Garbage waste treatment system

A technology for waste disposal and treatment system, applied in combustion methods, lighting and heating equipment, combustion types, etc., can solve the problems of carbon deposits that cannot be quickly discharged, affect the workshop environment, affect the work process, etc., to avoid the overflow of incineration waste gas, avoid The effect of exhaust gas overflow and quick positioning and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

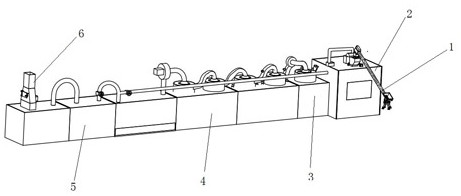

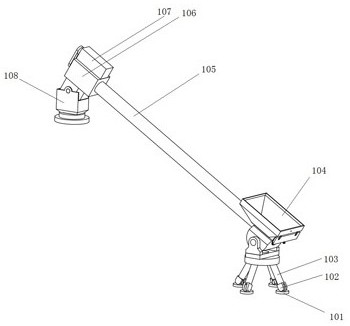

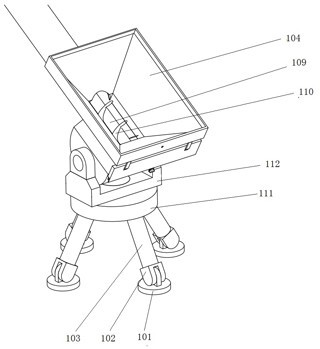

[0063] Such as Figure 1-27 As shown, the purpose of the present invention is achieved in this way: the garbage and waste treatment system includes sequentially connected: a feeding mechanism 1 for transporting garbage and waste; an incinerator mechanism 2 that transports the feeding mechanism into the incinerator mechanism The garbage and waste materials are incinerated; the exhaust gas cooling box 3 sucks the exhaust gas burned by the incinerator mechanism and quickly cools it down; the spray atomization reaction mechanism 4 performs spray atomization reaction on the gas after cooling down from the exhaust gas cooling box, Remove the harmful gas in the exhaust gas and absorb the dust in the exhaust gas, and return part of the gas after the spray atomization reaction to the incinerator, and the other part of the gas flows to the oil fume separation mechanism; the oil fume separation mechanism 5, spray and atomize Part of the exhaust gas after the reaction is subjected to oil fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com