Micro-valve system based on flow path state

A technology of micro-valve and flow path, which is applied in the direction of valve devices, mechanical equipment, engine components, etc., can solve the problems of complex processing and easy leakage, and achieve the effects of simple control method, comprehensive sample injection control, and easy production and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

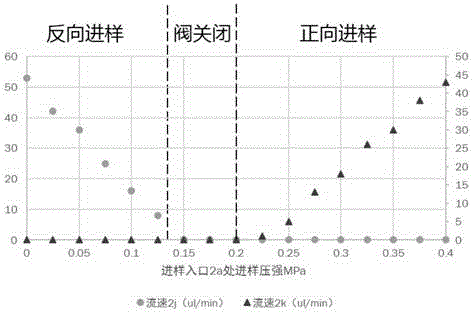

[0026] The working mode of embodiment 1 channel valve

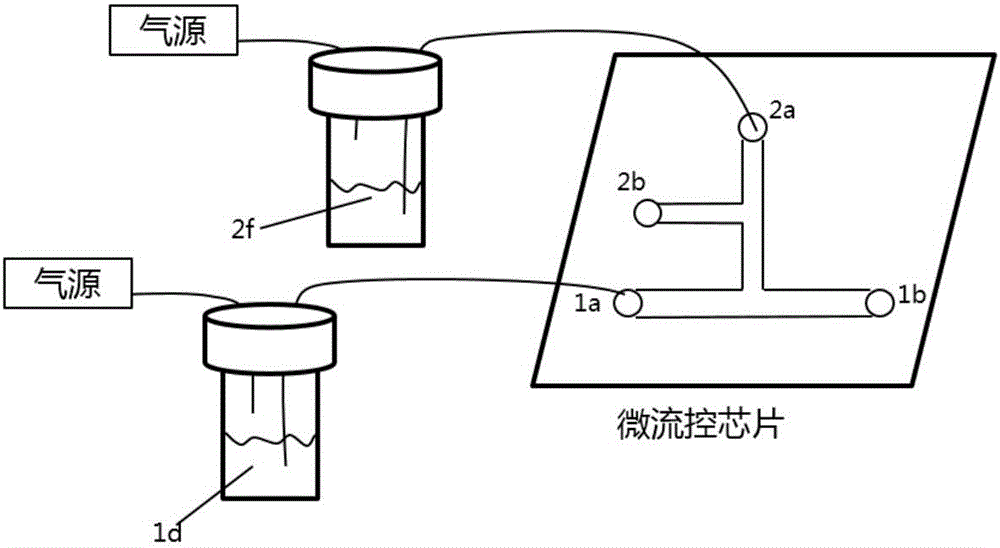

[0027] figure 1 Shown is a schematic diagram of the pneumatic sampling system outside the microfluidic chip. Among them, the air source is an air compressor with variable pressure, which can generate a relative pressure of 0-0.7MPa, which is used as the injection power of the liquid sample. The gas source is connected to the sample injector through a conduit. The injection sample 2f and the main flow sample 1d are respectively installed in the two injectors. The sample flows through a tube inserted into the bottom of the injector to the inlet of the microfluidic chip and eventually into the microtubes. By changing the sampling pressure of each gas source, each flow path valve can be in the desired working mode.

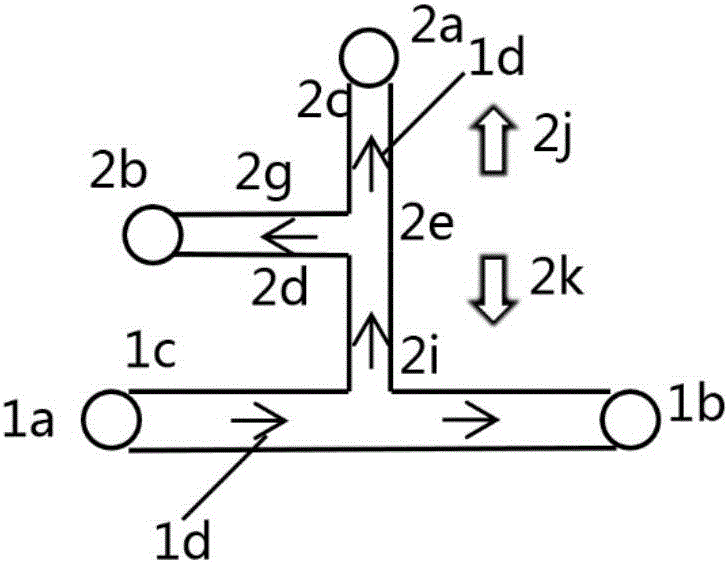

[0028] figure 2 Shown is a schematic diagram of the principle of the microvalve system in reverse injection mode. Wherein, the main channel 1 includes a main channel inlet 1a, a main channel outlet 1b, and...

Embodiment 2

[0032] Example 2 Using a multi-sample injection structure composed of multi-stream valves to realize multi-site DNA detection

[0033] Image 6 Shown is a schematic structural diagram of a multi-sample injection chip composed of multiple flow path valves. The chip structure includes a main channel 1 and multiple sample injection channels. The situation shown in the figure is that the sample injection flow path 3 is in the working state of forward sample injection, and the other sample flow paths are in the working mode with the valves closed. Therefore, at the main channel outlet 1b, a mixed sample containing the main channel sample 1d and the injection sample 3f will be obtained, and the concentration of the injection sample 3f in the mixed sample is determined by the pressure at the injection inlet 3a. In the same way, different sample combinations can be obtained at the outlet 1b by changing the working mode of other sample injection flow paths.

[0034] for further clar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com