Print head for on-demand ink jet printer

An on-demand inkjet and printer technology, applied in the field of print heads, can solve the problems of high cost of piezoelectric crystals, easy interference of electrostatic inkjet effects, and difficult to control air bubbles, avoiding direct heating, and is conducive to stability and structure. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to enable those skilled in the art to fully understand the technical solutions and beneficial effects of the present invention, further description will be given below in conjunction with specific embodiments and accompanying drawings.

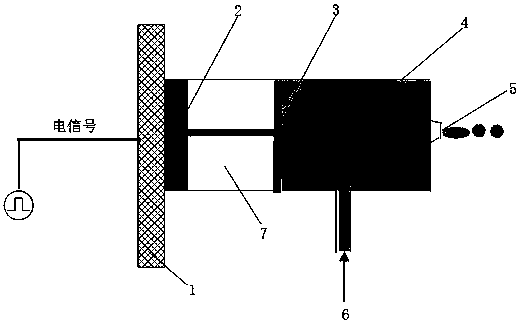

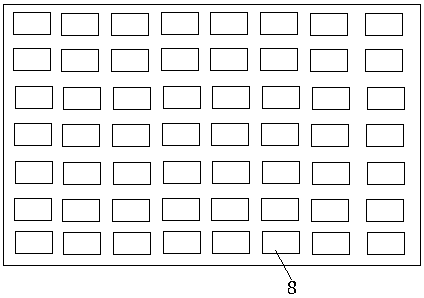

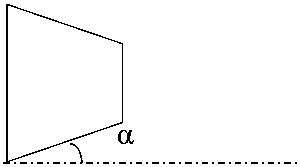

[0018] Such as figure 1 As shown, a print head of a drop-on-demand inkjet printer is provided with an active valve inside the print head to divide its internal space into two parts: a cavity and an ink tank. The cavity is filled with a gas with high thermal conductivity (such as air, helium or neon gas), and a T-shaped heat-conducting metal block (made of copper or silver and silver-plated on the surface) connected to the movable valve is arranged on one side of the cavity. Copper), the heating surface of the T-shaped heat-conducting metal block is closely attached to the heating surface of the electric heating plate to facilitate heat conduction. There are countless small independent heating units evenly distributed on the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com