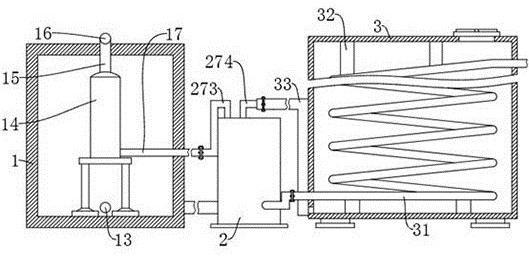

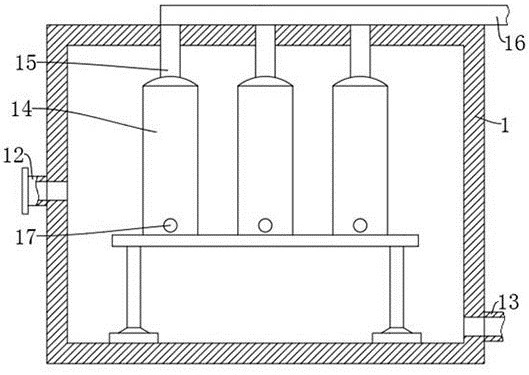

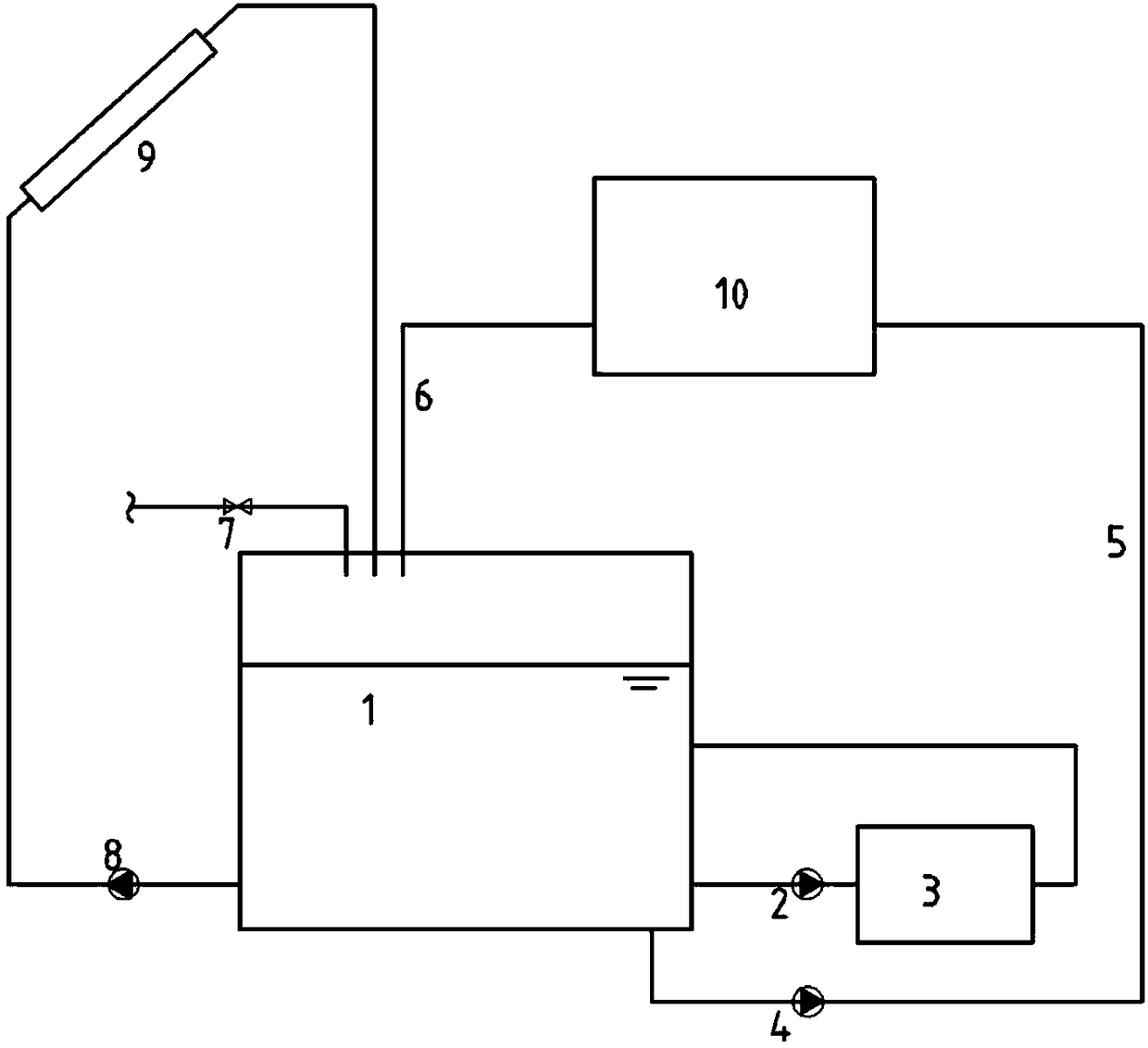

Aquatic cultivation box

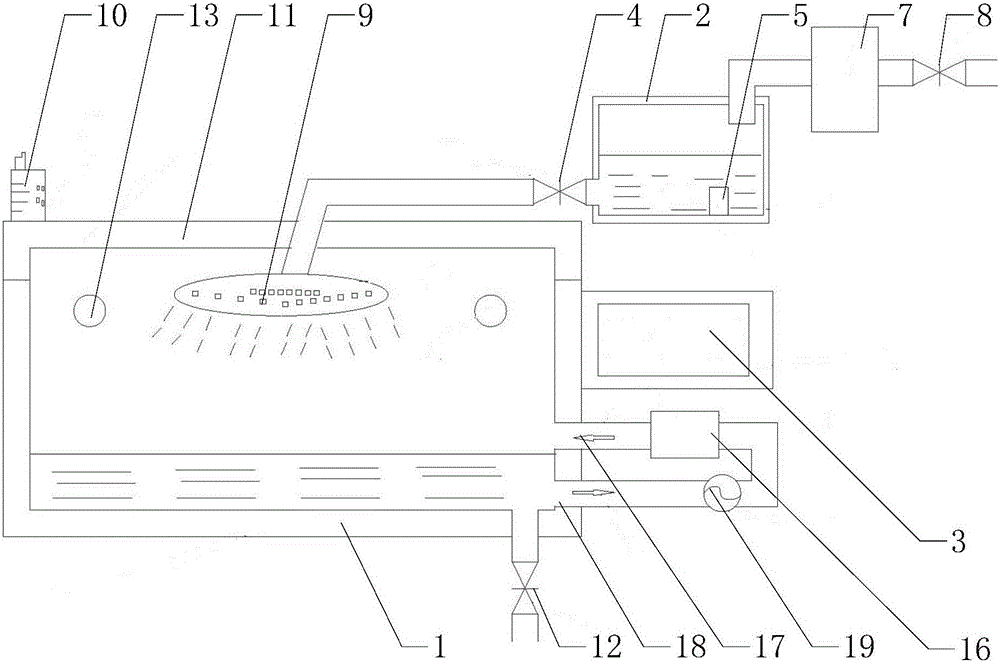

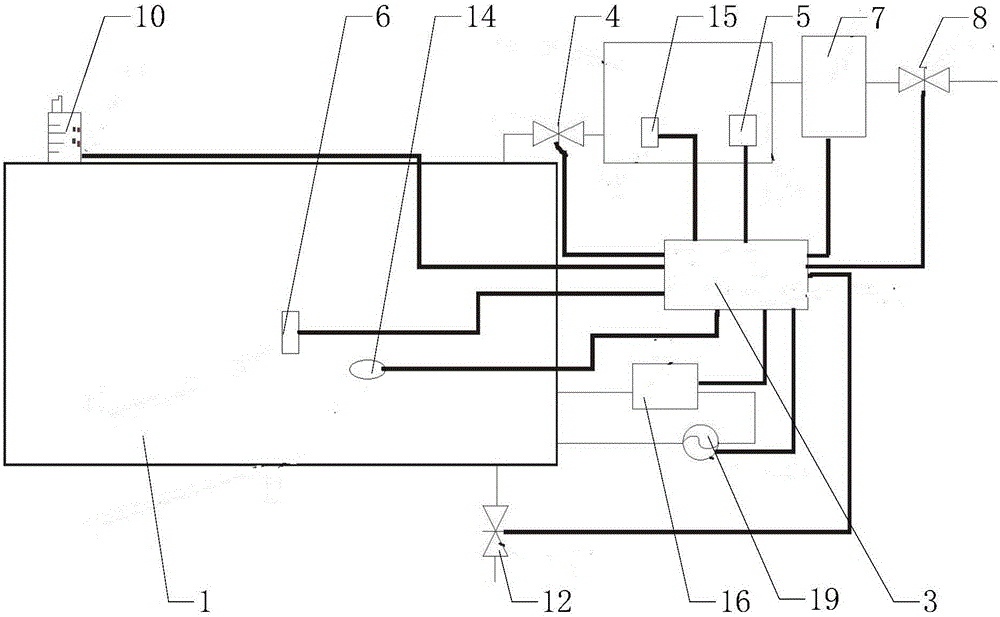

Disclosed in the invention is an aquatic cultivation box comprising a box body, a pre-heating water tank, and a controller. The pre-heating water tank is arranged outside the box body and is communicated with the box body. A hot water control valve is arranged between the pre-heating water tank and the box body and is used for controlling on / off state of the pre-heating water tank and the box body. A heater is arranged in the pre-heating water tank. A box body water-temperature detection device is arranged in the box body. The hot water control valve, the heater, and the box body water-temperature detection device are in communication connection with the controller. The pre-heating water tank arranged outside the box body is used for carrying out pre heating, so that direct heating of water in the box body can be avoided in temperature control and thus the aquatic life injury is reduced; and automatic controlling is realized.

Owner:GUANGDONG UNIV OF TECH

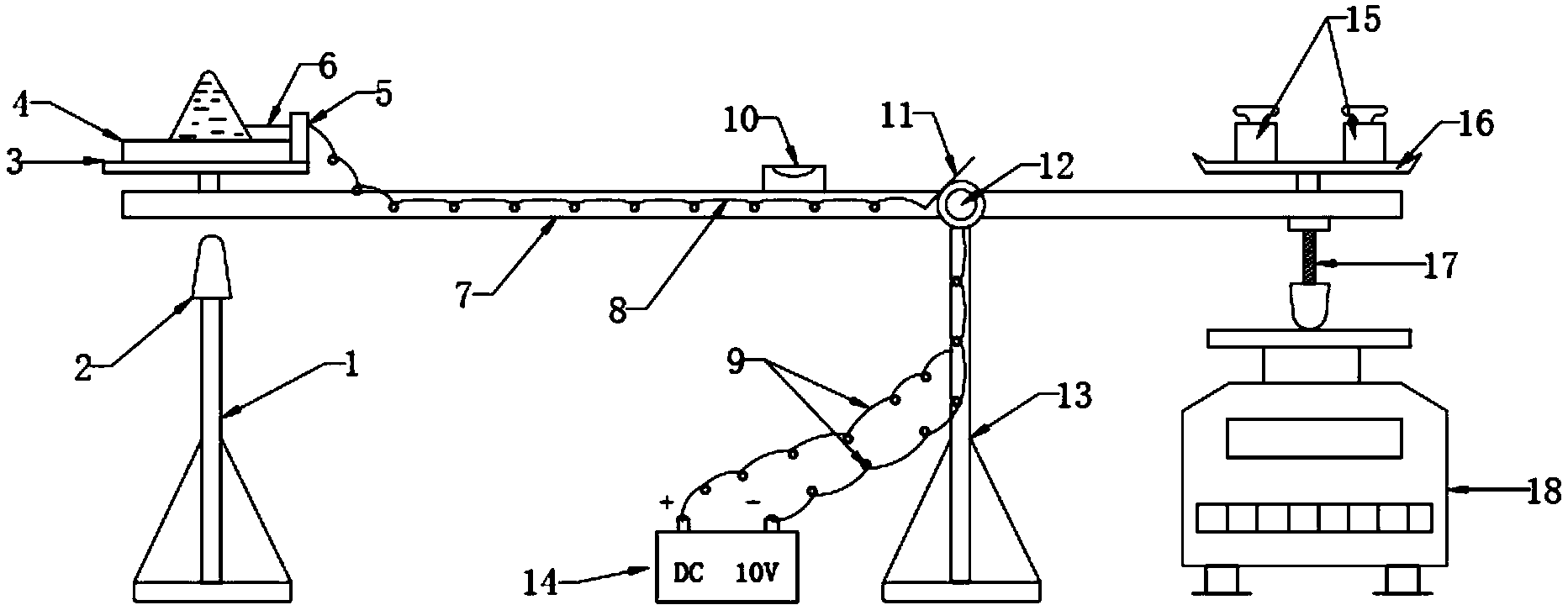

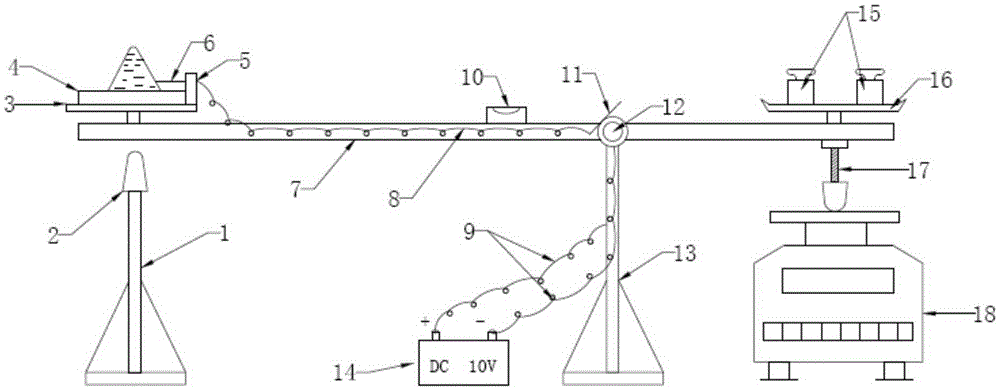

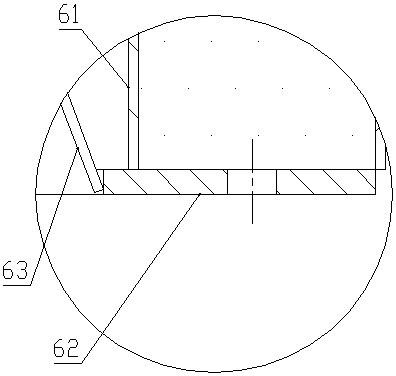

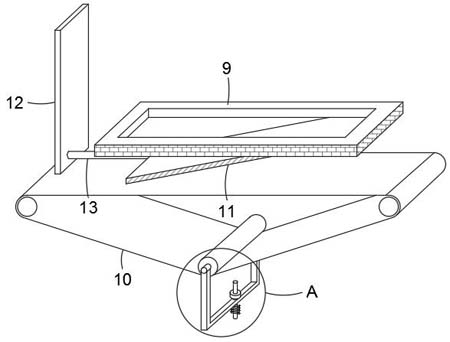

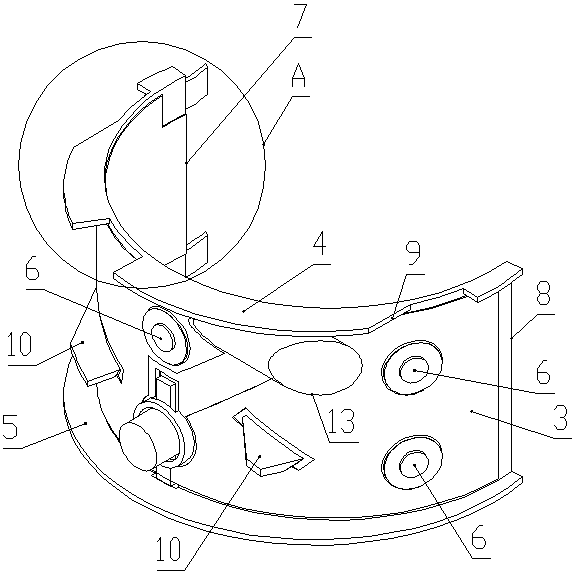

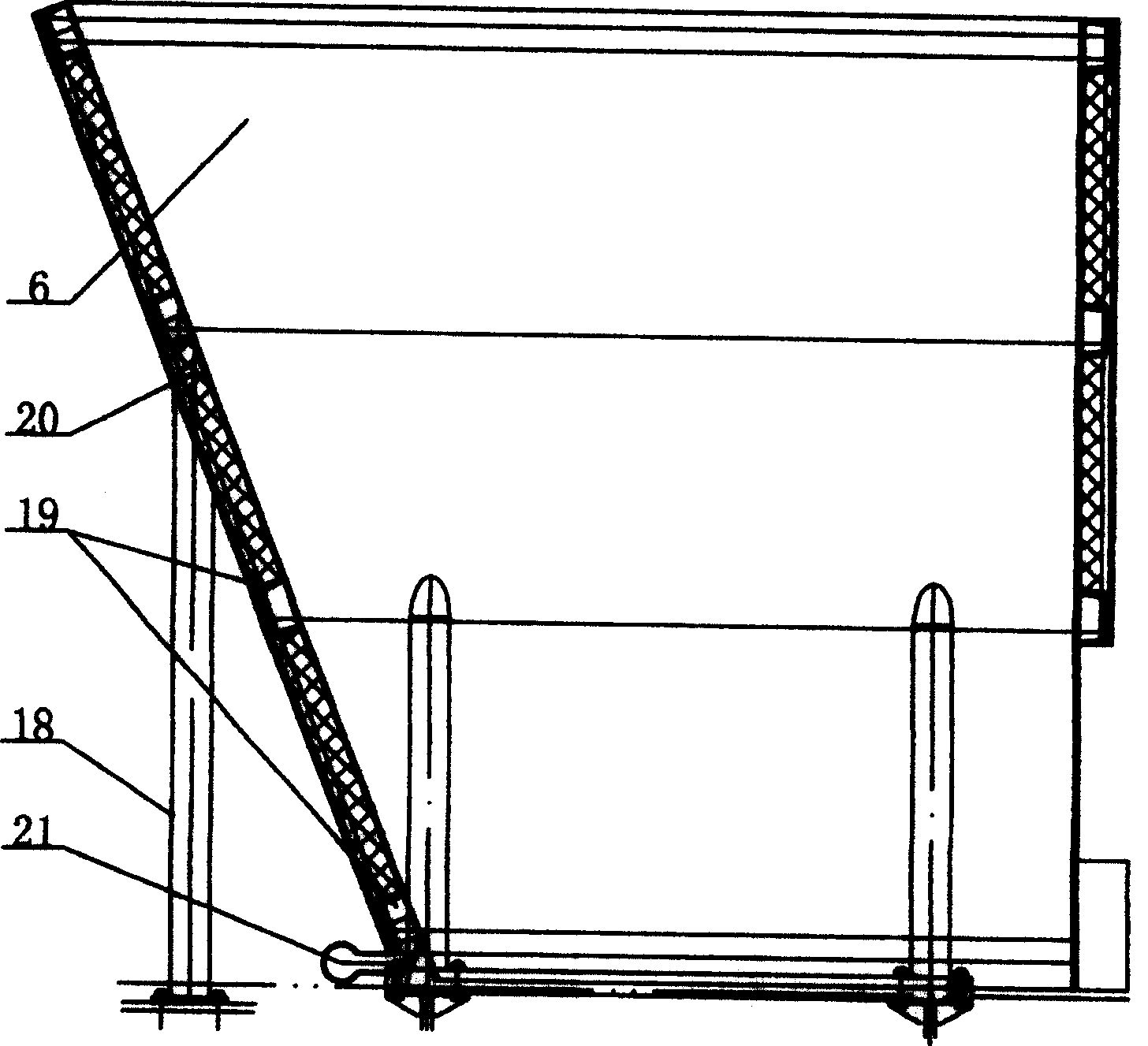

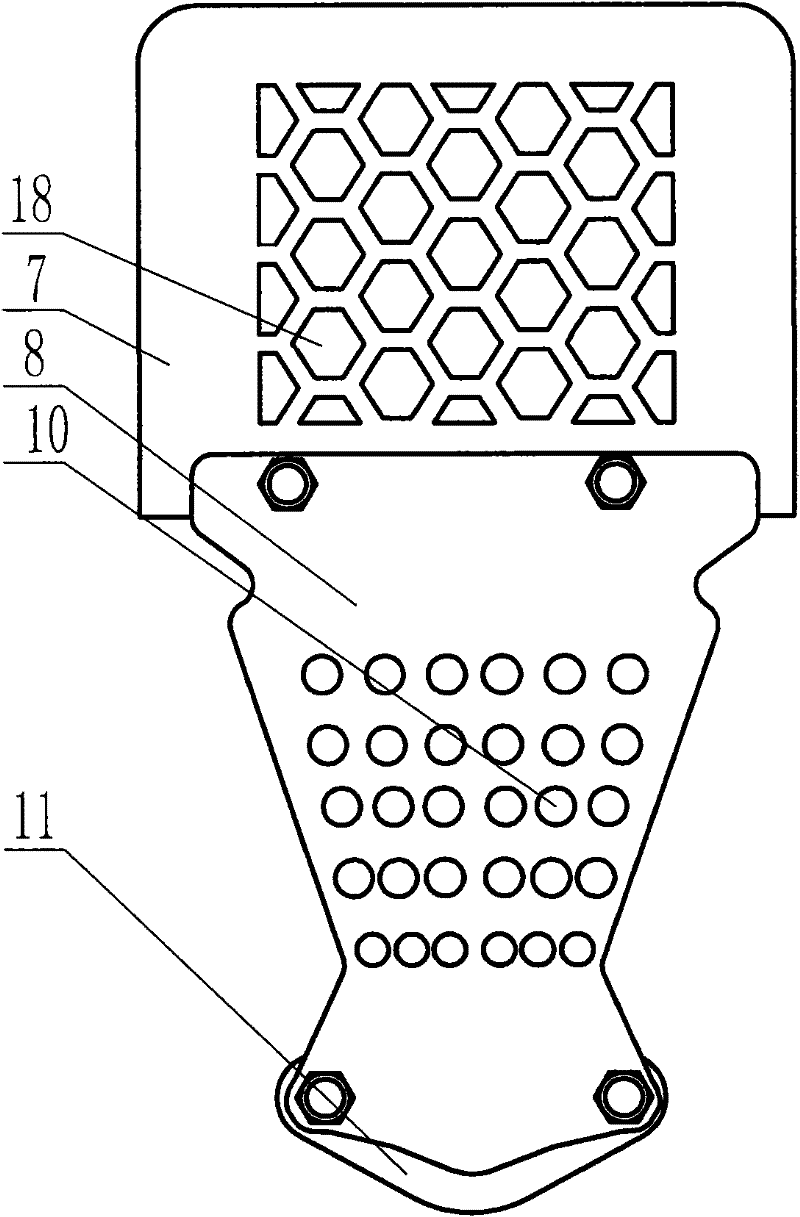

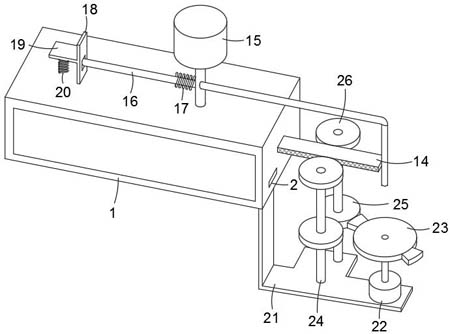

Improved test device for testing oxidizing solid

The invention relates to an improved test device for testing an oxidizing solid. The improved test device is provided with a test system and a measurement system and is characterized in that the test system and the measurement system are positioned at two ends of a lever system and are connected with each other through the lever system; the test system comprises a bracket A, a limiting block, a tray A, a heat isolation plate, a wiring post and a resistance wire; the lever system comprises a lever, a wire A, a wire B, an electric brush, a current collection ring, a bracket B and a power supply; the measurement system comprises a balance weight, a tray B, a level adjuster and a balancer. Compared with the prior art, the improved test device disclosed by the invention has the advantages that the test system can be separated from the measurement system, the measurement precision is improved according to an equal arm lever principle, and damage of heat and dust on the balancer during combustion can be eliminated.

Owner:SHANGHAI RES INST OF CHEM IND +1

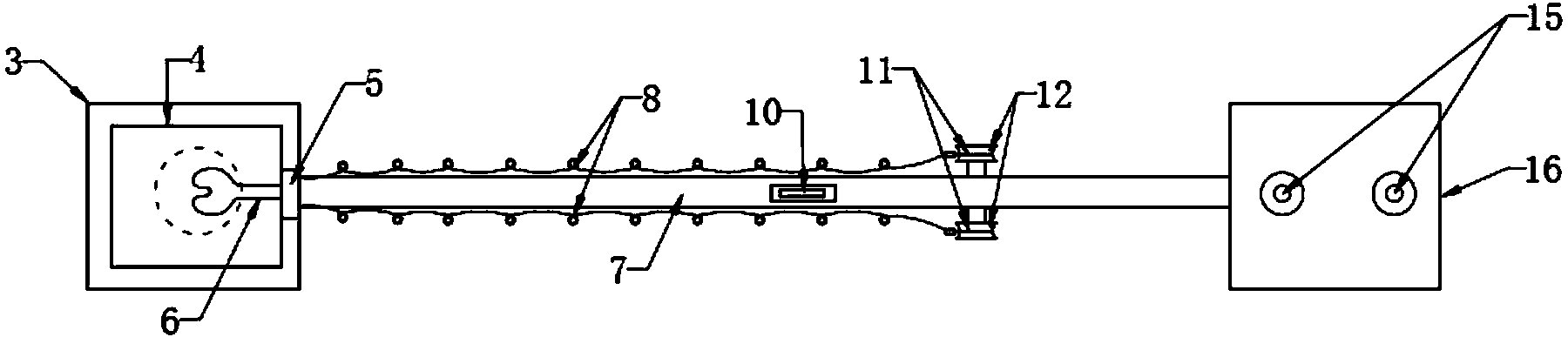

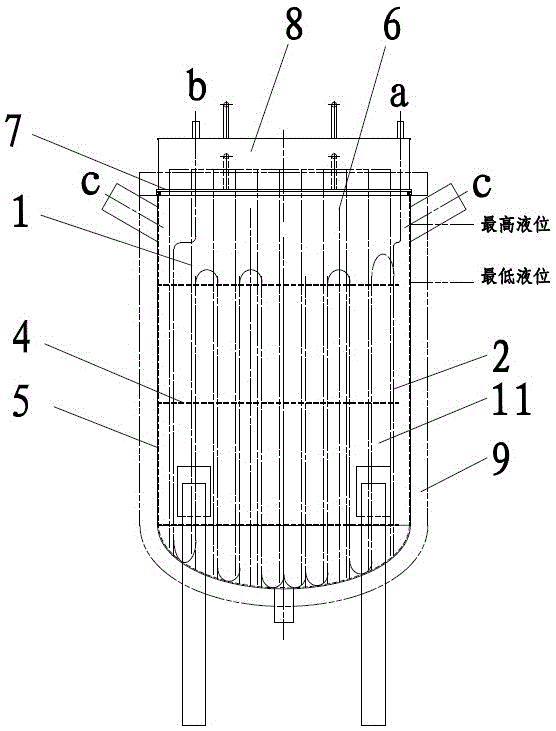

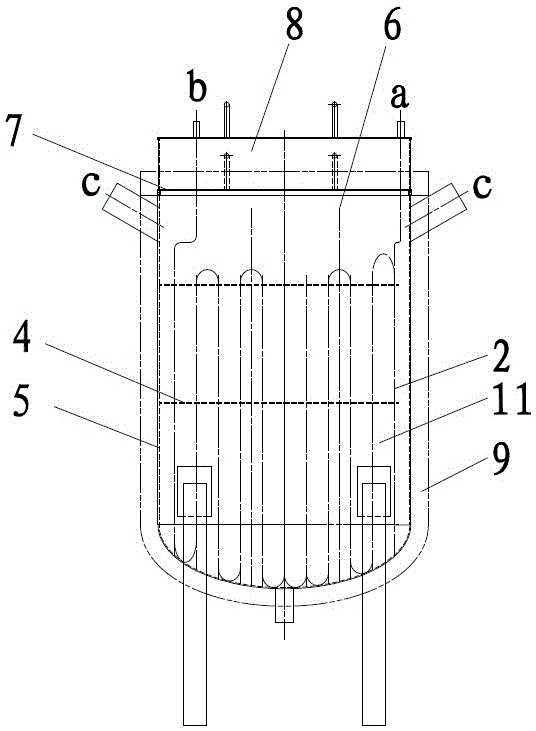

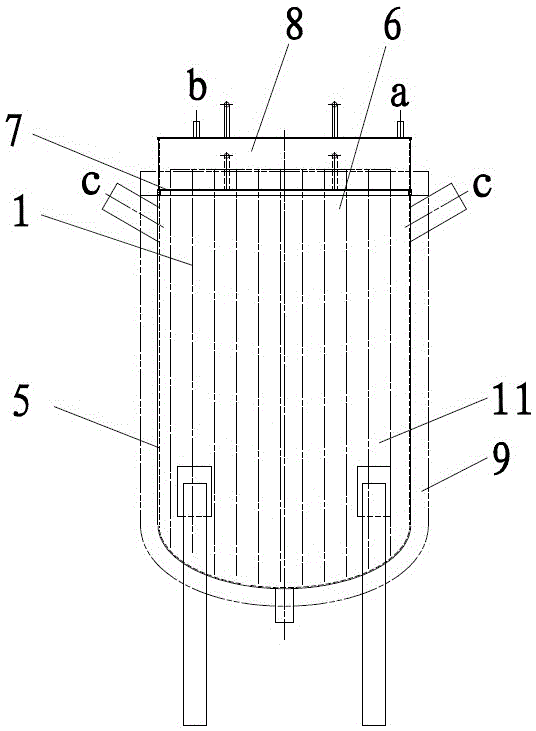

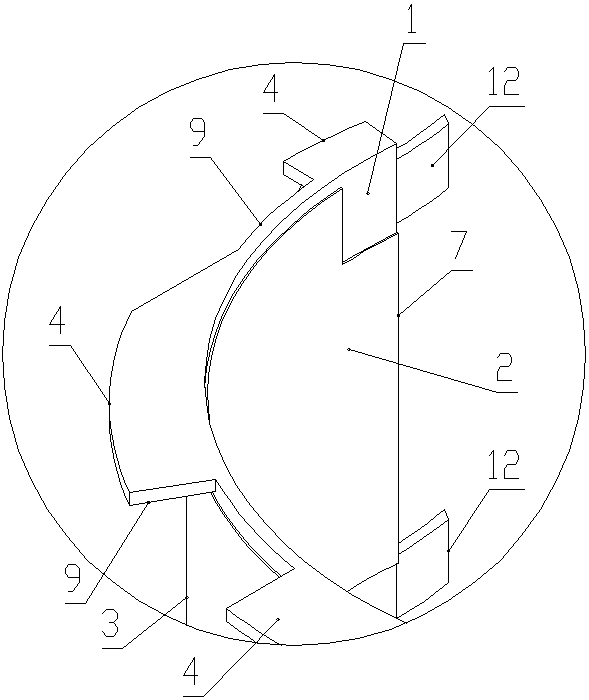

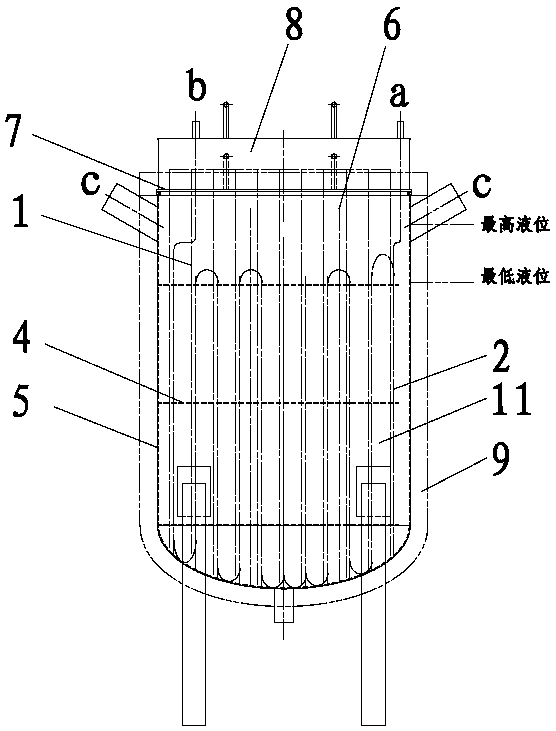

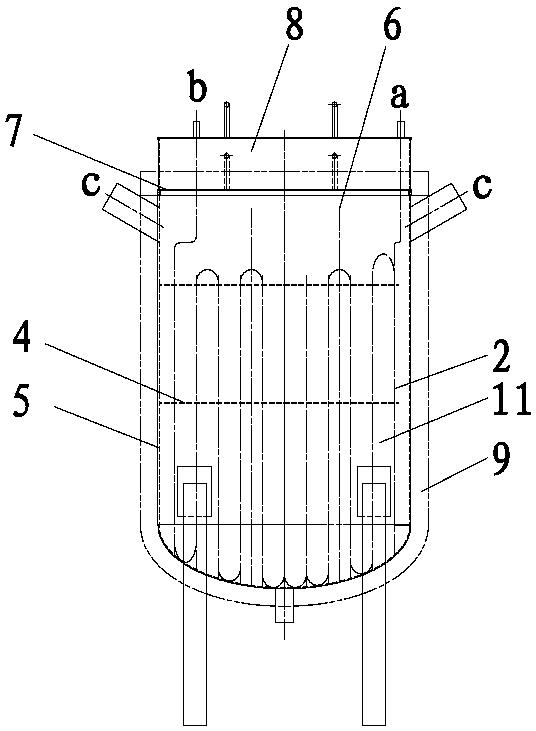

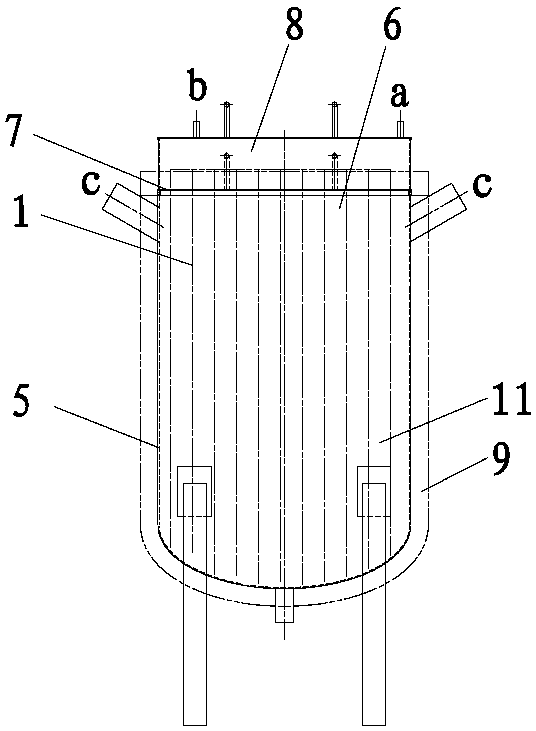

Electrically-heated energy-storage heat exchanger and heat storing and releasing method thereof

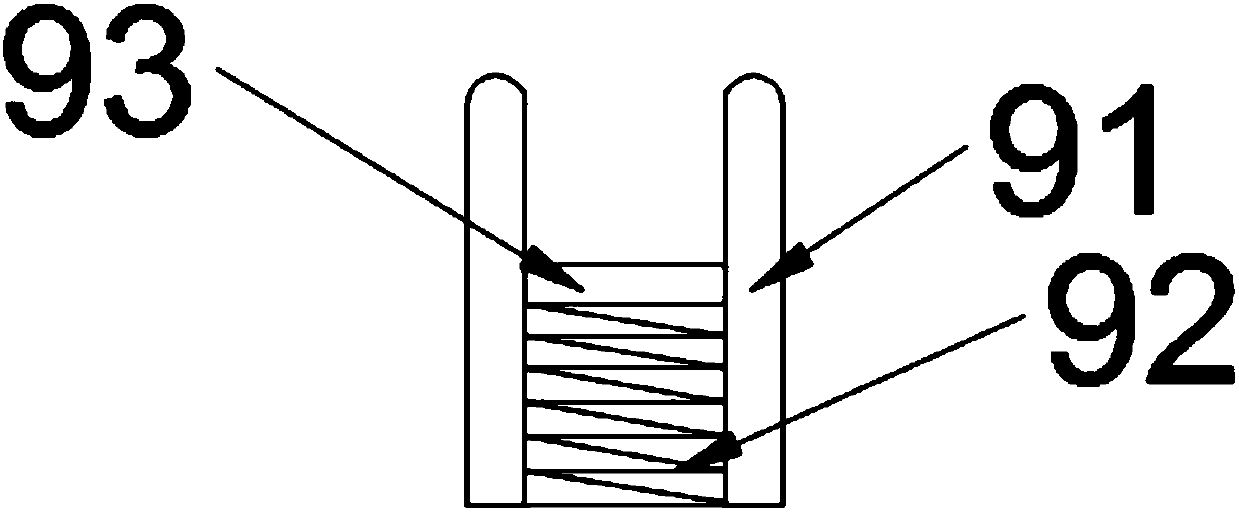

ActiveCN105758241AGuaranteed molten stateUniform heat exchangeHeat storage plantsHeating element shapesVertical planePlate heat exchanger

The invention relates to an electrically-heated energy-storage heat exchanger and a heat storing and releasing method thereof and solves the problems of non-uniform energy distribution and low energy utilization rate in the heat exchange process of an existing electrically-heated phase change heat storage and exchange device. The electrically-heated energy-storage heat exchanger comprises a tank-shaped shell and an electric heating pipe; the shell is filled with a heat storage medium. The electrically-heated energy-storage heat exchanger is characterized in that a heat exchange pipeline is also arranged in the shell and is vertically folded back in a vertical plane to be coiled in an S-shaped manner; the heat exchange pipeline is folded to and fro in a horizontal plane to be arranged in an S-shaped manner or spirally arranged inside the shell around a circle center; an opening is formed in the upper end of the shell, and a detachable cover plate is arranged at the upper end of the shell; an inlet and an outlet of the heat exchange pipeline penetrate out of the shell from the cover plate; the electric heating pipe extends into the inside of the shell downwards from the cover plate. The electrically-heated energy-storage heat exchanger provided by the invention performs uniform heat exchange on the heat storage medium with poor mobility, so that the heat utilization efficiency is improved.

Owner:上海联和投资有限公司

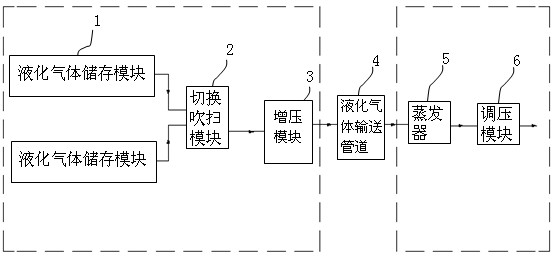

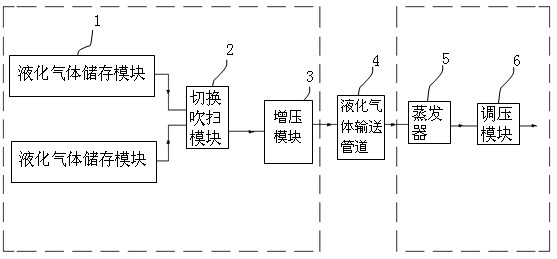

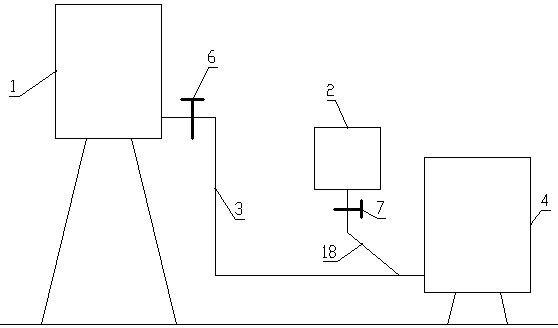

Method for conveying high-flow high-purity liquefied gas

The invention discloses a method for conveying high-flow high-purity liquefied gas. In the invention, a liquefied gas storage module, a supercharged module, a liquefied gas conveying pipeline, an evaporator and a pressure regulating module. The method comprises the following steps: educing the liquefied gas from the liquefied gas storage module, so that the liquefied gas enters the supercharged module; knocking the liquefied gas by the supercharged module, and conveying the liquefied gas into the evaporator through the liquefied gas conveying pipeline; vaporizing and heating the liquefied gas in the evaporator; and conveying the heated liquefied gas to a required machine bench when the heated liquefied gas passes through the pressure regulating module and the pressure of the liquefied gas is reduced to the technology requirement. According to the method for conveying high-flow high-purity liquefied gas provided by the invention, the liquefied gas is knocked out by the supercharged module, the liquefied gas is conveyed to the evaporator through the liquefied gas conveying pipeline, the liquefied gas is gasified and heated out of the liquefied gas storage module by adopting the evaporator, the direct heating of the liquefied gas storage module and the long-distance liquid conveying are avoided, and the gas conveying requirements of high purity and large flow rate are satisfied.

Owner:SHANGHAI ZHENGFAN TECH +1

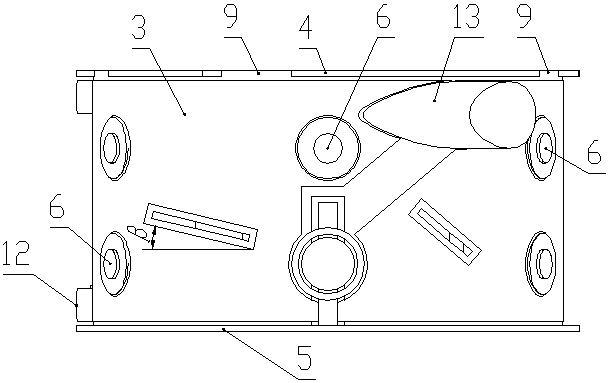

An improved test device for testing oxidizing solids

ActiveCN103630461BAvoid direct heatingAvoid affecting the measurementWeighing by removing componentElectrical resistance and conductanceCombustion

The invention relates to an improved test device for testing an oxidizing solid. The improved test device is provided with a test system and a measurement system and is characterized in that the test system and the measurement system are positioned at two ends of a lever system and are connected with each other through the lever system; the test system comprises a bracket A, a limiting block, a tray A, a heat isolation plate, a wiring post and a resistance wire; the lever system comprises a lever, a wire A, a wire B, an electric brush, a current collection ring, a bracket B and a power supply; the measurement system comprises a balance weight, a tray B, a level adjuster and a balancer. Compared with the prior art, the improved test device disclosed by the invention has the advantages that the test system can be separated from the measurement system, the measurement precision is improved according to an equal arm lever principle, and damage of heat and dust on the balancer during combustion can be eliminated.

Owner:SHANGHAI RES INST OF CHEM IND +1

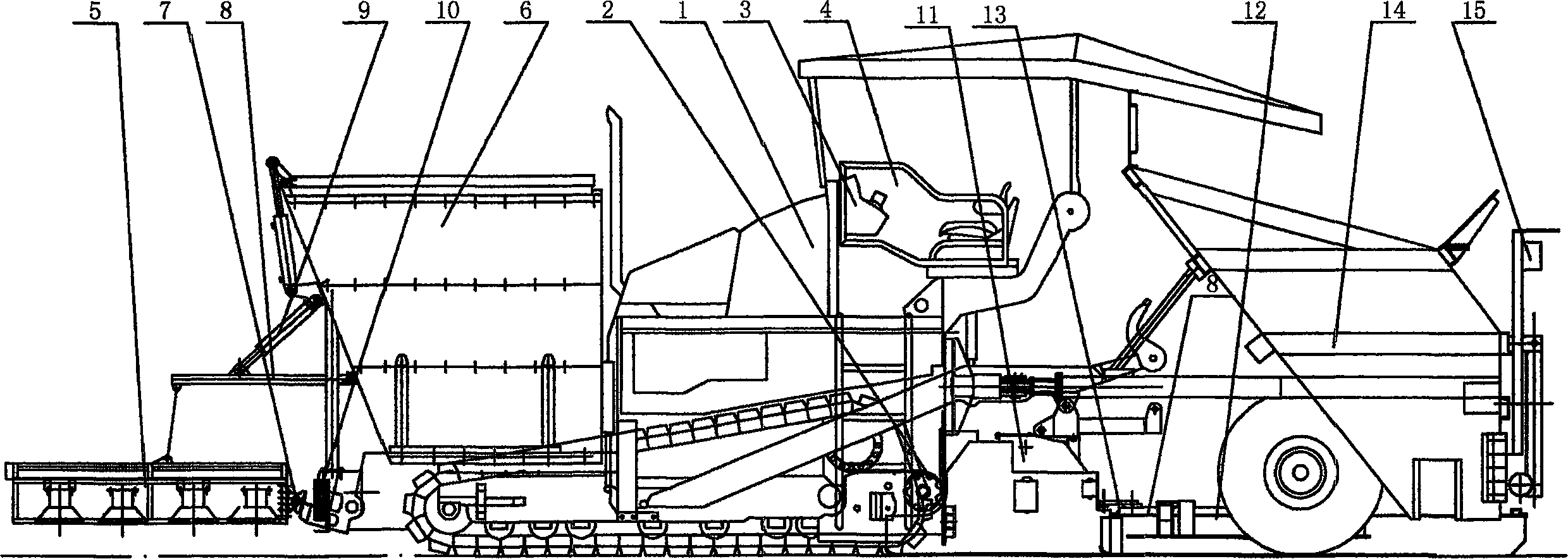

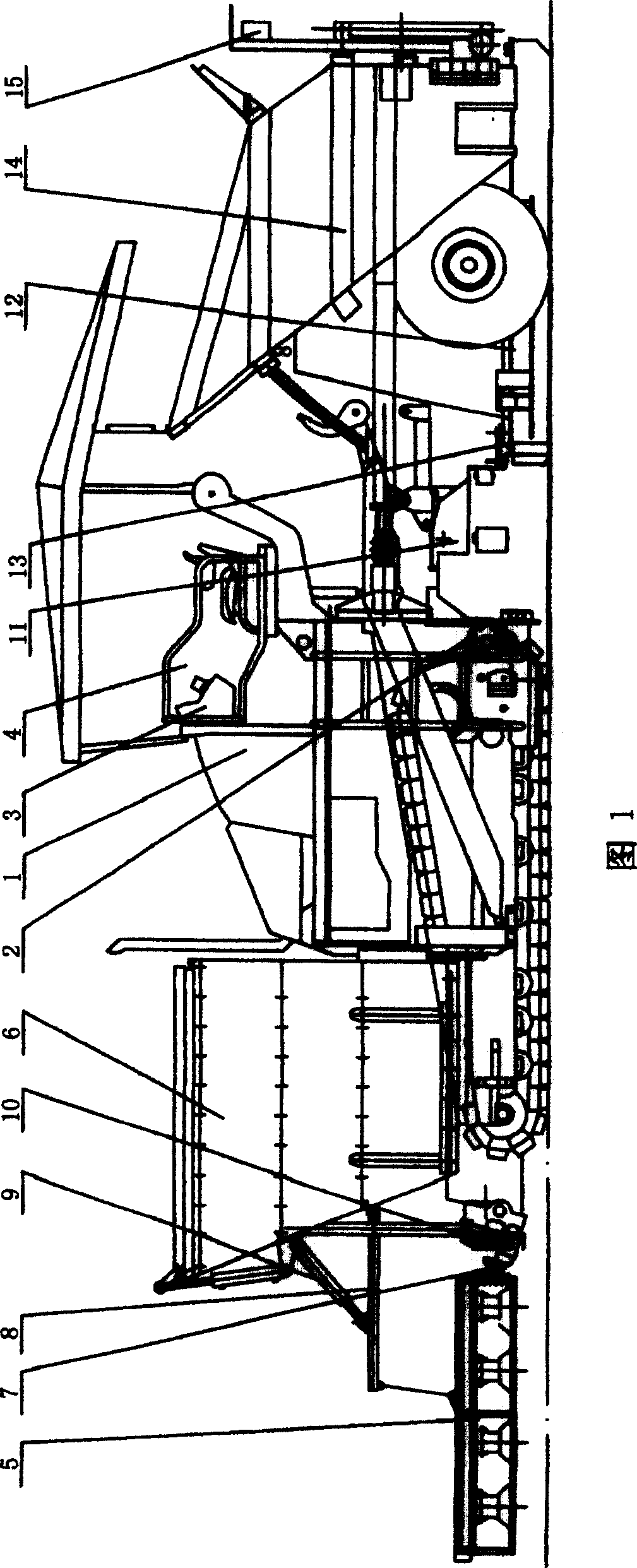

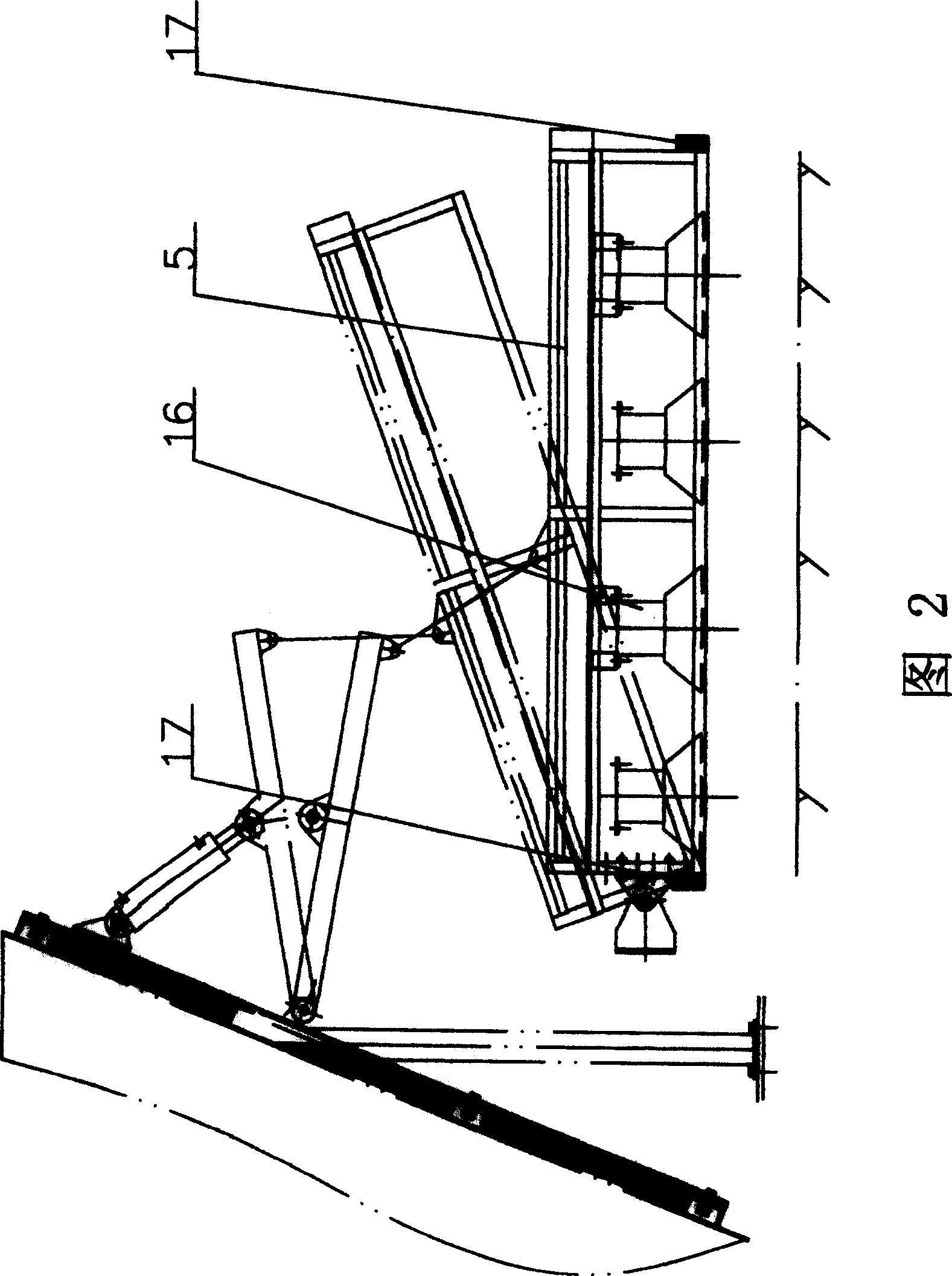

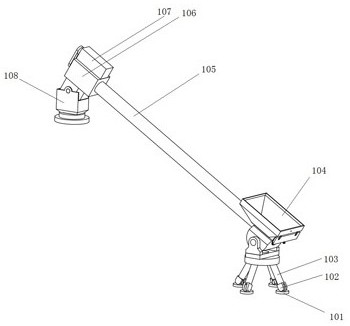

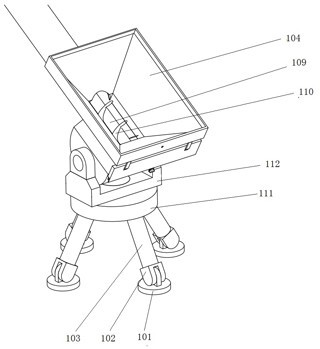

Crawler type spreading machine for rolling core wall of asphalt concrete in hydraulic engineering

InactiveCN1873111APrevent oxidative aging and even burningAvoid getting lostFoundation engineeringMixed materialsHydraulic engineering

A crawler united paver for rolling asphalt concrete is prepared as setting infrared heating unit and insulated hopper of asphalt mixed material at host head; setting alignment monitoring unit at connection point of infrared heating unit and host; setting shock-ironing plate and frame die at host back, riding transition material sub hopper on frame die and setting scraper, scraper lifting up and lowering down unit and receiver of laser leveling unit at back of transition material sub hopper.

Owner:CHINA GEZHOUBA GRP INT ENG

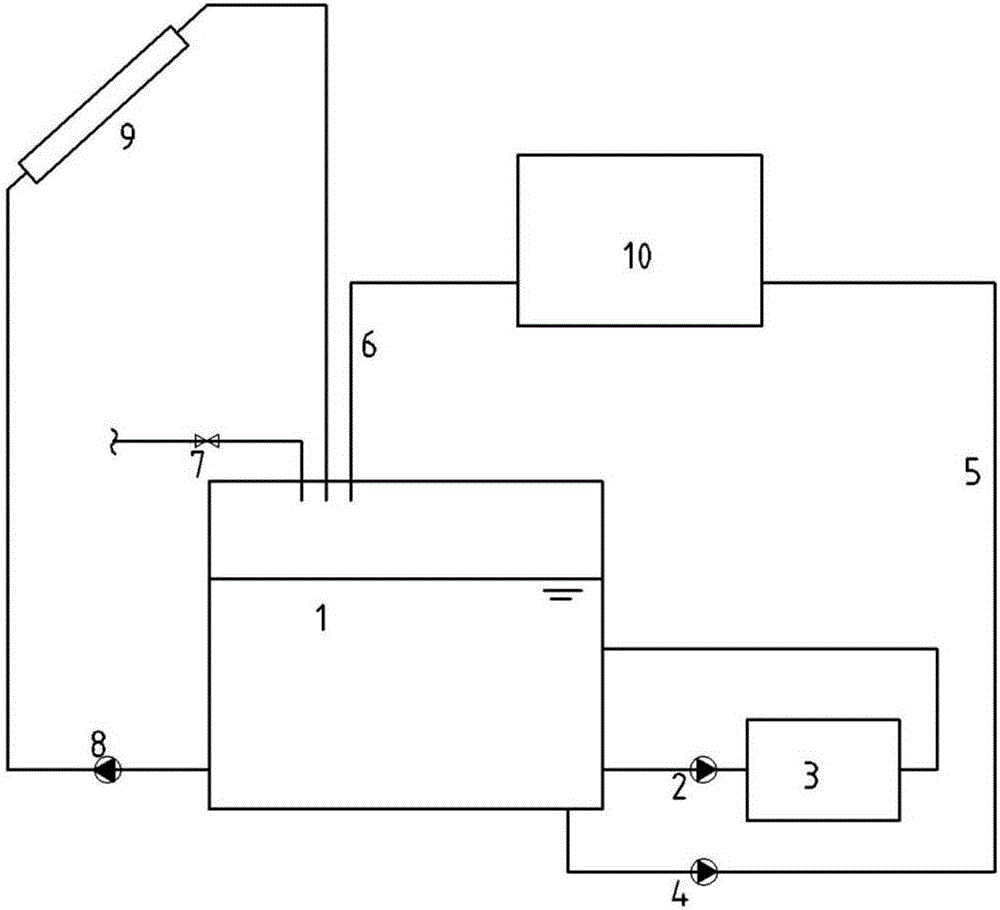

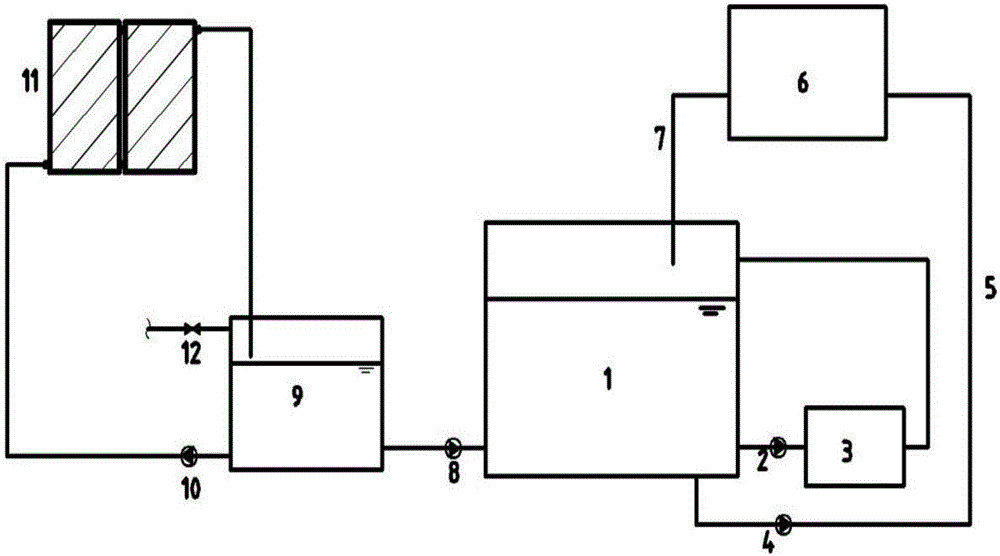

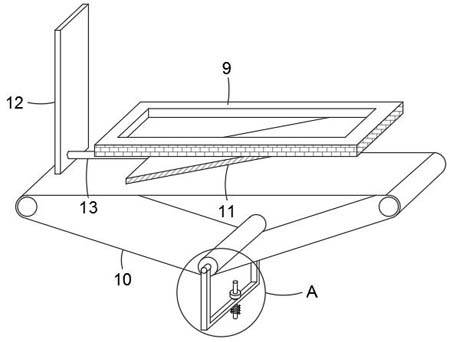

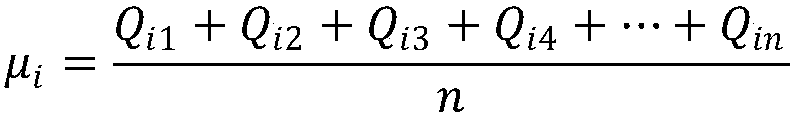

Control method for lowest-water-level-changing double-water-tank solar water heating system

InactiveCN106839467AReduce the temperatureIncreased load-bearing capacitySolar heating energySolar heat collector controllersWater useStart time

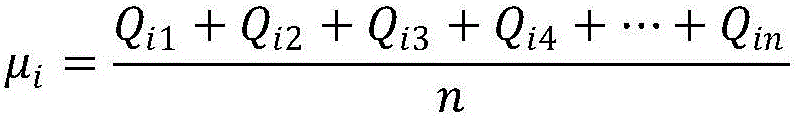

The invention discloses a control method for a lowest-water-level-changing double-water-tank solar water heating system. The control method includes the following steps that multiple parameters of the double-water-tank solar water heating system in all time periods in n days before a forecasting day are collected; calculation is conducted to obtain the water use amounts of all the time periods in the n days before the forecasting day by subtracting the water flow of a water return main pipe in the corresponding time periods from the water flow of a water supply main pipe of all the time periods in the n days before the forecasting day; with the combination of a statistical method of t distribution in applied mathematical statistics and under the set confidence coefficient, the following formulas are adopted for calculating the forecasting values of the water use amounts of all the time periods in the forecasting day; the water level set value of a gradient temperature control heat supply water tank in the forecasting day is calculated; heat collection circulation is conducted; a heat collection water tank supplements water to the heat supply water tank; water supplementation of the heat collection water tank is conducted; the heat collection water tank supplements water to the heat supply water tank; and gradient temperature control water supplementation and overheat protection are conducted. By the adoption of the method, the starting time of an auxiliary heat source is shortened, and it is expected that the energy is saved by 20% or higher than that of a single-water-tank solar water heating system.

Owner:TIANJIN UNIV

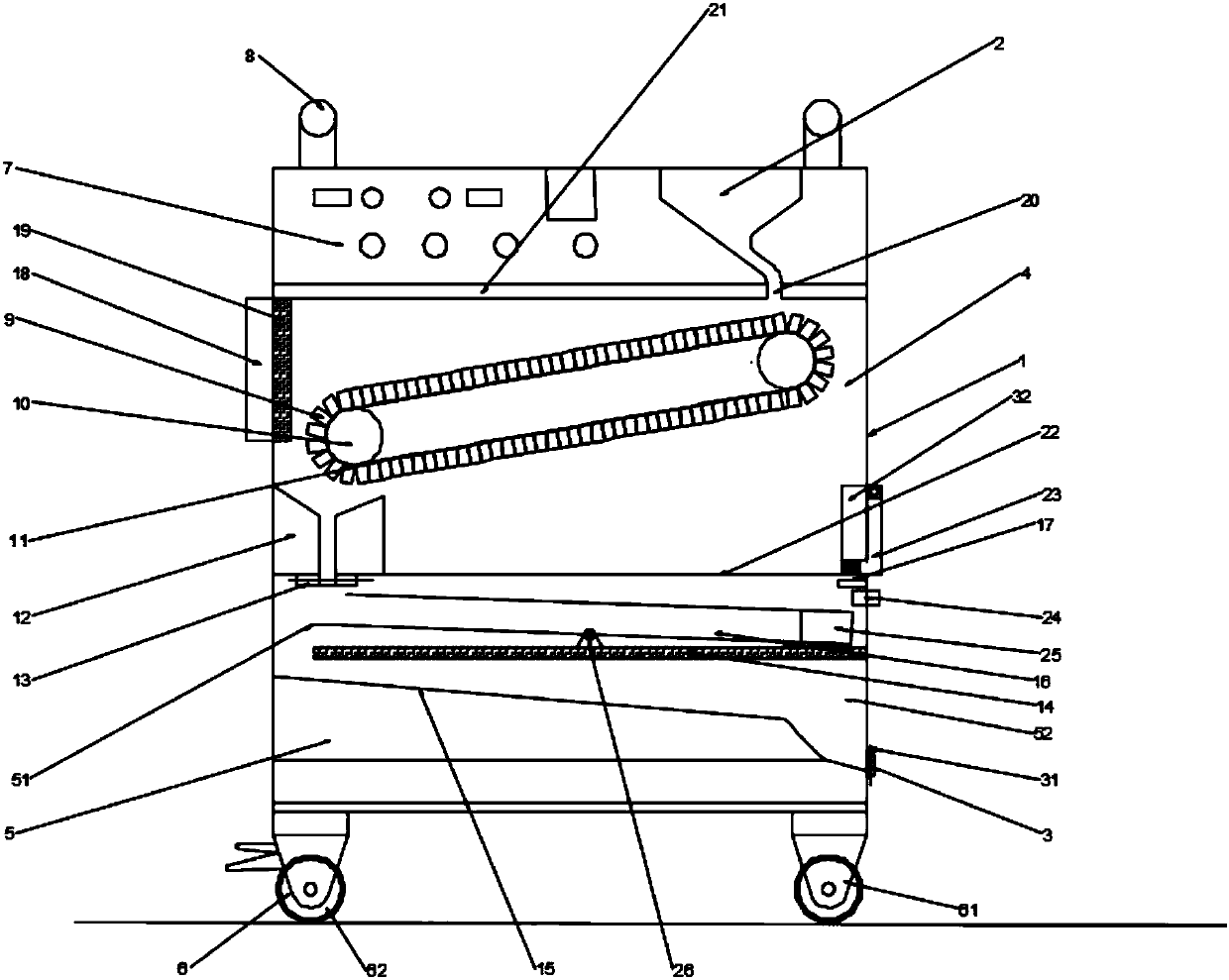

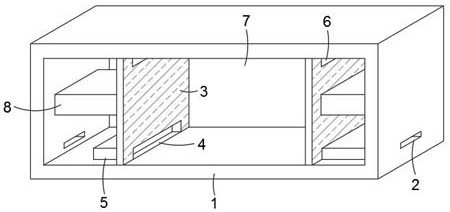

Convenient and fast welding rod drying trolley

InactiveCN107906915AAvoid secondary moistureAvoid direct heatingDrying gas arrangementsDrying machines with progressive movementsAgricultural engineeringMoisture

The invention discloses a portable welding rod drying vehicle, which comprises a box body, a material inlet, a material outlet, a drying box, a storage box and a walking device. The top of the box body is provided with symmetrically arranged lifting rings, and the upper part of the box body is provided with The control panel and the drying box are composed of pulley, blower, electric heating wire, air outlet, belt, material transfer port 1, material transfer port 2 and card slot. The card slot is evenly laid on the pulley, and the air outlet is equipped with an elastic door , the storage box includes: an upper storage box and a lower storage box, and the upper storage box and the lower storage box are separated by a heater. The counterweight device, the lower storage box is composed of a guide ramp and a discharge port. The present invention avoids the cracking phenomenon of the electrode coating caused by sudden cooling and sudden heating, and the electrode drying vehicle can be transferred, and single rods can be taken out during use, so that the electrodes are always kept under a suitable constant temperature condition, and secondary moisture is avoided.

Owner:WUXI WEI KELAI TECH CO LTD

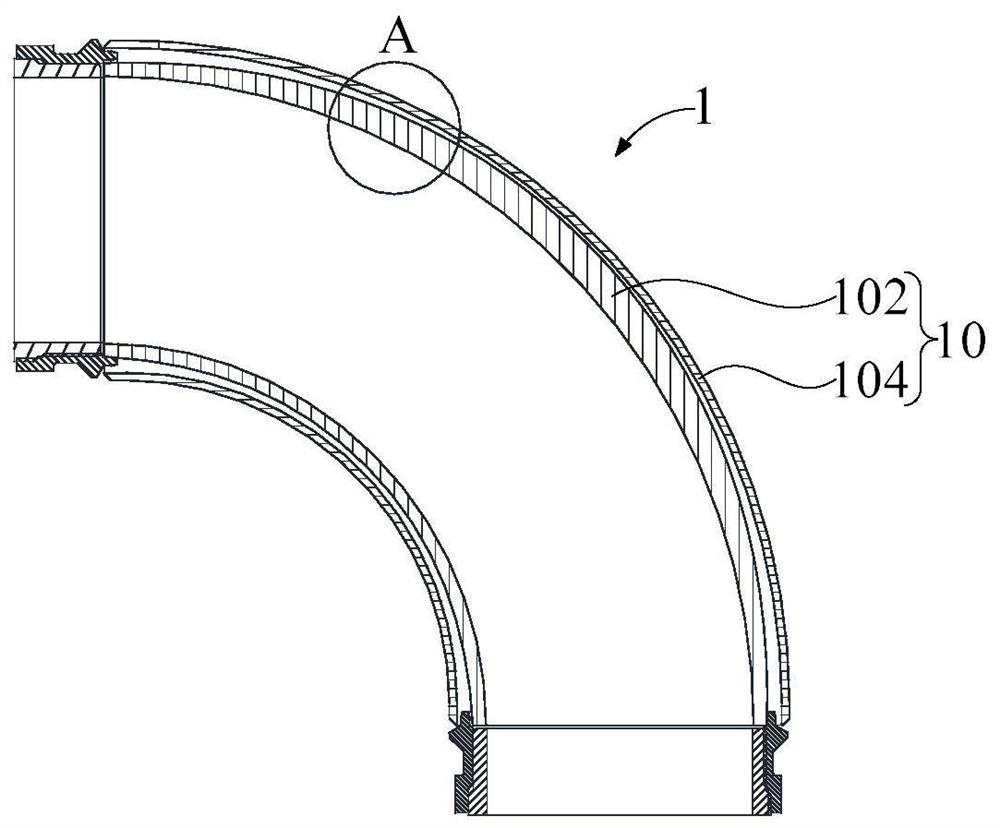

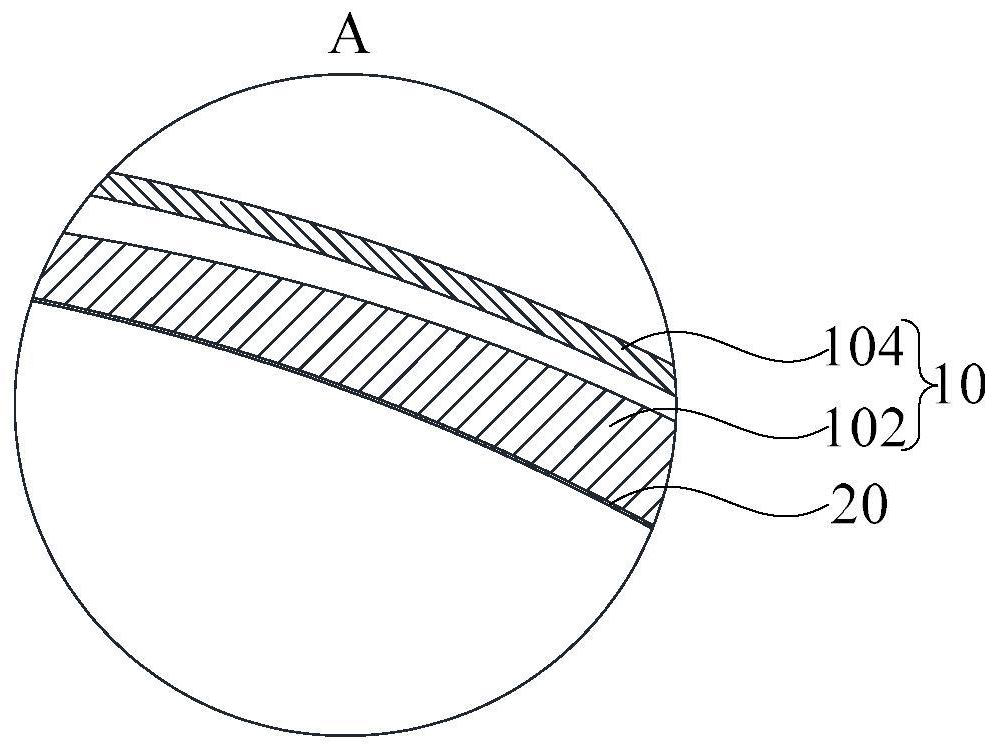

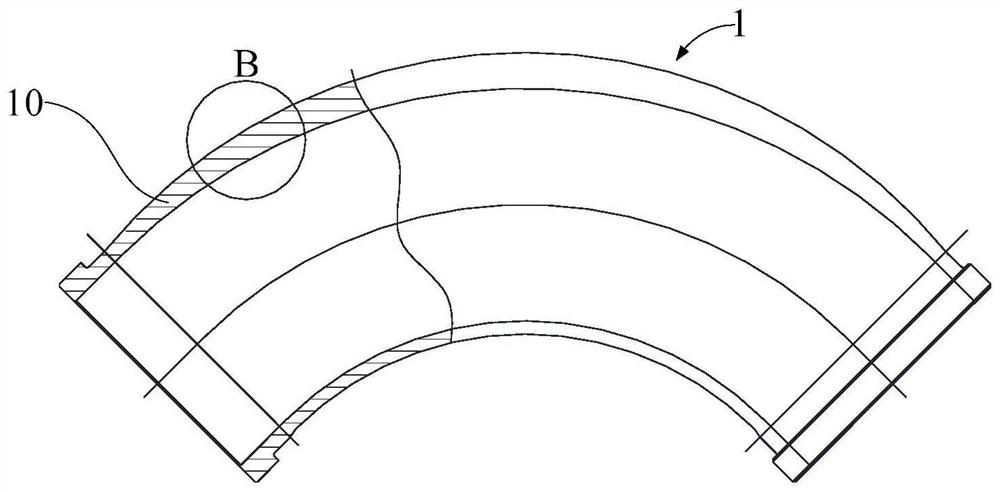

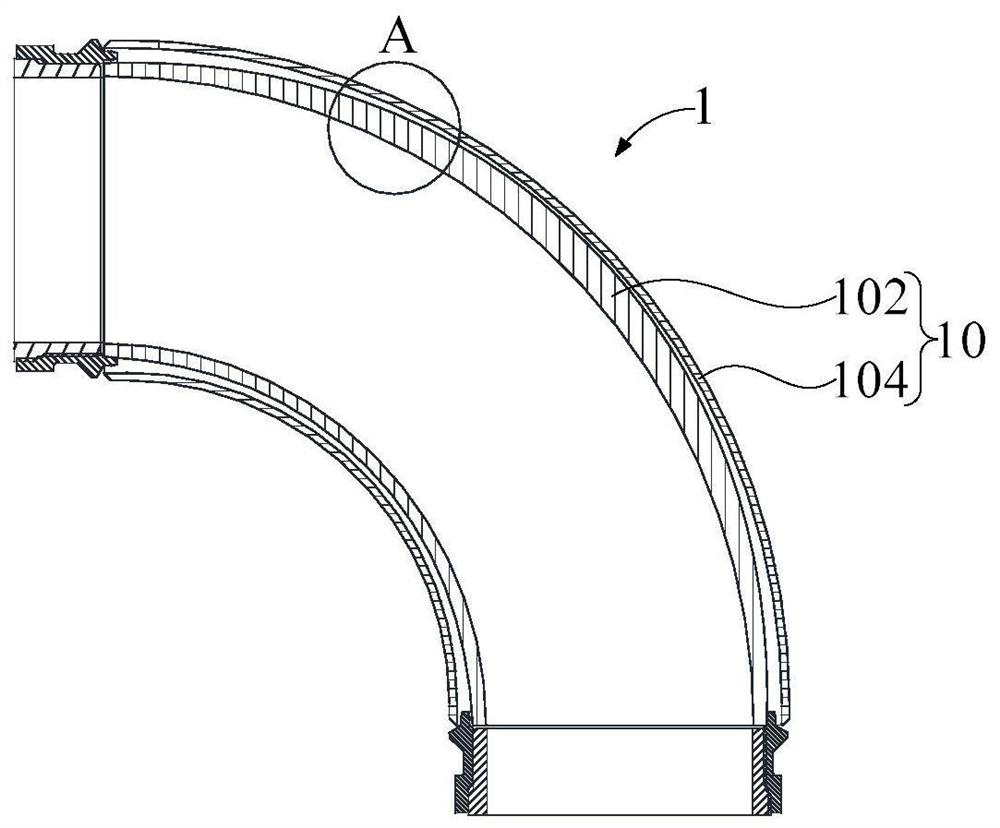

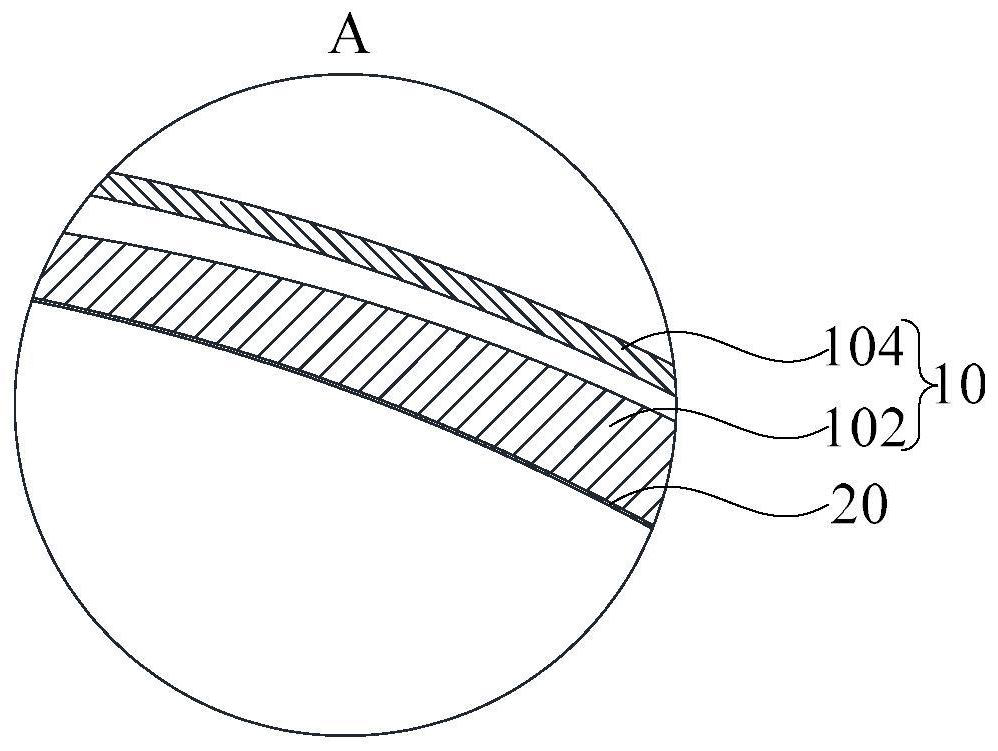

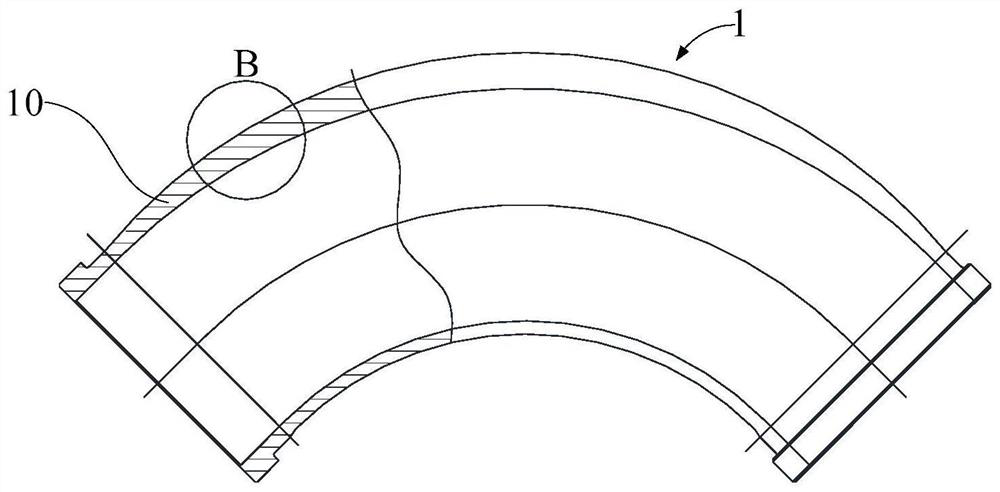

Pipeline, pipeline preparation method and concrete machinery

ActiveCN111765326ASimple structureReduce the difficulty of productionMolten spray coatingRigid pipesCeramic coatingArchitectural engineering

The invention provides a pipeline, a pipeline preparation method and concrete machinery. The pipeline comprises a pipe body and a wear-resisting coating; the wear-resisting coating is formed in the inner wall of the pipe body through heat spray coating; and the wear-resisting coating comprises a ceramic coating. Through the arrangement of the wear-resisting coating, materials can be prevented fromdirectly impacting and wearing the pipe body, so the pipe body is protected from wear by the materials and the service life of the pipe body is prolonged; and the pipe body can be prepared from regulate metal other than wear-resisting alloys, so the weight and production cost of the pipe body are lowered. The wear-resisting coating is of an integral structure formed by heat spray coating; on theone hand, the integral structure is high in structural stability, structural connection fracture does not exist, and the phenomenon of structural damage or falling can be effectively avoided; and on the other hand, heat spray coating technology has the advantages of high forming efficiency and high stability, so the pipeline production cost can be lowered while structural stability of the wear-resisting coating can be further improved.

Owner:SANY AUTOMOBILE MFG CO LTD

Wellhead heating storage tank

PendingCN112027386AImprove insulation effectAvoid direct heatingLarge containersTank wagonsWater jacketThermal safety

The invention provides a wellhead heating storage tank, and relates to the technical field of oil extraction equipment. A water jacket is arranged on the outer side of the storage tank and buried underground, and an electric heater is arranged in the water jacket; an output pump is arranged in the storage tank, and an outlet of the output pump is connected with two electric valves in parallel andconnected with an output pipe and a back flushing pipe. The wellhead heating storage tank has the following advantages that produced liquid in the storage tank is indirectly heated, the heating safetyis high, the purpose of flowing output is achieved, and potential safety hazards caused by the fact that crude oil is directly heated by the electric heater are prevented; a spray head arranged at the bottom of the storage tank impacts liquid at the bottom of the storage tank upwards to form hydraulic stirring, the liquid in the whole storage tank is stirred and output in a homogeneous state, thetendency of impurity deposition at the bottom of the storage tank is reduced, and the homogeneous produced liquid is beneficial for subsequent treatment; terrestrial heat is stored and released through the energy storage performance of a phase change energy storage material, and the temperature field outside the water jacket is improved; and meanwhile, energy is supplemented to the storage tank through solar energy, and energy consumption is reduced.

Owner:大庆市普罗石油科技有限公司

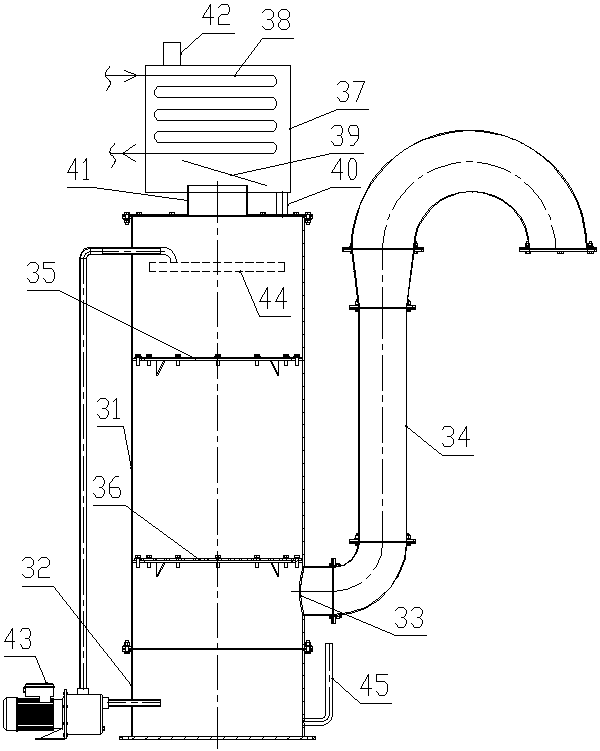

Waste liquid combustion treatment system

The invention discloses a waste liquid combustion treatment system. The system comprises a waste liquid combustion device, a heat recovery heat exchanger and a tail gas treatment device; the waste liquid combustion device comprises a collecting tank and a high-pressure air source, the collecting tank is connected with a waste liquid combustion furnace through a waste liquid pipe; the waste liquidcombustion furnace comprises a furnace body, a refractory mud layer is arranged on the inner wall of the furnace body, the lower end of the furnace body is closed, and an opening is formed in the upper end of the furnace body; the high-pressure air source communicates with the waste liquid pipe through a high-pressure air pipe, and an igniter is arranged at an opening of one end, extending into the furnace body, of the waste liquid pipe; the heat recovery heat exchanger comprises a heat exchange barrel which is vertically arranged; and the tail gas treatment device comprises a tower body, a water tank is arranged at the bottom of the tower body, a tail gas inlet is formed in the side wall of the tower body arranged on the water tank, two layers of porous plates are arranged at intervals inthe portion, above the tail gas inlet, of the tower body, a filling material is arranged on each porous plate, and the top end of the tower body is connected with a condenser through a tail gas outlet pipe. According to the system, liquid fuel waste liquid generated in a laboratory can be sufficiently combusted, heat generated by combustion can be recycled, and harmful components in the tail gascan be fully absorbed.

Owner:HENAN WANHE MACHINERY

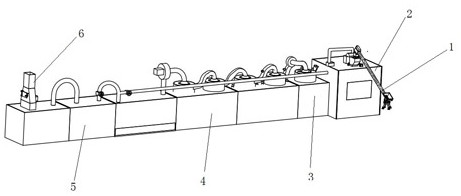

Double-side heat exchange tunnel type drying room with built-in heat source

ActiveCN113280603AAvoid direct heatingReduce energy consumptionDrying gas arrangementsDrying solid materialsElectric machineGear wheel

The invention discloses a double-side heat exchange tunnel type drying room with a built-in heat source. The double-side heat exchange tunnel type drying room with the built-in heat source comprises a room body, the interior of the room body is divided into a drying chamber and a heating chamber through two partition plates, and a drying frame is arranged in the drying chamber; and a supporting plate is fixed to the lower side wall of the room body, a motor is fixed to the upper side wall of the supporting plate, the driving end of the motor faces upwards and is fixedly provided with an incomplete gear, two rotating rods are installed on the supporting plate, a first gear and a second gear are fixed to each rotating rod, the two second gears are located on one side of the incomplete gear, a sliding plate is slidably inserted into the outer wall of the room body, and the left end of the sliding plate is fixedly connected with the outer wall of the drying frame. According to the double-side heat exchange tunnel type drying room, materials are automatically dried through automatic feeding of a material storage box, full contact between the materials and high-temperature airflow is guaranteed through left-right reciprocating movement of the drying frame, drying blind spots are avoided, a dense net plate automatically rotates downwards, the materials are guided out to a conveying belt to be conveyed and guided out, and automation of drying work is achieved.

Owner:南通腾宇环保设备有限公司

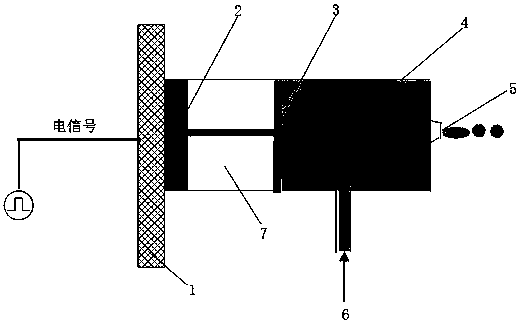

Print head for on-demand ink jet printer

The invention relates to a print head for an on-demand ink jet printer. The internal of the print head is divided into a cavity and a cartridge via a movable valve, heat conductive gas and ink are injected into the cavity and the cartridge respectively, an electric hot plate at one side of the cavity starts heating after receiving an electric signal from the printer, a heat conductive metal blockand the heat conductive gas are thermally expanded to push the movable valve to move towards the cartridge, and ink is extruded and injected out; and when printing is completed, the electric hot platestops heating, the heat conductive metal block and the heat conductive gas are contracted, and the movable valve moves towards the cavity to stop ink jetting. An ink inlet valve is provided with an inductor; in the process that an ink drop is formed and injected, namely when the electric hot plate is heated, the valve is closed automatically, and when the ink drop is sprayed, namely the electrichot plate stops heating, the valve is opened automatically, and ink is input. The print head of the invention is simple in structure, spray-out and stop of the ink are controlled by fully utilizing apressure generated by expansion with heat and contraction with cold, and the production cost is lower.

Owner:HUBEI POLYTECHNIC INST

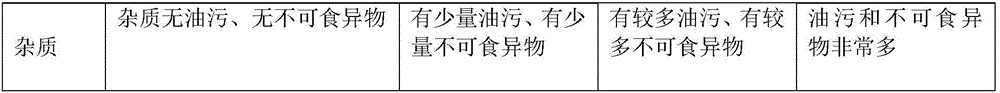

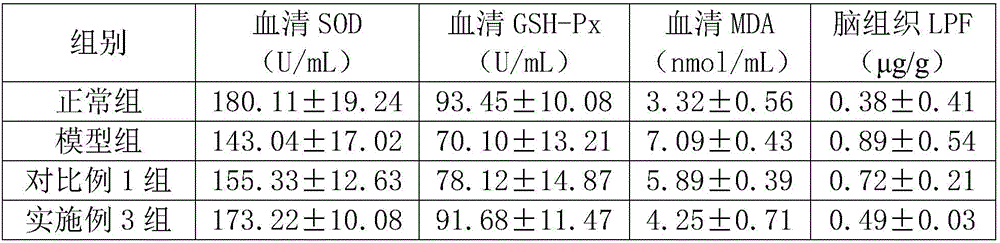

Pitaya flower cake and making method thereof

InactiveCN105994533AGreat tasteGuaranteed active substance activityDough treatmentBakery productsGlucose-Fructose SyrupAdditive ingredient

The invention belongs to the technical field of food processing, and particularly relates to a pitaya flower cake. The pitaya flower cake is made from, by weight, 50-100 parts of flour, 10-20 parts of glutinous rice flour, 12-22 parts of pitaya flowers, 3-8 parts of flos rosae rugosae, 3-9 parts of shiitake mushrooms, 2-6 parts of mangoes, 3-7 parts of corn stigmas, 4-9 parts of white granulated sugar, 1-4 parts of honey, 1-5 parts of glucose syrup, 1-4 parts of egg yolk powder, 1-4 parts of malt flour, 1.2-2 parts of salt and 20-40 parts of water. The invention further provides a making method of the pitaya flower cake. By means of synergistic action of the method and the formula, the effective ingredients of pitaya flowers are effectively protected, the activity of pitaya flowers is improved, and the made pitaya flower cake has high anti-aging, anti-oxidation and anti-cancer effects.

Owner:钦州市钦南区科学技术情报研究所

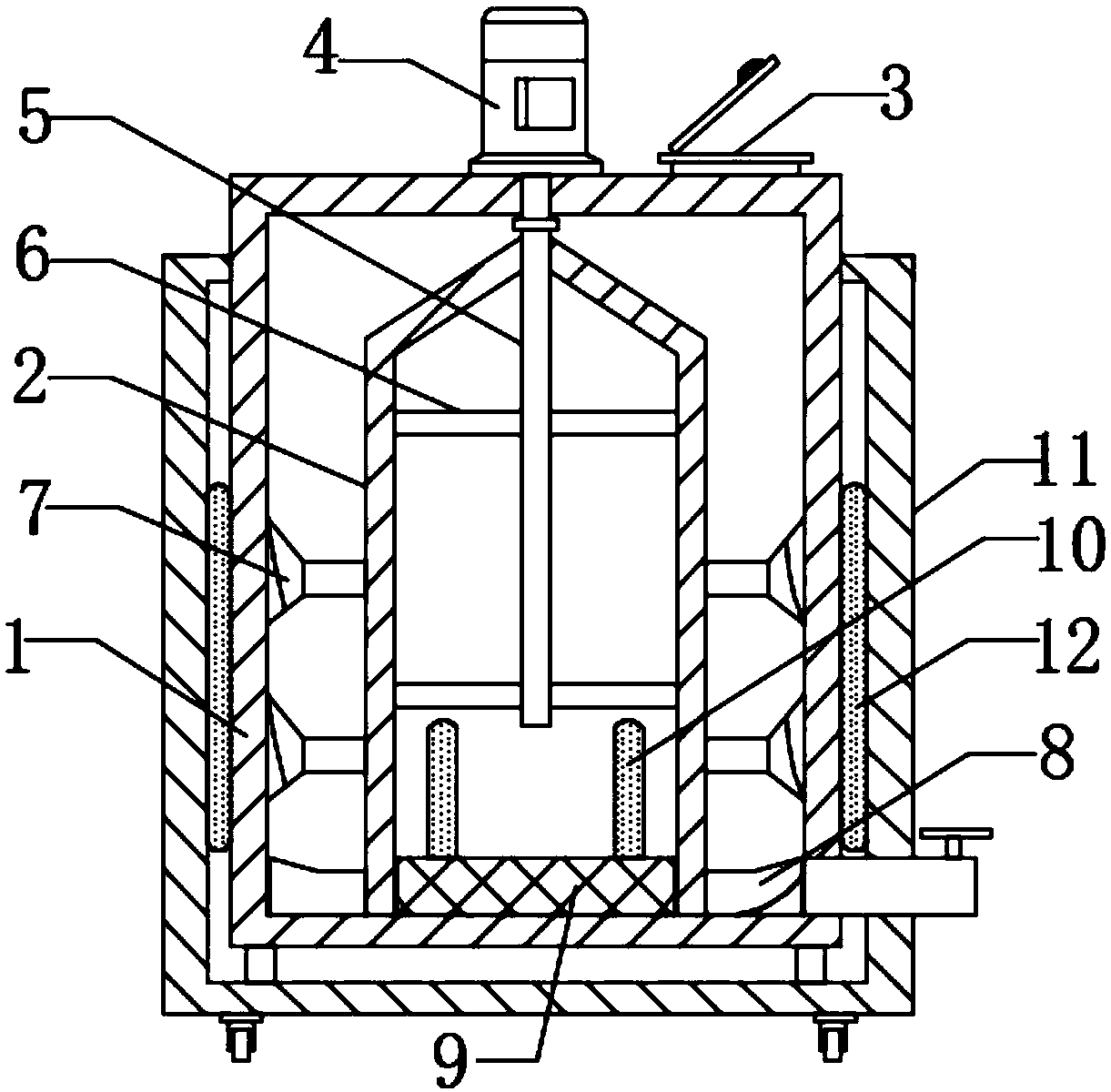

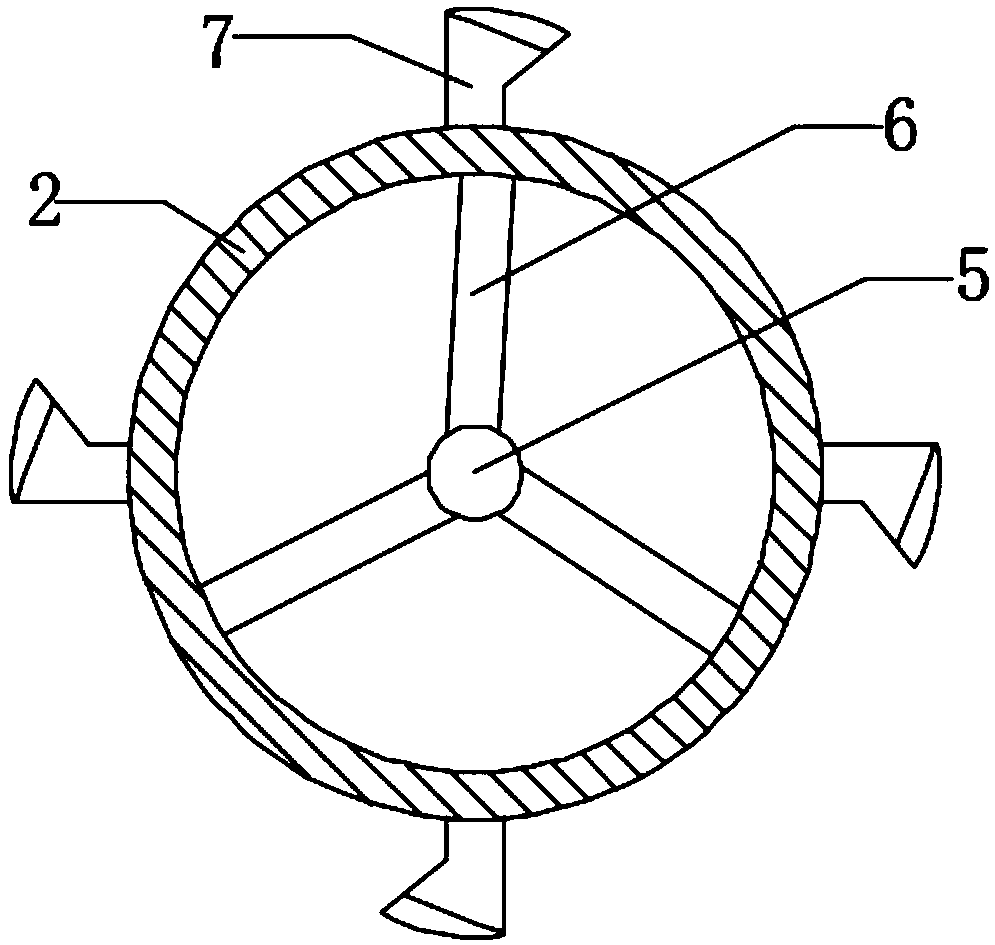

Fusion device for yellow lead production

InactiveCN109431804AImprove the heating effectEasy dischargePharmaceutical product form changeDirect heatingShovel

The invention discloses a fusion device for yellow lead production. The fusion device comprises a fusion box, a rotary roller is rotatably connected to the inside of the fusion box, and a motor is fixedly installed in the middle of the upper end of the fusion box; a rotary shaft is fixedly connected with an output shaft of the motor, several fixed rods are fixedly connected to the side surface ofthe rotary shaft, and the rotary shaft is fixedly connected to the inside of the rotary roller through the fixed rods; several side wall shovel plates are fixedly connected to the side surface of therotary roller, several bottom shovel plates are fixedly connected to the lower end of the side surface of the rotary roller, and a fixed column is fixedly connected to the bottom of the fusion box; afirst heating pipe is fixedly installed at the upper end of the fixed column, a temperature preservation bucket is fixedly connected with an outer ring of the fusion box, and a second heating pipe isfixedly installed between the fusion box and the temperature preservation box. The using efficiency of the fusion device for yellow lead production is improved, fused yellow lead can be discharged better, direct heating is avoided, and yellow lead of a thick layer is prevented from wrapping the heating pipes.

Owner:许五妮

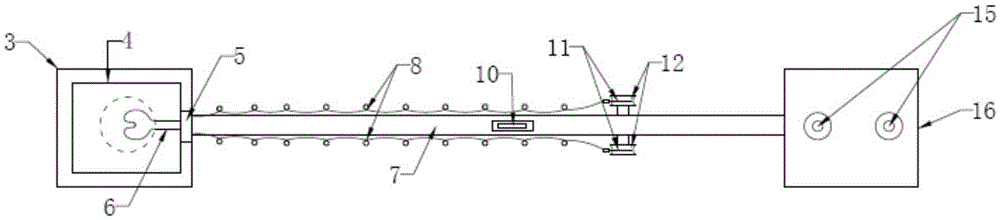

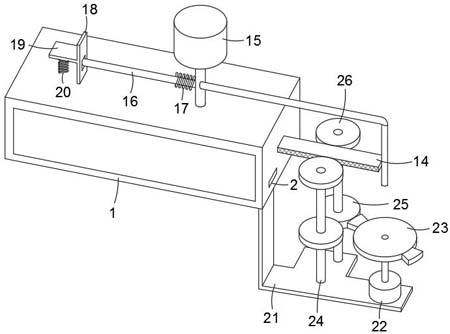

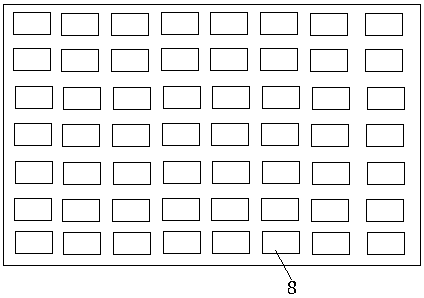

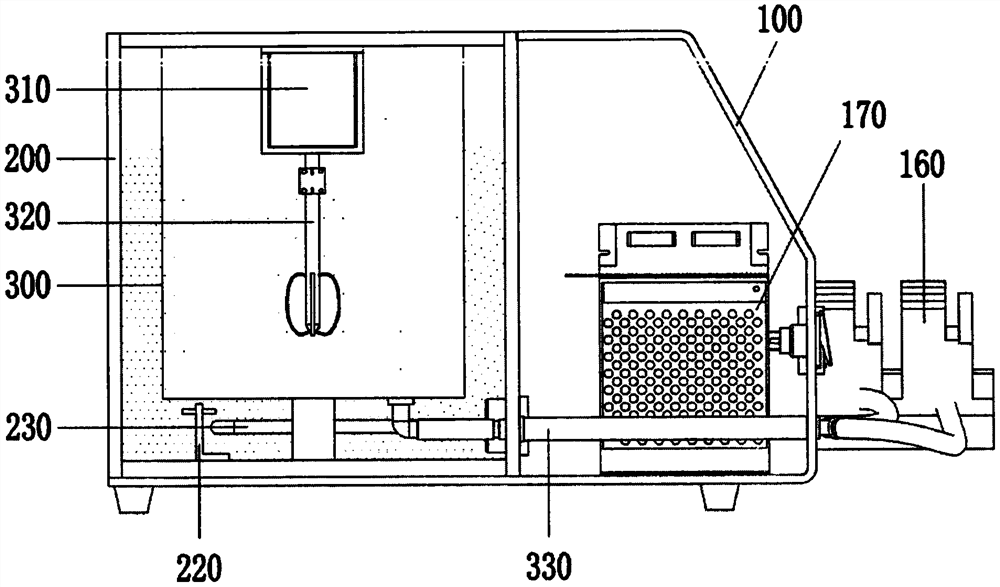

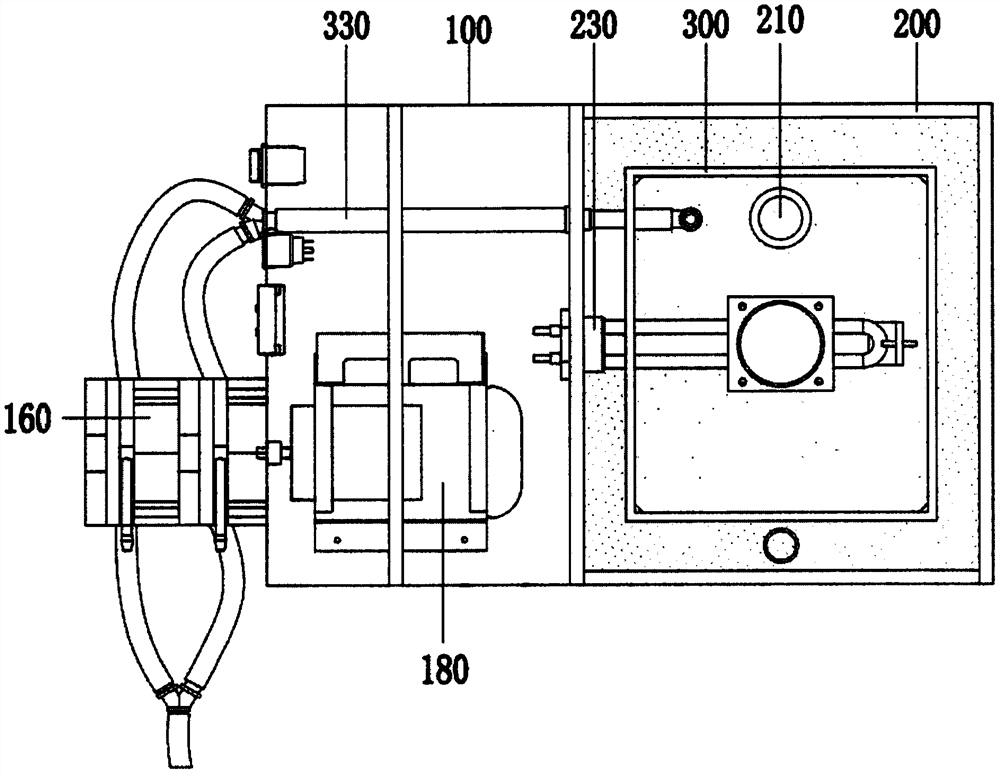

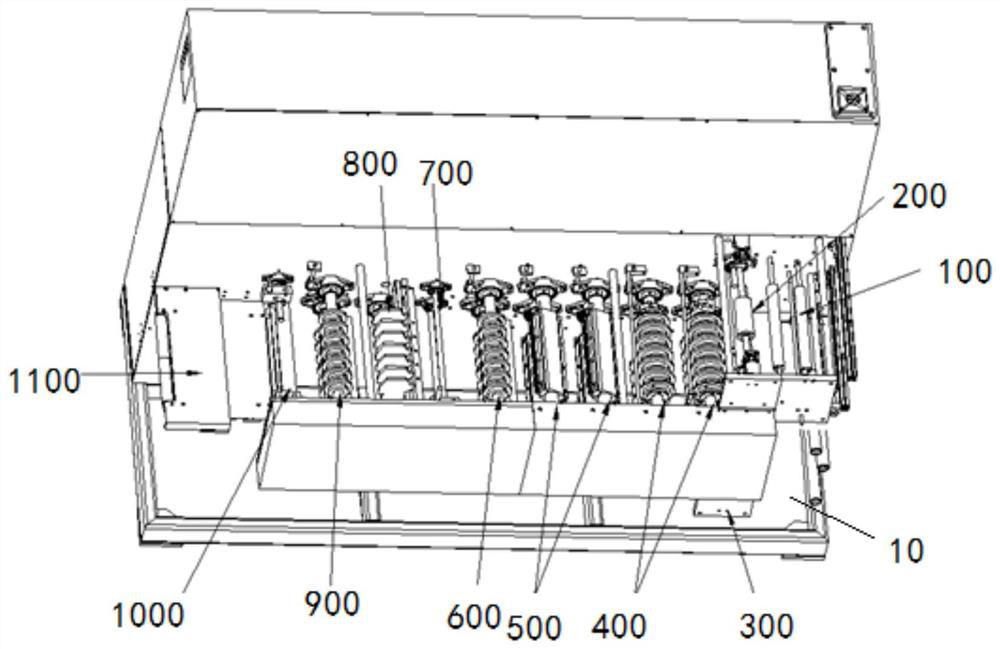

Automatic liquid adding control system for absorption product detection

PendingCN112649339AAvoid direct heatingAvoid destructionPermeability/surface area analysisSaline waterDC - Direct current

The invention discloses an automatic liquid adding control system for absorption product detection in the technical field of disposable hygienic product testing devices. The automatic liquid adding control system comprises a control box, a clean water tank and a saline water tank, wherein the control box is located at the right part of the clean water tank, the saline water tank is located in an inner cavity of the clean water tank, two groups of water adding ports are formed in the top wall of the clean water tank, the two groups of water adding ports are communicated with inner cavities of the clean water tank and the saline water tank respectively, a temperature sensor is arranged on the bottom wall of the clean water tank, a direct-current motor is installed on the top wall of the inner cavity of the saline water tank through a welding support, a stirring paddle is installed on an output shaft of the direct-current motor through a coupler, the outer wall of the water outlet of the saline water tank is sleeved with a silicone tube, and one end of the silicone tube penetrates through the outer walls of the clean water tank and the control box respectively. According to the automatic liquid adding control system, the clean water tank and the saline water tank are independently arranged, and raw saline water is injected into the inner cavity and indirectly heated by tap water outside the cavity, so that the raw saline water is effectively prevented from being directly heated by the heating pipe, and the oxidation effect caused by direct contact heating and the damage to tissue components of the raw saline water are avoided.

Owner:英氏控股集团股份有限公司

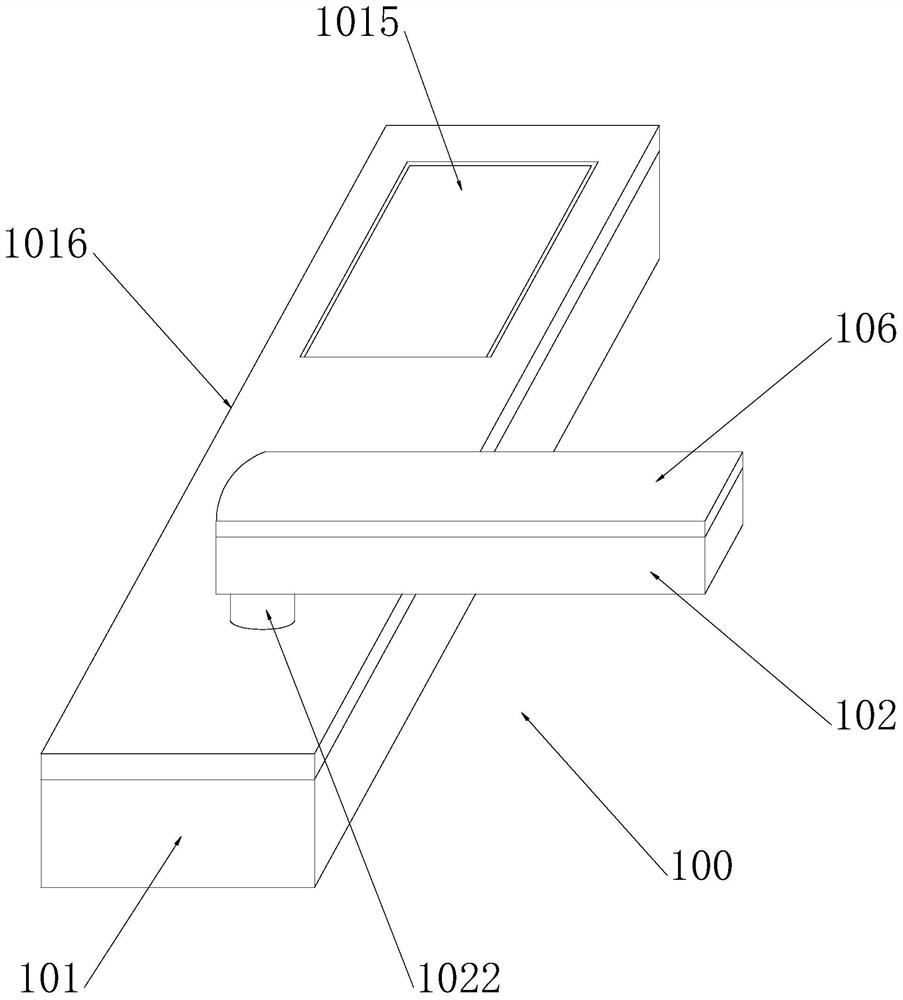

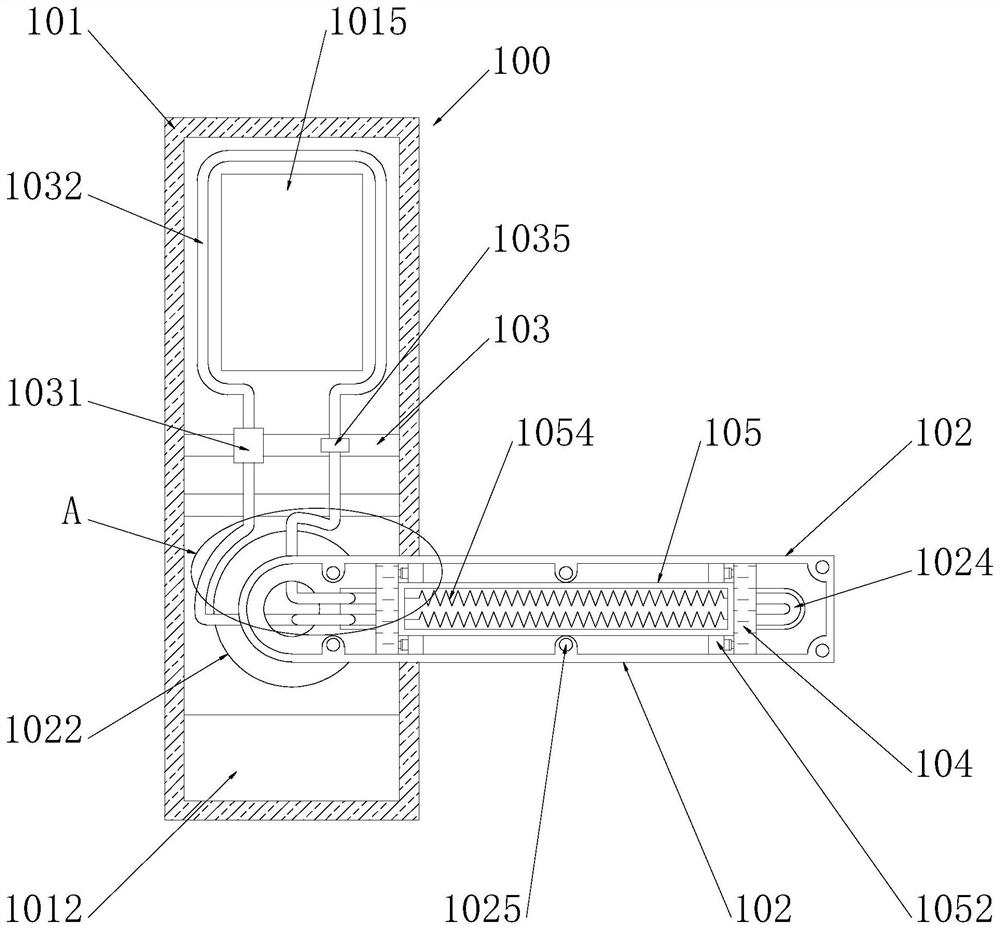

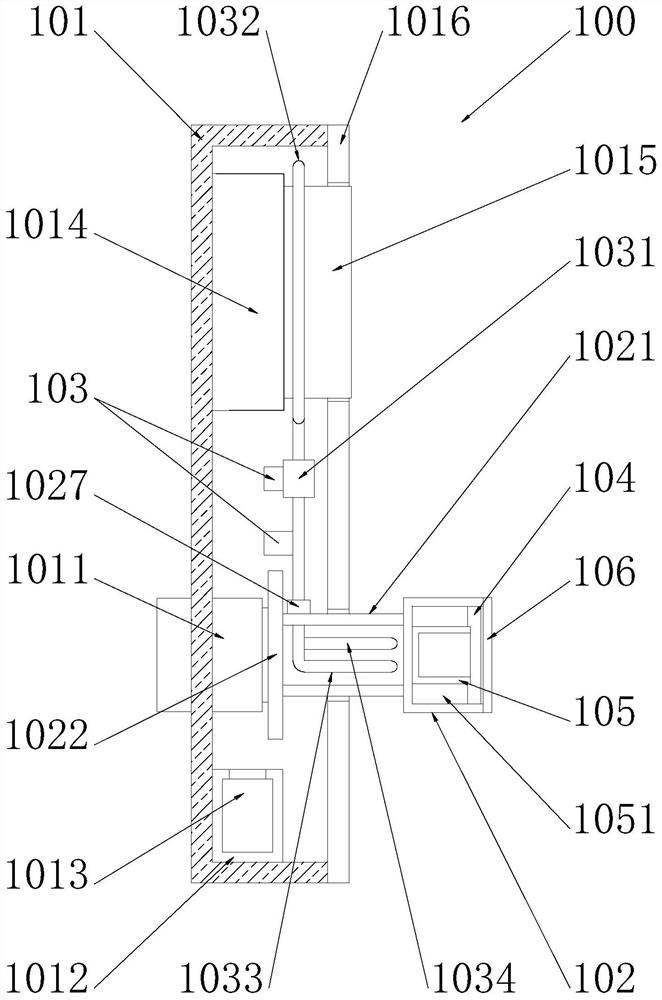

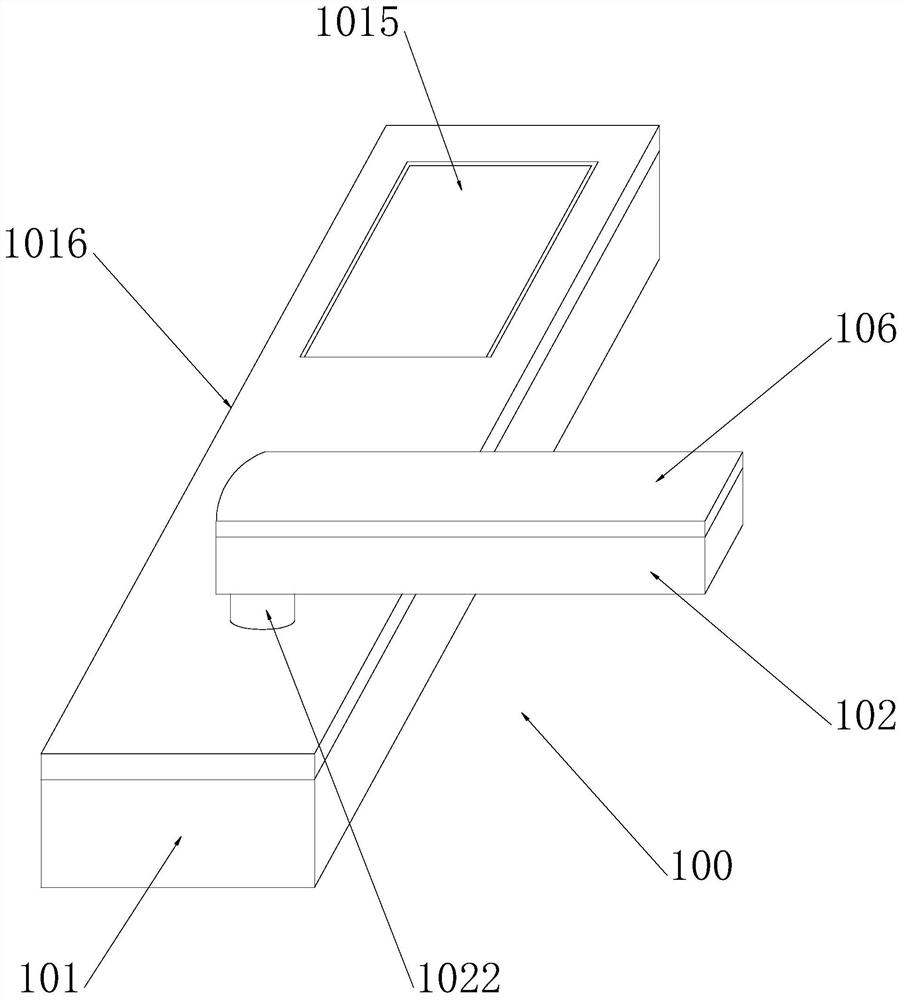

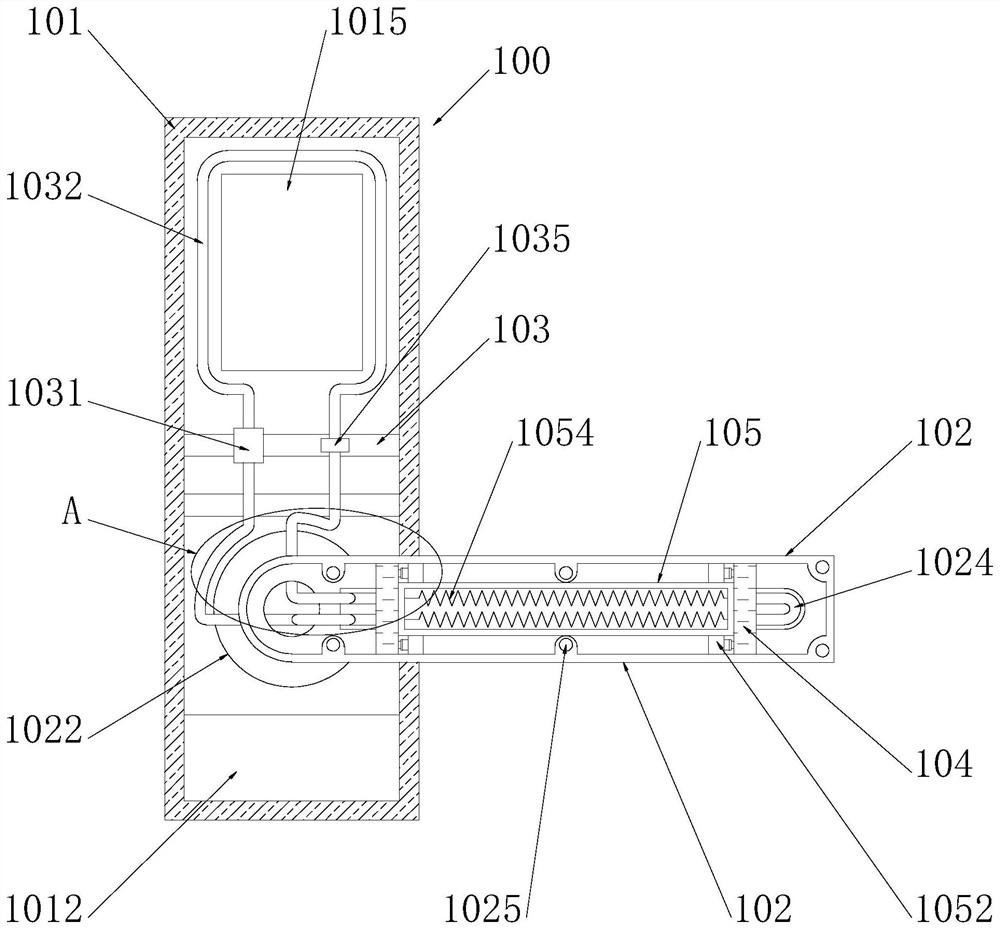

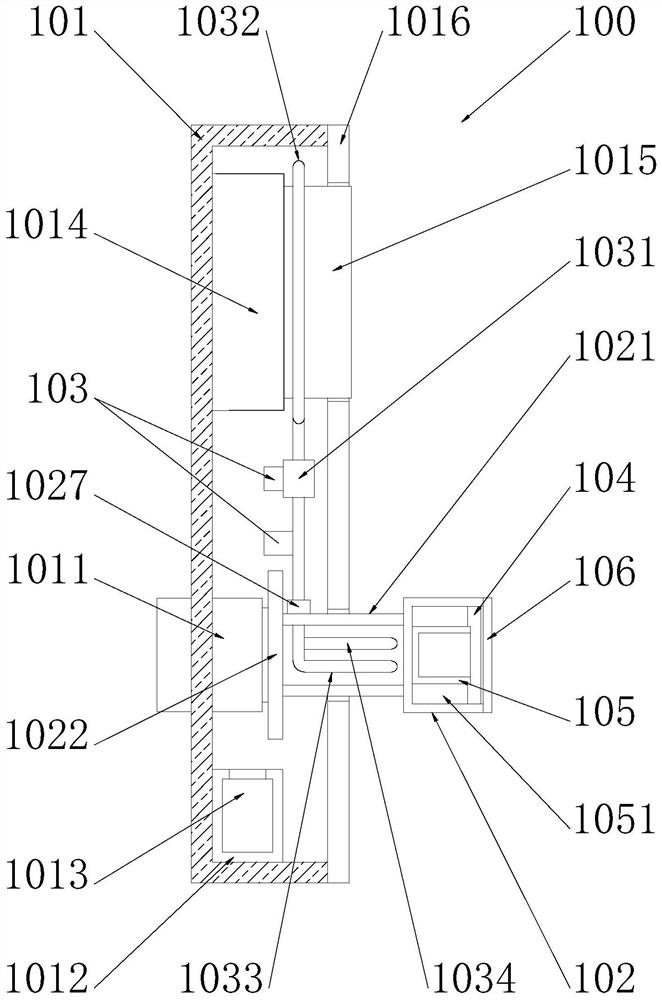

Intelligent lock with heating structure

ActiveCN113107274AReasonable and reliable structureEasy to installWing handlesDrying solid materials without heatDirect touchTouchscreen

The invention discloses an intelligent lock with a heating structure. The intelligent lock comprises a lock body, a lock shell, a storage box, a drying agent, a fingerprint identifier, a fingerprint touch screen, a lock cover, a handle, a connecting shaft, a fixed plate, a fixed shell, a heat exchange pipe, a threaded hole, a bolt, a connector, a supporting plate, a micro water pump, a heating pipe, a water inlet pipe, a water outlet pipe, a fixed buckle, a partition plate, a protective shell, a fixed block, an elastic piece, a clamping block, an electric heating wire, a cover body, a pressing plate and a notch. The intelligent lock has the beneficial effects that a heating source can be arranged on the handle to heat the handle, the anti-freezing problem in winter is achieved, the surface of the intelligent lock can be heated, the heating source is arranged on the handle, the situation that the heating source directly heats the interior of the intelligent lock can be avoided, and the problem that the heating source damages the intelligent lock is solved; and heat exchange is achieved through a closed pipeline, it can be guaranteed that the surface heating temperature of the intelligent lock is appropriate, and meanwhile the fixed shell and the cover body can prevent the heating source at the handle from making direct contact with a user.

Owner:DESSMANN CHINA MACHINERY & ELECTRONICS

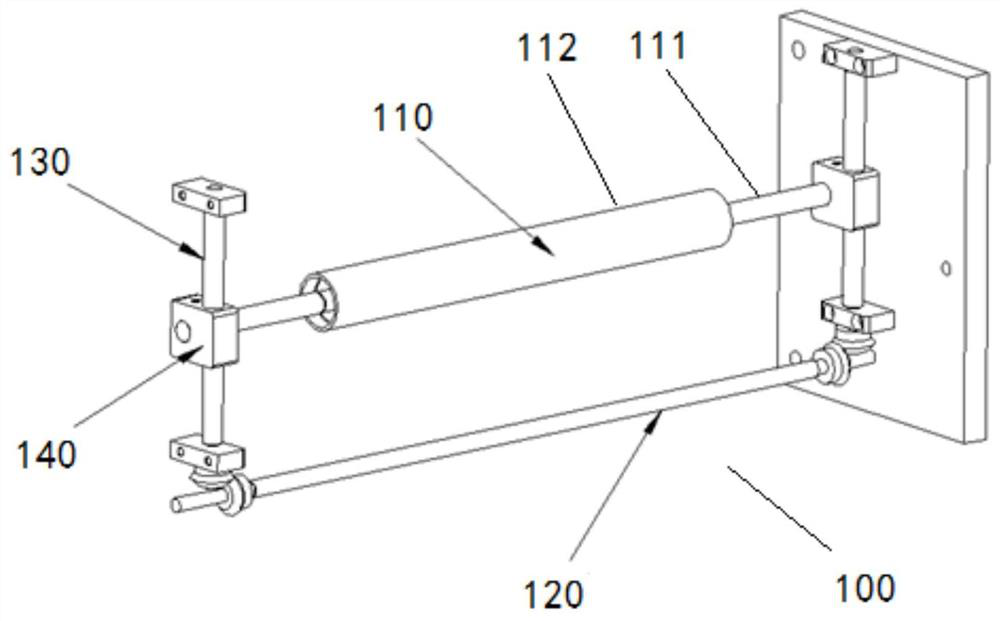

Package forming device

PendingCN113548256AImprove versatilityAvoid designWrapper twisting/gatheringMechanical engineeringPhysics

The invention discloses a package forming device which comprises a supporting base, at least one transverse sealing mechanism and at least one vertical sealing mechanism. The transverse sealing mechanisms and the vertical sealing mechanisms are sequentially arranged on the supporting base. Each transverse sealing mechanism comprises first supporting assemblies, at least two transverse sealing assemblies arranged on the first supporting assemblies and first heating assemblies arranged between the first supporting assemblies and the transverse sealing assemblies, and the distance between the transverse sealing assemblies can be adjusted according to the size of a product to be machined. Each vertical sealing mechanism comprises second supporting assemblies, at least two vertical sealing assemblies arranged on the second supporting assemblies, second heating assemblies arranged in the vertical sealing assemblies and heat insulation assemblies arranged between the second supporting assemblies and the at least two vertical sealing assemblies, and the rotating speed of the vertical sealing assemblies can be adjusted according to the size of the product to be machined. The package forming device can be suitable for machining products of different sizes, the universality of the device is improved, the situation that special equipment is specially designed for each product is avoided, and the production cost is reduced.

Owner:郑州中顺智能设备有限公司

Channel type and static heating combined fuel oil heating structure

PendingCN111336046AAvoid direct heatingSmall filter resistanceMachines/enginesLiquid fuel feedersEngineeringFuel filter

The invention discloses a channel type and static heating combined fuel oil heating structure. The channel type and static heating combined fuel oil heating structure comprises a middle vertical platewith an arc-shaped horizontal section, wherein the surface of the side, facing the circle center of the fuel oil heating structure, of the middle vertical plate serves as the inner surface, and the surface of the other side serves as the outer surface; an inner heat dissipation plate and an outer heat dissipation plate are fixedly connected to the inner surface and the outer surface of the middlevertical plate in an attached mode, an upper support plate is connected to the top end of the middle vertical plate, a lower support plate is connected to the lower end of the middle vertical plate,and the upper support plate and the lower support plate are used for being connected with the inner surface of a shell of the fuel filter in a pressing mode, so that a gap is formed between the outerheat dissipation plate and the inner wall of the shell of the fuel filter, the shell is prevented from being heated directly, heat dissipated to the outside is reduced, and the fuel oil heating efficiency is improved. After the channel type and static heating combined fuel oil heating structure is adopted, a heating mode of combining channel type heating and static heating is realized, the heatingefficiency is higher, the energy loss is little, fuel oil at a channel is heated more uniformly, the fuel oil at the channel and static fuel oil are both heated, and the filter resistance when the fuel oil passes through a filter layer is reduced to the maximum extent while the energy is saved.

Owner:PINGYUAN FILTER

Injection molding machine material taking method based on mechanical arm

PendingCN114030146AImprove the efficiency of mold opening and reclaimingImprove reclaiming efficiencyInjection molding machineIndustrial engineering

The invention relates to an injection molding machine material taking method based on a mechanical arm. In a mold opening process, when a movable mold of an injection molding machine moves to the position where the movable mold is completely located on the outer side of an injection molding product and does not hinder the mechanical arm to execute a material taking action, the mechanical arm is controlled to start the material taking action. According to the injection molding machine material taking method based on the mechanical arm, before the movable mold reaches the starting position to complete the mold opening action, a material suction frame can be controlled to start the material taking action. Compared with the prior art that the material suction frame is controlled to act after the movable mold completes the whole mold opening process and returns to the starting position, the methodimproves the mold opening and material taking efficiency of the injection molding machine.

Owner:TECHNIMARK PRECISION CASTING SUZHOU CO LTD

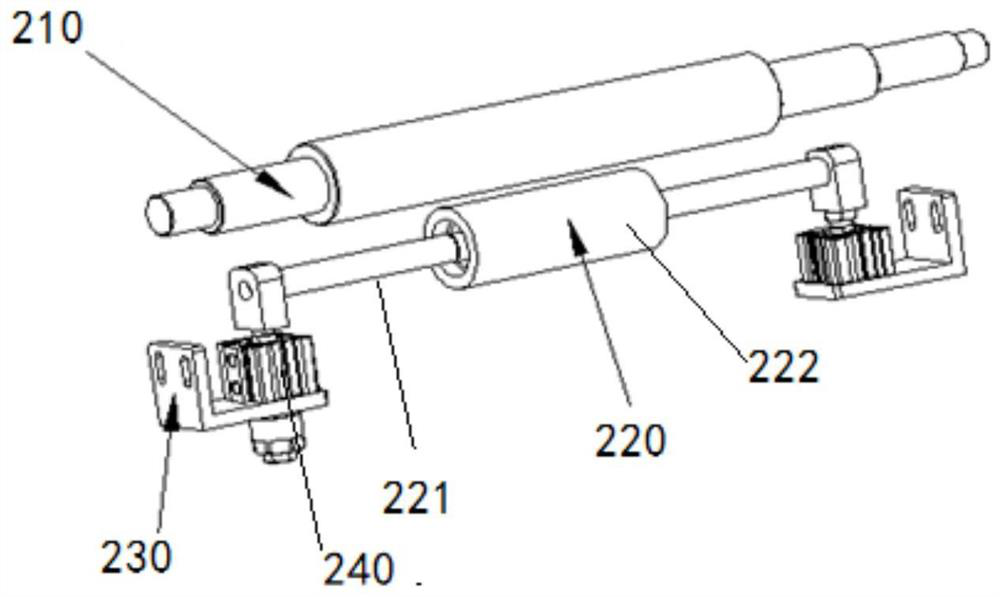

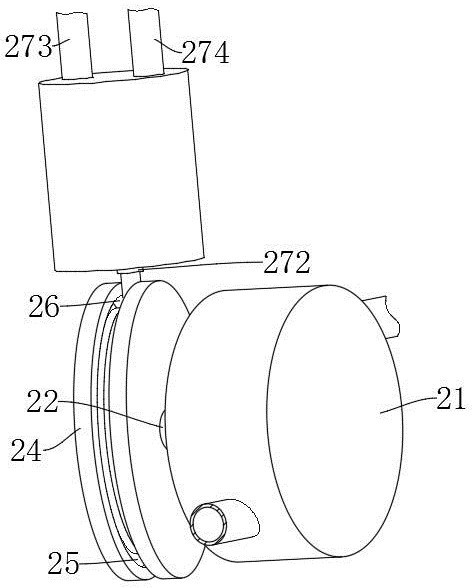

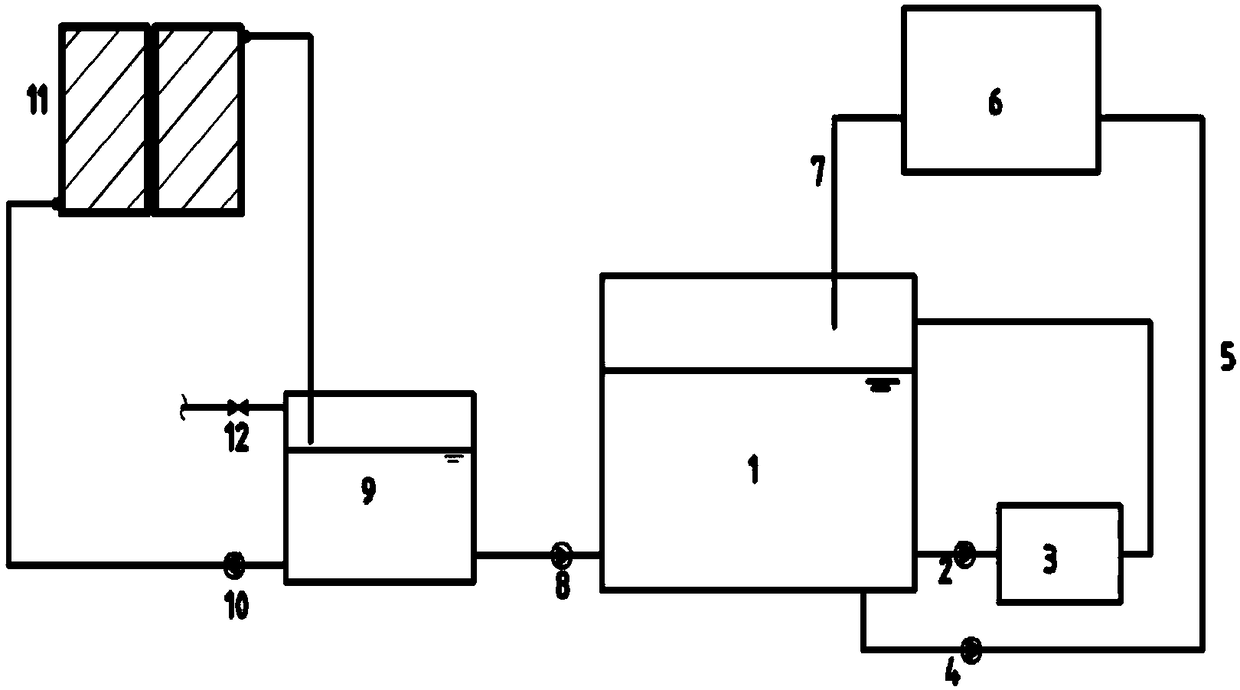

Multi-tube-bundle clean steam generator and using method thereof

PendingCN113669709AIncrease temperatureAvoid direct heatingMachines/enginesSteam generation using hot heat carriersProcess engineeringElectric heating

The invention discloses a multi-tube-bundle clean steam generator and a using method thereof, and belongs to the field of clean steam generators. A multi-tube-bundle clean steam generator comprises a heating box and a water storage tank, wherein a driving box is arranged between the heating box and the water storage tank, and the multi-tube-bundle clean steam generator further comprises: a steam inlet tube and a first steam outlet tube which are both fixedly connected to the heating box; and a plurality of steam tanks which are fixedly connected in the heating box; industrial steam is guided into the heating box, then the steam tanks and the water storage tank are heated to indirectly heat pure water, direct heating of the pure water through an electric heating rod is avoided, and the situation that after the electric heating rod is burnt in a dry mode due to water quantity reduction, the exposed surface of the electric heating rod expands and peels to pollute the pure water is avoided; and the heating area of the pure water can be increased through the plurality of the steam tanks and scattering nets, so that the pure water can be quickly and efficiently evaporated to form clean steam.

Owner:泰山集团泰安华电热工有限公司

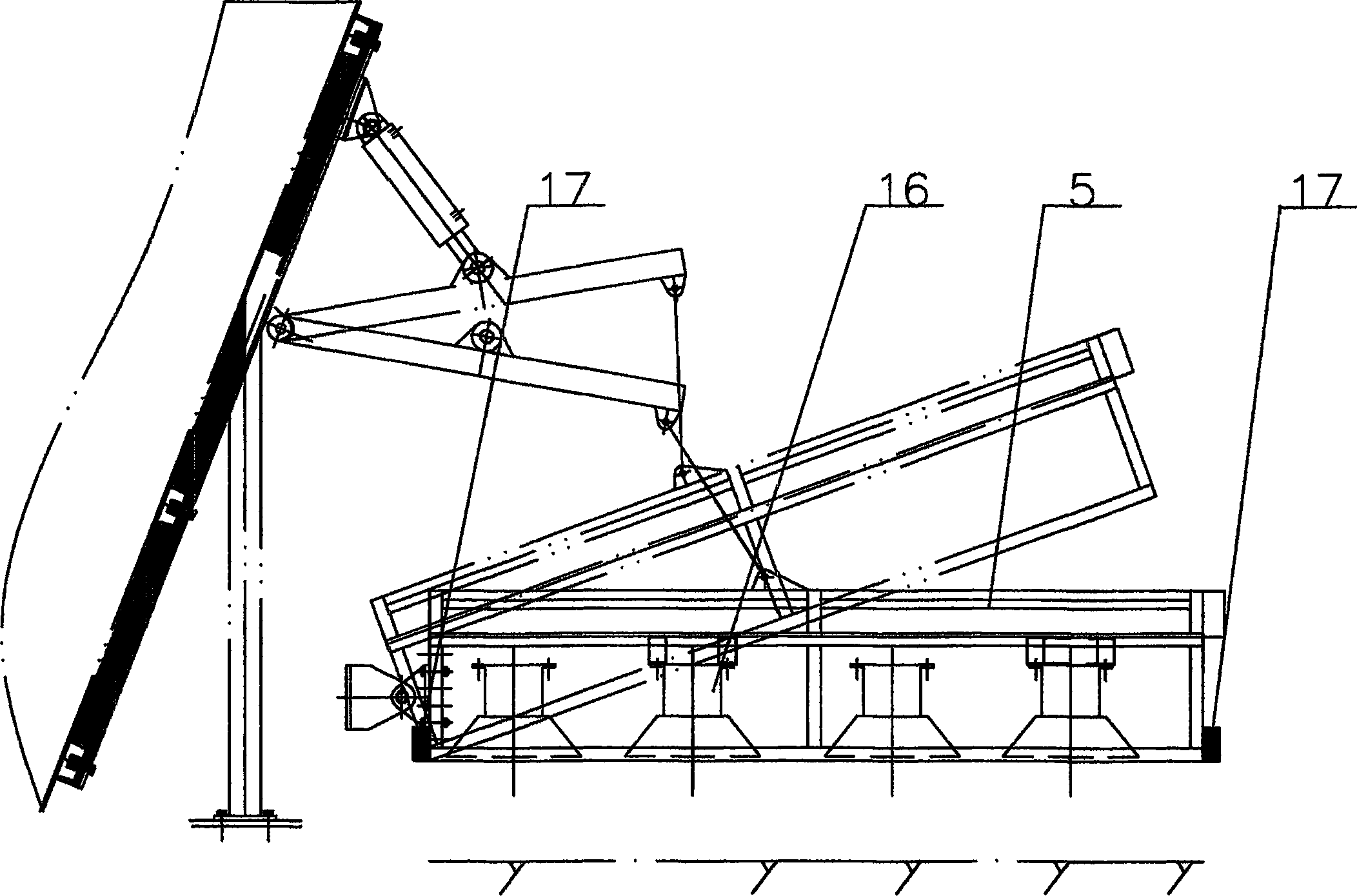

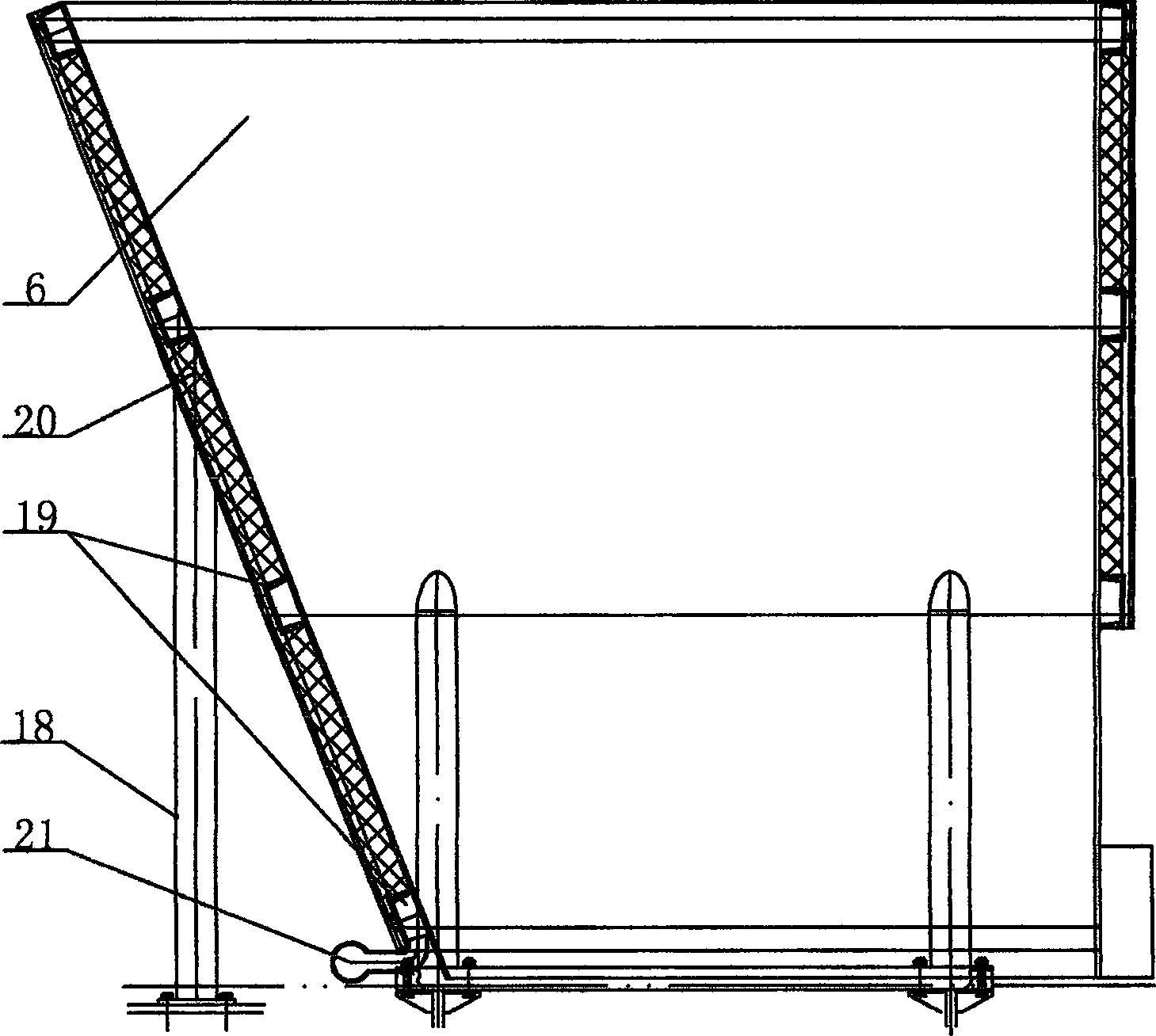

A crawler type spreading machine for rolling core walls of asphalt concrete in the hydraulic engineering

InactiveCN100465385CPrevent oxidative aging and even burningAvoid getting lostFoundation engineeringMixed materialsHydraulic engineering

A crawler united paver for rolling asphalt concrete is prepared as setting infrared heating unit and insulated hopper of asphalt mixed material at host head; setting alignment monitoring unit at connection point of infrared heating unit and host; setting shock-ironing plate and frame die at host back, riding transition material sub hopper on frame die and setting scraper, scraper lifting up and lowering down unit and receiver of laser leveling unit at back of transition material sub hopper.

Owner:CHINA GEZHOUBA GRP INT ENG

A smart lock with heating structure

ActiveCN113107274BReasonable and reliable structureEasy to installWing handlesDrying solid materials without heatEngineeringTouchscreen

The application discloses a smart lock with a heating structure, which includes: a lock body, a lock case, a storage box, a desiccant, a fingerprint reader, a fingerprint touch screen, a lock cover, a handle, a connecting shaft, a fixing plate, a fixing case, a replacement Heat pipes, threaded holes, bolts, joints, support plates, micro pumps, heating pipes, water inlet pipes, water outlet pipes, fixing buckles, partitions, protective shells, fixing blocks, shrapnel, clamping blocks, electric heating wires, covers, pressure plates and notch. The benefit of this application is that a heating source can be set on the handle to heat the handle, which not only realizes the problem of antifreezing in winter, but also can heat the surface of the smart lock. Setting the heating source on the handle can avoid direct damage to the inside of the smart lock by the heating source Heating to prevent the heating source from damaging the smart lock. The closed pipe is used to realize heat exchange, which can ensure the heating temperature of the smart lock surface is appropriate. At the same time, the fixed shell and cover can avoid direct contact between the heating source at the handle and the user.

Owner:DESSMANN CHINA MACHINERY & ELECTRONICS

Garbage waste treatment system

PendingCN114001355AStable supportRealize cooling and dust removalIncinerator apparatusDust controlExhaust fumes

The invention particularly relates to a garbage waste treatment system which comprises a feeding mechanism and an incinerator mechanism which are connected in sequence, wherein garbage waste conveyed into the incinerator mechanism by the feeding mechanism is incinerated; a waste gas cooling box which is used for sucking waste gas generated after incineration of the incinerator mechanism and rapidly cooling the waste gas; a spraying atomization reaction mechanism which is used for carrying out spraying atomization reaction on the gas cooled by the waste gas cooling box, removing harmful gas in the waste gas, adsorbing and removing dust in the waste gas, and enabling one part of the gas subjected to the spraying atomization reaction to flow back to the incinerator and the other part of the gas to flow to the oil smoke separation mechanism; an oil-smoke separation mechanism which is used for carrying out oil-smoke separation on part of the waste gas after the spraying atomization reaction; and a tail gas treatment mechanism which is used for carrying out high-temperature heating treatment on gas obtained after oil fume separation and combusting a small amount of combustible gas contained in treated waste gas. According to the garbage incinerator, garbage waste can be incinerated, and incinerated waste gas is purified.

Owner:HENAN LUTAI ROAD MAINTENANCE MACHINERY

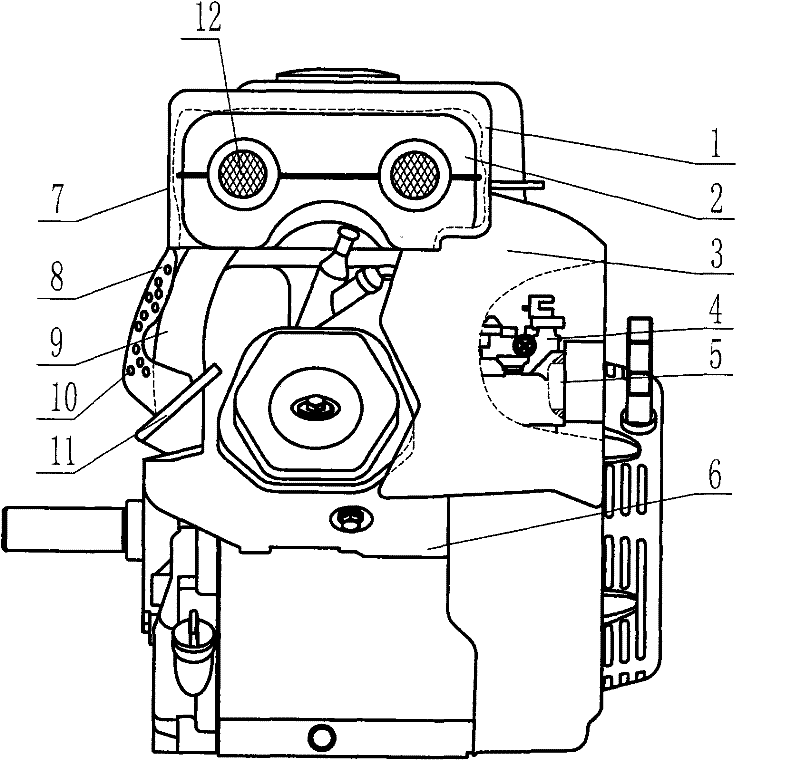

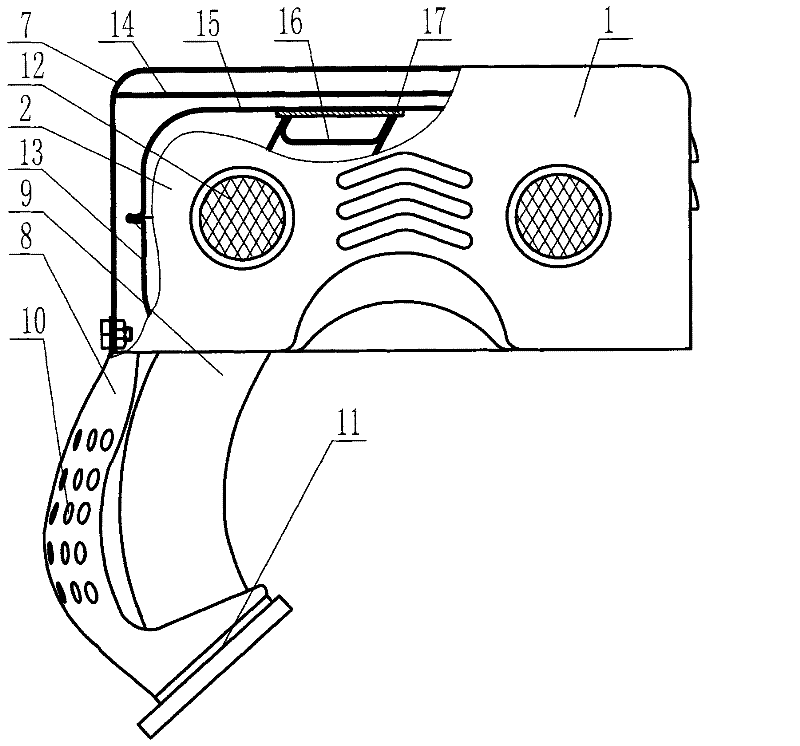

Gasoline engine for snow sweeper

ActiveCN101725399BAvoid temperature riseAvoid scalding the operatorExhaust apparatusSilencing apparatusAir filterGasoline

The invention provides a gasoline engine for a snow sweeper, which comprises a silencer, a face guard, a carburetor and a cylinder body, wherein the silencer is provided with a silencer chamber, a silencer housing, a silencer intake pipe and a spark arrester; the silencer chamber is arranged in the silencer housing and is a cavity formed by a silencer chamber lower shell and a silencer chamber upper shell; the silencer intake pipe penetrates through the silencer chamber lower shell and extends upwards; the upper end part of the silencer intake pipe is installed on the inner wall surface of the silencer chamber upper shell; the upper end of the face guard is connected with the lower part of the silencer housing, and the lower end of the face guard is connected with the cylinder body; a space, the upper part of which is communicated with the silencer, is formed between the face guard and the cylinder body; an air filter is omitted at the air inlet of the carburetor; and the carburetor and the air inlet of the carburetor are positioned in the space enclosed by the face guard. By using the structure, the invention inhibits the temperature rise of the silencer, avoids scalds, increasesthe air temperature at the air inlet of the carburetor, and improves the ignition performance and the power performance.

Owner:盐城博尔福机电科技发展有限公司 +1

Pipes, pipe preparation methods and concrete machinery

ActiveCN111765326BSimple structureReduce the difficulty of productionMolten spray coatingRigid pipesPipeMechanical engineering

The invention provides a pipe, a preparation method of the pipe and a concrete machine. The pipe includes: a pipe body; a wear-resistant coating formed on the inner wall of the pipe body by thermal spraying; wherein the wear-resistant coating includes a ceramic material coating. The wear-resistant coating can prevent the material from directly impacting and wearing the pipe body, thereby preventing the pipe body from being abraded by the material and prolonging the service life of the pipe body. weight and production costs. The wear-resistant coating is an integral structure formed by thermal spraying. On the one hand, the structural stability of the integral structure is strong, and there is no structural connection section, which can effectively avoid structural damage or shedding. On the other hand, thermal spraying technology has the ability to form The advantages of high efficiency and strong stability can reduce the production cost of the pipeline and further improve the structural stability of the wear-resistant coating.

Owner:SANY AUTOMOBILE MFG CO LTD

An electric heating heat storage heat exchanger

ActiveCN105758241BGuaranteed molten stateUniform heat exchangeHeat storage plantsHeating element shapesVertical planePlate heat exchanger

The invention relates to an electrically-heated energy-storage heat exchanger and a heat storing and releasing method thereof and solves the problems of non-uniform energy distribution and low energy utilization rate in the heat exchange process of an existing electrically-heated phase change heat storage and exchange device. The electrically-heated energy-storage heat exchanger comprises a tank-shaped shell and an electric heating pipe; the shell is filled with a heat storage medium. The electrically-heated energy-storage heat exchanger is characterized in that a heat exchange pipeline is also arranged in the shell and is vertically folded back in a vertical plane to be coiled in an S-shaped manner; the heat exchange pipeline is folded to and fro in a horizontal plane to be arranged in an S-shaped manner or spirally arranged inside the shell around a circle center; an opening is formed in the upper end of the shell, and a detachable cover plate is arranged at the upper end of the shell; an inlet and an outlet of the heat exchange pipeline penetrate out of the shell from the cover plate; the electric heating pipe extends into the inside of the shell downwards from the cover plate. The electrically-heated energy-storage heat exchanger provided by the invention performs uniform heat exchange on the heat storage medium with poor mobility, so that the heat utilization efficiency is improved.

Owner:上海联和投资有限公司

A double-sided heat exchange tunnel drying room with built-in heat source

ActiveCN113280603BAvoid direct heatingReduce energy consumptionDrying gas arrangementsDrying machines with non-progressive movementsElectric machineGear wheel

The invention discloses a double-sided heat exchange tunnel drying room with a built-in heat source, which includes a room body, and the inside of the room body is divided into a drying room and a heating room by two partitions. Dry frame; the lower side wall of the house body is fixed with a support plate, the upper side wall of the support plate is fixed with a motor, the driving end of the motor is upward and an incomplete gear is fixed, and two gears are installed on the support plate. Two rotating rods, gear 1 and gear 2 are fixed on the two rotating rods, the two gears are located on the side of the incomplete gear and meshed with the incomplete gear, slidingly inserted on the outer wall of the housing body There is a slide plate, and the left end of the slide plate is fixedly connected with the outer wall of the drying frame. The invention realizes the automatic drying of the material through the automatic feeding of the material storage box, and the left and right reciprocating movement of the drying frame ensures the full contact between the material and the high-temperature airflow, avoids drying blind spots, and makes the dense mesh plate automatically turn down to export the material to the conveyor belt Transport and export on the machine to realize the automation of drying work.

Owner:南通腾宇环保设备有限公司

A control method for a double-tank solar water heating system with varying minimum water levels

InactiveCN106839467BReduce the temperatureIncreased load-bearing capacitySolar heating energySolar heat collector controllersWater useStart time

The invention discloses a control method for a lowest-water-level-changing double-water-tank solar water heating system. The control method includes the following steps that multiple parameters of the double-water-tank solar water heating system in all time periods in n days before a forecasting day are collected; calculation is conducted to obtain the water use amounts of all the time periods in the n days before the forecasting day by subtracting the water flow of a water return main pipe in the corresponding time periods from the water flow of a water supply main pipe of all the time periods in the n days before the forecasting day; with the combination of a statistical method of t distribution in applied mathematical statistics and under the set confidence coefficient, the following formulas are adopted for calculating the forecasting values of the water use amounts of all the time periods in the forecasting day; the water level set value of a gradient temperature control heat supply water tank in the forecasting day is calculated; heat collection circulation is conducted; a heat collection water tank supplements water to the heat supply water tank; water supplementation of the heat collection water tank is conducted; the heat collection water tank supplements water to the heat supply water tank; and gradient temperature control water supplementation and overheat protection are conducted. By the adoption of the method, the starting time of an auxiliary heat source is shortened, and it is expected that the energy is saved by 20% or higher than that of a single-water-tank solar water heating system.

Owner:TIANJIN UNIV

Formula of paper-wrapped bullfrog and preparation method of paper-wrapped bullfrog

PendingCN114376158AGuaranteed flavor and nutritional valueGuaranteed smooth tasteFood scienceMouthfeelEngineering

The invention discloses a formula of paper-wrapped bullfrogs and a preparation method thereof, and relates to the technical field of food processing, and the paper-wrapped bullfrogs comprise the following raw materials: ingredients, main materials, secret red oil spices, condiments and side dishes. The preparation method comprises the following steps: pickling main materials by arranging special red oil spices, then frying condiments, pouring the fried condiments into the pickled main materials, firstly pouring the auxiliary materials into silicone oil paper to serve as a base material, then pouring the main materials mixed with the fried condiments into the base material, then sprinkling side dishes one by one, wrapping the silicone oil paper with the base material, and compacting the base material; according to the preparation method, the flavor and the nutritional value of the bullfrogs can be guaranteed to the greatest extent, meanwhile, the bullfrogs are prevented from being directly heated through the silicone oil paper and the ingredients, and the smooth and tender taste of the bullfrogs can be guaranteed to the greatest extent by heating and processing the bullfrogs in a boiling and pickling manner; therefore, the problems that most bullfrog preparation methods in the prior art have the defects that oil is much, the smooth and tender taste of bullfrogs is reduced, and the nutritional value is lost are solved.

Owner:东营川鱼阁餐饮管理有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com