Gasoline engine for snow sweeper

A technology for gasoline engines and snowplows, which is applied to machines/engines, carburetors, mechanical equipment, etc. It can solve the problems of high muffler temperature, complex structure of gasoline engines for snowplows, and increased cost, and achieve the purpose of suppressing temperature rise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

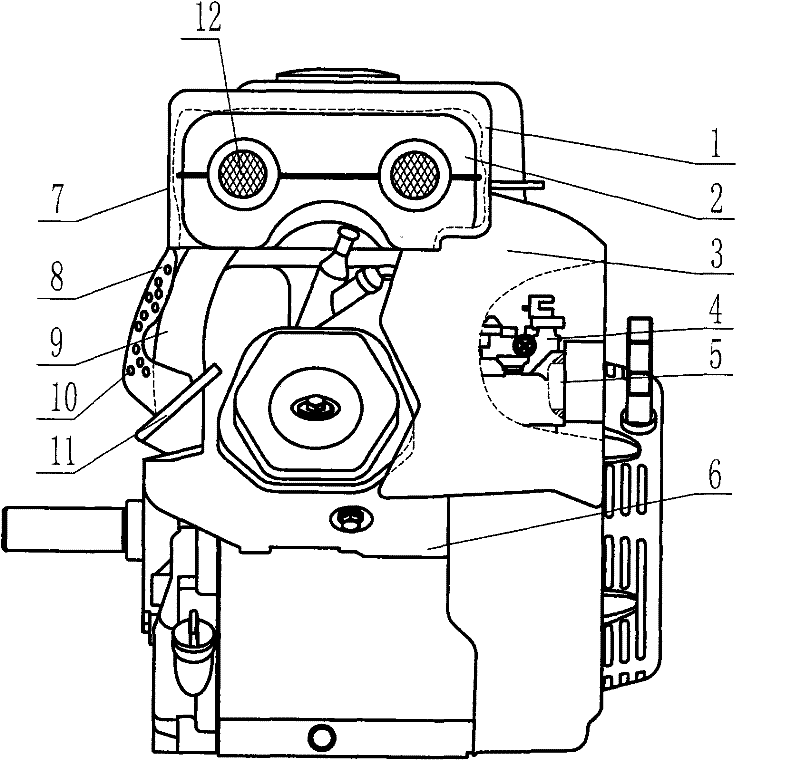

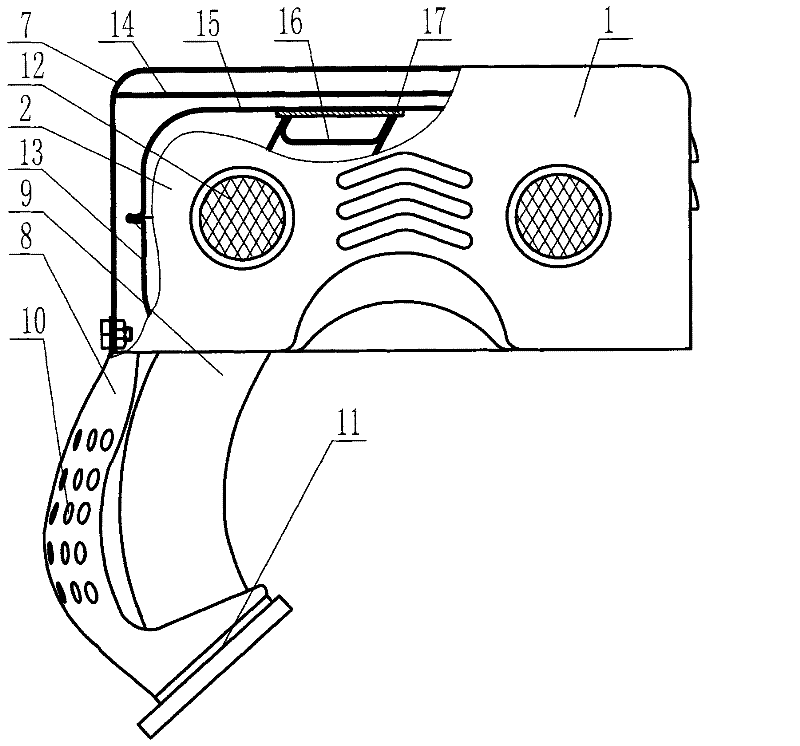

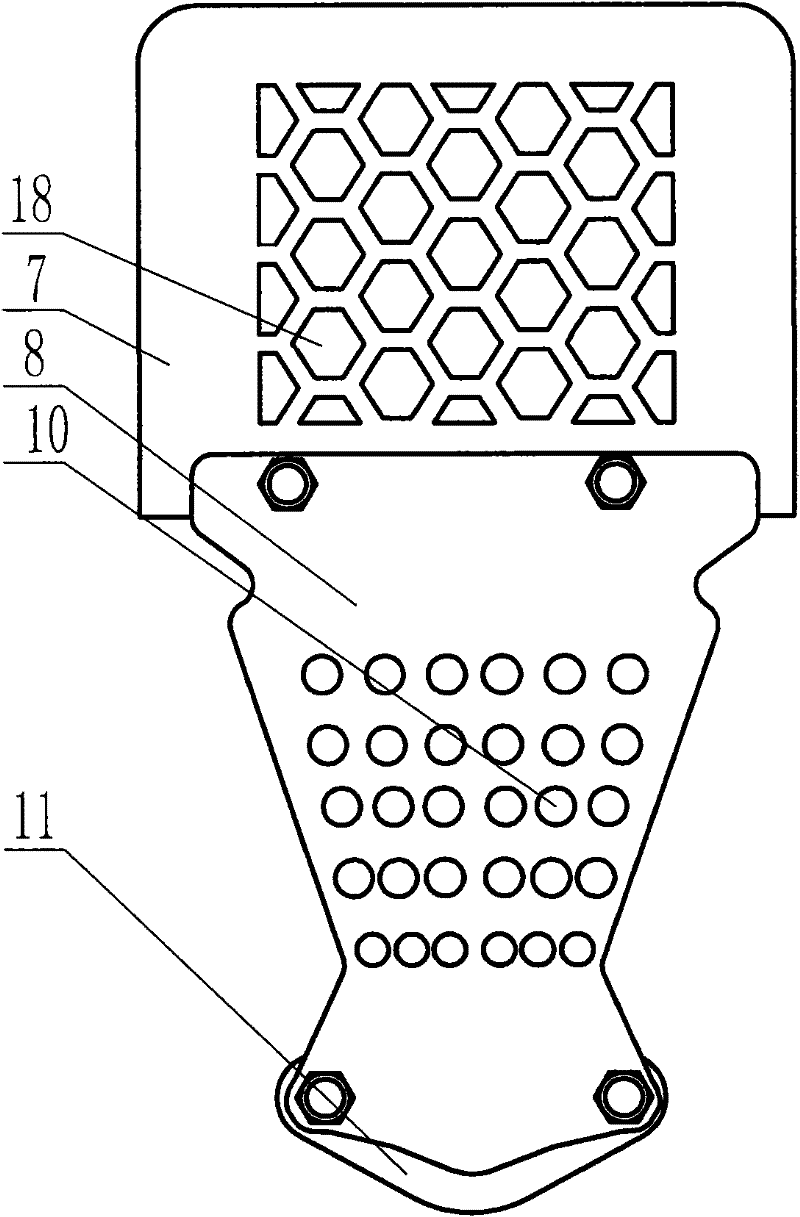

[0019] The structure of the gasoline engine for a snow blower according to the present invention will be described in detail below. figure 1 It is a structural schematic diagram of a gasoline engine for a snowplow according to the present invention. figure 1 Among them, reference numeral 1 represents the muffler of the gasoline engine for the snowplow as a whole, 2 represents the muffler chamber of the muffler 1, 3 represents the mask provided on one side of the gasoline engine, 4 represents the carburetor as a whole, and 5 represents the air inlet of the carburetor, 6 represents the cylinder block of gasoline engine, and 7 represents the muffler outer cover. Because the gasoline engine for a snowplow according to the present invention usually works in a very cold (for example, about -30°C) snowy day, and the air in the snowy day is very clean at this time, therefore, the snowplow according to the present invention The gasoline engine omits the air filter at the carburetor in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com