An improved test device for testing oxidizing solids

A test device and oxidative technology, applied in the measurement device, by removing certain components, weighing, instruments, etc., can solve the problems of inability to separate the test system and the measurement system, low accuracy, etc., to achieve simple structure, improve sensitivity, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

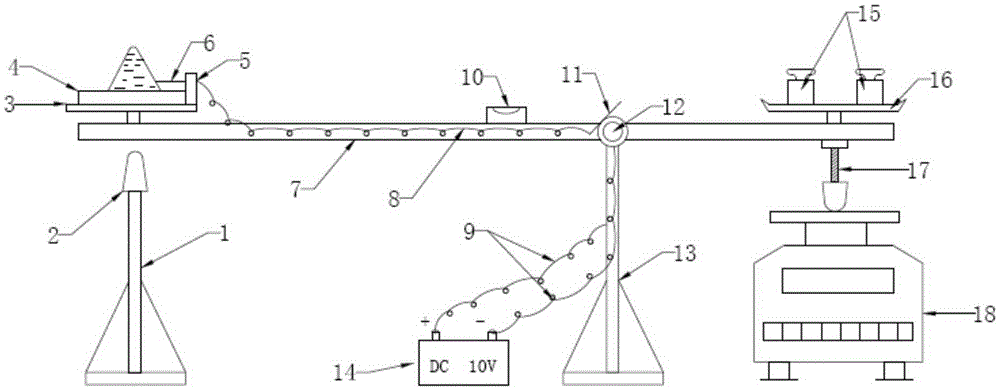

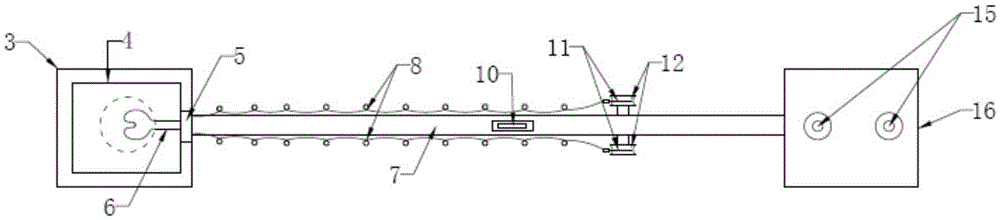

[0040] Such as Figure 1~2 As shown, an improved oxidizing solid test device includes bracket A1, limit block 2, tray A3, heat shield 4, terminal post 5, resistance wire 6, lever 7, wire A8, wire B9, level 10 , Brush 11, collector ring 12, bracket B13, power supply 14, balance counterweight 15, tray B16, level adjuster 17, balance 18.

[0041] Among them, the bracket A1 is connected to the limit block 2, the limit block 2 is installed on the top of the bracket A1, the tray A3 is installed on the test end of the lever 7, the heat shield 4 is placed on the tray A3, the terminal post 5 is installed on the tray A3, and the resistance wire 6 is placed on the heat shield 4, and connected to one end of the wire A8 through the terminal 5, the lever 7 is connected to the bracket B13, there are two wires A8, one end is connected to the terminal 5, the other end is connected to the brush 11, and the wire B9 has Two, respectively, one end is connected to the collector ring 12, and the ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com