A crawler type spreading machine for rolling core walls of asphalt concrete in the hydraulic engineering

A technology of asphalt concrete and asphalt mixture, which is applied in the direction of infrastructure engineering, construction, etc., and can solve the difficulty of adjusting the width of the transition material paving slide, the transition hopper scraper does not have a control switch, and increases the cost of the construction unit project, etc. problems, to achieve the effect of preventing oxidation aging or even burning, preventing heat loss, and convenient processing and operation adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

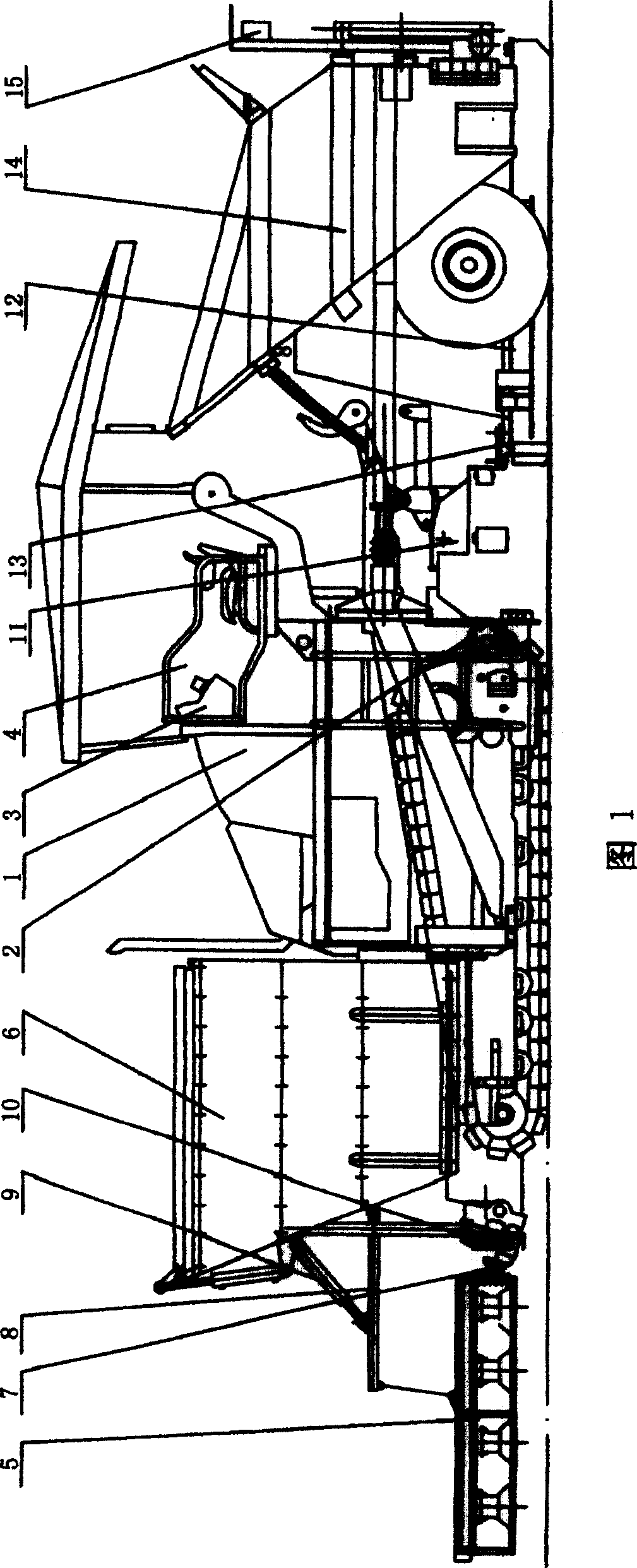

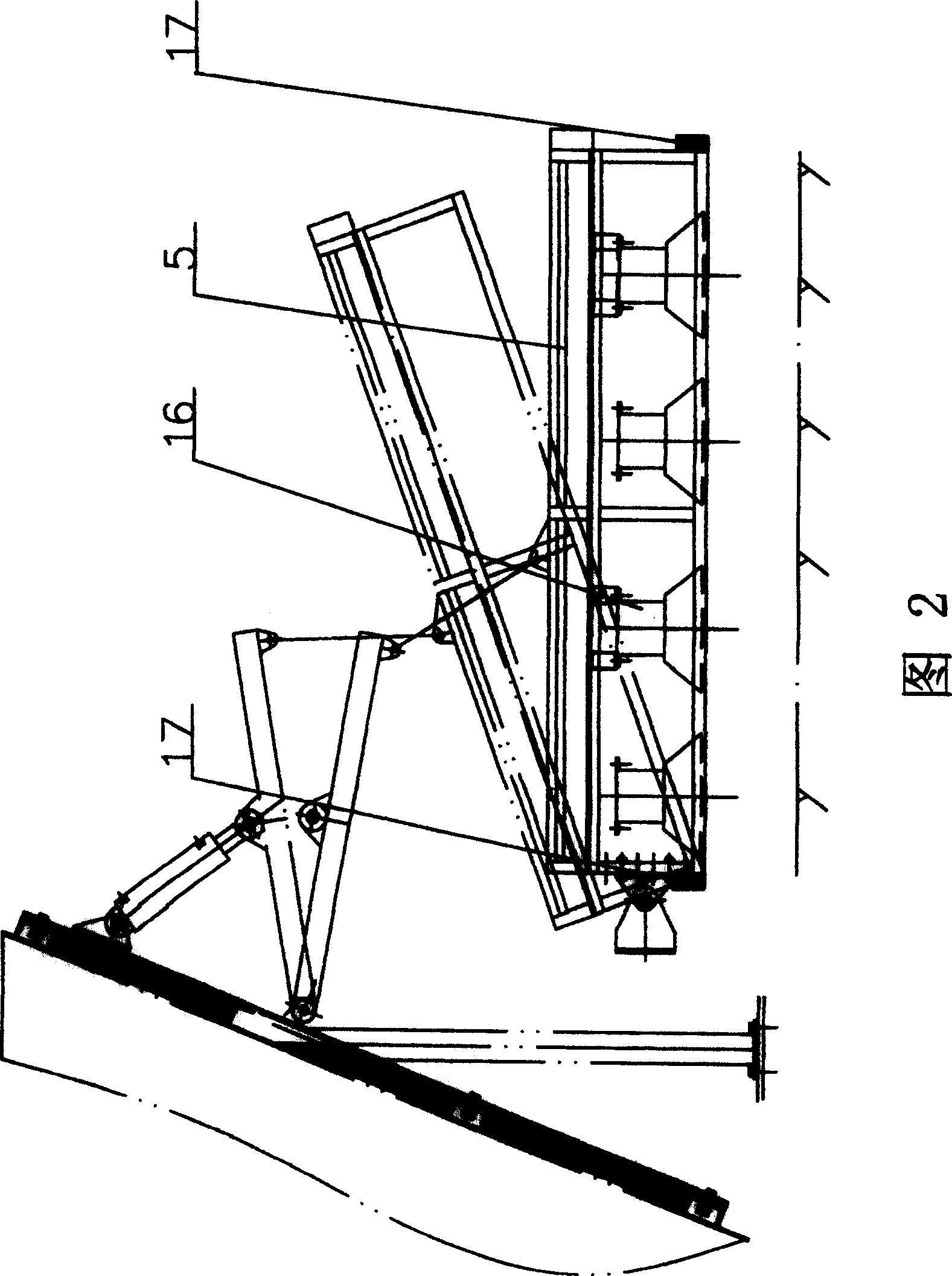

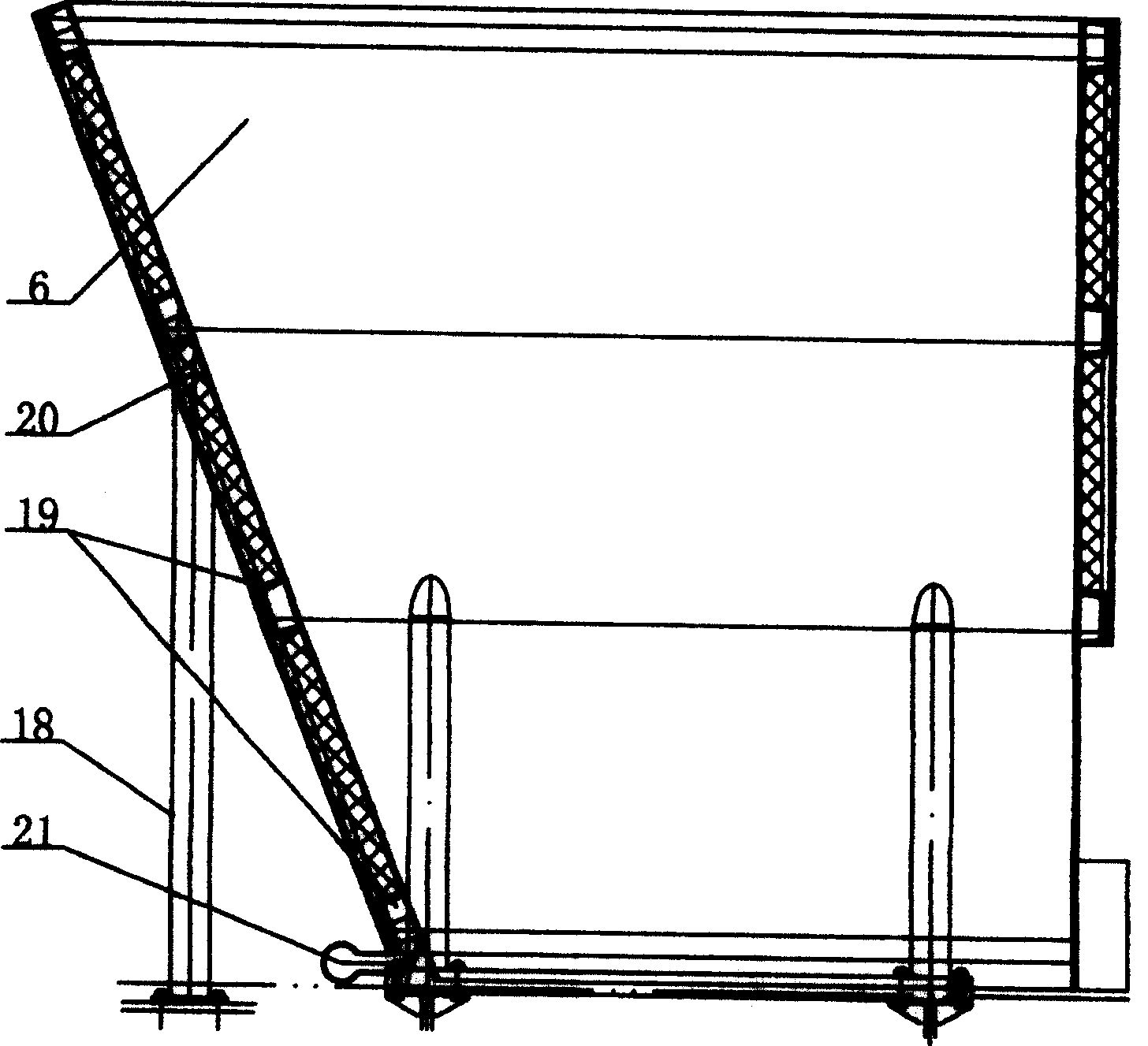

[0013] As shown in Figure 1, Figure 2 and image 3 As shown, a hydraulic roller compacted asphalt concrete core wall crawler combined paver includes a host 1, an infrared heating device 5, a centering monitoring device 10, an asphalt mixture insulation hopper 6, a scraper conveyor 2, a vibrating iron Plate 11, frame mold 12, transition material hopper car 14 and laser leveling device, the main machine 1 is equipped with a scraper conveyor 2, which is a large-pitch sprocket mechanism, and the console 3 is set on the main machine 1. In the driver’s cab 4, the front of the main engine 1 is provided with an infrared heating device 5 and an asphalt mixture insulation hopper 6. The infrared heating device 5 is connected to the main engine 1 through a hinge shaft 7, and is also connected to the main engine 1 through a suspension rod 8 and a telescopic cylinder 9. Asphalt mixture insulation hopper 6 is connected, a centering monitoring device 10 is provided at the connection between infrar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com