Wellhead heating storage tank

A technology for heating storage tanks and storage tanks, which is applied to tank cars, containers, large containers, etc. It can solve problems such as difficult handling, rapid deterioration of heat transfer oil, and corrosion of furnace chambers, and achieve high heating safety, good thermal insulation performance, and improved temperature field Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

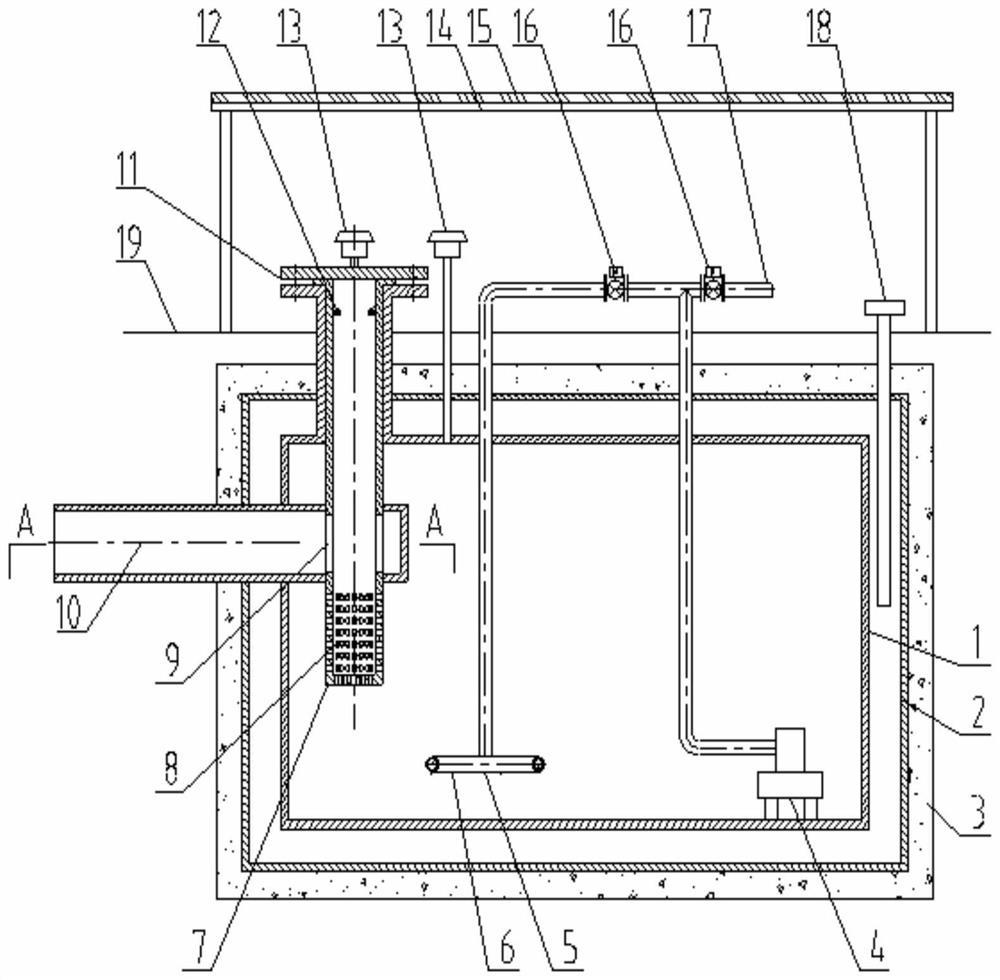

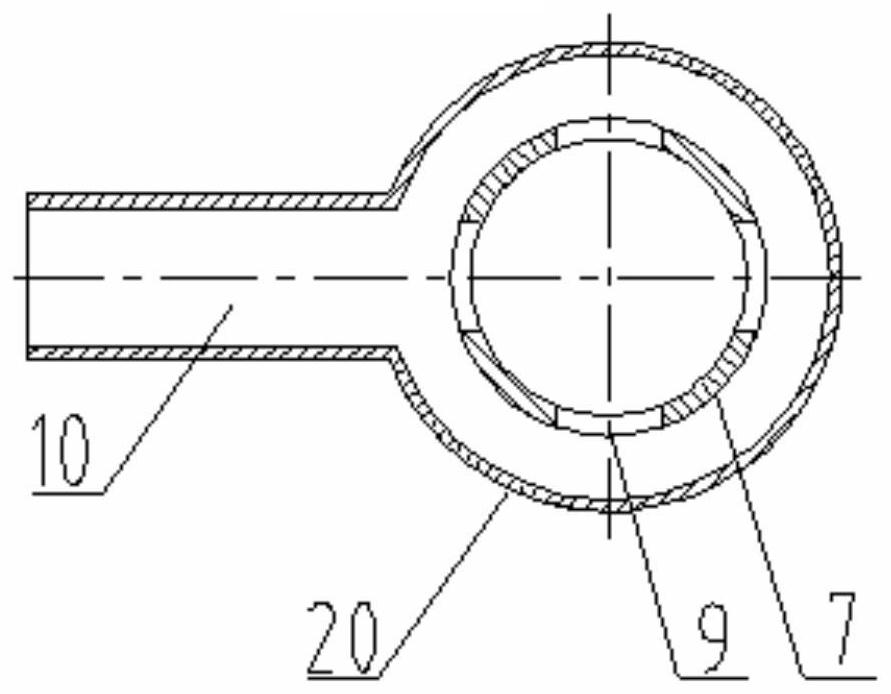

[0015] The present invention will be further described below in conjunction with accompanying drawing:

[0016] Depend on figure 1 combine figure 2 As shown, the wellhead heating storage tank includes a storage tank 1, and a water jacket 2 is arranged on the outside of the storage tank 1. The water jacket 2 is buried below the ground 19, and the soil is used as an external insulation layer to reduce the energy consumption of the storage tank 1. The water jacket 2 There is an electric heater 18 inside, and the electric heater 18 is used to heat the water in the water jacket 2 and indirectly heat the production fluid in the storage tank 1. The heating safety is high, and the purpose of flowing and exporting is achieved, preventing the electric heater from 18 directly heats the crude oil, the surface of the electric heater 18 is overheated, and the crude oil evaporates to cause a safety hazard of oil gas deflagration;

[0017] The storage tank 1 is provided with an external tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com