Method for conveying high-flow high-purity liquefied gas

A technology of liquefied gas and large flow, which is applied in the direction of gas/liquid distribution and storage, pipeline system, mechanical equipment, etc., to ensure safety and operability, meet the needs of transportation, and save the effect of gas transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

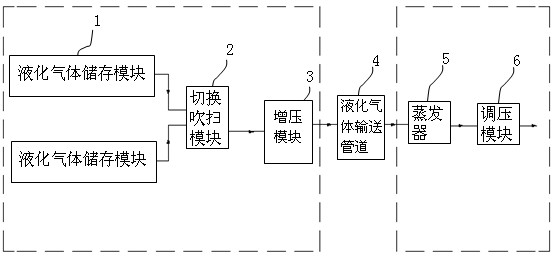

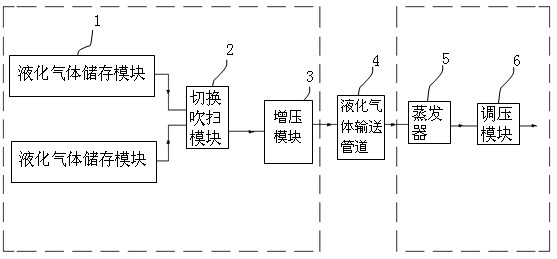

[0022] figure 1 It is a schematic diagram of the delivery method of the large-flow high-purity liquefied gas of the present invention.

[0023] See figure 1 , the method for delivering high-flow high-purity liquefied gas provided by the present invention includes a liquefied gas storage module 1, a pressurization module 3, a liquefied gas delivery pipeline 4, an evaporator 5, and a pressure regulating module 6, wherein the method includes the following in sequence Steps: lead out the liquefied gas from the liquefied gas storage module 1, and make it enter the booster module 3; pump out the liquefied gas from the booster module 3, and transport it to the evaporator 5 through the liquefied gas delivery pipeline 4; heat the liquefied gas in the evaporator 5 Make it vaporize; the heated superheated liquefied gas passes through the pressure regulating modu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com