Multi-tube-bundle clean steam generator and using method thereof

A clean steam generator technology, applied in the field of clean steam generators, can solve the problems of pure water pollution and achieve the effect of increasing the heating area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

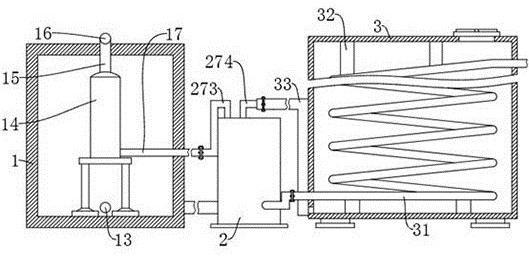

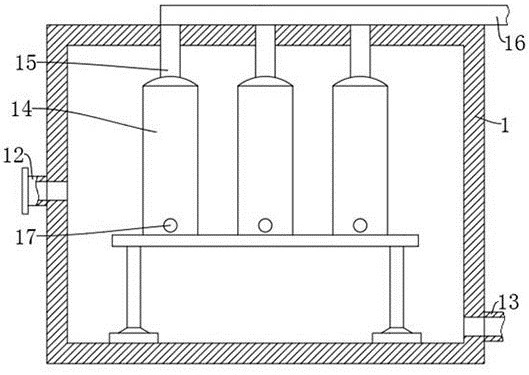

[0041] refer to Figure 1-7, a multi-bundle clean steam generator, including a heating box 1, a water storage tank 3, a driving box 2 is arranged between the heating box 1 and the water storage tank 3, and also includes: a steam inlet pipe 12, a first steam outlet pipe 13 , are all fixedly connected on the heating box 1; several steam tanks 14 are all fixedly connected in the heating box 1; The water outlet hole is fixedly connected with a breaking net 142; the steam pipe 15 is fixedly connected to the upper end of the steam tank 14; the steam collecting pipe 16 is fixedly connected to the upper surface of the heating box 1; Connected, and the steam pipe 15 communicates with the steam tank 14.

[0042] When using this device, the steam inlet pipe 12 of the heating box 1 is connected with the industrial steam transmission pipe, and then the industrial steam can be introduced into the heating box 1 to increase the temperature in the heating box 1. When the industrial steam is f...

Embodiment 2

[0044] refer to Figure 2-3 , a multi-bundle clean steam generator, which is basically the same as Embodiment 1, furthermore: the steam inlet pipe 12 is located on one side of the heating box 1 near the middle, and the first steam outlet pipe 13 is located on the other side of the heating box 1 side near the lower end.

[0045] Since the industrial steam is high-temperature steam, the industrial steam entering the heating box 1 will float upward firstly. When the heating box 1 is filled with industrial steam, the industrial steam will be discharged from the heating box 1 through the first steam outlet pipe 13 In this way, the temperature of the heating box 1 can be increased by the industrial steam, so as to prevent the industrial steam passing into the heating box 1 from being directly discharged from the heating box 1, which makes it difficult to increase the temperature in the heating box 1.

Embodiment 3

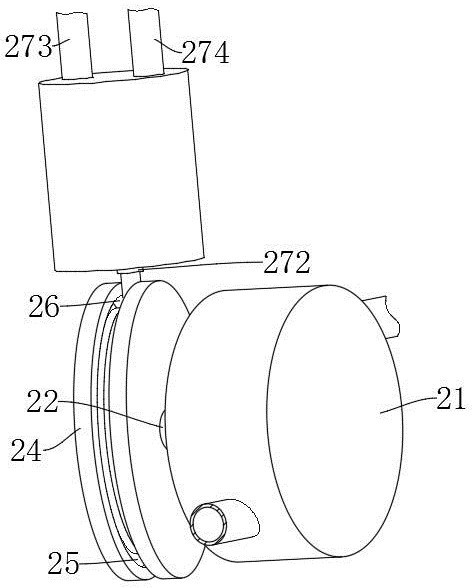

[0047] refer to figure 1 , Figure 5-6 , a multi-bundle clean steam generator, which is basically the same as in Embodiment 1, furthermore: a drive cylinder 21 is fixedly connected to the drive box 2, and a drive shaft 22 is rotatably connected to the drive cylinder 21, and one part of the drive cylinder 21 A driving wheel 24 is arranged on the side, and the driving shaft 22 extends through the driving cylinder 21 to be fixedly connected with the driving wheel 24 . The outer surface of the driving shaft 22 is fixedly connected with several power blades 23 , and the several power blades 23 are all located in the driving cylinder 21 .

[0048] When the power blade 23 is pushed, it can drive the drive shaft 22 to rotate, and then the drive shaft 22 drives the drive wheel 24 to rotate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com