Patents

Literature

65results about How to "Easy width" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

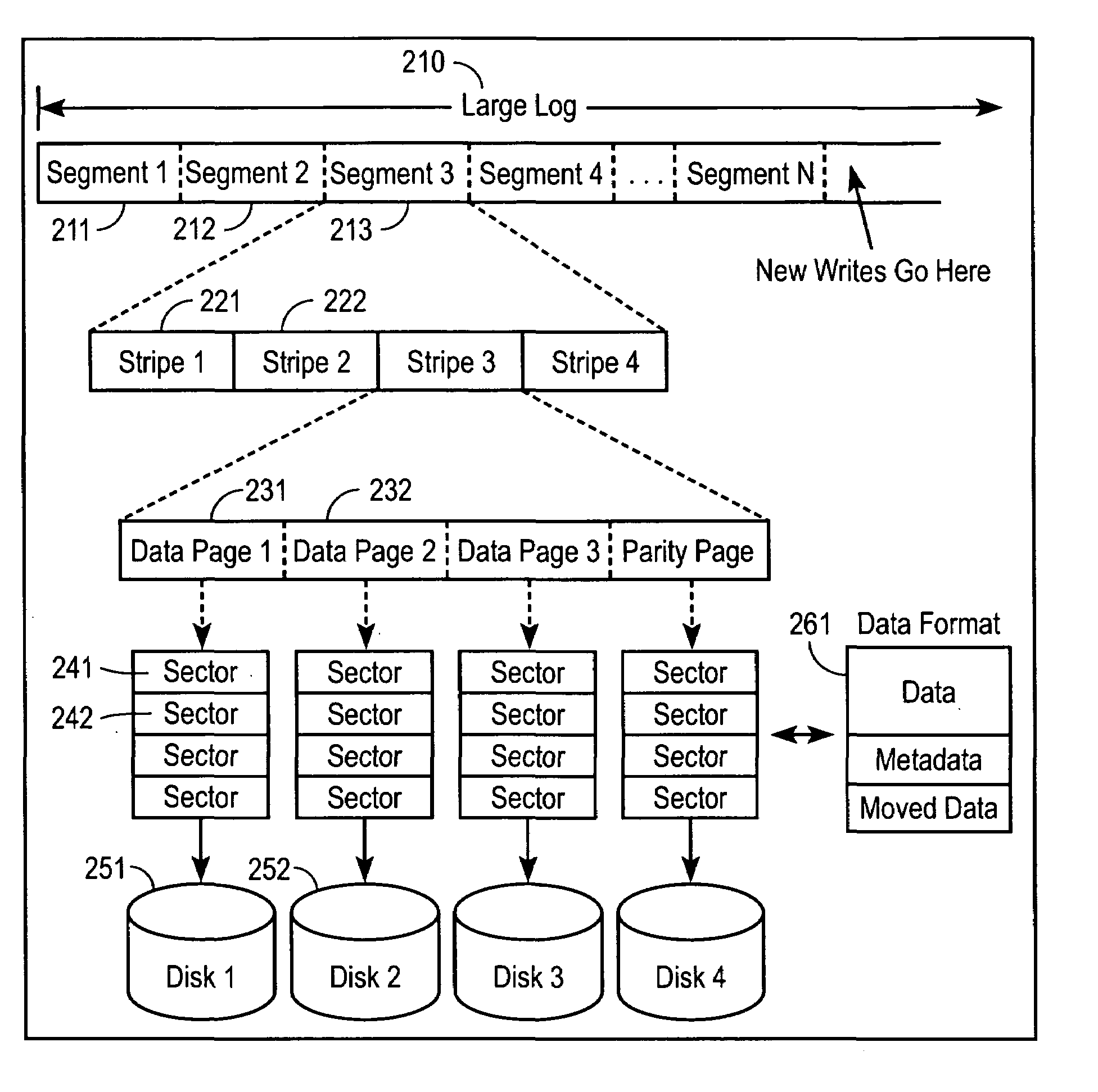

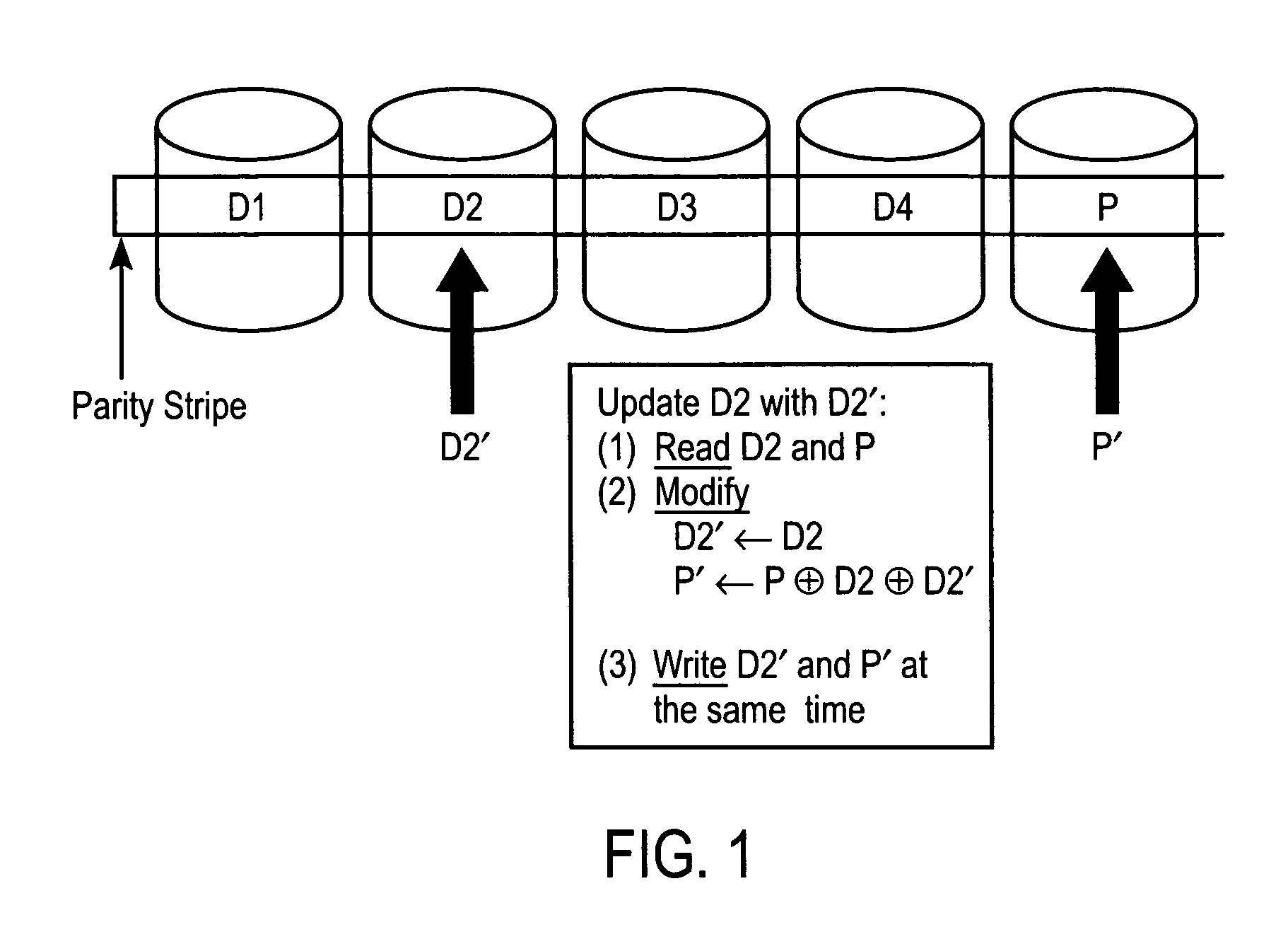

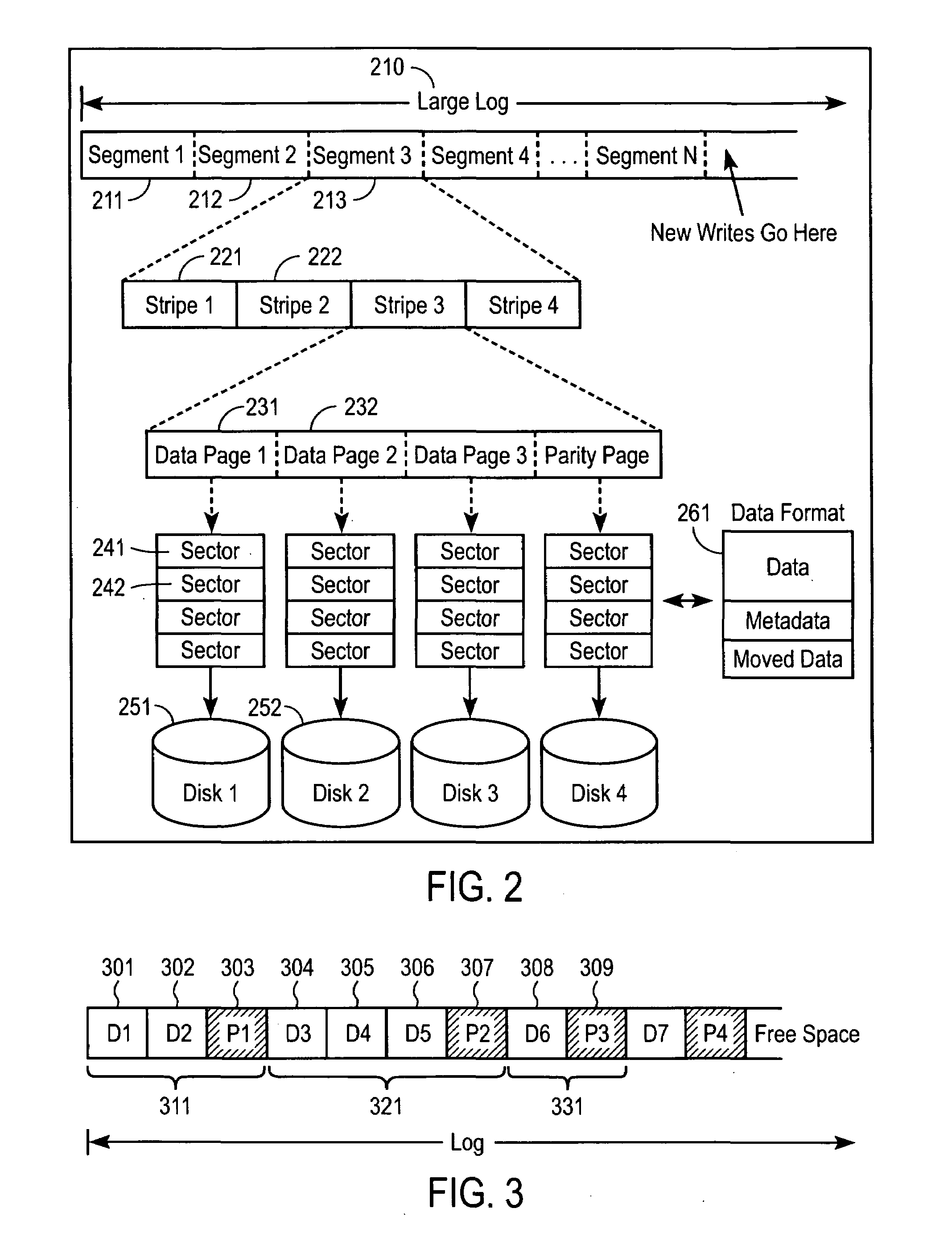

High-performance log-structured RAID

InactiveUS7047358B2Easily made atomicSmall write performanceData processing applicationsRedundant data error correctionRAIDNon-volatile memory

This invention describes a high-performance, log-structured implementation of a RAID subsystem that can be efficiently implemented in software. The methods described here allow the RAID subsystem to achieve high performance without using specialized hardware such as non-volatile memory or hardware XOR / DMA engines. Furthermore, the RAID implementation described here is well suited for supporting many functions required for advanced storage virtualization such as virtual disks, graceful addition and removal of disks, tolerating multi-disk failures, and snapshots.

Owner:MIDDLEFIELD VENTURES +7

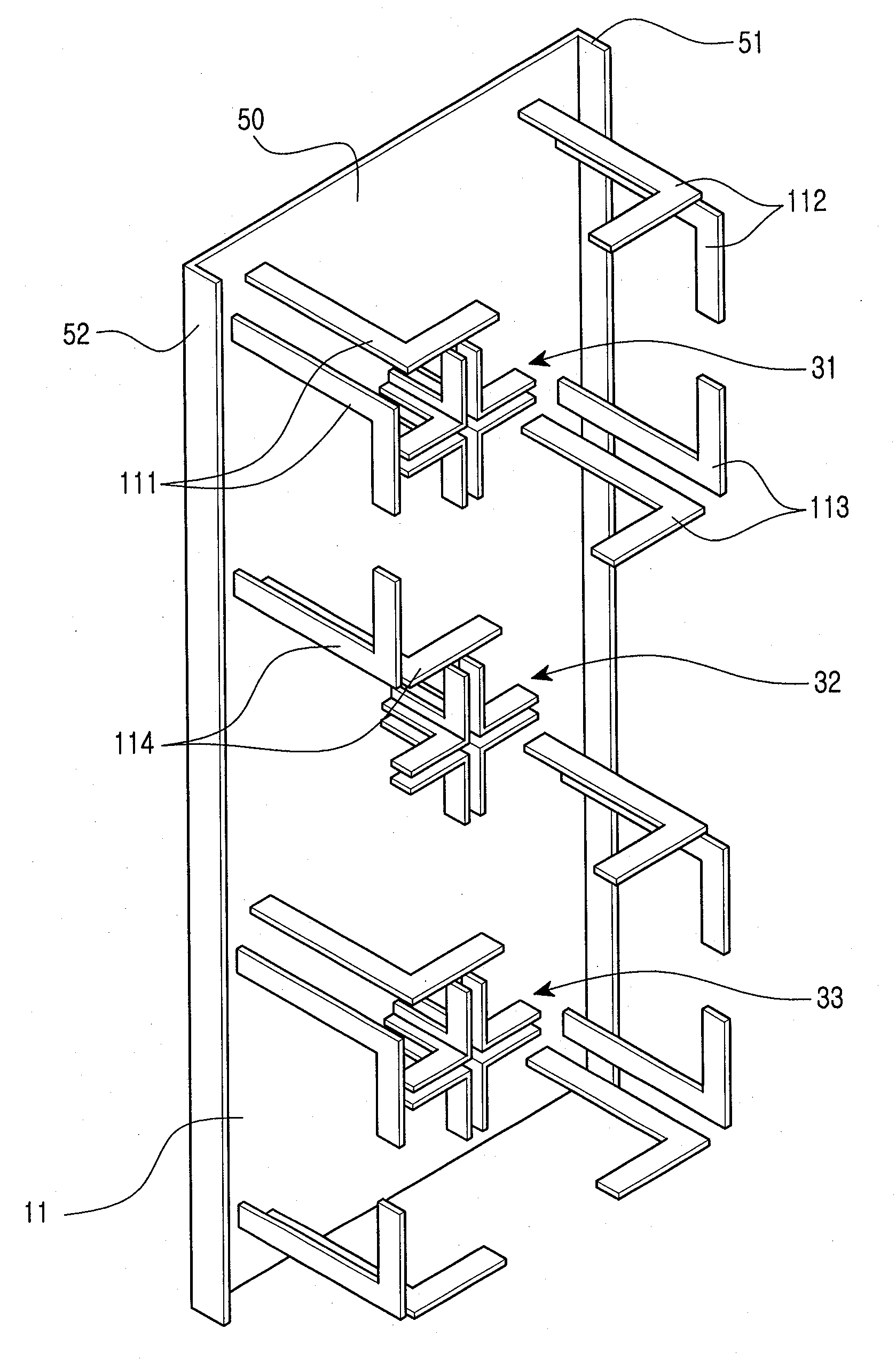

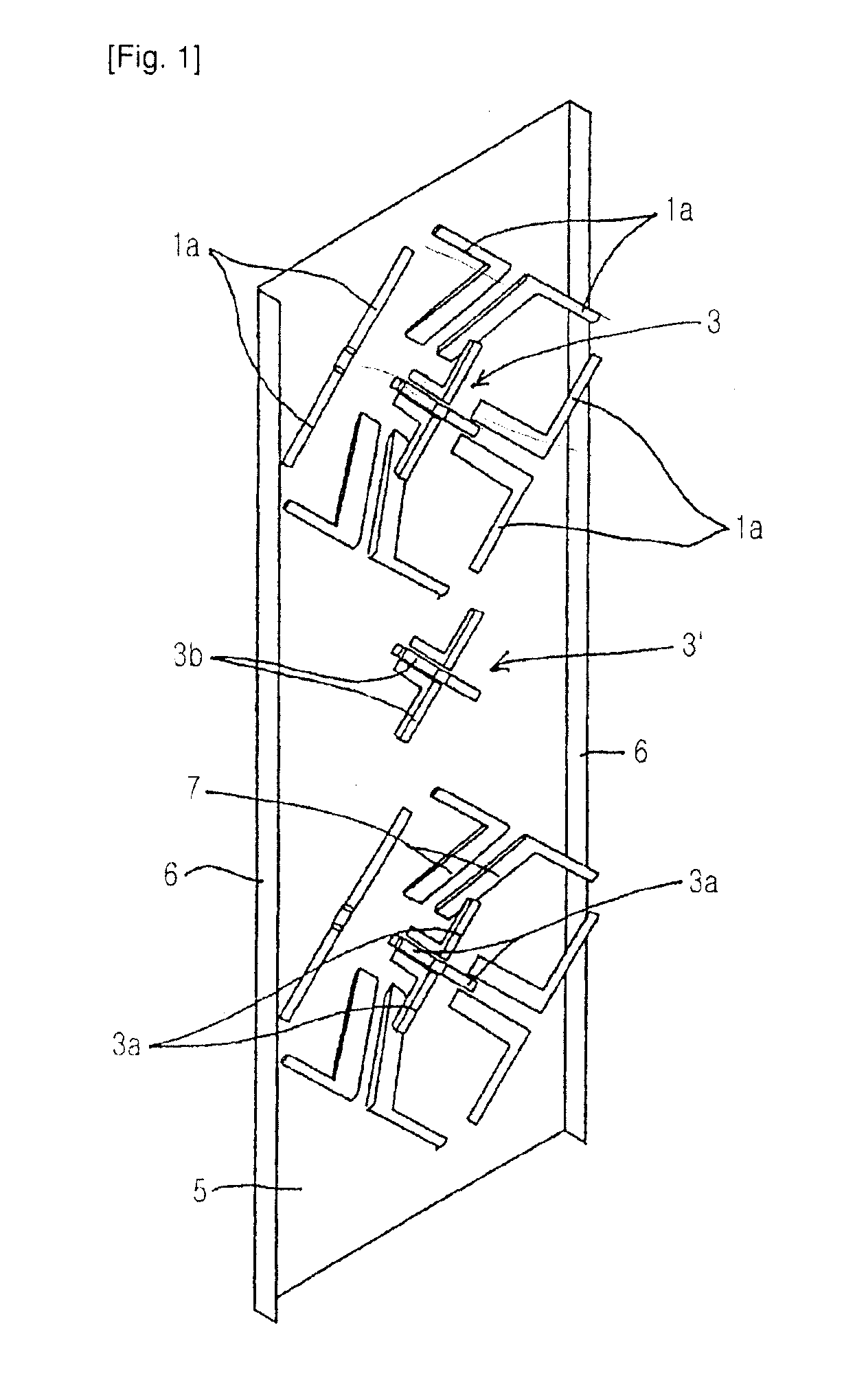

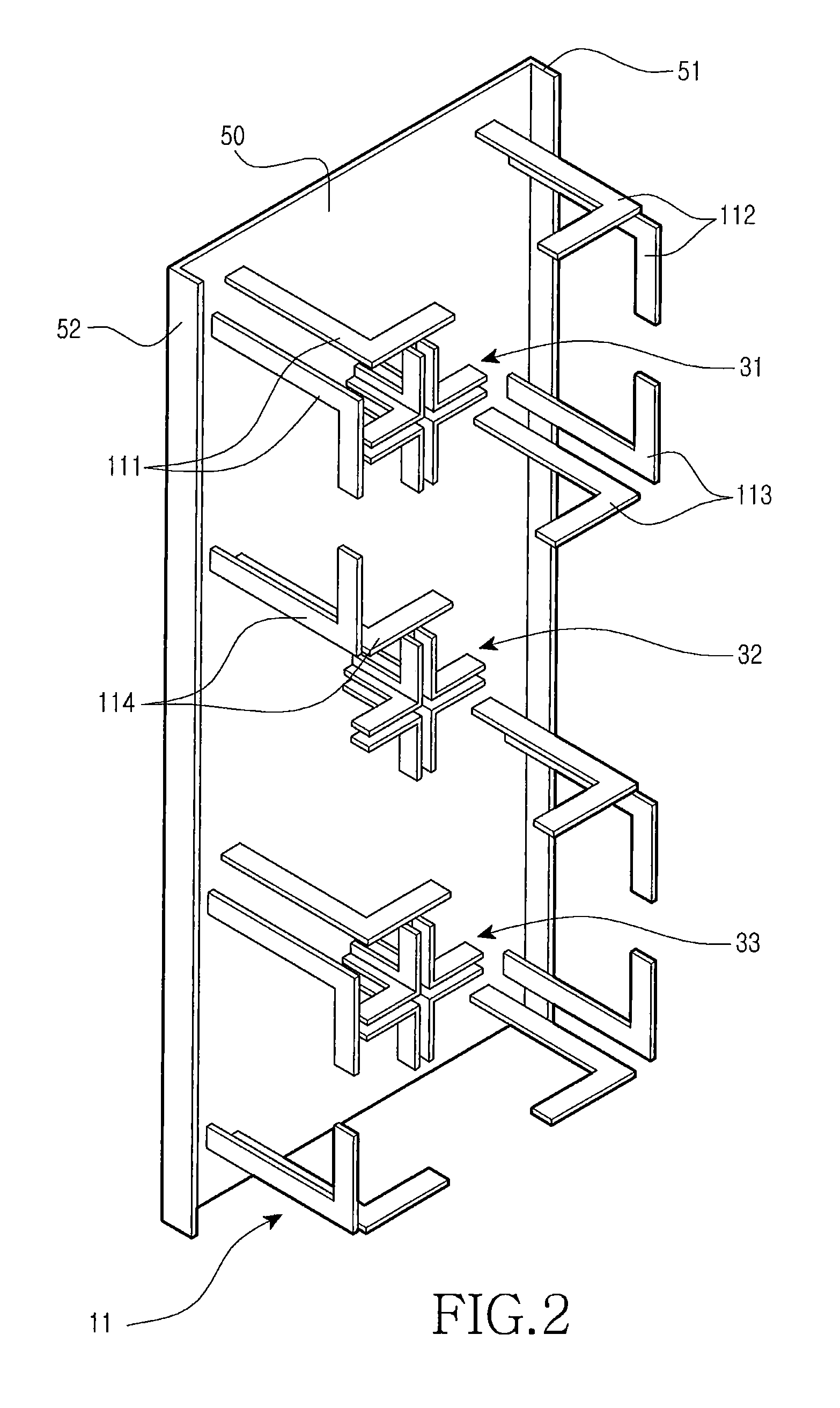

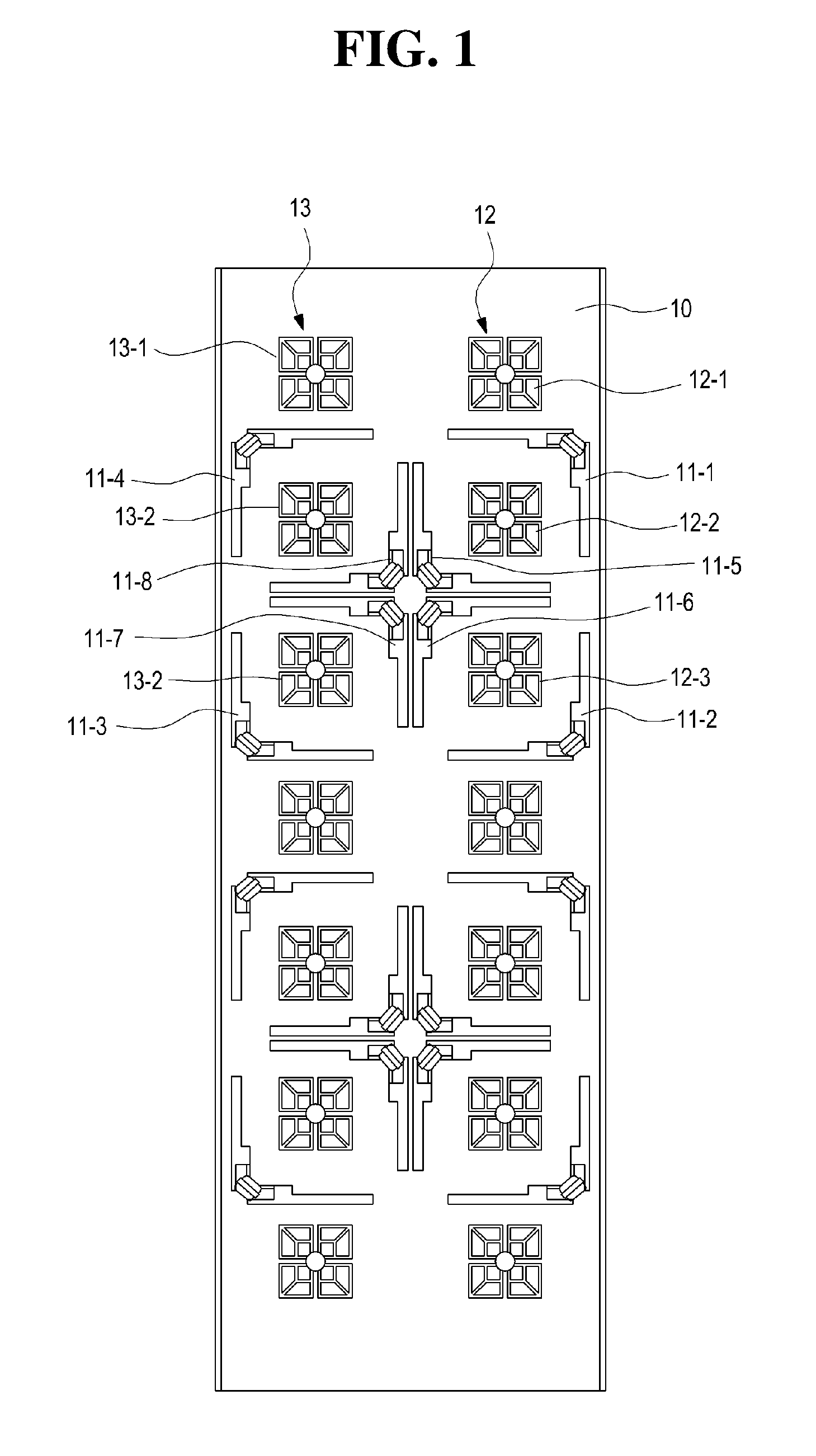

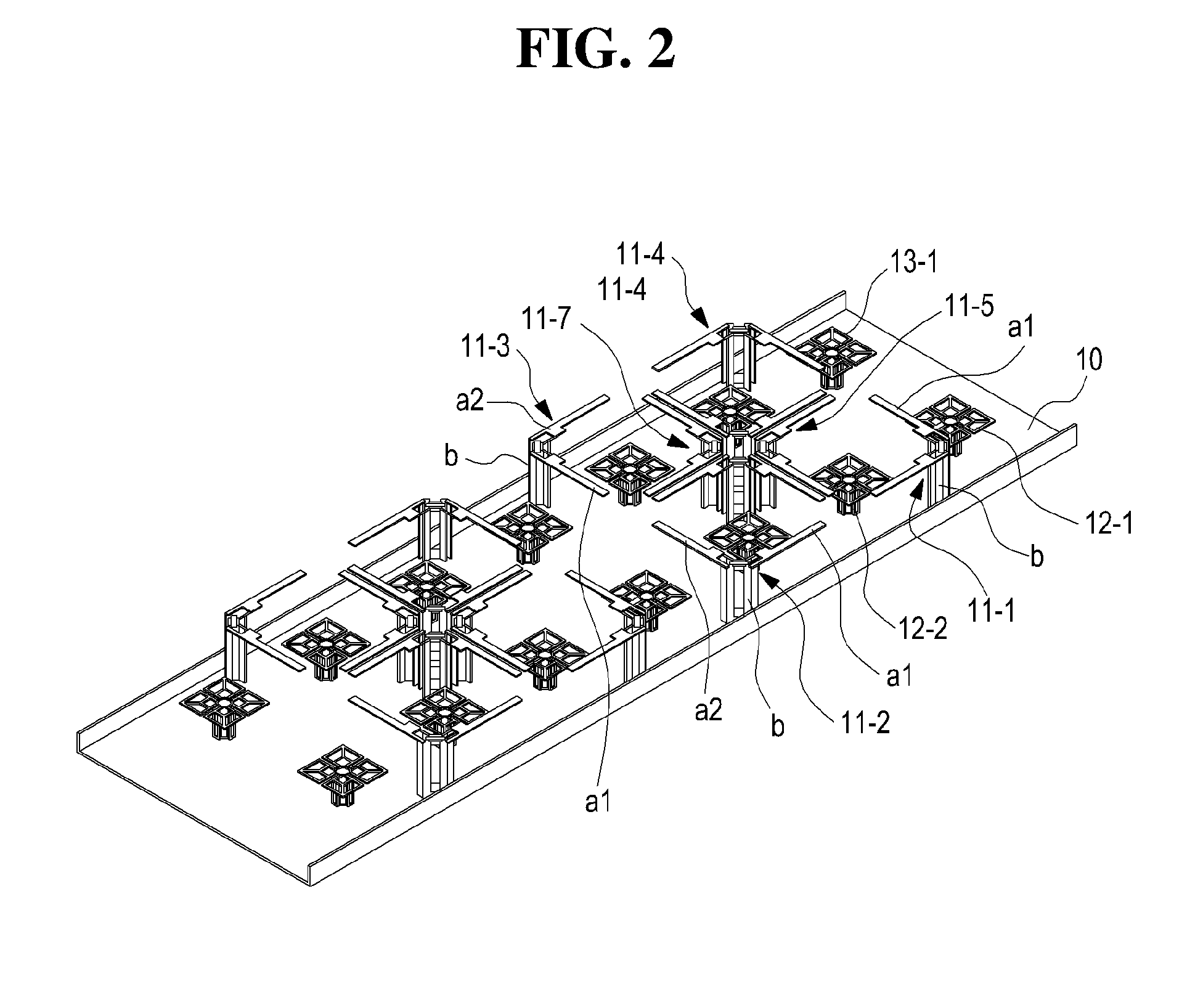

Dual-Band Dual-Polarized Base Station Antenna for Mobile Communication

ActiveUS20090278759A1Width of beam is easilySimple designSimultaneous aerial operationsIndividually energised antenna arraysDual frequencySquare Shape

Disclosed is a dual-band dual-polarized antenna for a mobile communication base station, which includes: a reflection plate; a first radiation device module for transmitting and receiving two linear orthogonal polarizations for a first frequency band, the first radiation device module generally having a square shape, the first radiation device module including a plurality of dipoles arranged to form the square shape, each of the dipoles substantially having a transverse side and a vertical side; and a second radiation device module for a second frequency band which is arranged within the square shape of the first radiation device module, and includes a plurality of dipoles generally arranged to form a cross-shape.

Owner:KMW INC

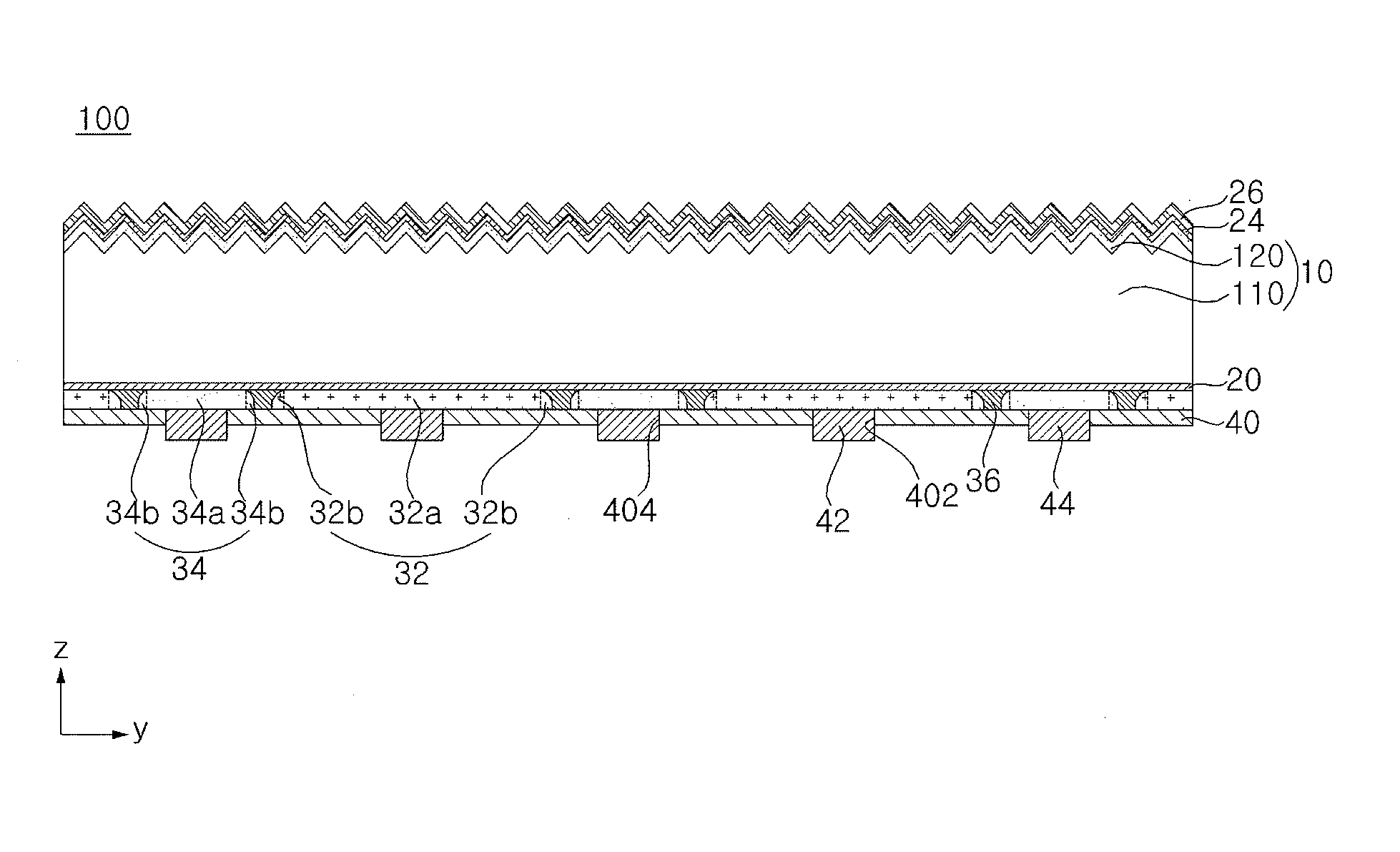

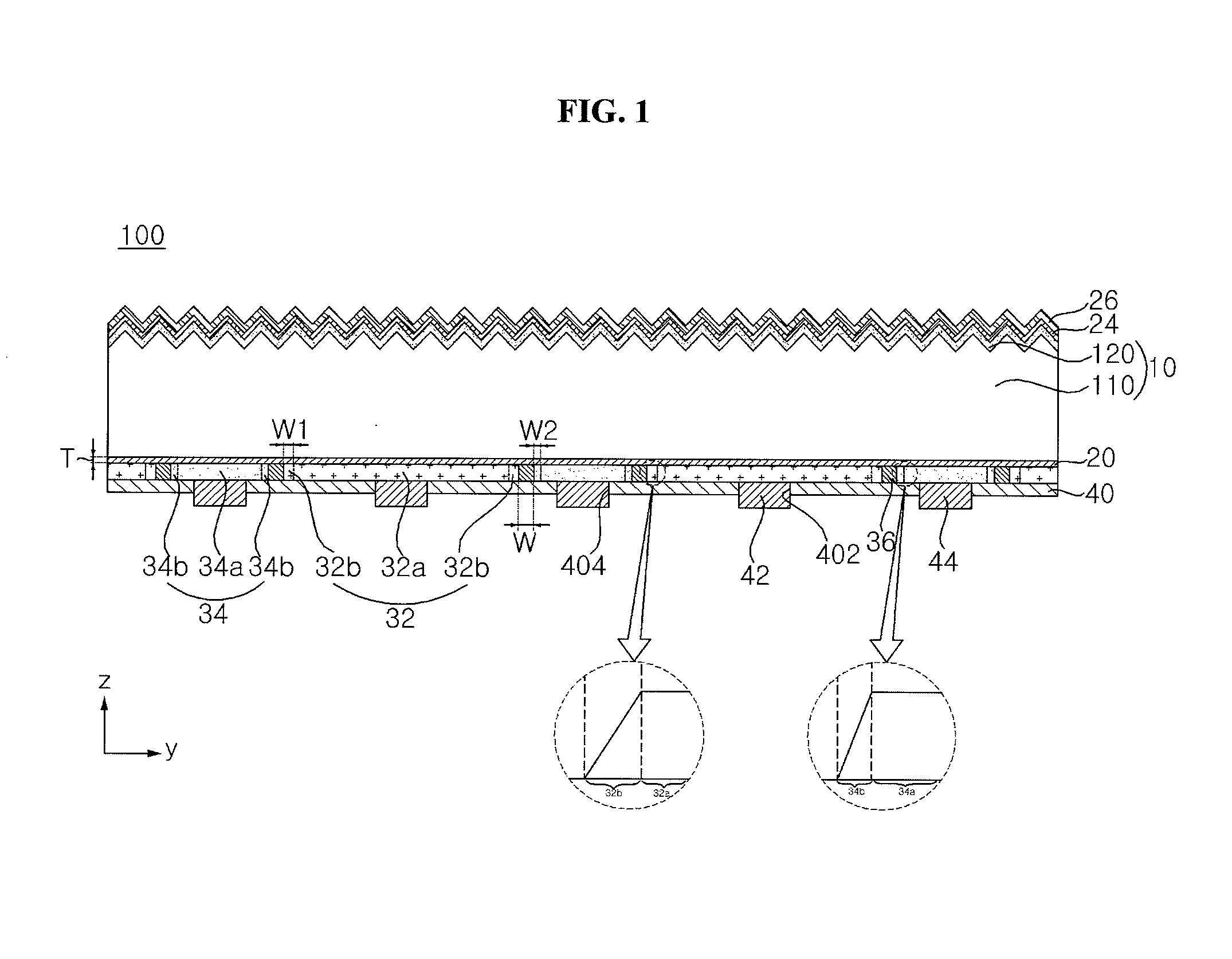

Solar cell and method of manufacturing the same

ActiveUS20150144183A1Improve efficiencyMaximizing conversionFinal product manufactureSemiconductor/solid-state device manufacturingBoundary regionSolar cell

A solar cell is discussed. The solar cell according to an embodiment includes a semiconductor substrate, a first conductive type region and a second conductive type region disposed on the same side of the semiconductor substrate, wherein at least one of the first and second conductive type regions includes a main region and a boundary region disposed at a peripheral portion of the main region, and the boundary region has at least one of a varying doping concentration and a varying doping depth.

Owner:SHANGRAO JINKO SOLAR TECH DEV CO LTD

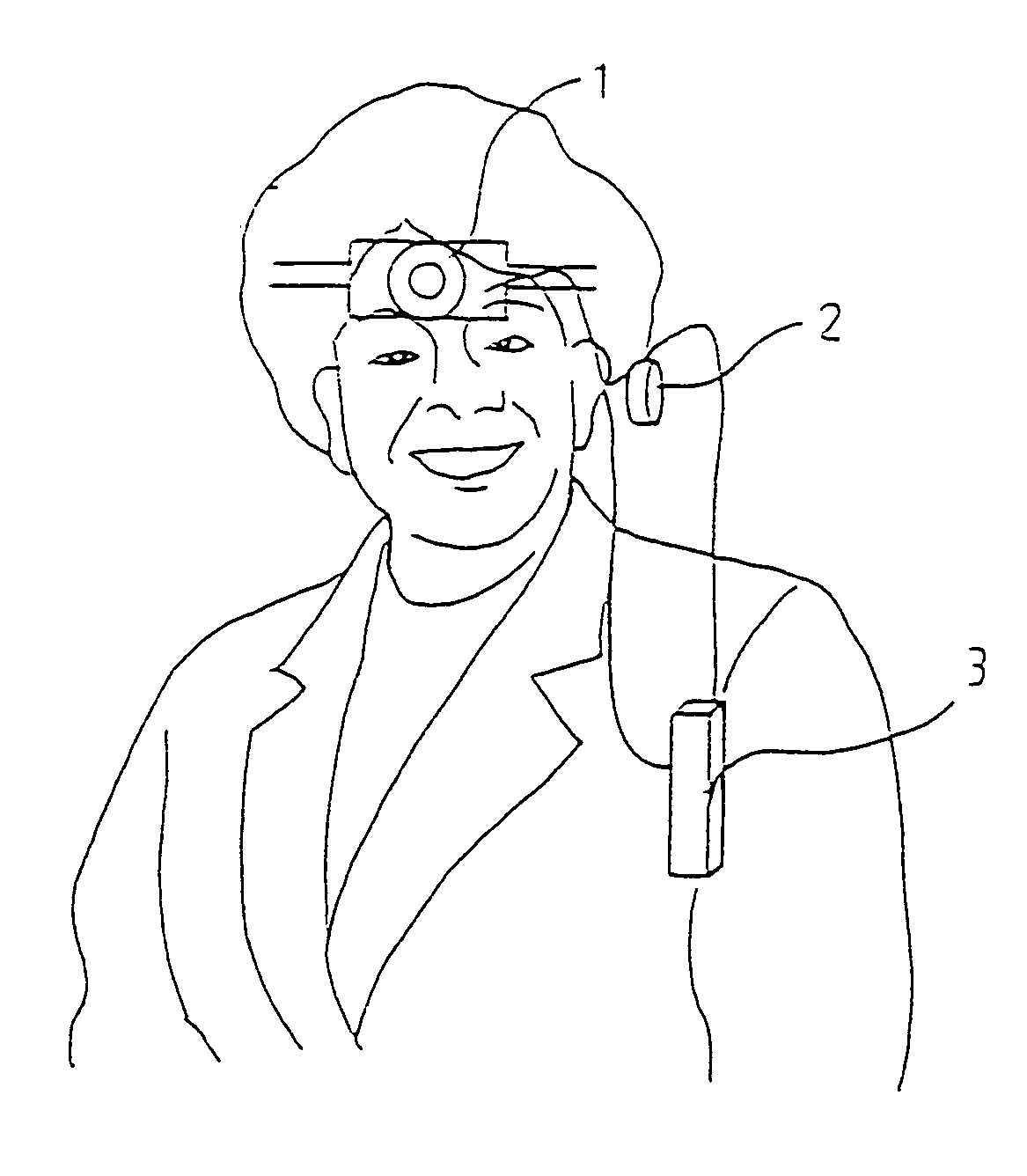

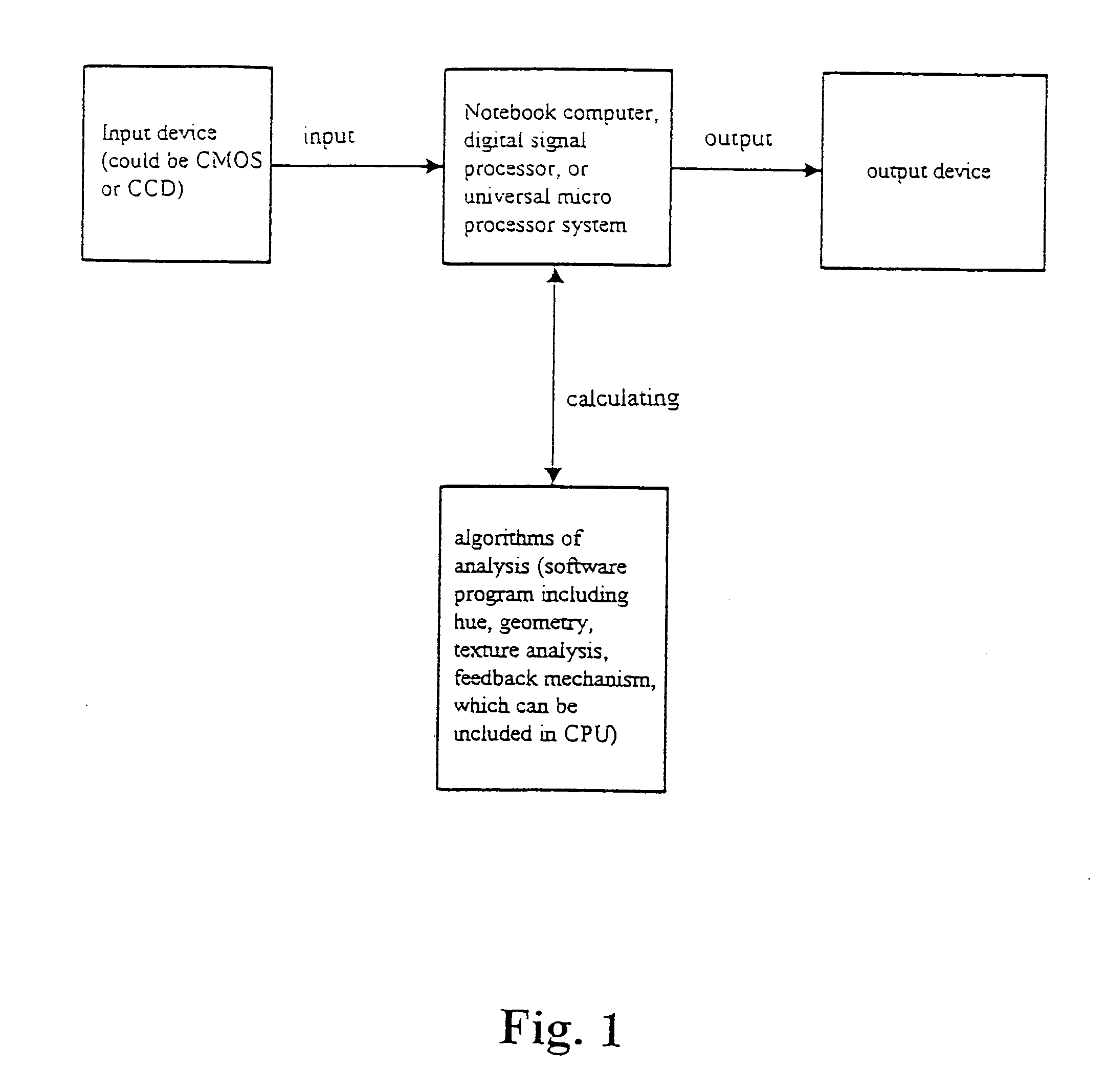

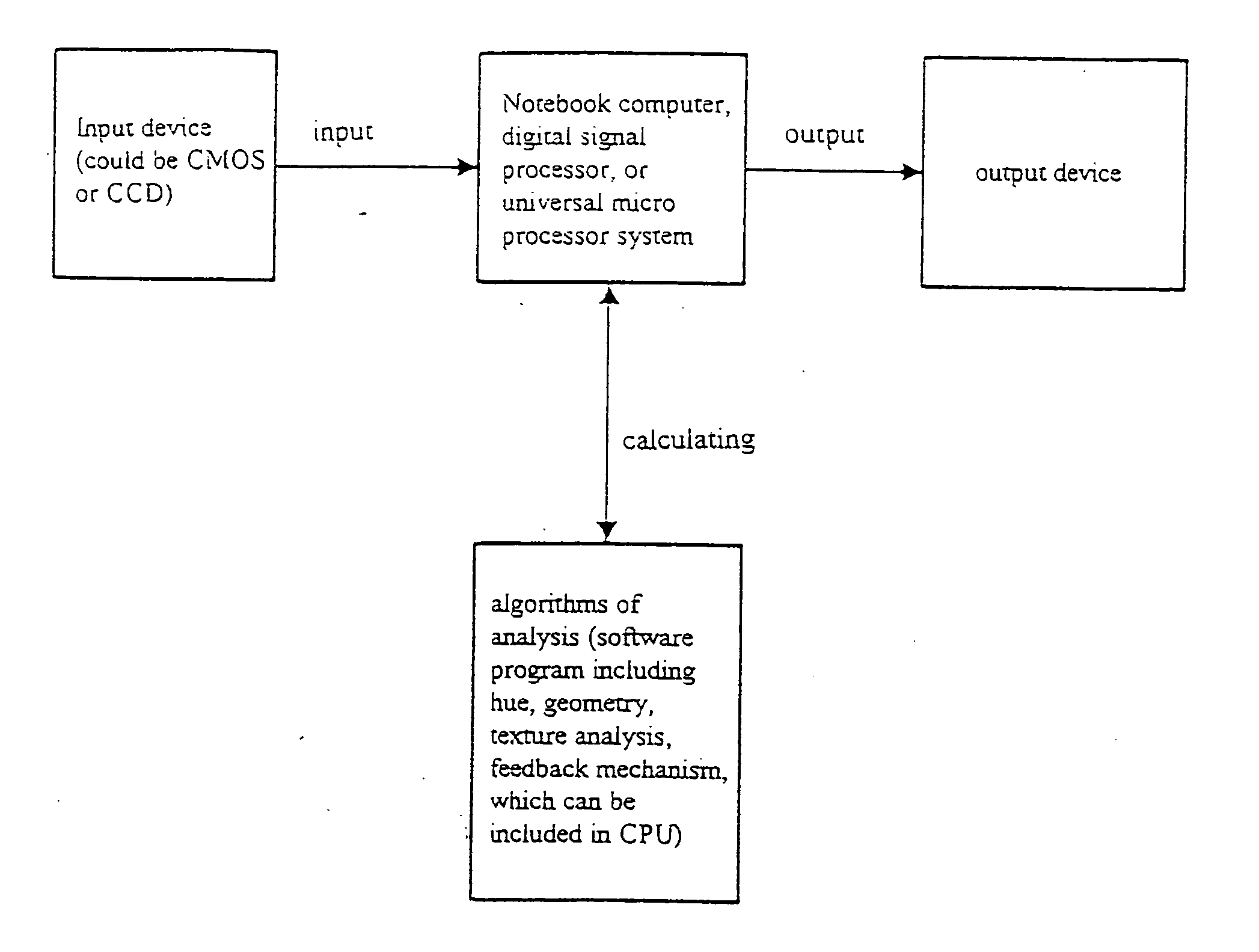

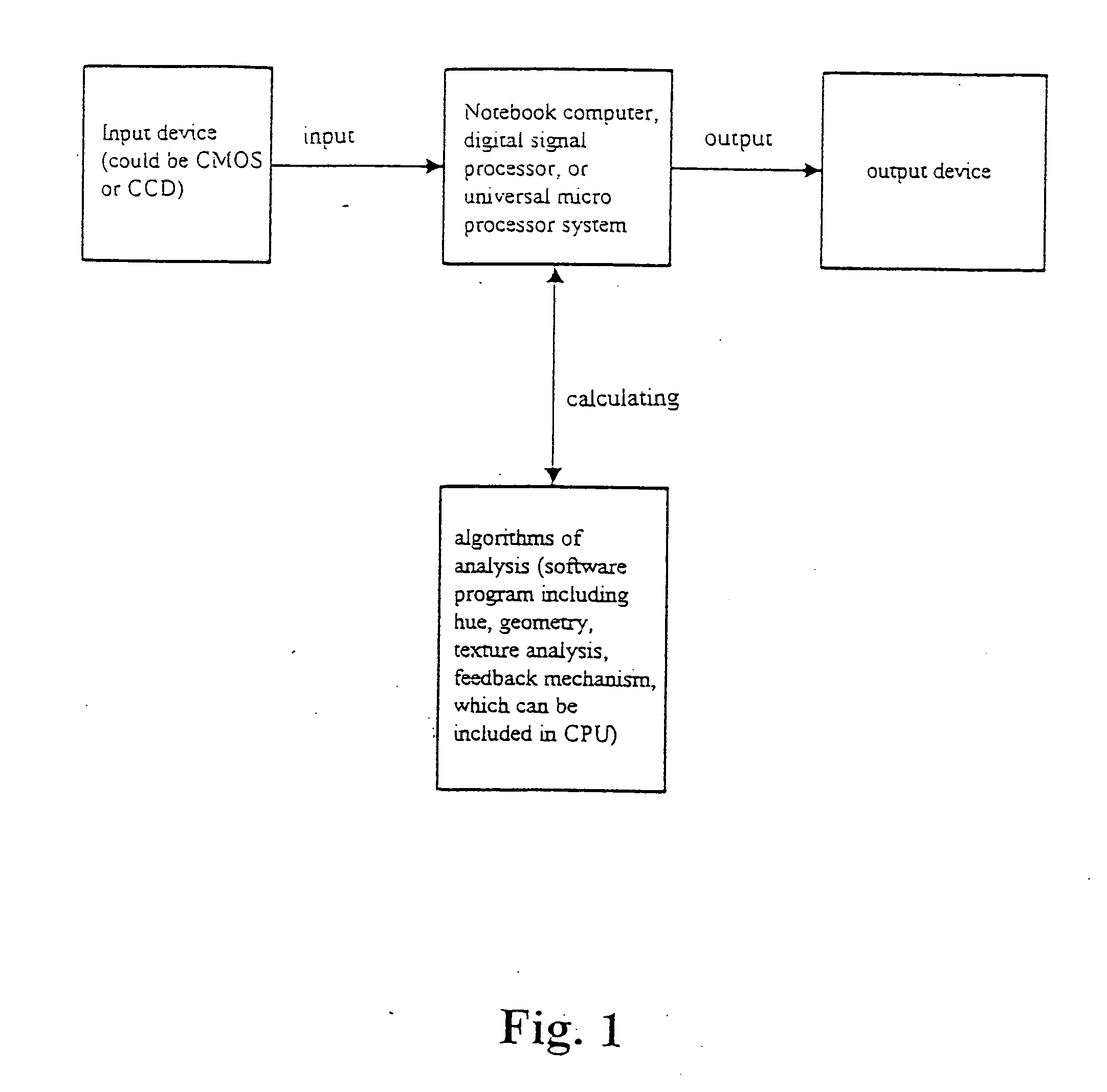

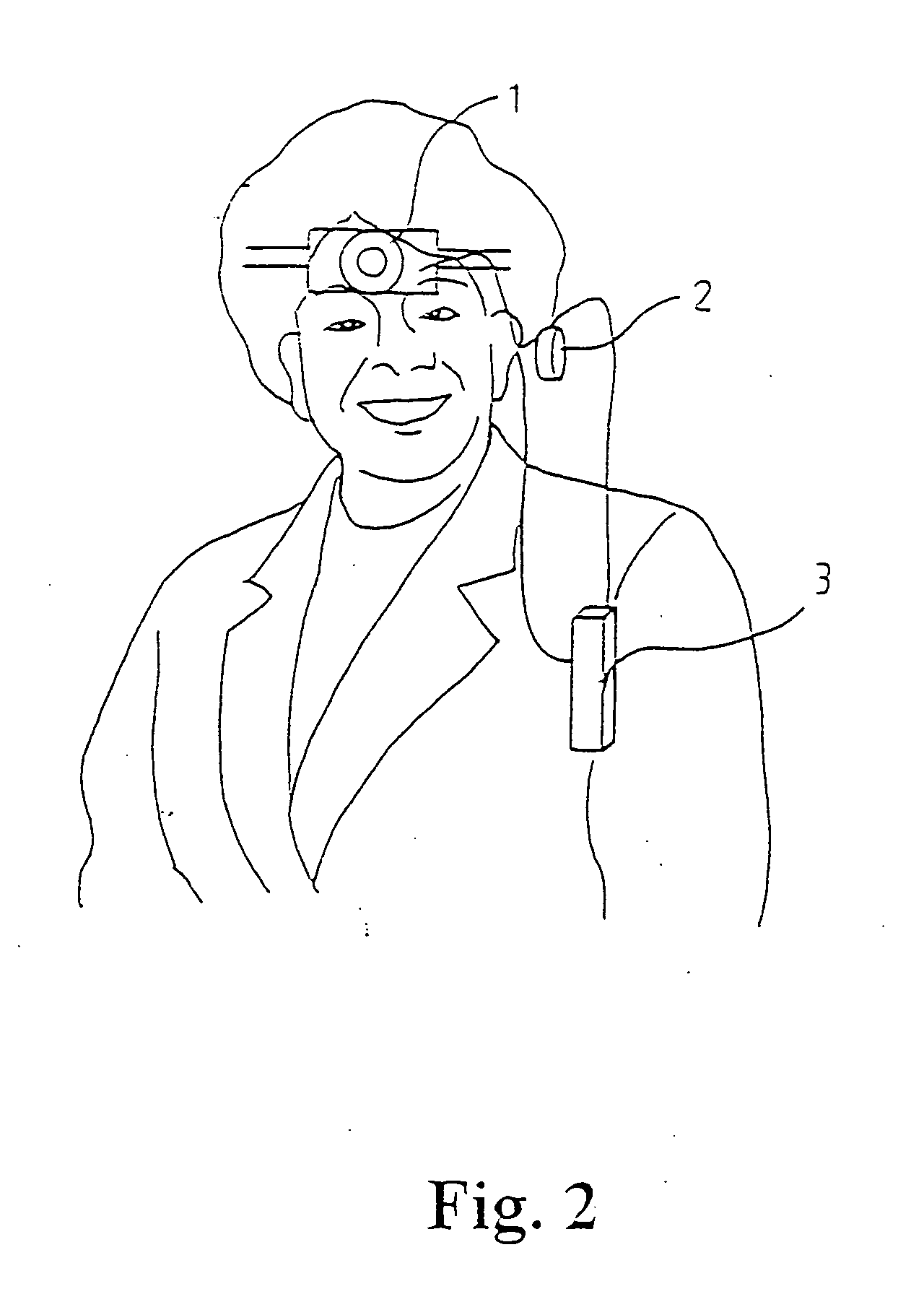

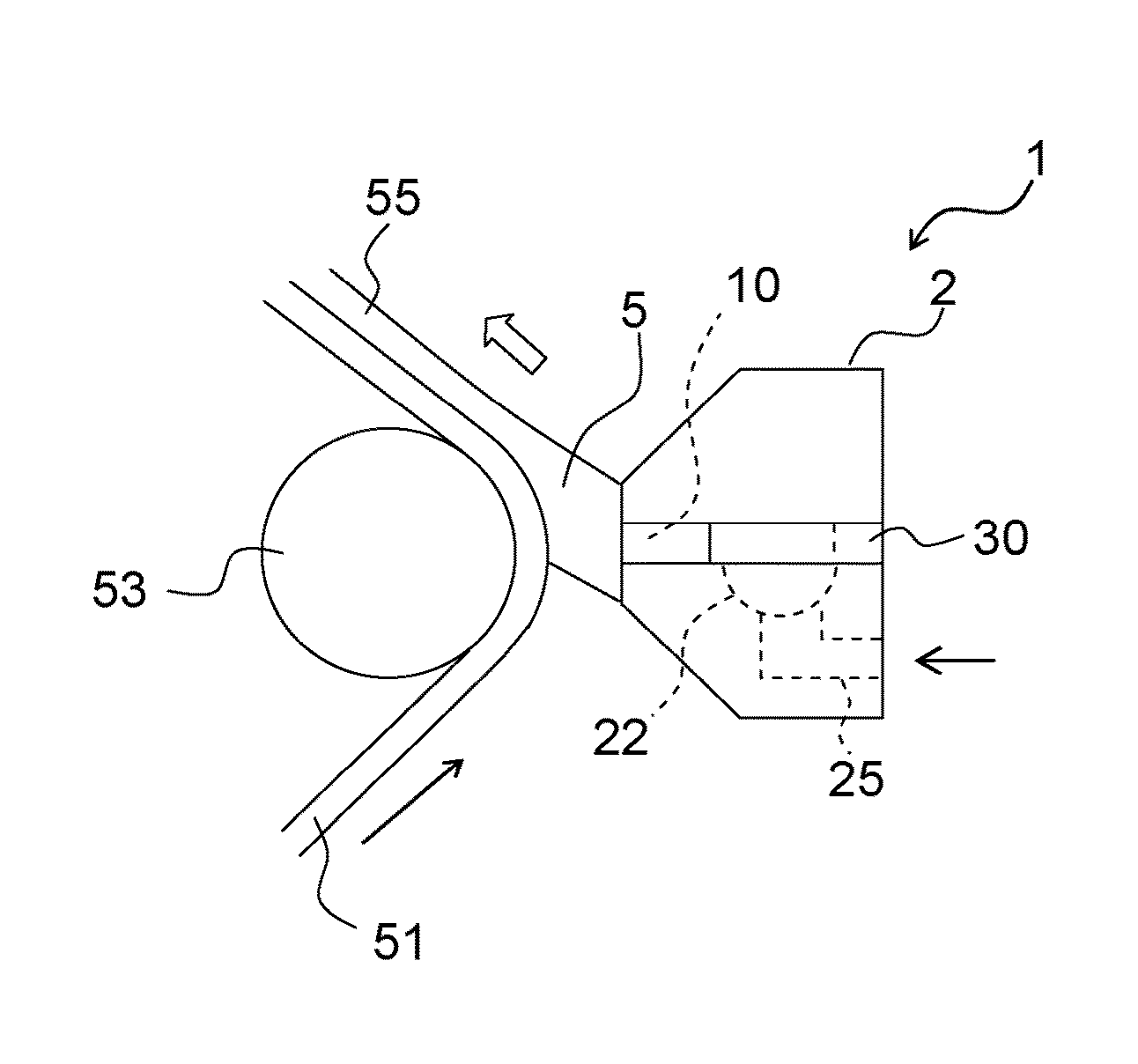

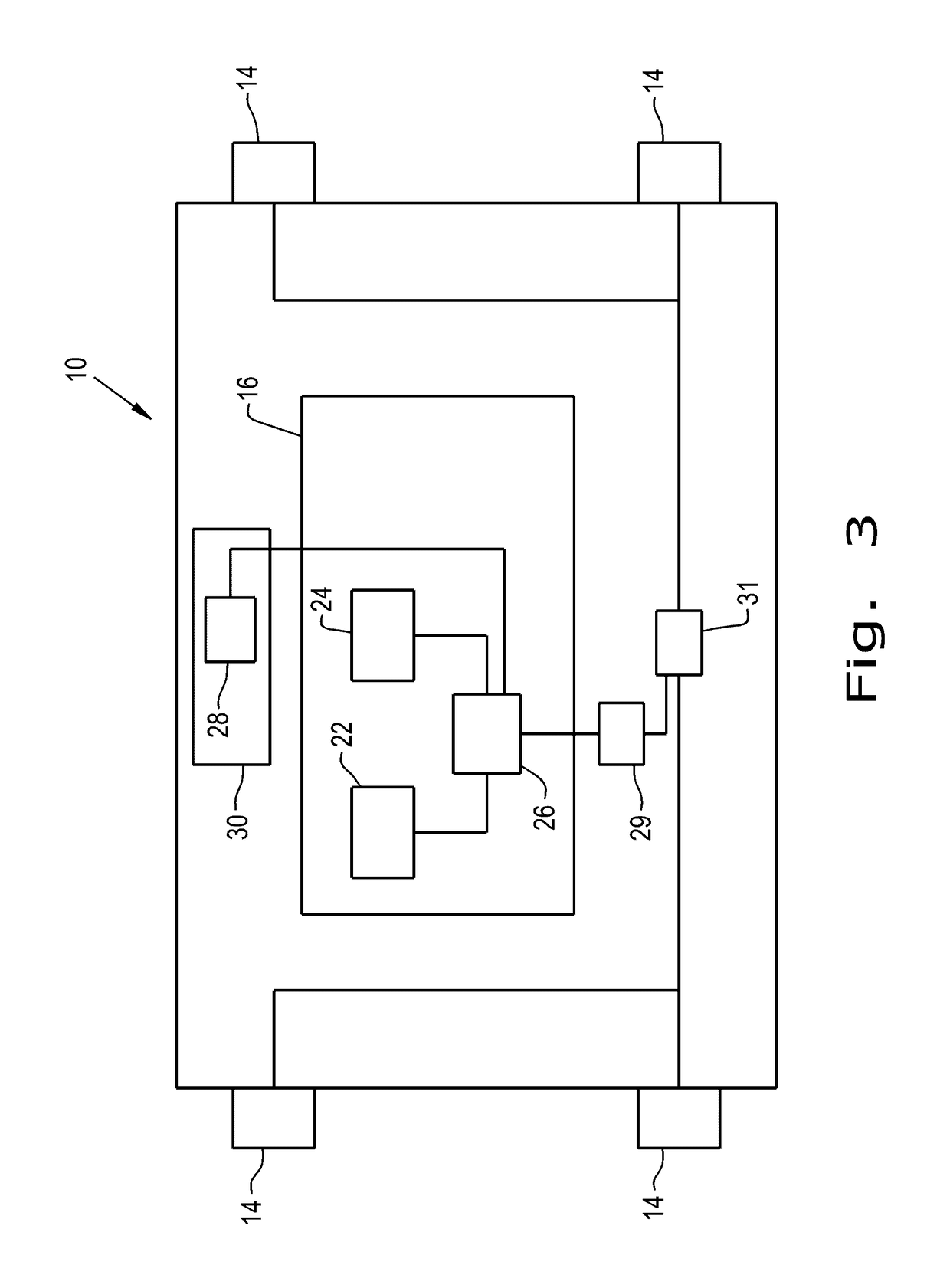

Apparatus and method for identifying surrounding environment by means of image processing and for outputting the results

InactiveUS7230538B2Function increaseDirection easyImage analysisRoad vehicles traffic controlCMOSTraffic signal

Owner:ORIENTAL INST TECH +1

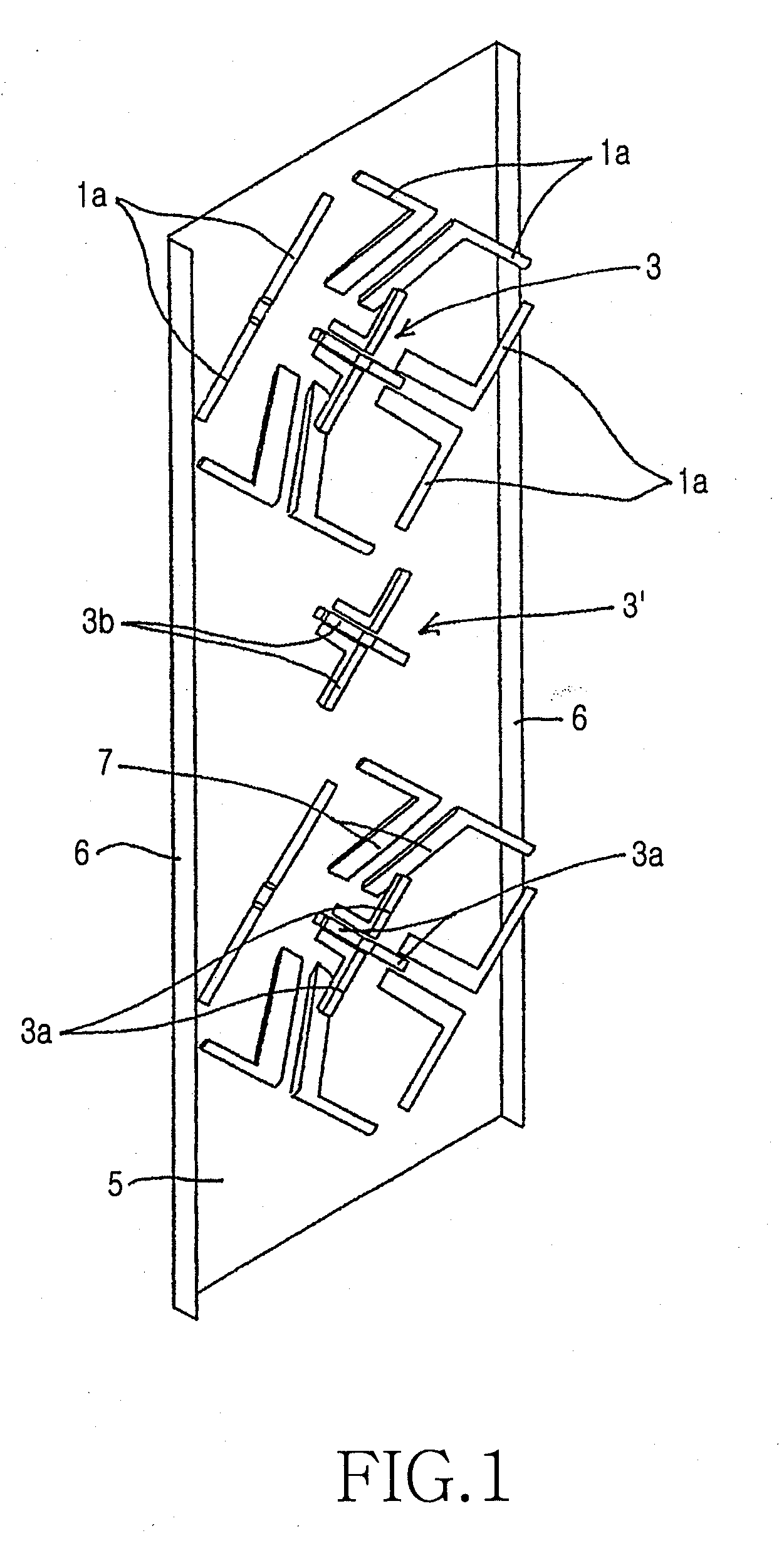

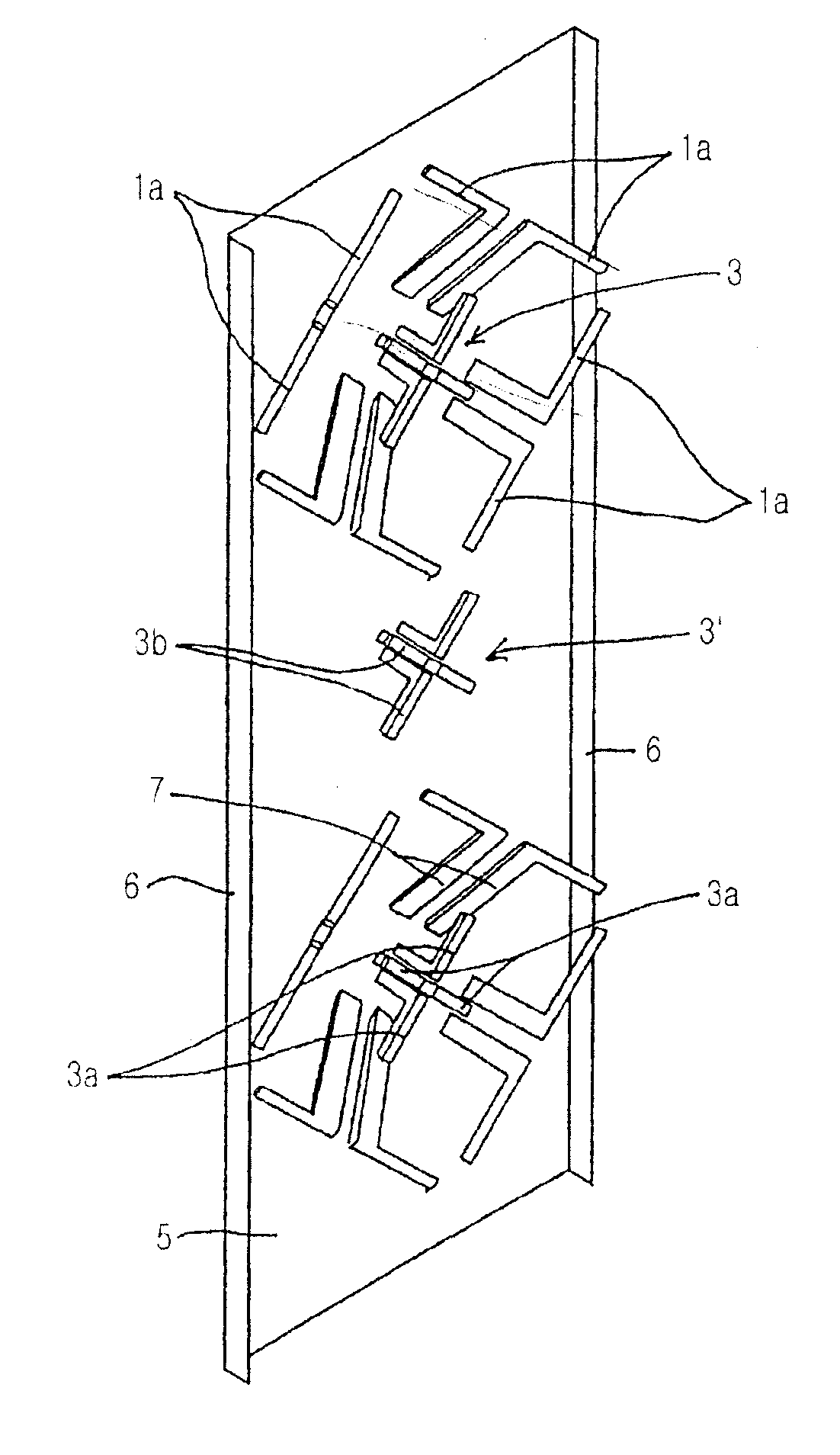

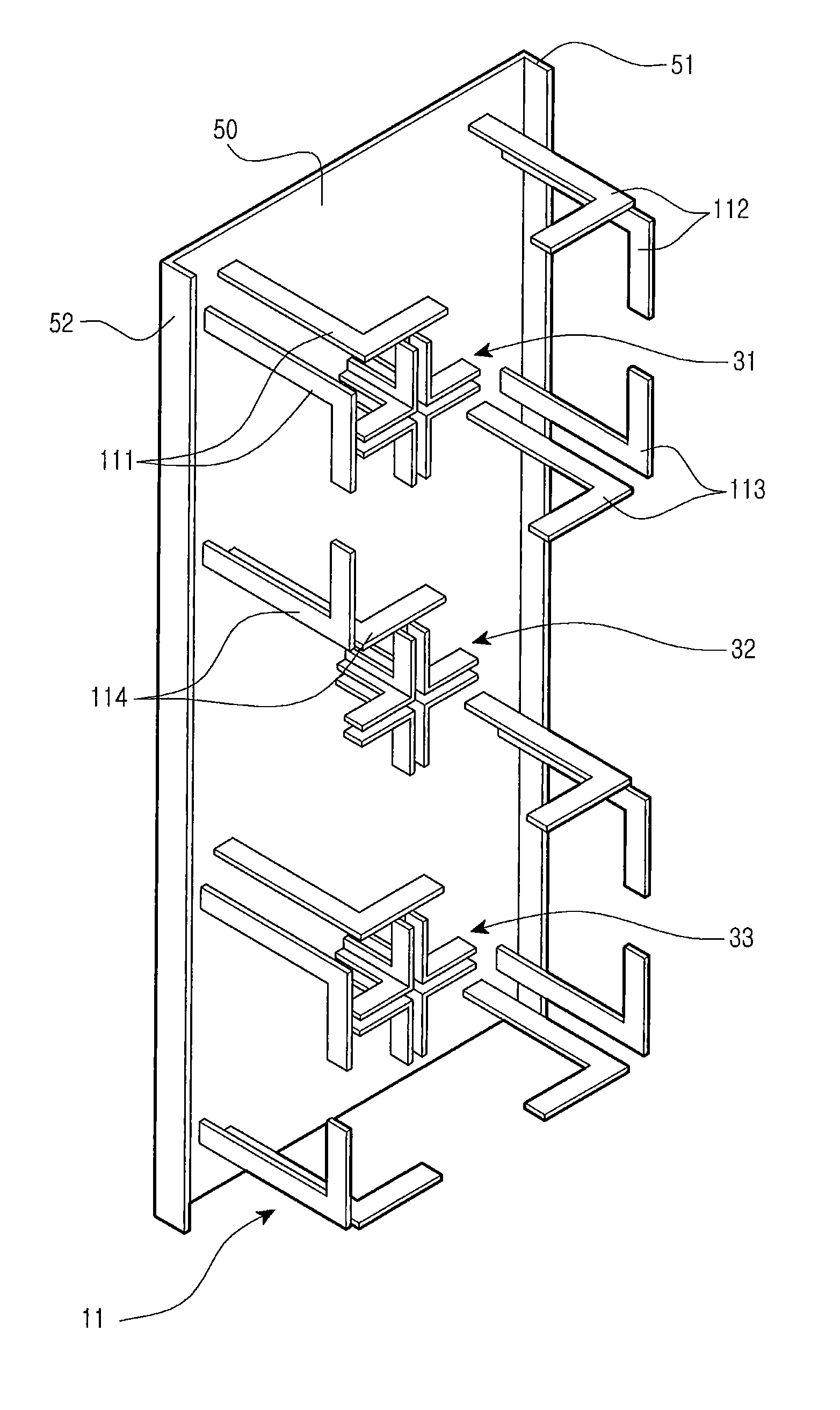

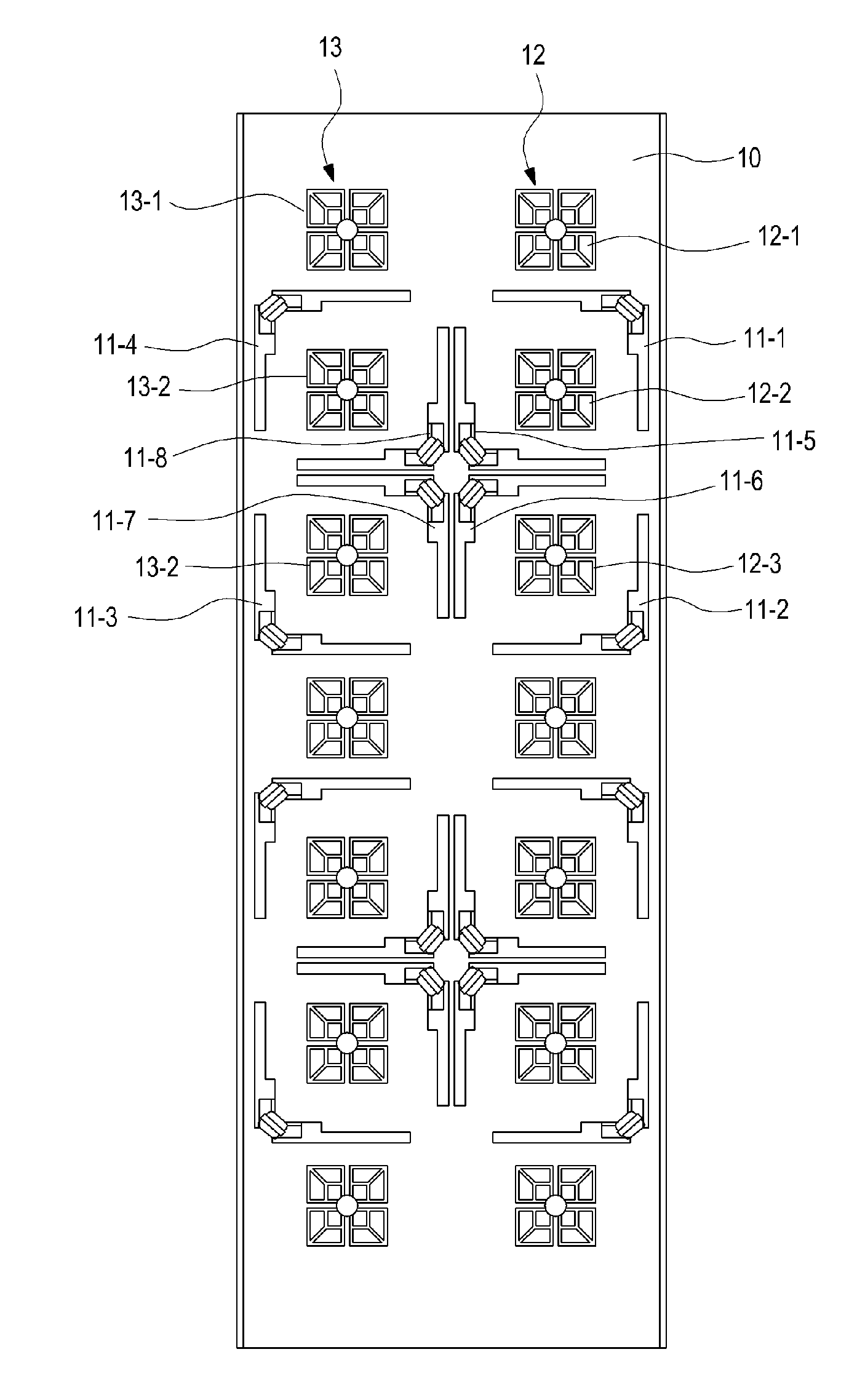

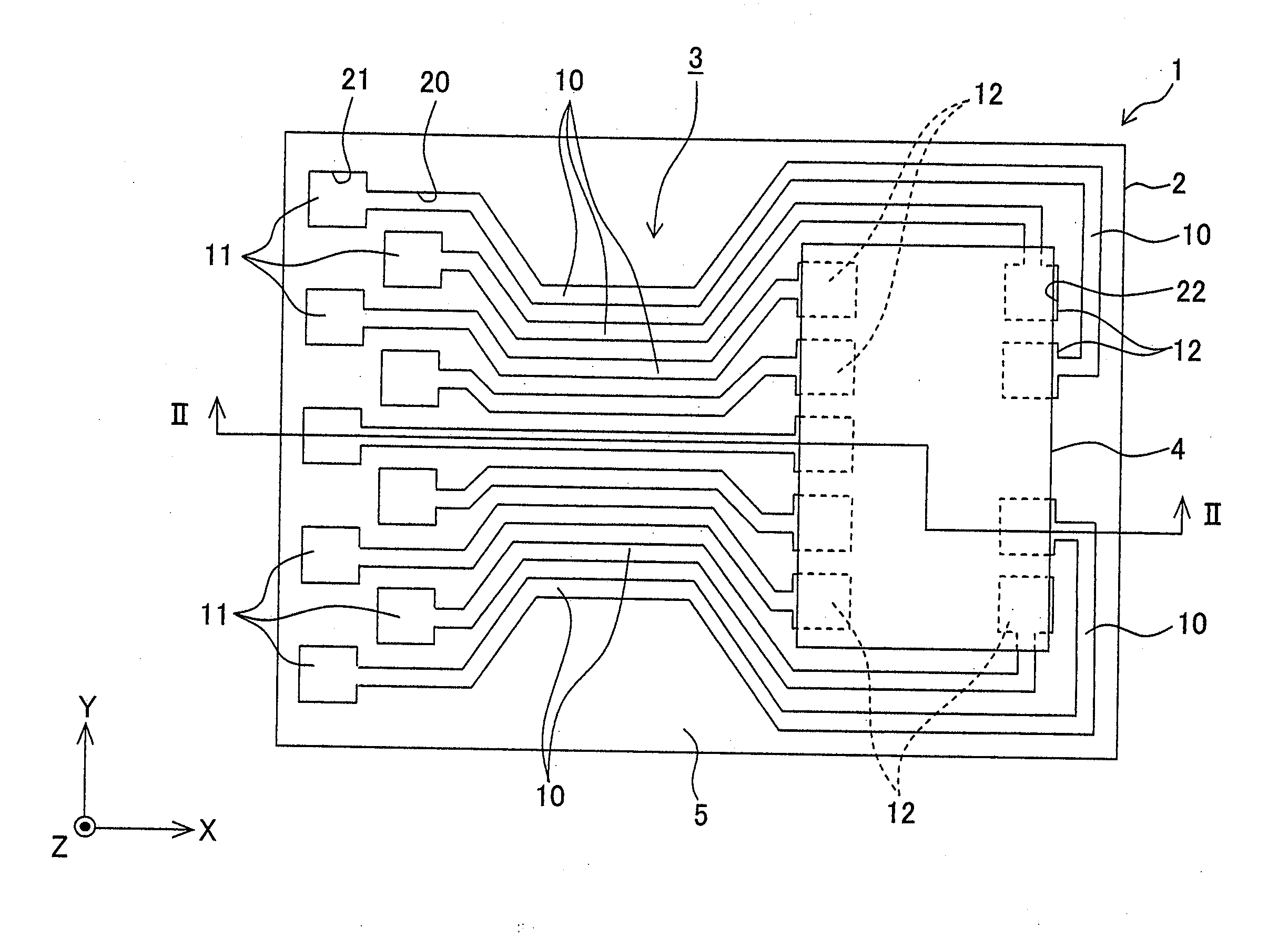

Dual-band dual-polarized antenna of base station for mobile communication

InactiveUS20110175782A1Optimal structure arrangementOptimal antenna sizeSimultaneous aerial operationsIndividually energised antenna arraysFrequency bandPhysics

Disclosed is a dual-band dual-polarized antenna of a base station for mobile communication, the dual-band dual-polarized antenna including: a reflection plate; one or more first radiating element modules formed on the reflection plate to transmit and receive two linear orthogonal polarized waves for a first frequency band, the one or more first radiating element modules including a plurality of dipoles installed in a general ‘X’ shape; and one or more second radiating element modules for a second frequency band, which are interleaved between the first radiating element modules on the reflection.

Owner:KMW INC

Apparatus and method for identifying surrounding environment by means of image processing and for outputting the results

InactiveUS20050275718A1Easy maintenanceSimple environmentImage analysisRoad vehicles traffic controlCMOSTraffic signal

The present invention relates to an apparatus for identifying surrounding environment by means of image processing, so as to be used by blind people or unmanned vehicles. The said apparatus comprises an input device, which includes at least one CCD or CMOS means for capturing images, a processing device, which could be a micro processing unit such as a notebook computer, DSP or other embedded system, and an output device, such as a speech earphone. The processing device applies hue analysis and geometric analysis to identify traffic signals and markings.

Owner:ORIENTAL INST TECH +1

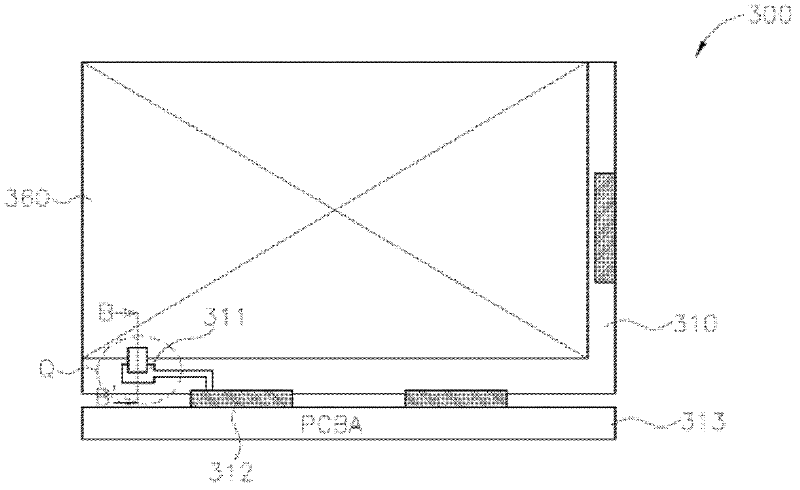

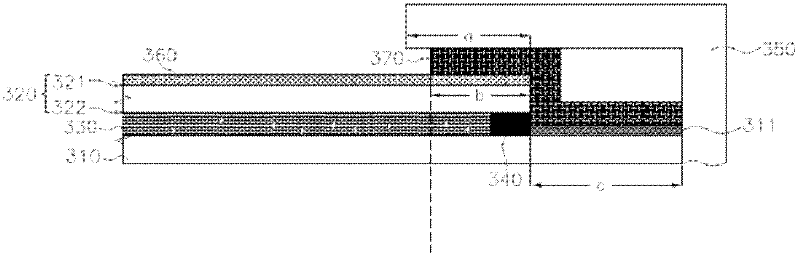

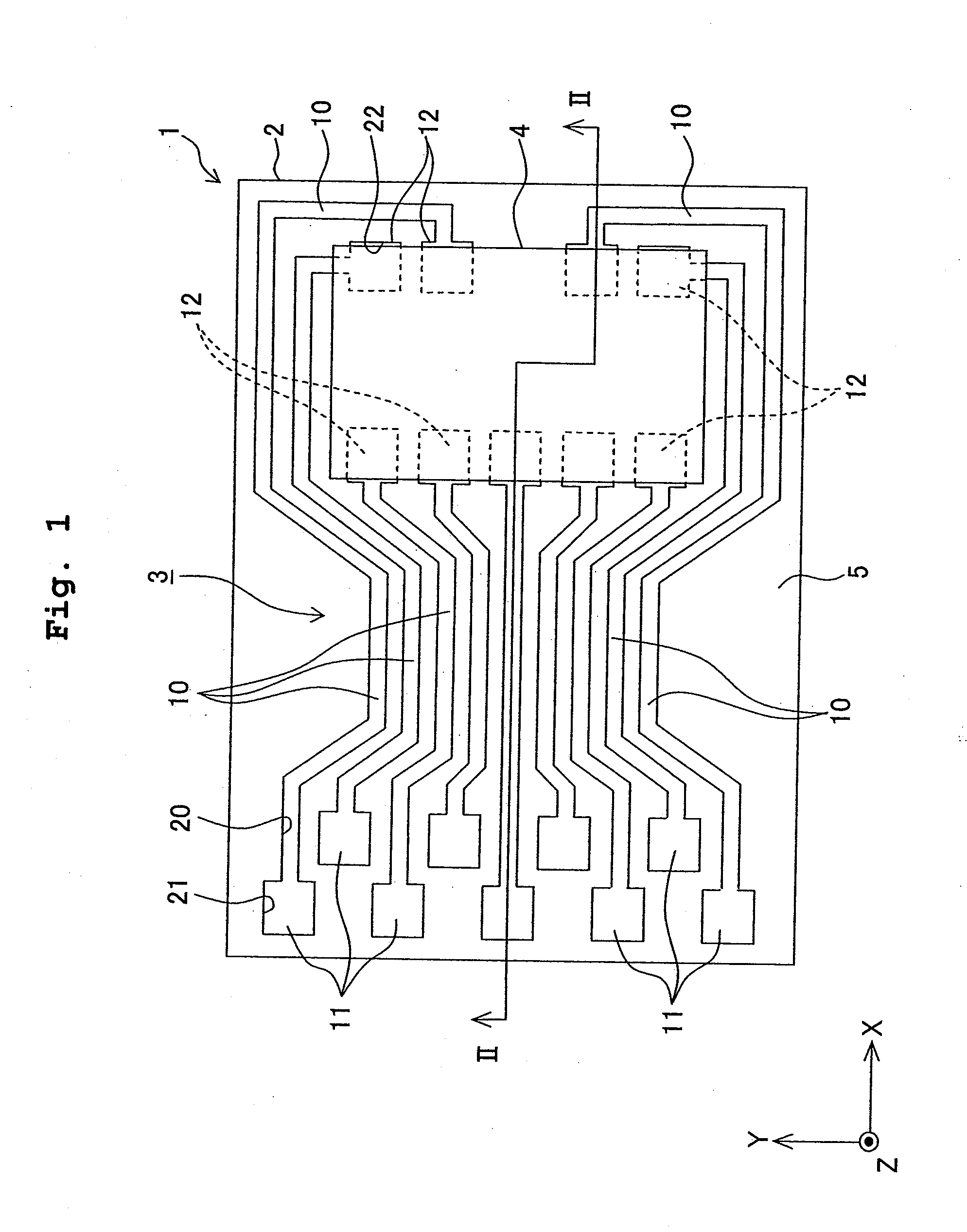

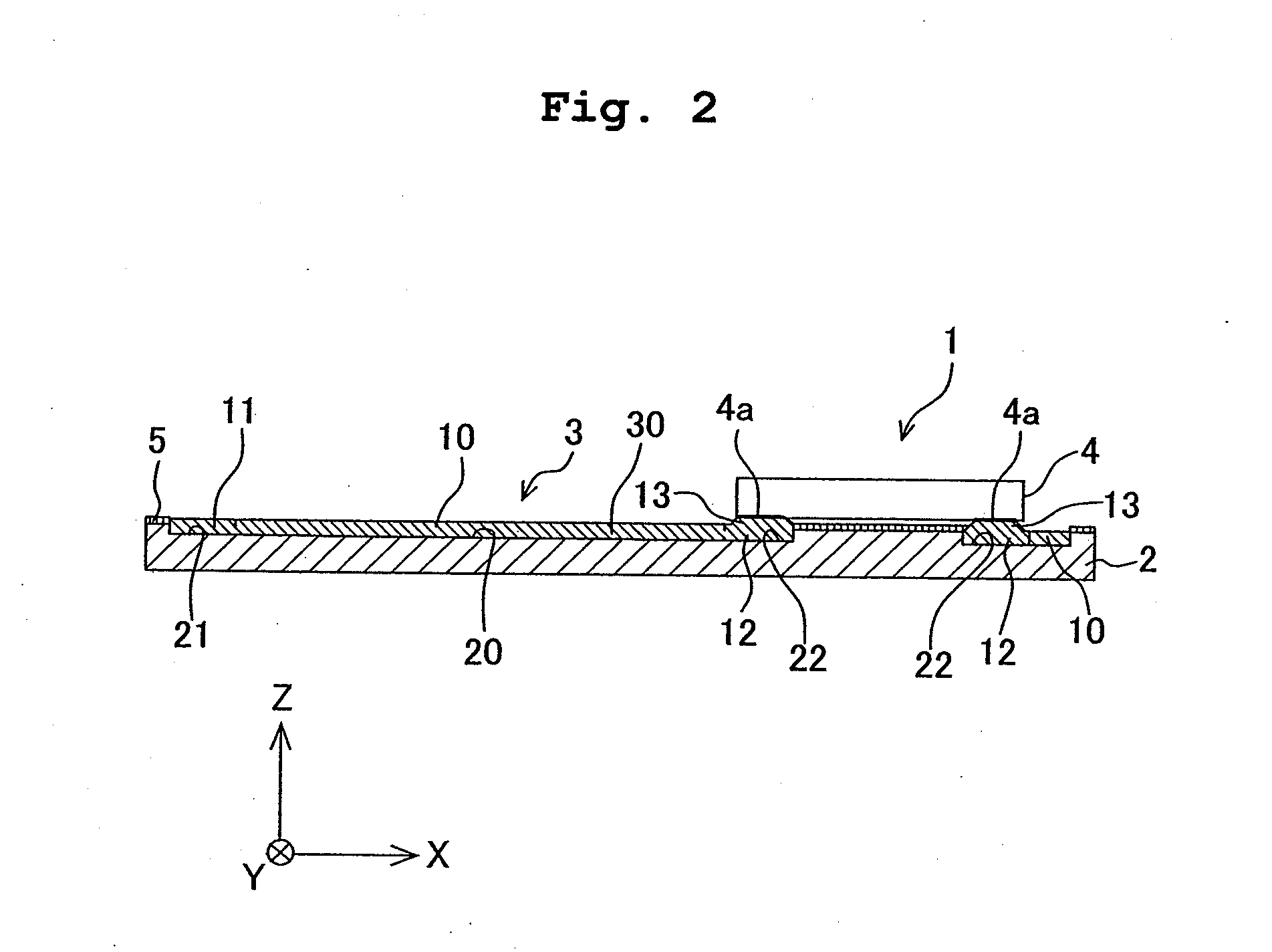

A liquid crystal display device and its manufacturing method

ActiveCN102262313ACompact designReduce widthStatic indicating devicesNon-linear opticsLiquid-crystal displayElectromagnetic shielding

The invention provides a liquid crystal display device for the touch panel. The liquid crystal display device comprises a first substrate, a second substrate, a liquid crystal layer, a plastic frame and an electromagnetic shielding layer, wherein the first substrate and the second substrate are oppositely arranged in a spaced way; the liquid crystal layer is mounted between the first and second substrates; the plastic frame is arranged between the first and the second substrates so as to seal the liquid crystal layer; the electromagnetic shielding layer is arranged on the first and second substrates. And a conductive metal layer arranged in a grounded way is mounted on the first substrate; the conductive metal layer is electrically connected to the electromagnetic shielding layer; the electromagnetic shielding layer comprises a main body part and an extending part. The main body part is arranged on the second substrate; the extending part extends from the main body part to the conductive metal layer of the first substrate so as to electrically connect the main body part with the conductive metal layer.

Owner:CENTURY DISPLAY (SHENZHEN) CO LTD

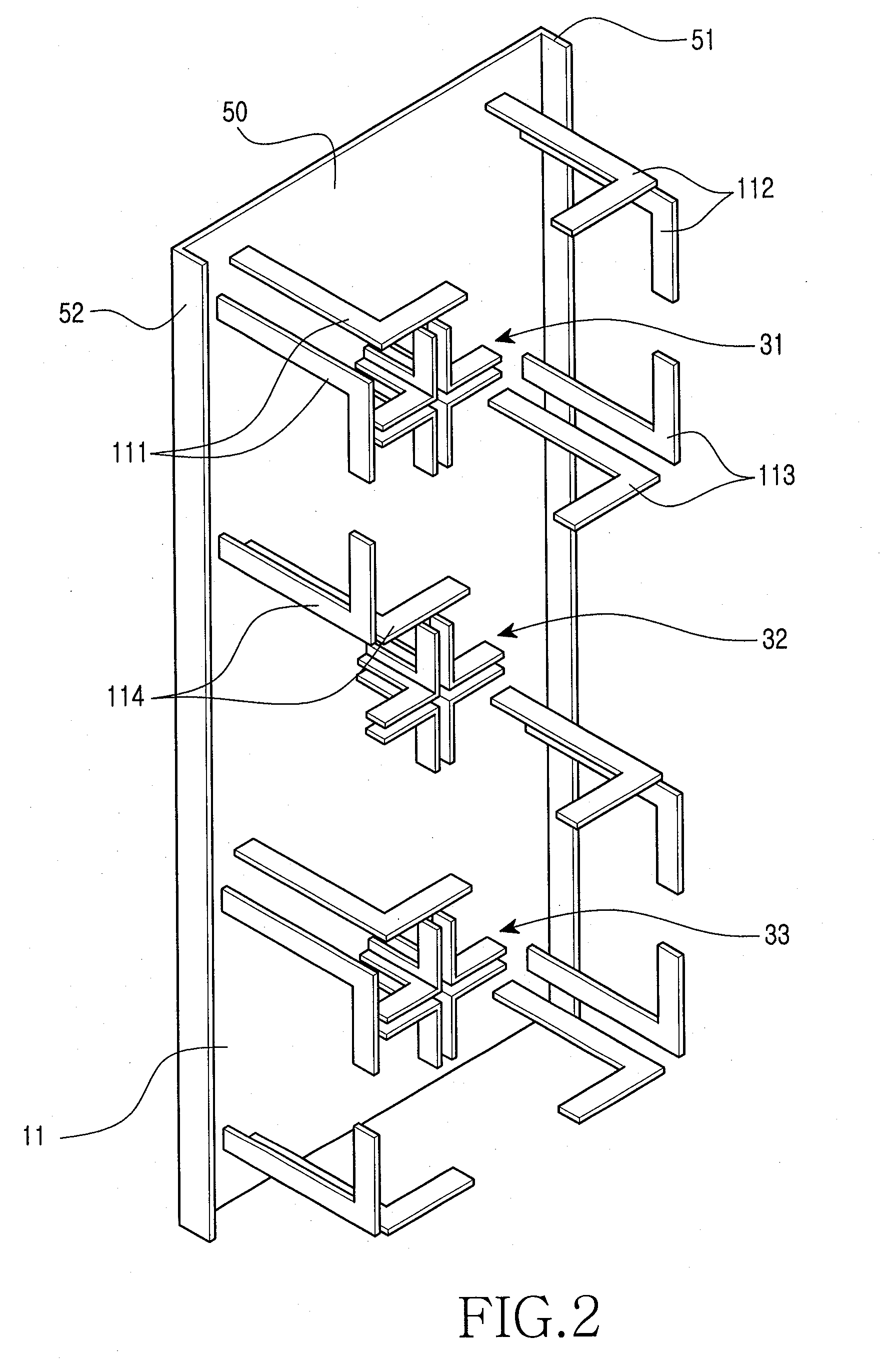

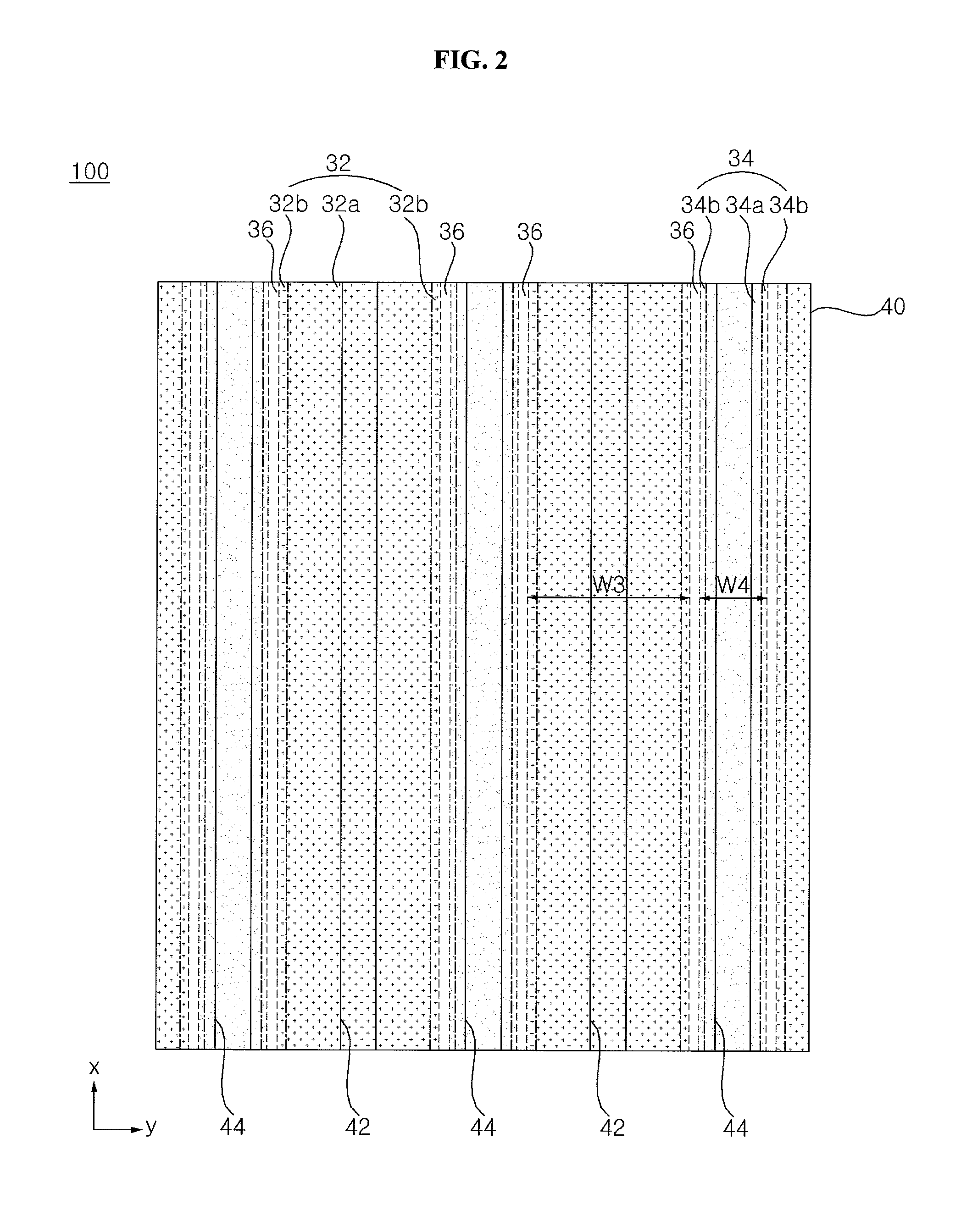

Dual-band dual-polarized base station antenna for mobile communication

ActiveUS8199063B2Easy widthSimple designSimultaneous aerial operationsIndividually energised antenna arraysSquare ShapePhysics

Disclosed is a dual-band dual-polarized antenna for a mobile communication base station, which includes: a reflection plate; a first radiation device module for transmitting and receiving two linear orthogonal polarizations for a first frequency band, the first radiation device module generally having a square shape, the first radiation device module including a plurality of dipoles arranged to form the square shape, each of the dipoles substantially having a transverse side and a vertical side; and a second radiation device module for a second frequency band which is arranged within the square shape of the first radiation device module, and includes a plurality of dipoles generally arranged to form a cross-shape.

Owner:KMW INC

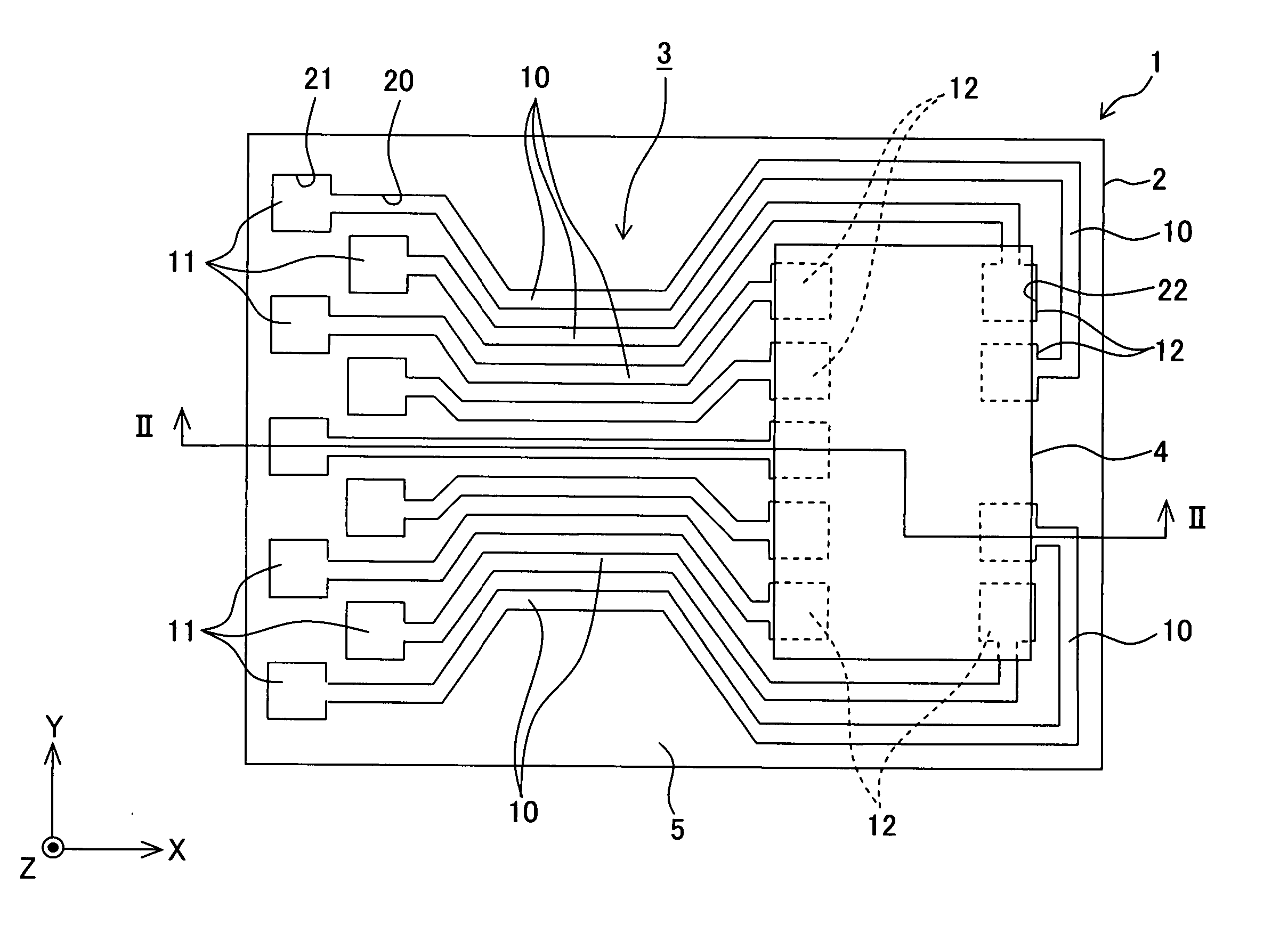

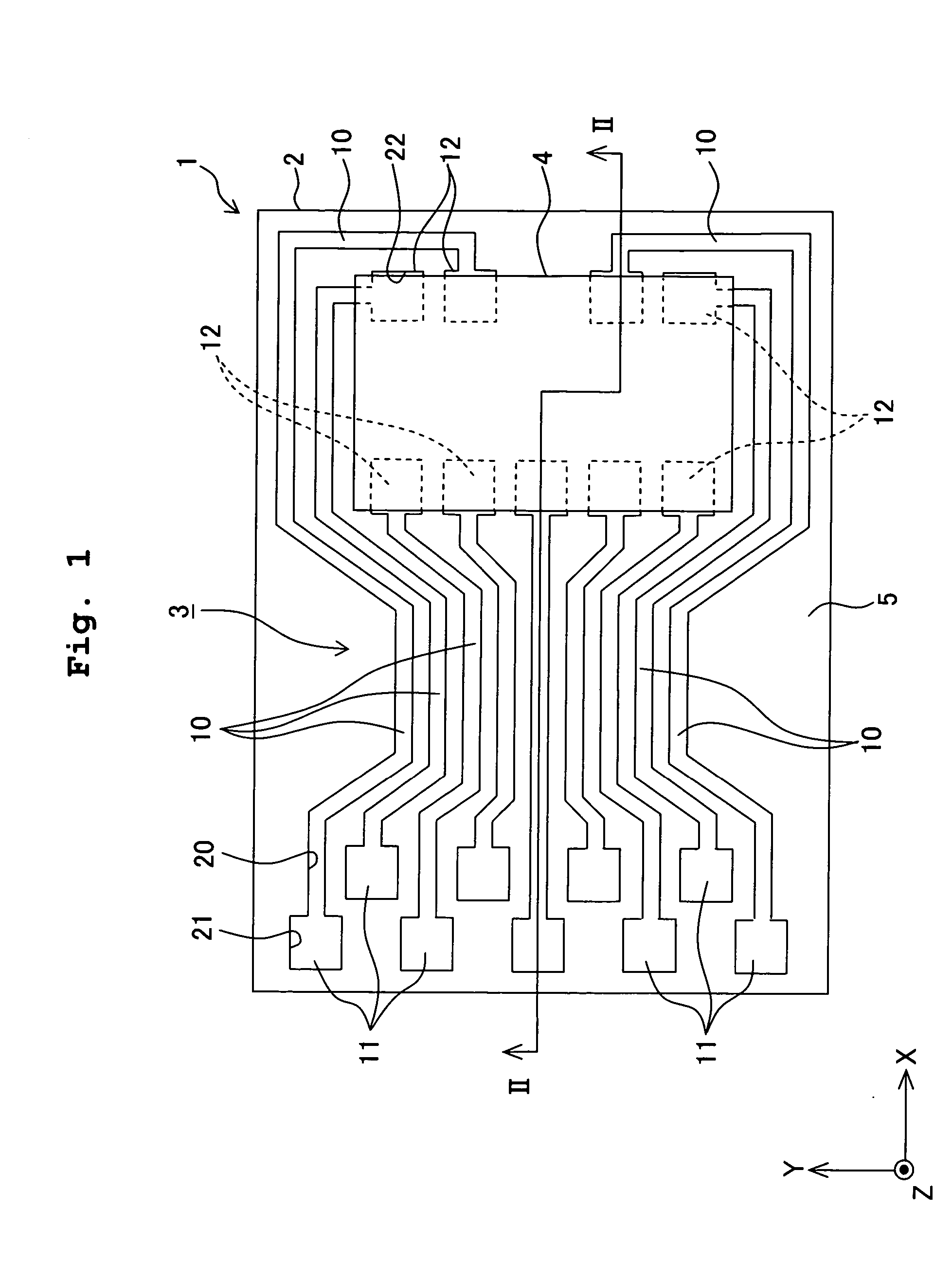

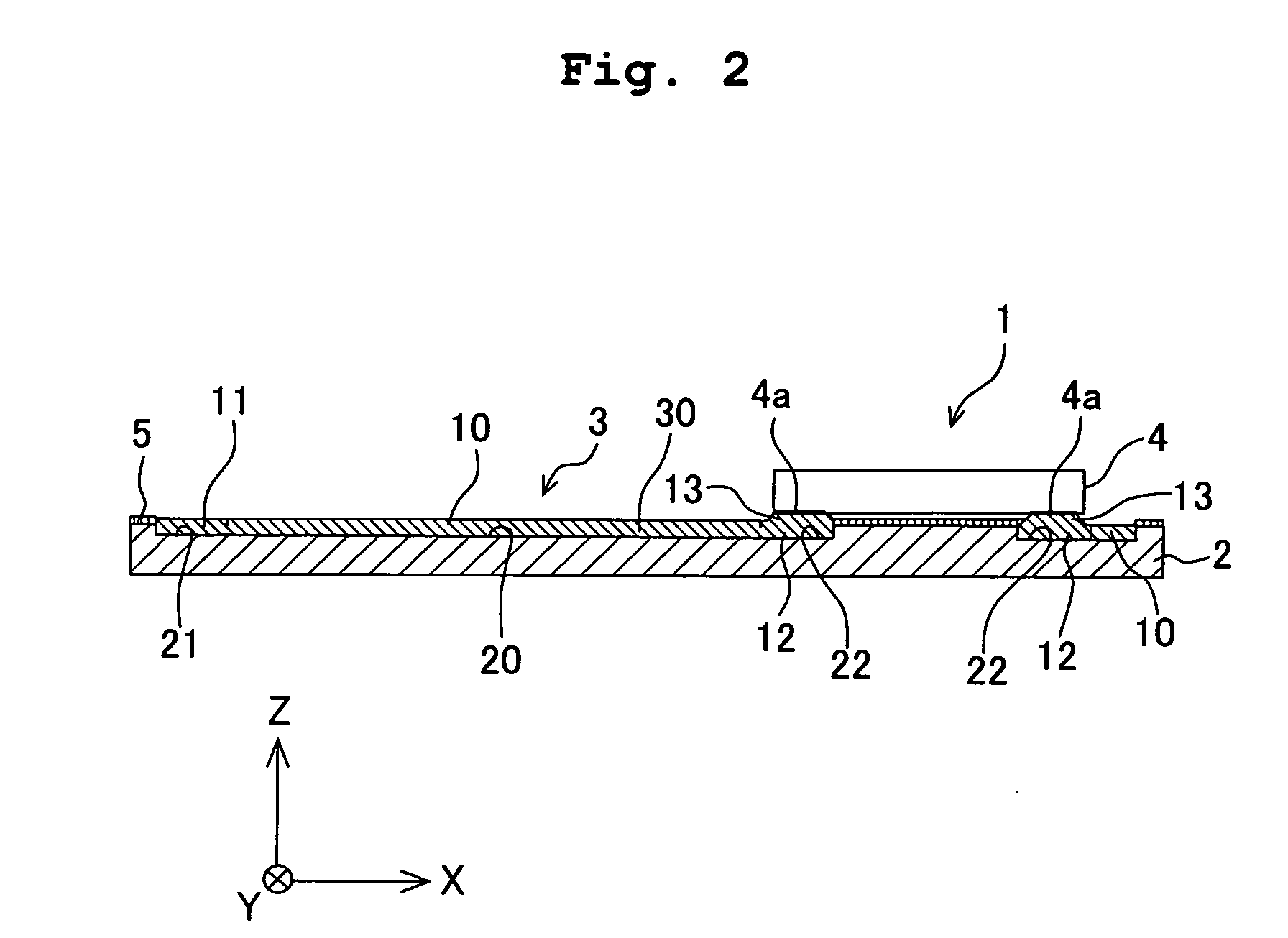

Method for forming pattern and a wired board

InactiveUS20060237229A1Well formedFine conductive patternPrinted circuit assemblingPrinted circuit aspectsEngineering

Owner:BROTHER KOGYO KK

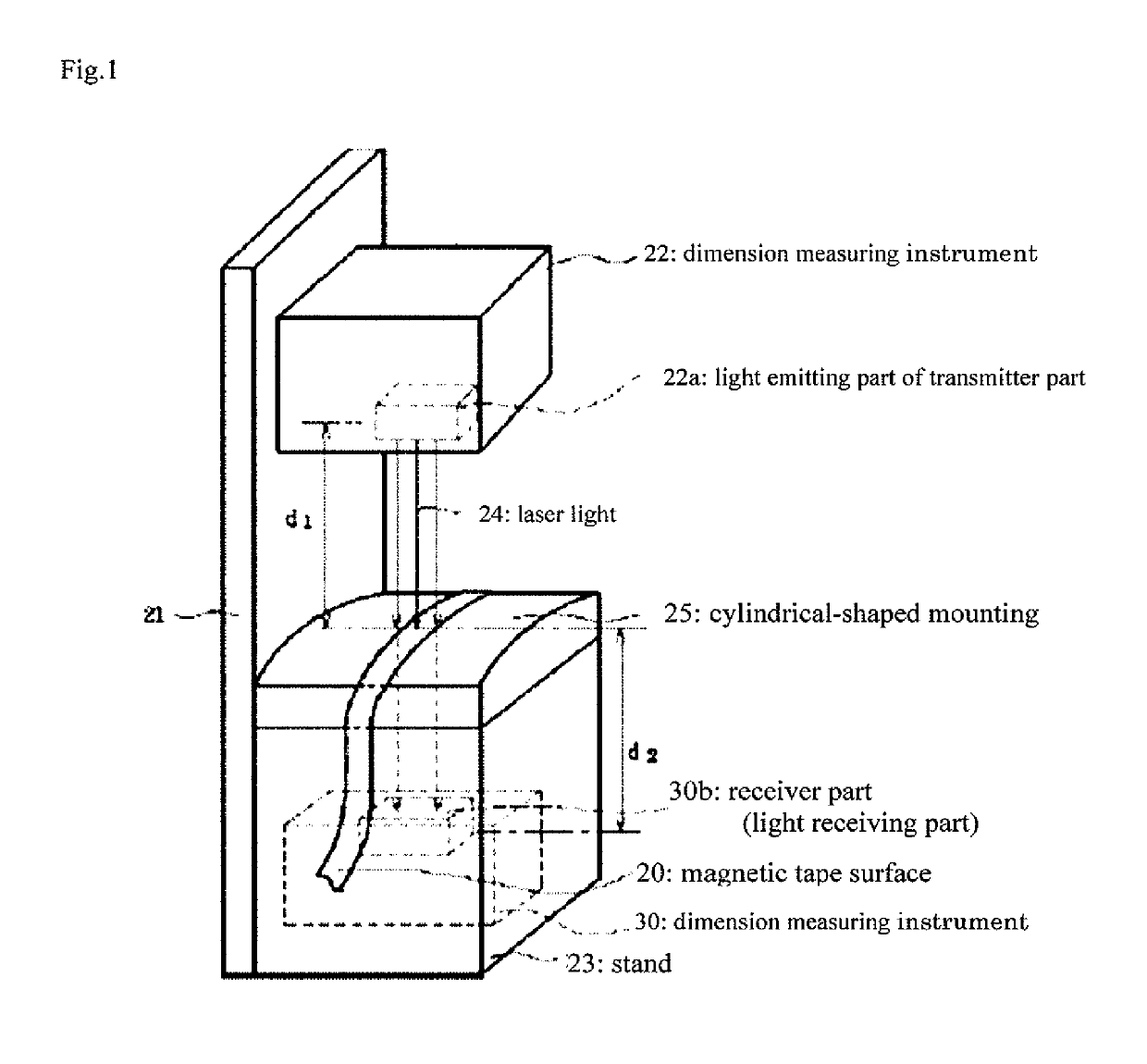

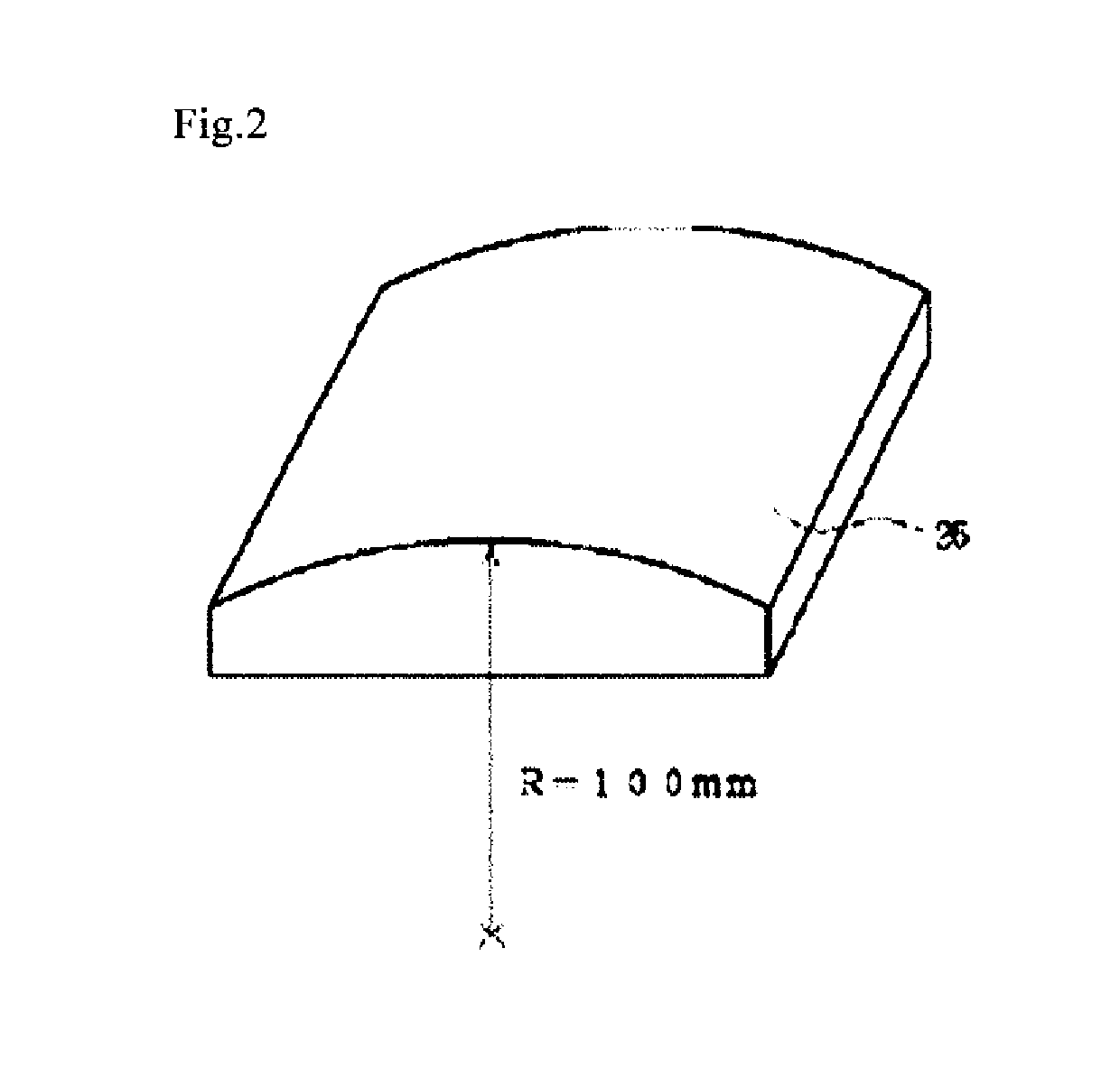

Resin film

ActiveUS20190180781A1High-density recordingAdjustmentDisposition/mounting of recording headsBase layers for recording layersYoung's modulusEngineering

To provide a resin film, of which dimensional stability required of an ultra-high density recording medium can be controlled easily by drive tension, and which has processability at high temperature in a processing step of the resin film into a magnetic recording medium. A resin film having a Young's modulus in the film longitudinal direction of 1 GPa or more and a film thickness of 1 μm or more, wherein the product of the Young's modulus in the longitudinal direction and the thickness is 5 GPa·μm or more and 20 GPa·μm or less and wherein a dimensional change in the film longitudinal direction is −2% or more and +2% or less when the film is heated at a rate of 5° C. / min under a load of 2 kg / mm2 applied in the longitudinal direction and the temperature has reached 110° C., the resin film satisfying at least either of the following (1) or (2): (1) the Young's modulus in the film longitudinal direction is 6 GPa or less and the film thickness is 4.5 μm or less; and (2) the Young's modulus in the film longitudinal direction is 4 GPa or less and the film thickness is 6 μm or less.

Owner:TOYOBO CO LTD

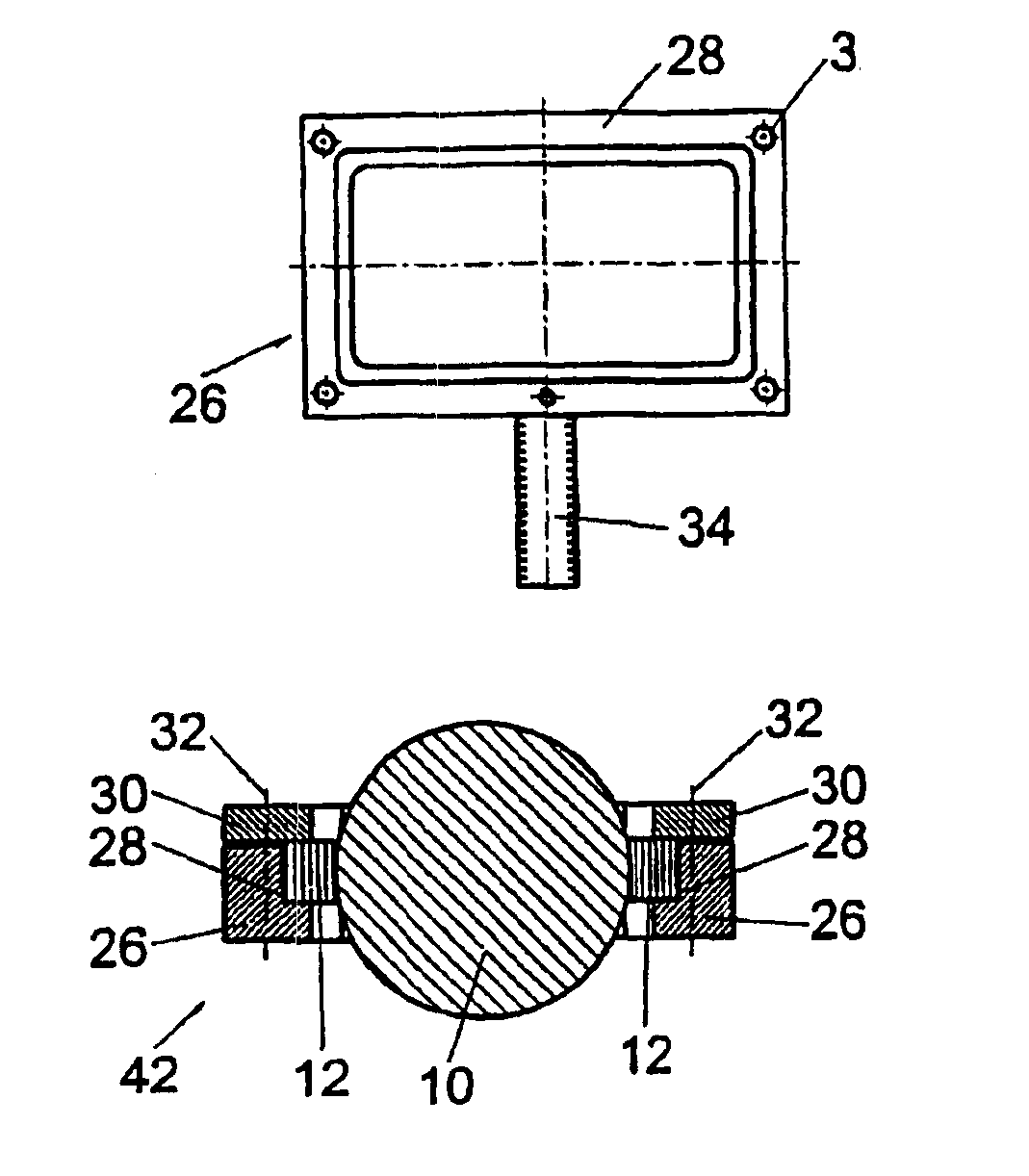

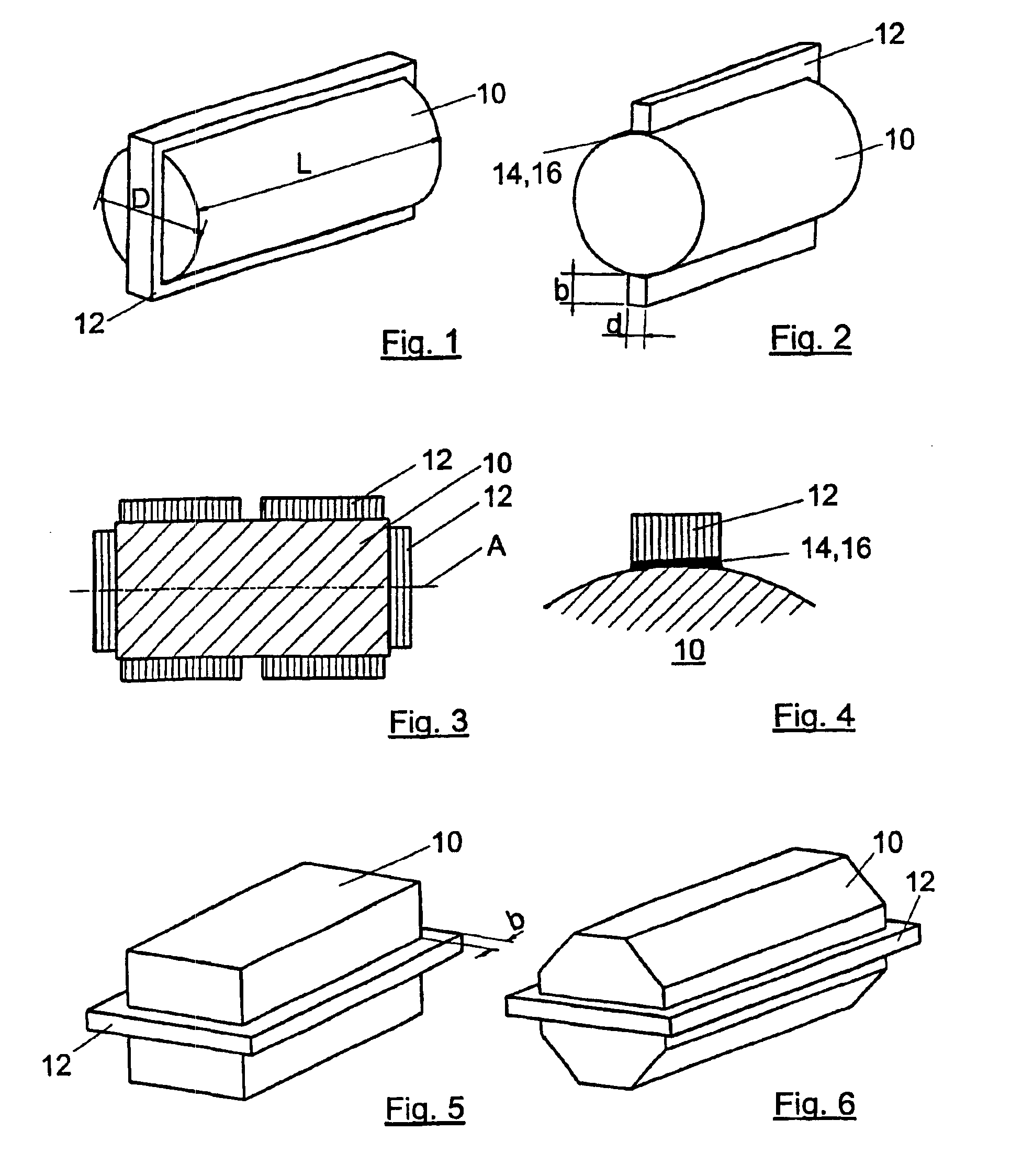

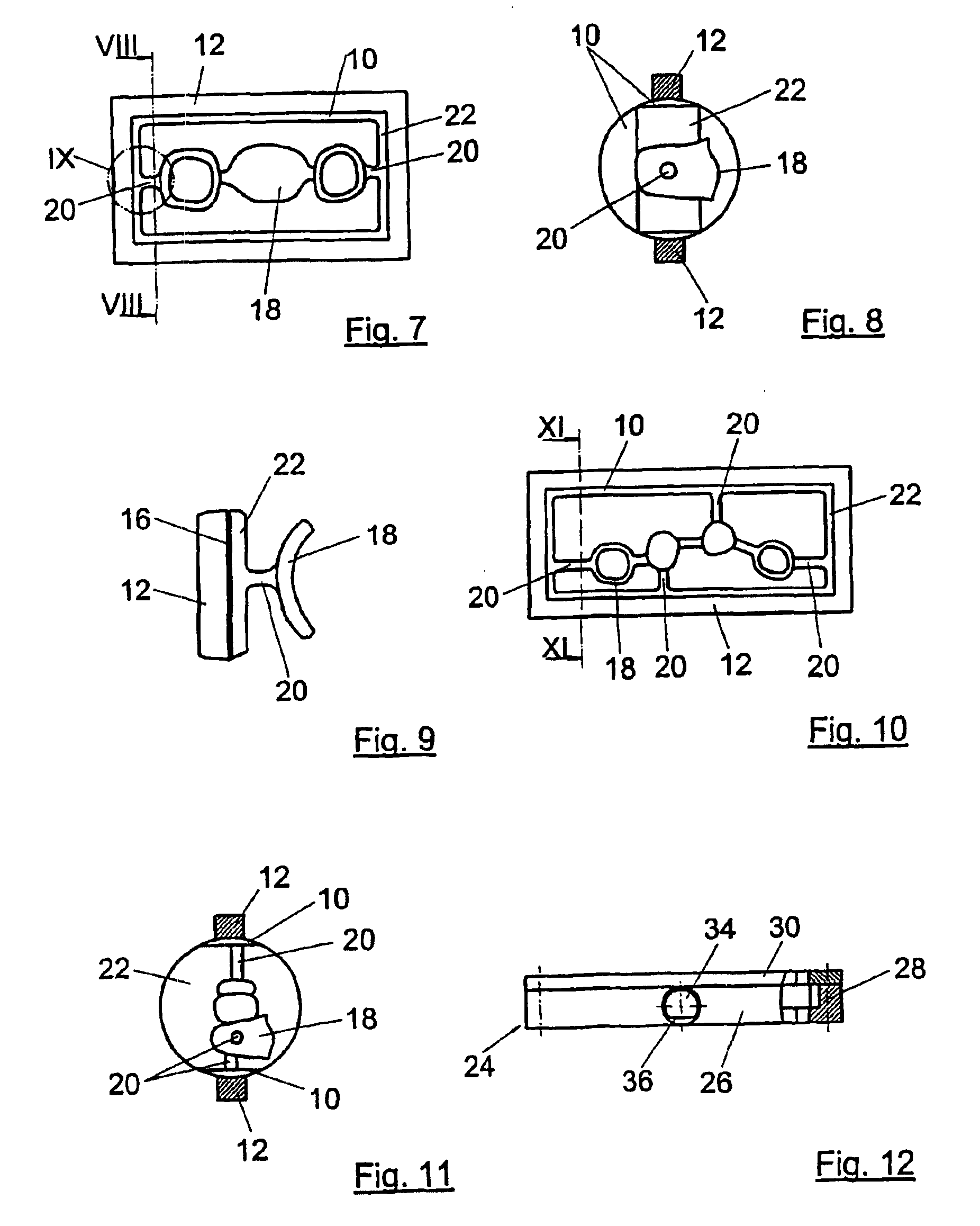

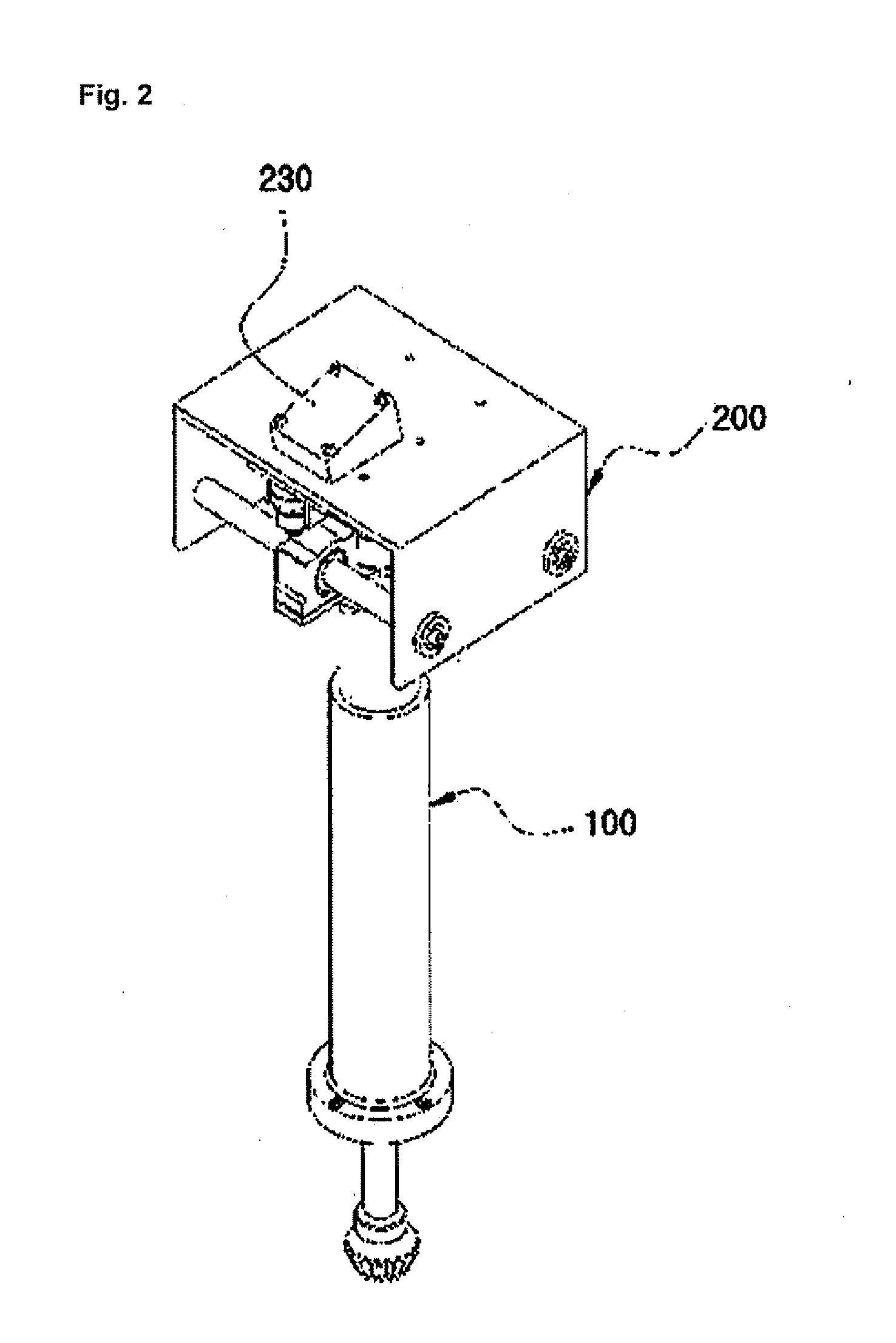

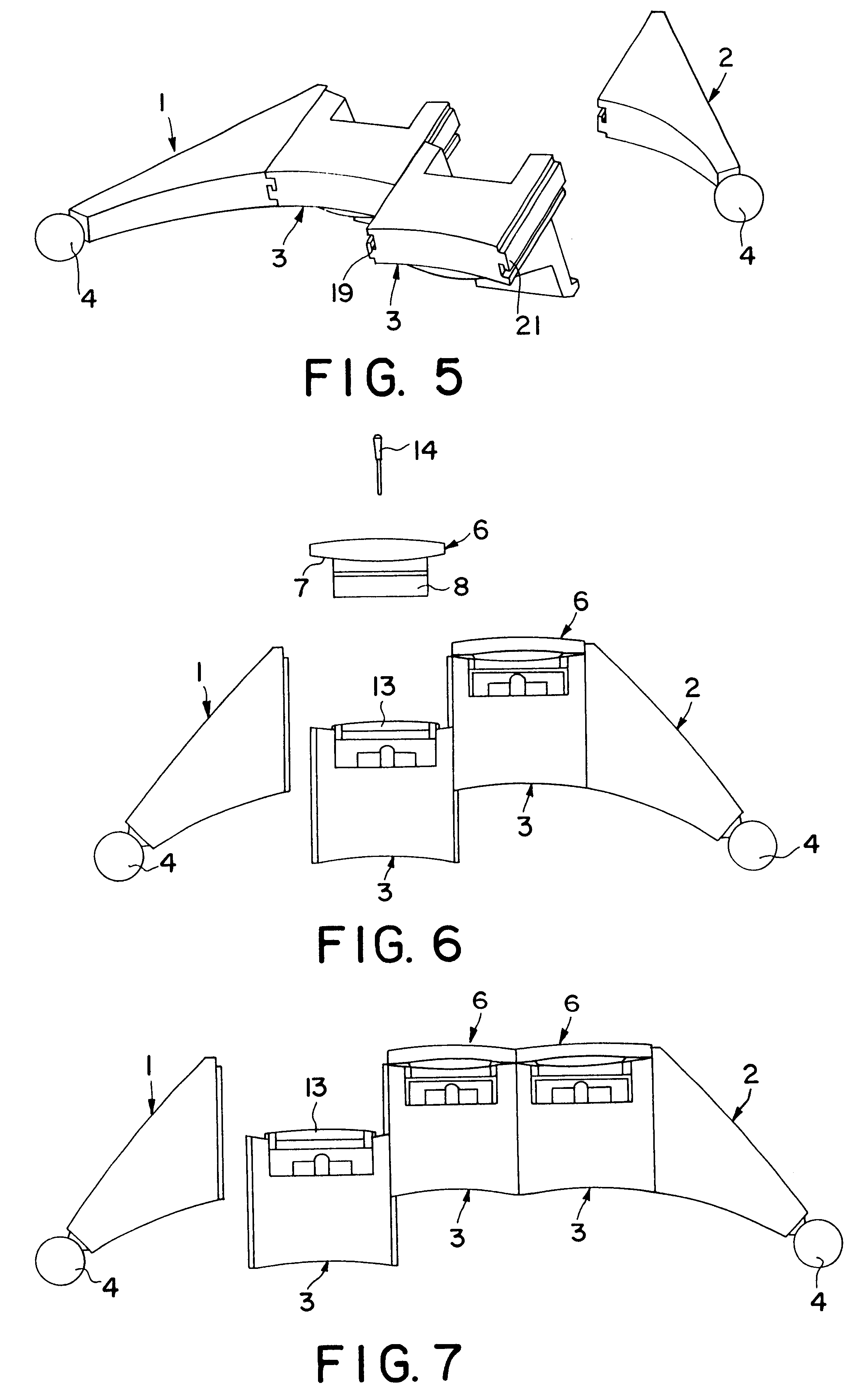

Holding device for a ceramic blank

A holding device comprises a cylindrical or prismatic, porous ceramic blank and elements for clamping in a machine tool for processing the blank by removing material, in order to produce a ceramic workpiece. A narrow frame is fixed by an adhesive connection over at least part of the periphery of the blank, which is held without stresses, in the area of a plane encompassing the longitudinal middle axis (A) of the blank. The frame only covers a small part of the surface of the blank and can be detached and held in a stable holder with a clamping adapter, in such a way that it cannot slide. The entire combination is fixed in the machine tool in such a way as to be resistant to twisting and sliding. The ceramic workpiece emerges continuously form the ceramic blank without predetermination of the advance direction, until holding segments which can then only be freely selected according to number and location have been formed. The holding segments end on the residual material of the blank in the area of the frame or on the frame itself. The holding device is used especially as a workpiece for producing fully ceramic dental prostheses, particularly crowns or bridges.

Owner:EIDGENOSSISCHE TECHN HOCHSCHULE ZURICH NICHTMETALLISCHE WERKSTOFFE

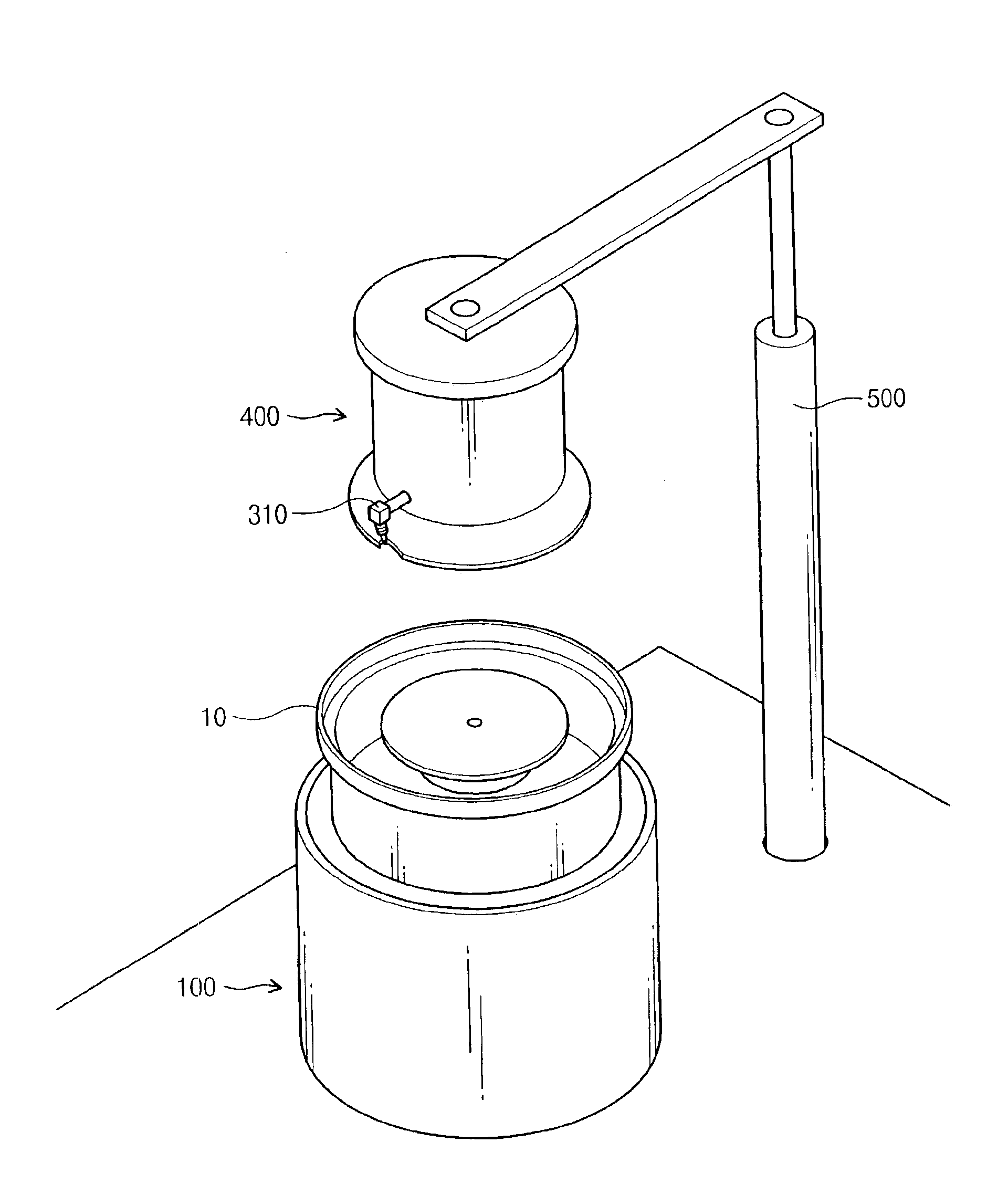

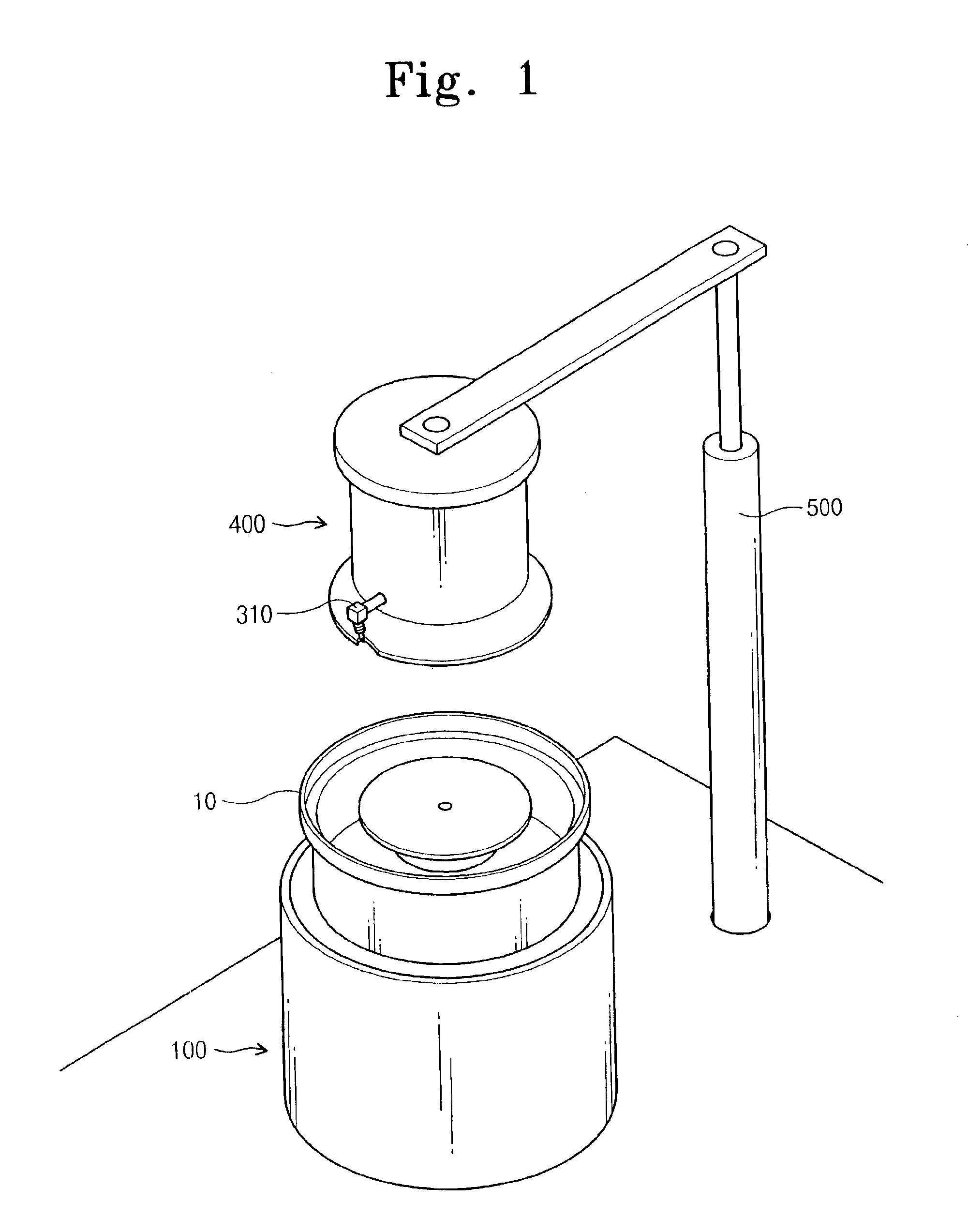

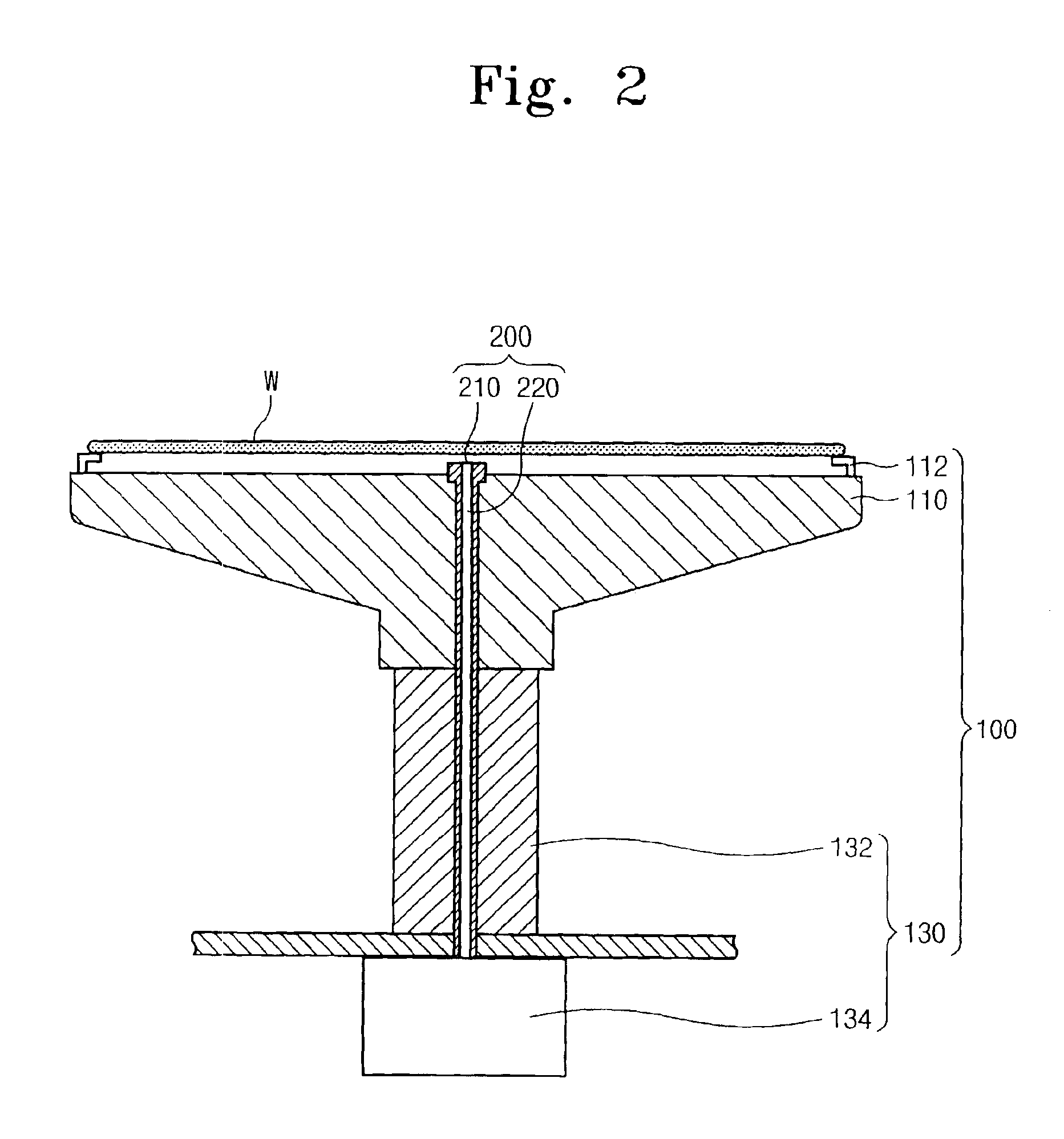

Apparatus for manufacturing semiconductor devices with a moveable shield

InactiveUS6939807B2Fast and readily etchReadily etch widthDecorative surface effectsSemiconductor/solid-state device manufacturingChemical solutionEngineering

An apparatus for manufacturing semiconductor devices includes a supporter portion on which a semiconductor substrate is placed, a nozzle portion for injecting a fluid to an edge of the substrate placed on the supporter portion, a shielding cover for preventing the fluid injected from the nozzle portion from flowing to a shielding portion among a pattern-formed portion, and a shielding cover moving portion device for moving the shielding cover up and down. The apparatus makes it possible to prevent a chemical solution injected to the edge of a wafer from flowing to a shielding portion of the wafer when the wafer edge is etched.

Owner:SEMES CO LTD

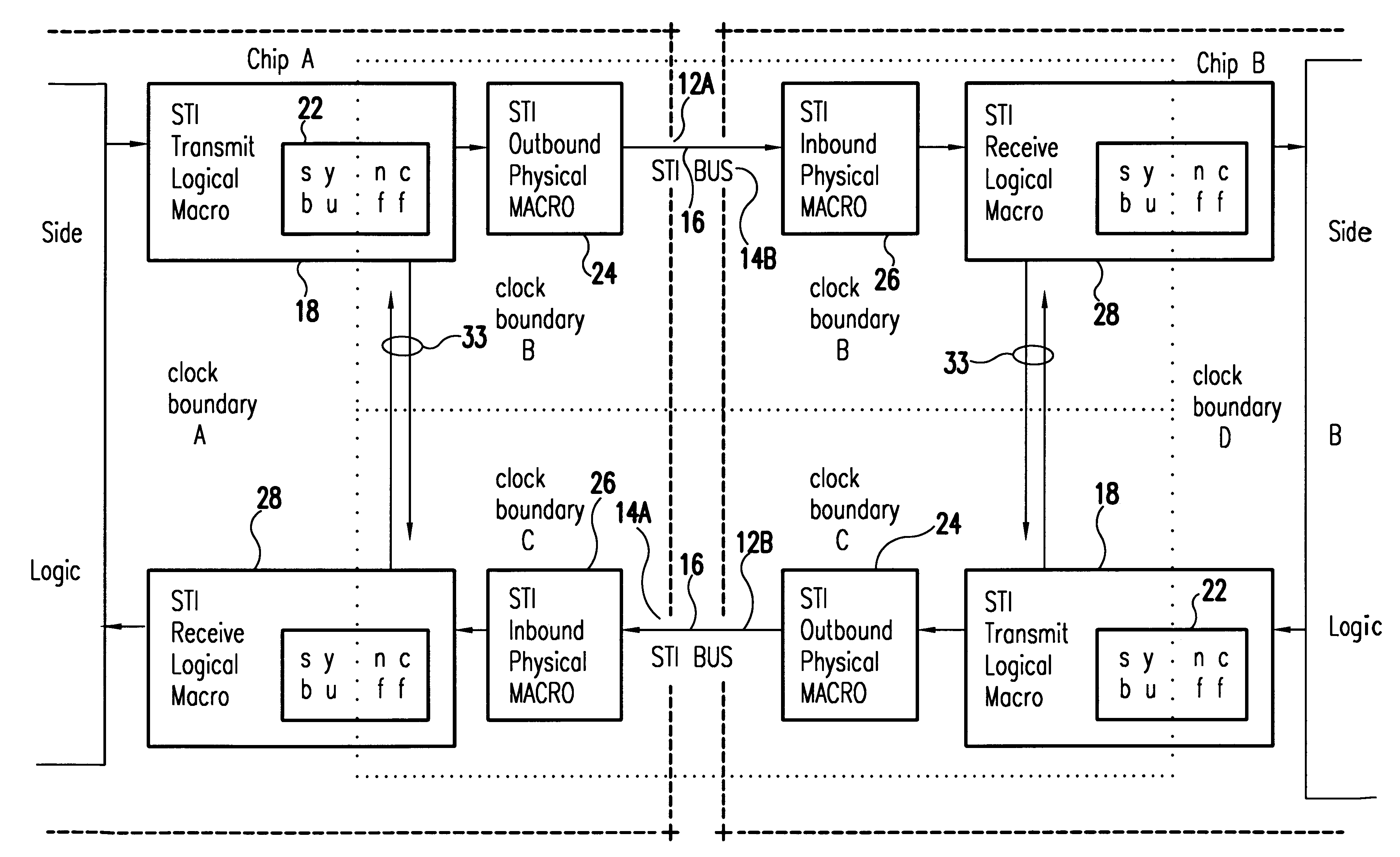

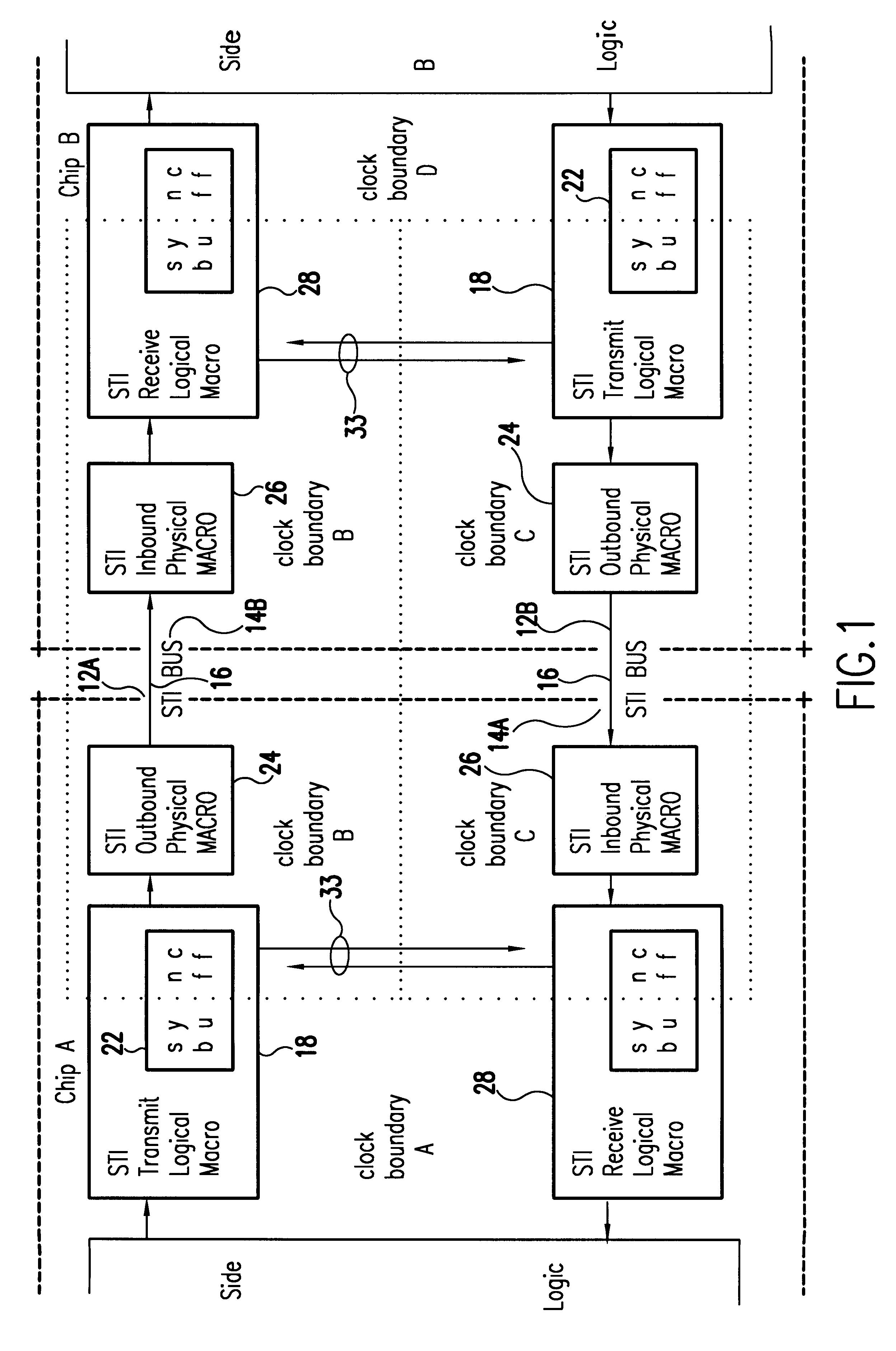

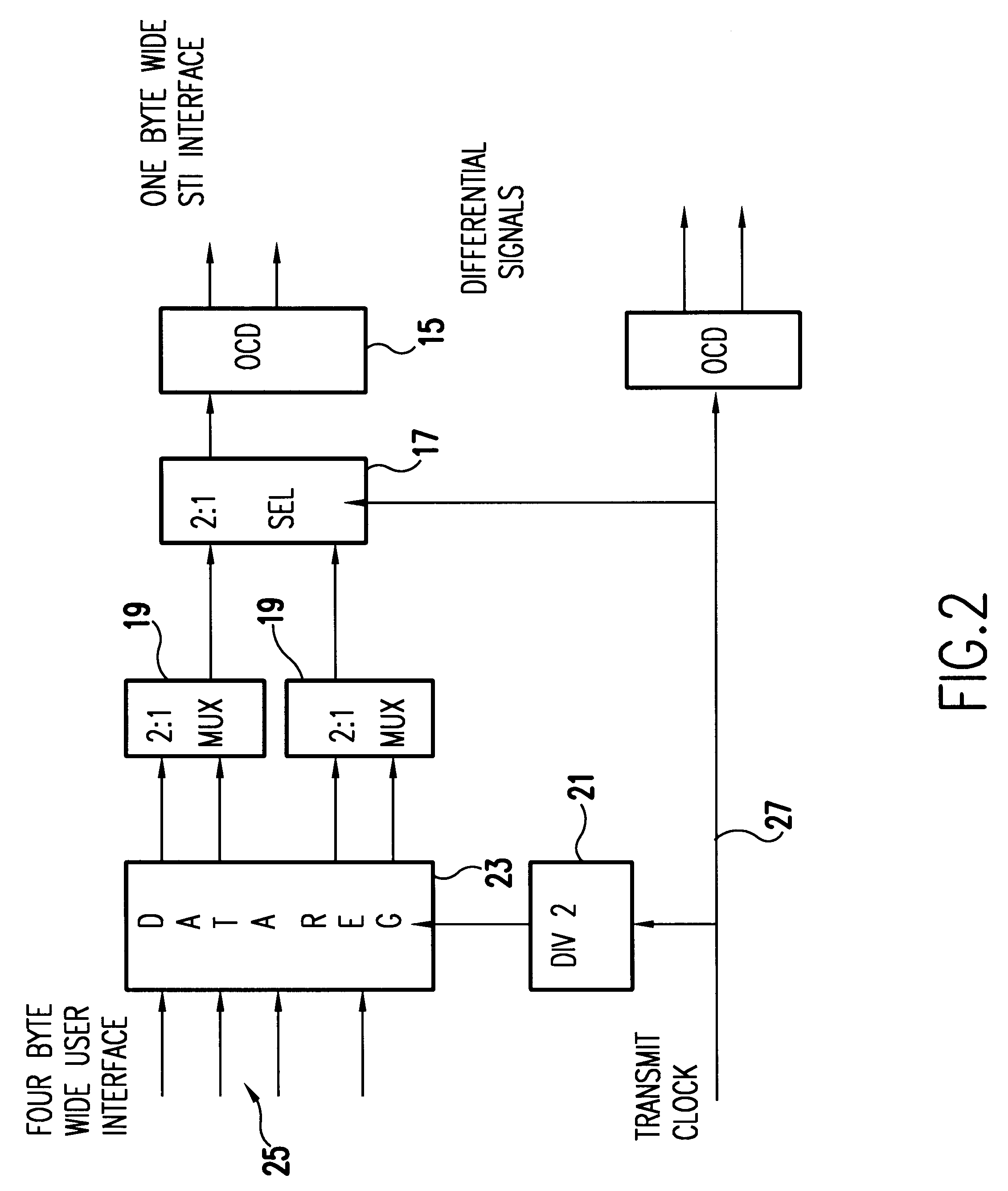

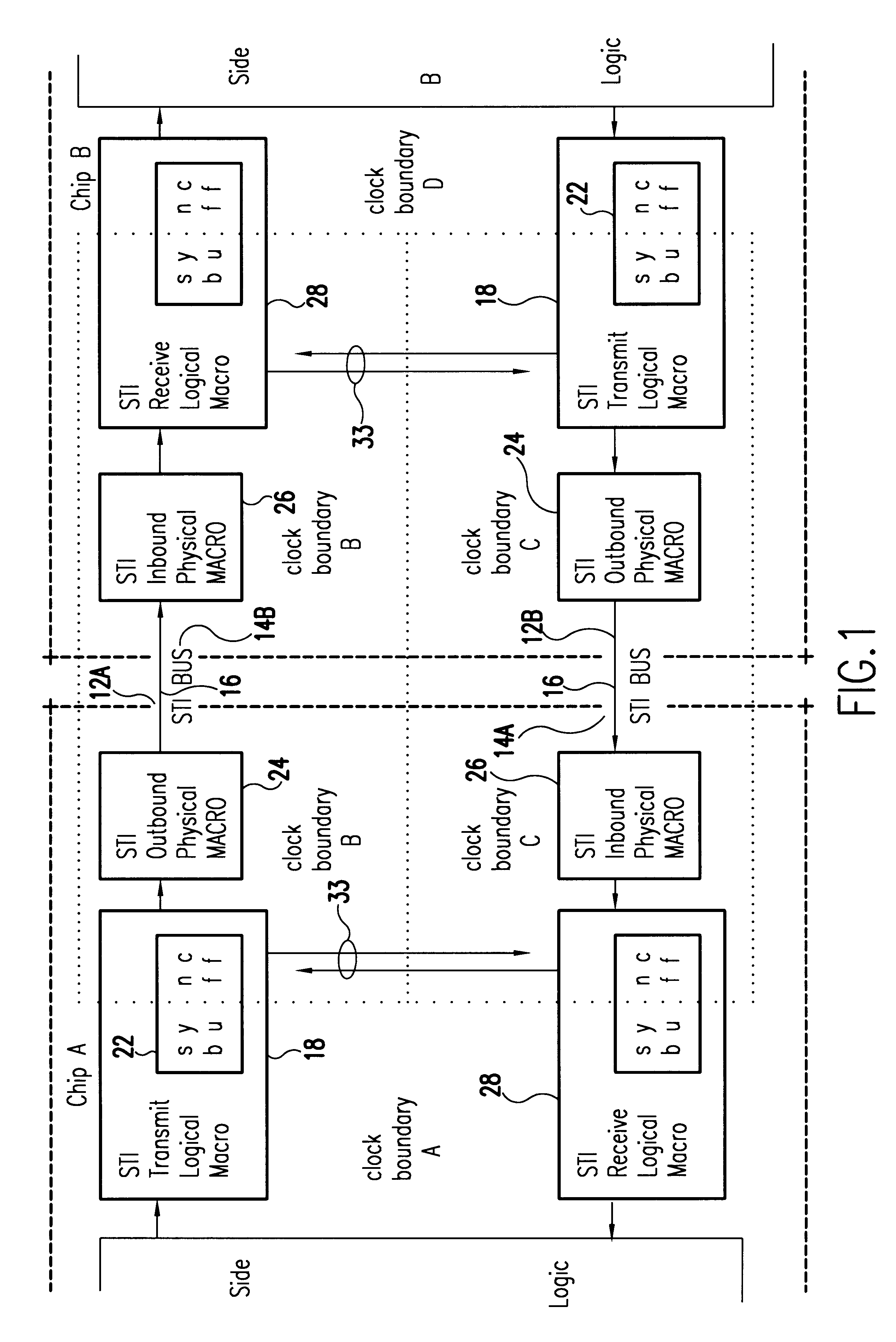

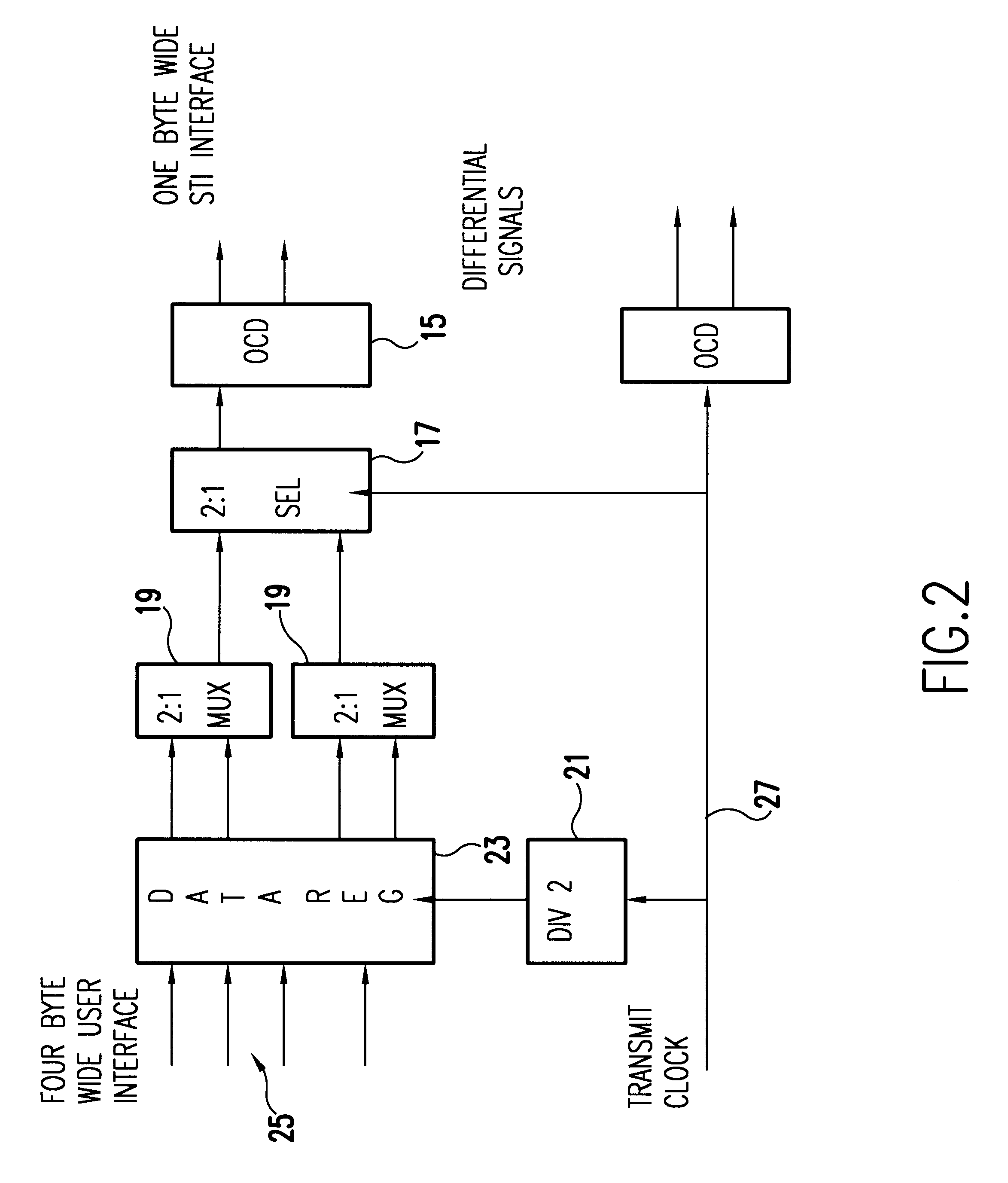

Self-timed parallel data bus interface to direct storage devices

InactiveUS6192482B1Low costImprove performanceError detection/correctionData resettingDirect-access storage deviceBus interface

An attached storage media link has a self-timed interface (STI) in which a clock signal clocks bit serial data onto a parallel, electrically conductive bus and the clock signal is transmitted on a separate line of the bus. The received data on each line of the bus is individually phase aligned with the clock signal, providing a high speed, cost effective interface to a direct access storage device.

Owner:IBM CORP

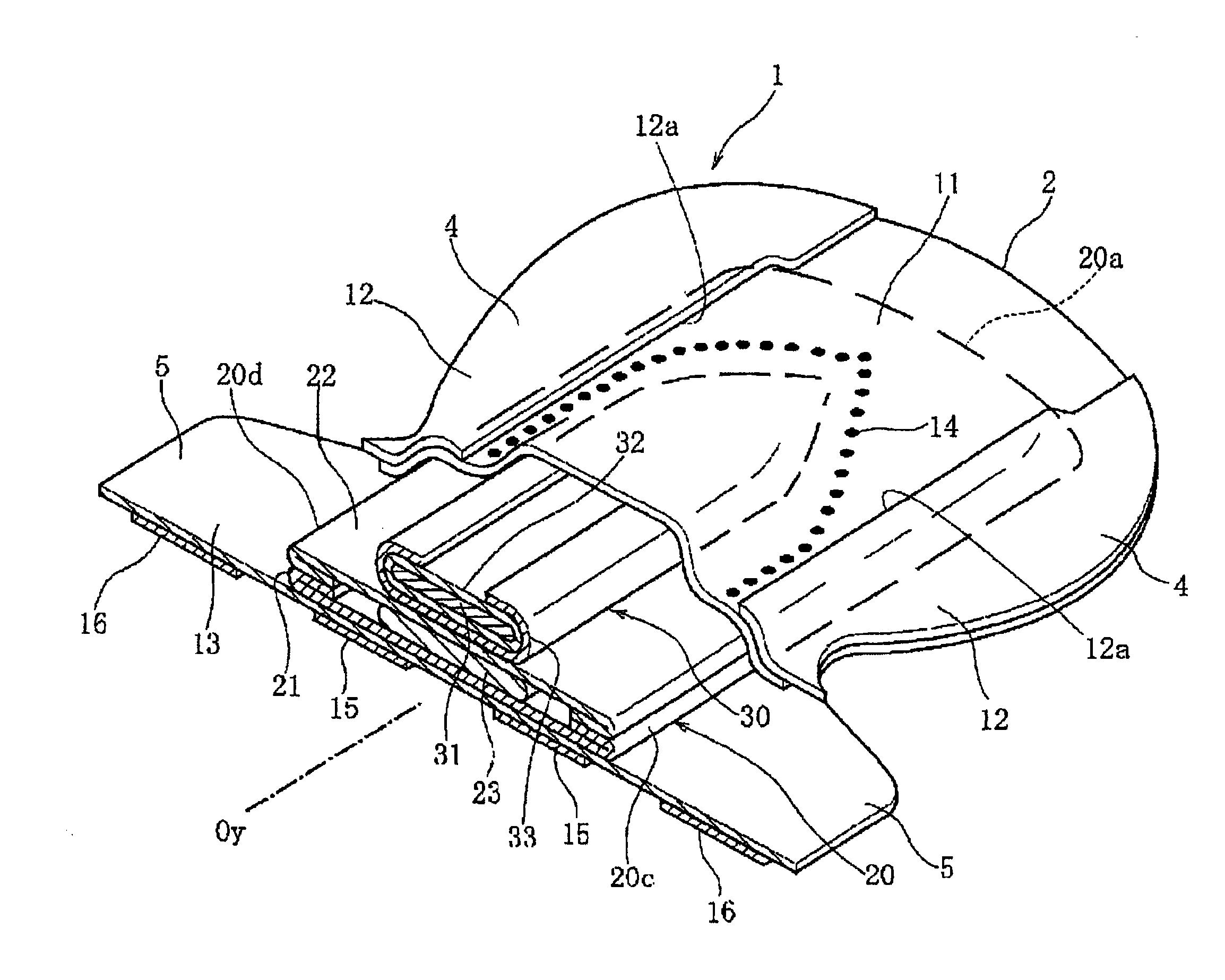

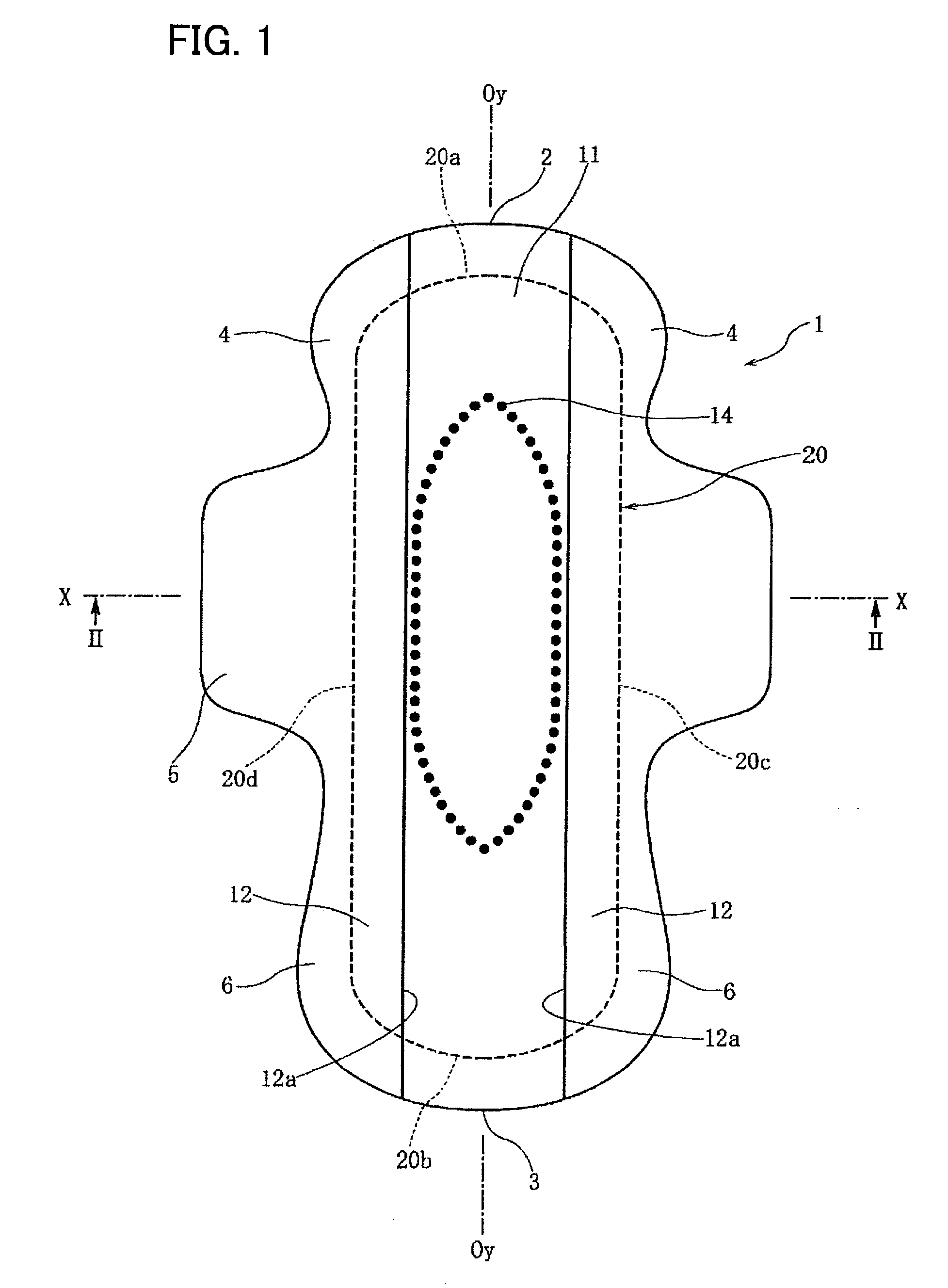

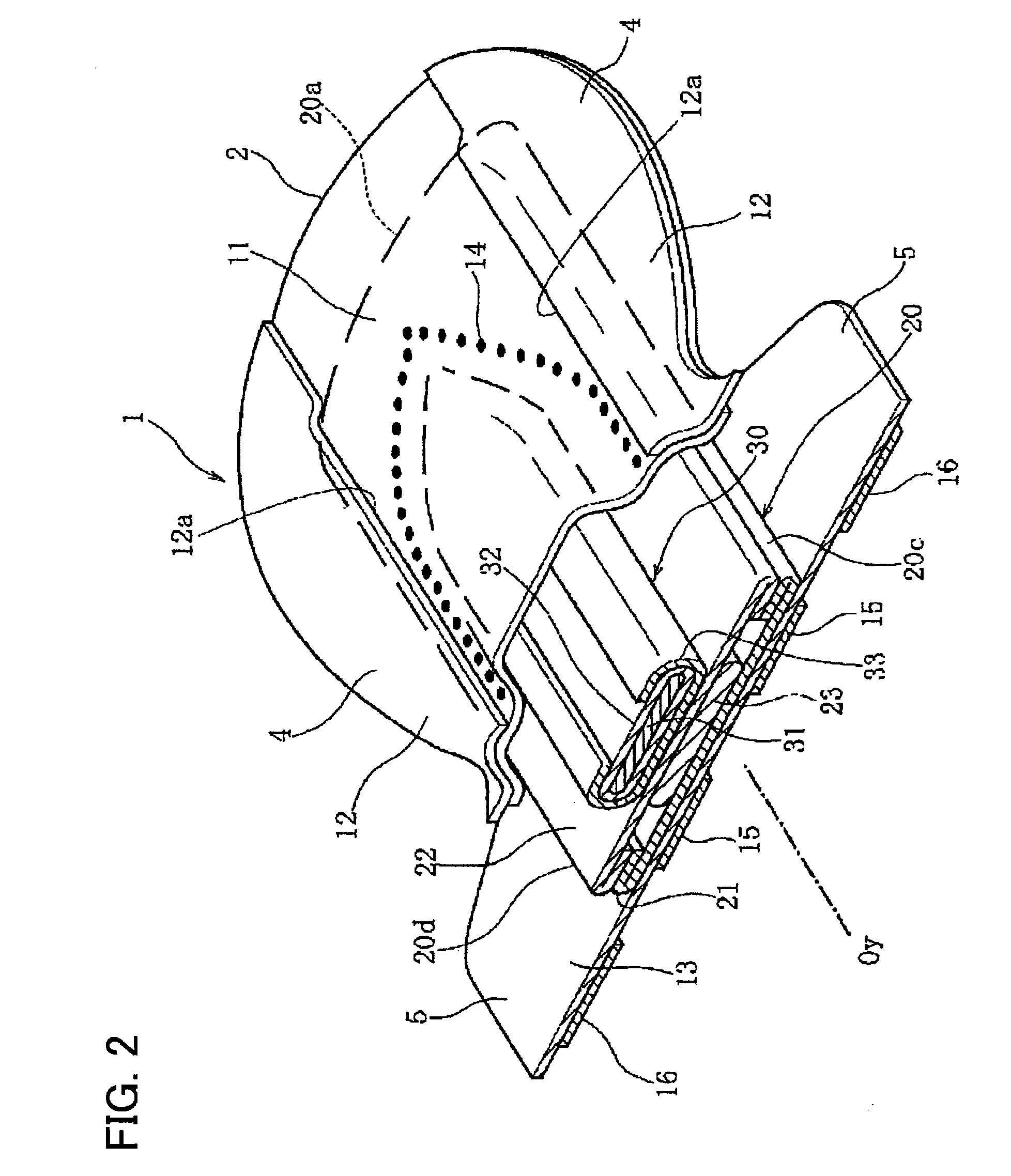

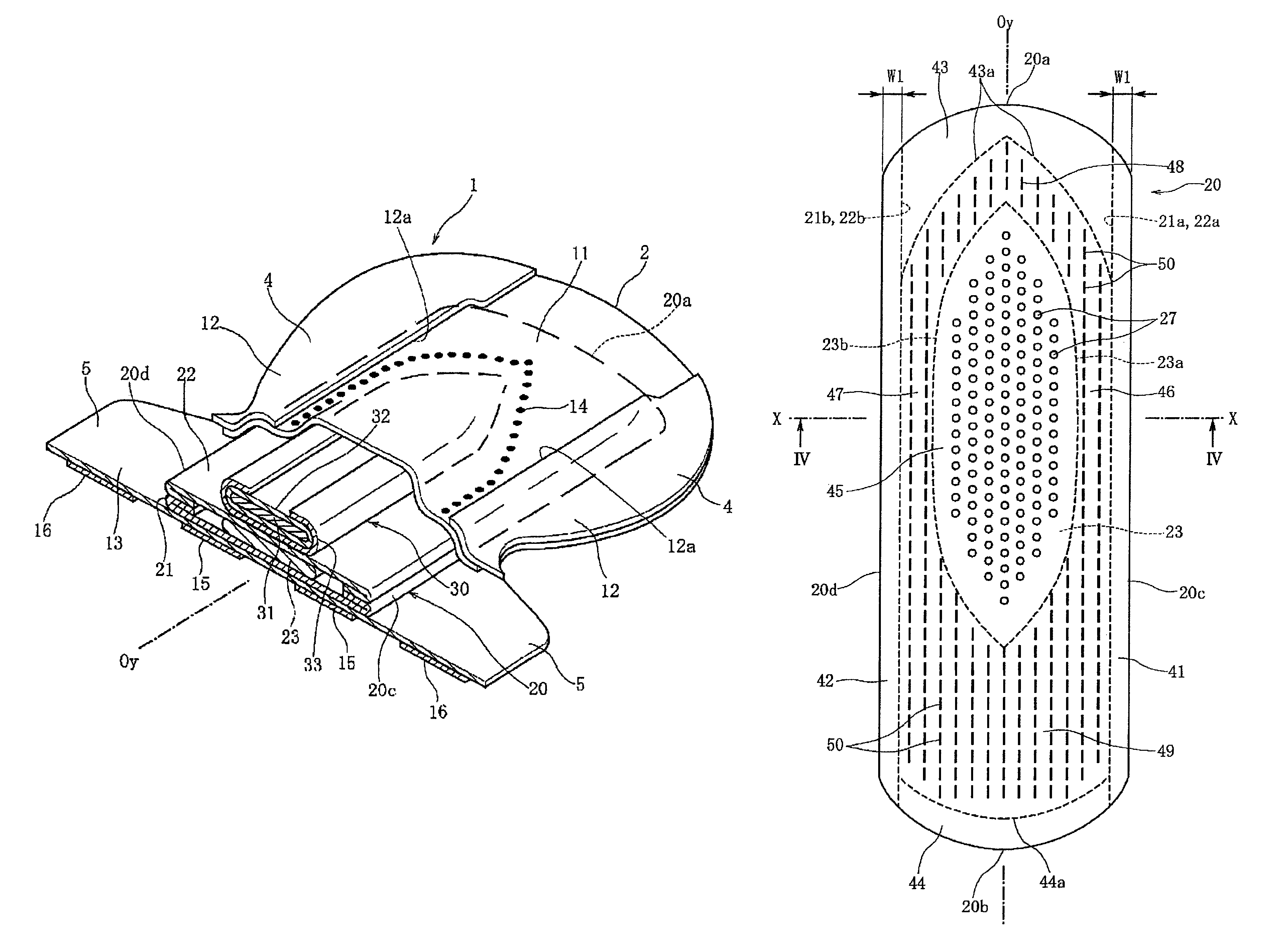

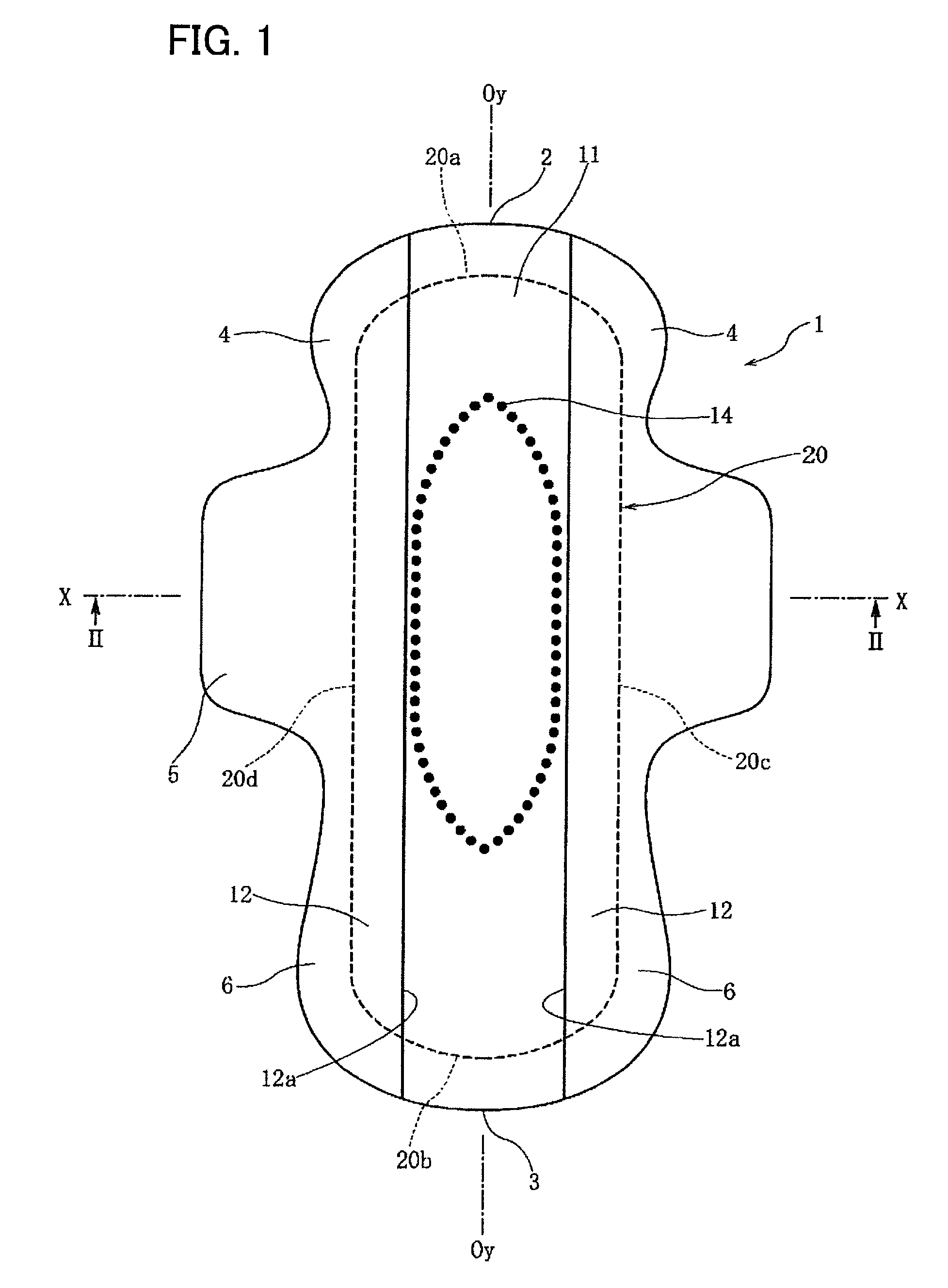

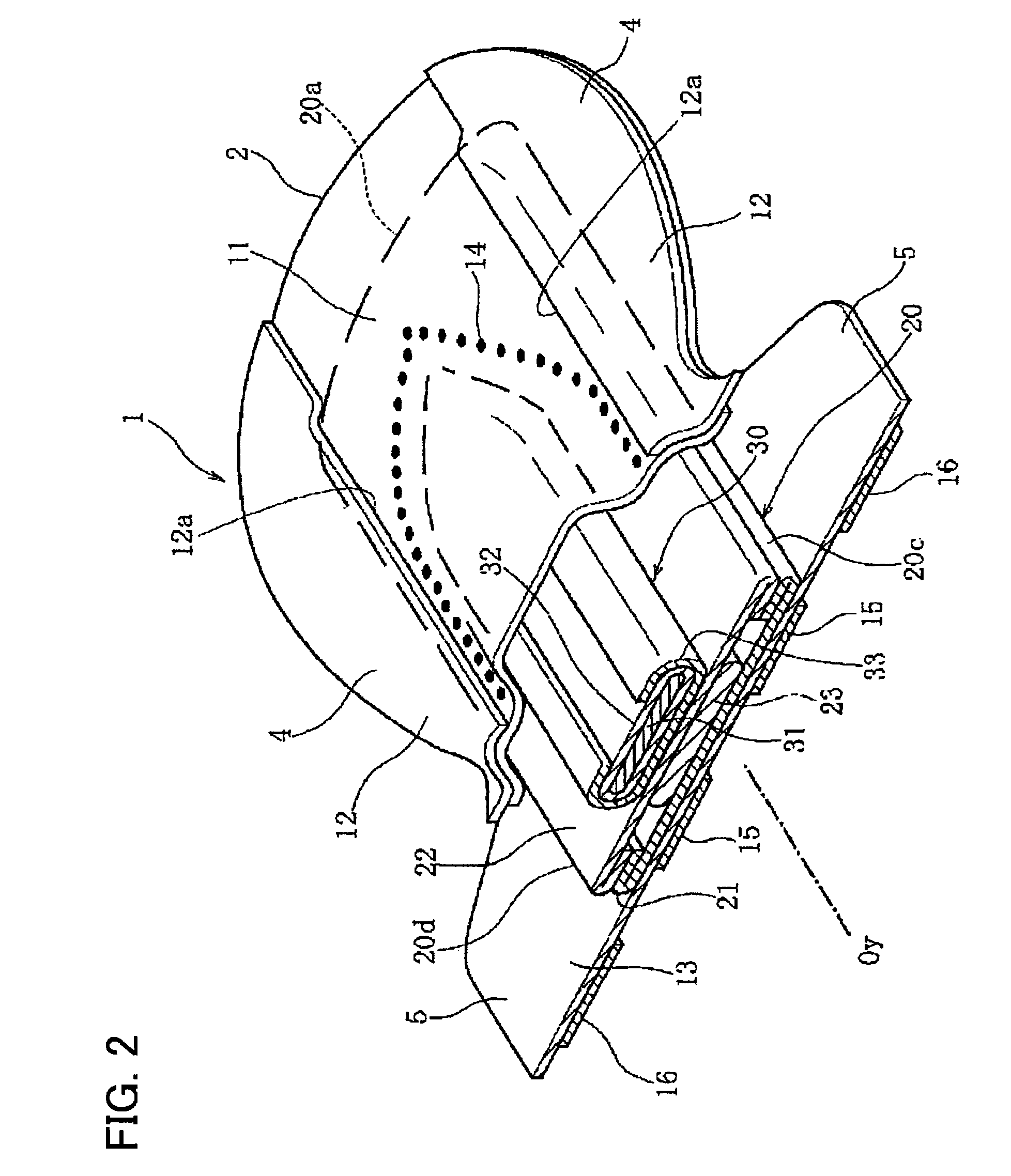

Absorbent article

An absorbent article worn in the groin area, in which, when a compressive force is received from a lateral direction, a main absorbent region can oppose an excretion area of a wearer's body without twists or wrinkles occurring, and when the compressive force is relaxed, the article easily recovers to its original shape. An absorbent body provided in the absorbent article has a main absorbent region, reinforcing regions, and buffer regions. The bending stiffness of the reinforcing regions is larger than that of the buffer regions, and the bending stiffness of the main absorbent region is larger than that of the buffer regions. When compressive force is received from a wearer's thigh areas in the lateral direction, the reinforcing regions that are positioned to the left and right deform in a curved shape, and the buffer regions that are to the left and right are compressed. As a result, the main absorbent region does not easily deform, and the main absorbent region can have a tight fit to the excretion area of the wearer's body in a non-deformed state.

Owner:UNI CHARM CORP

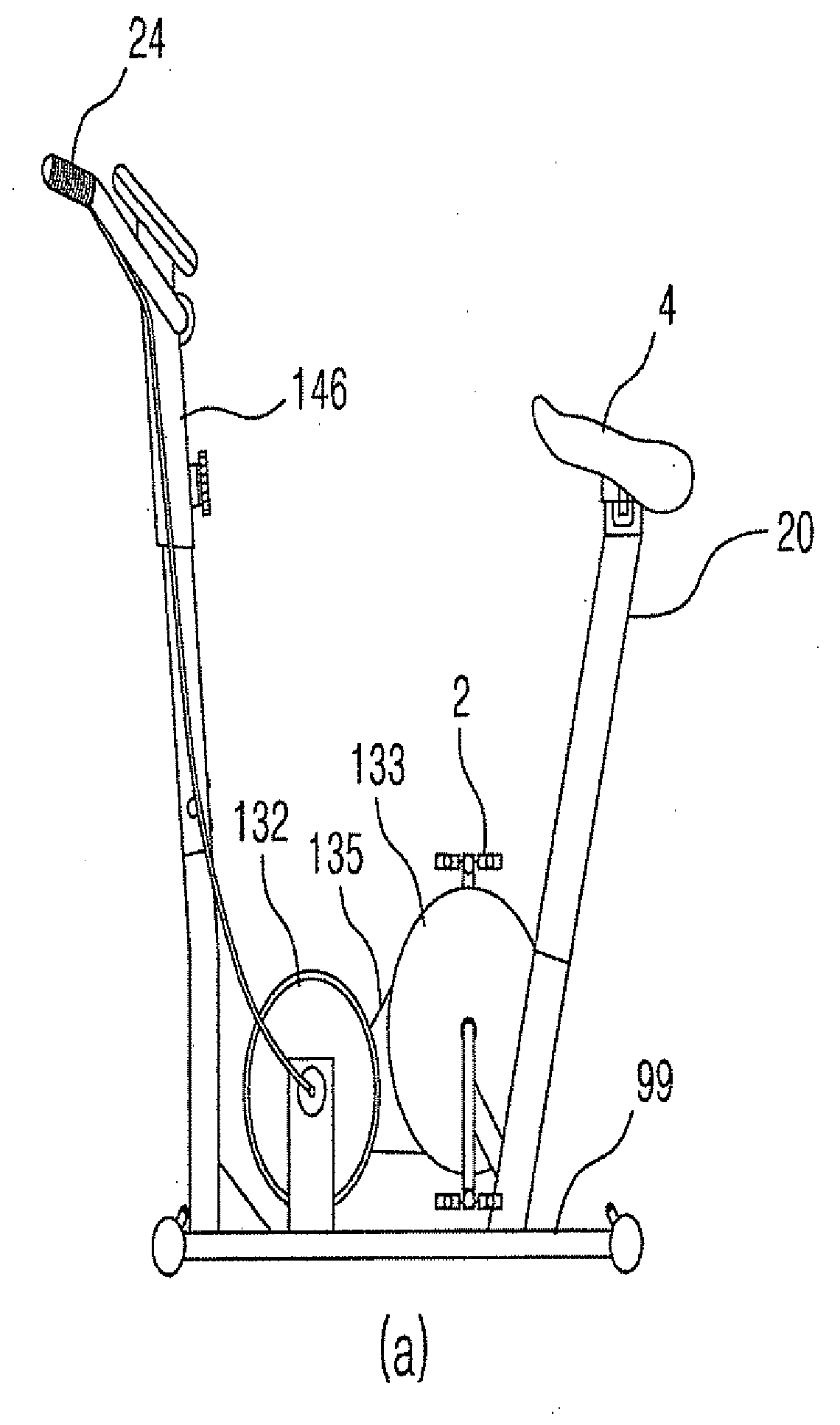

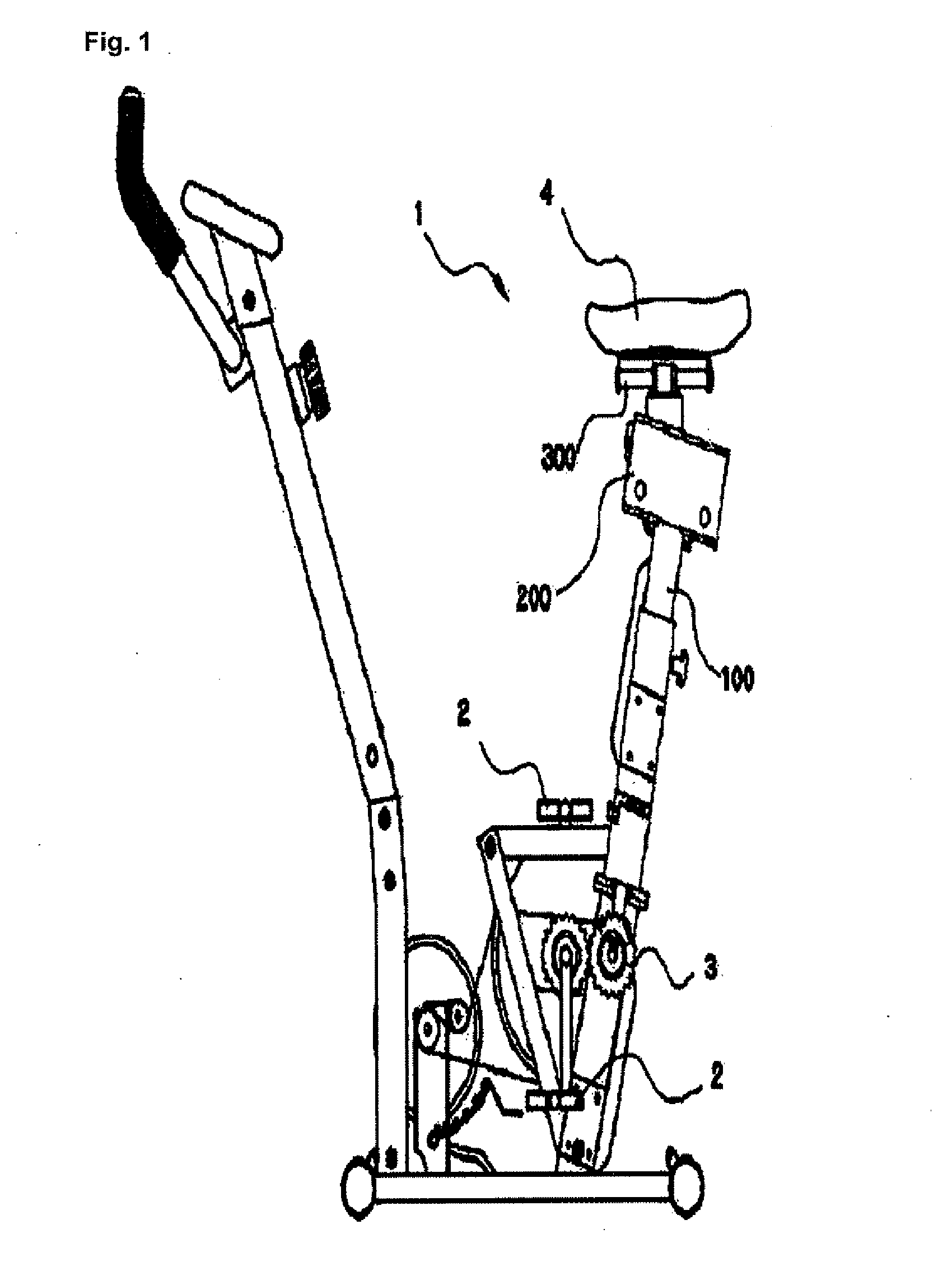

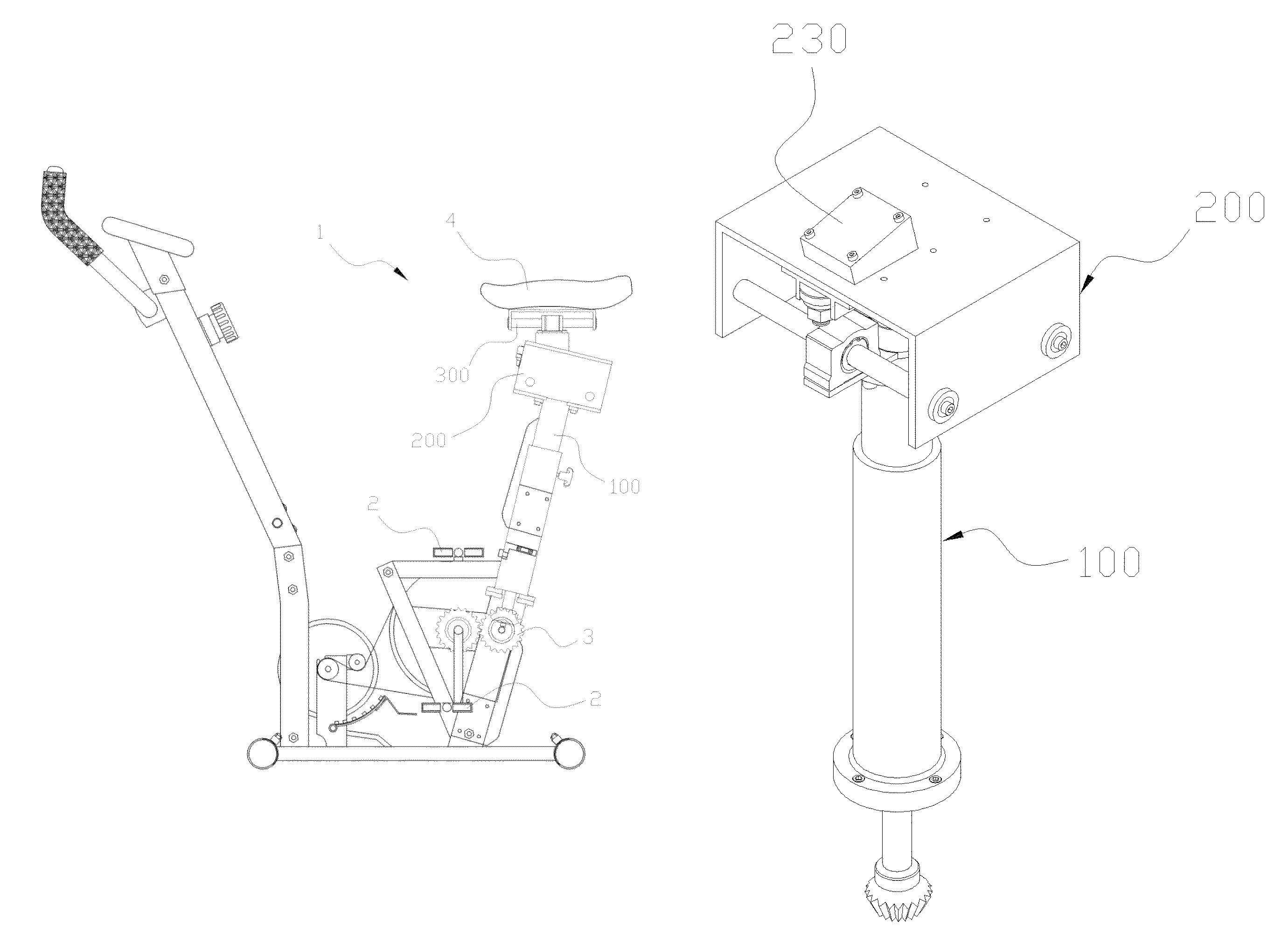

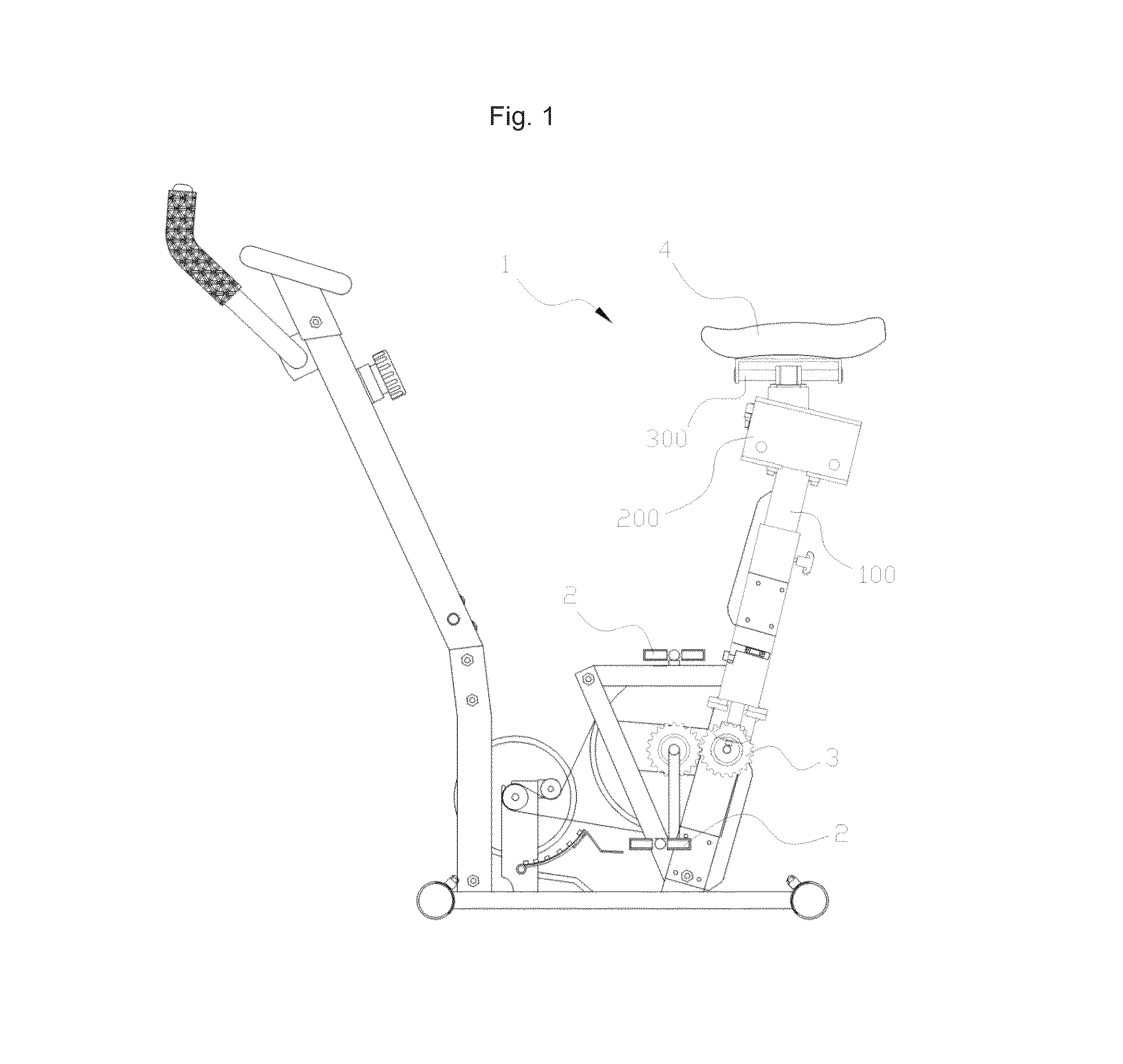

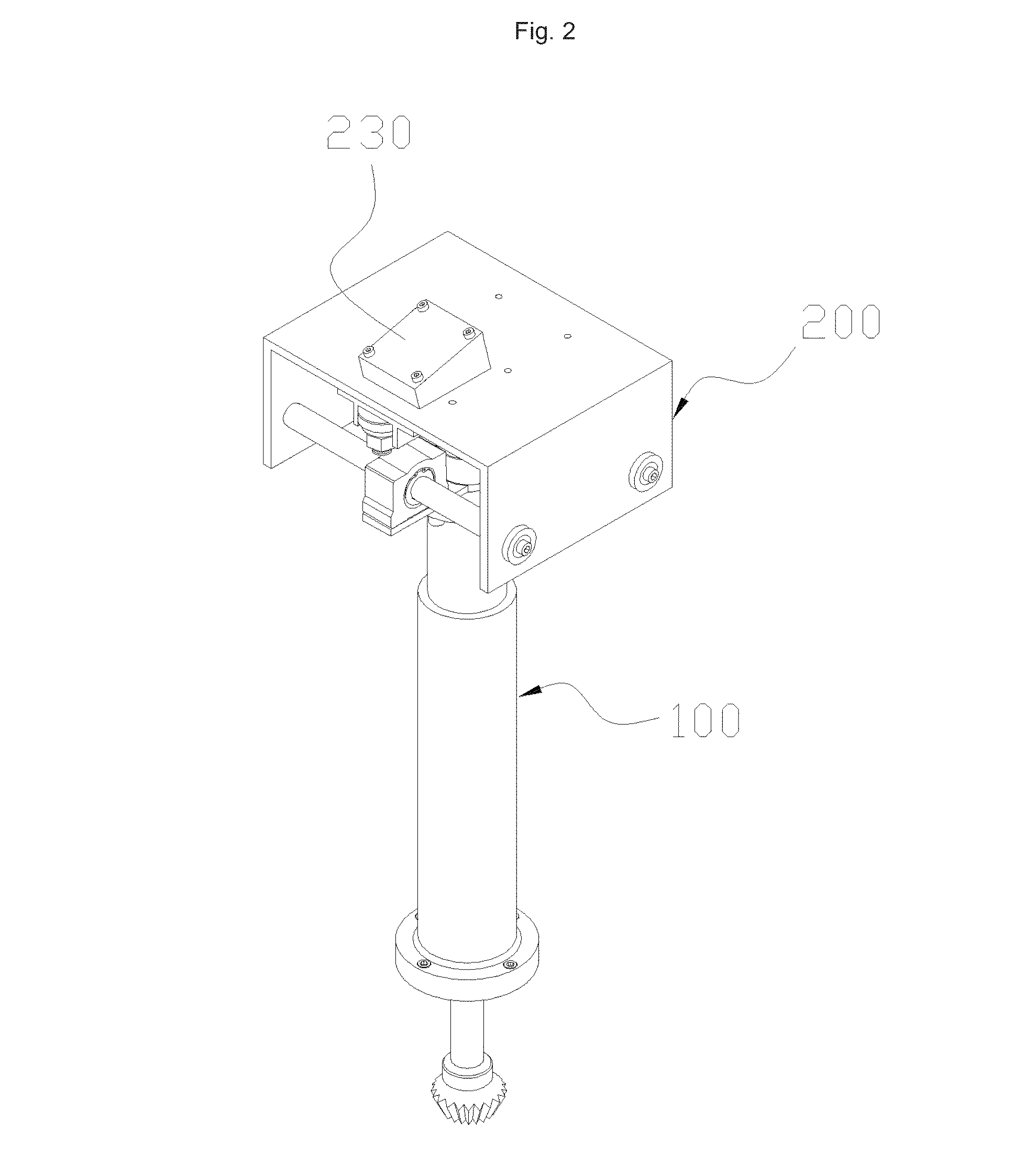

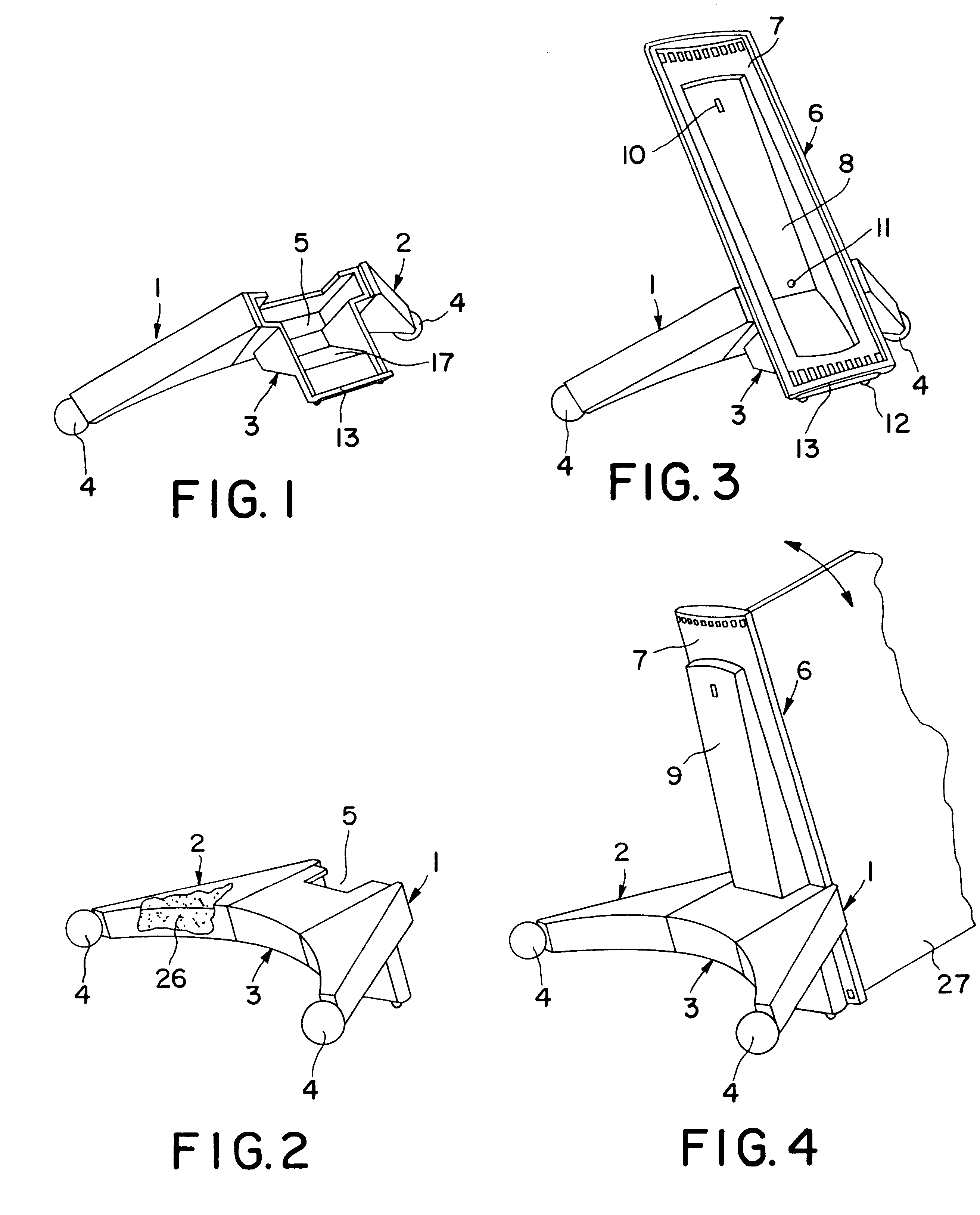

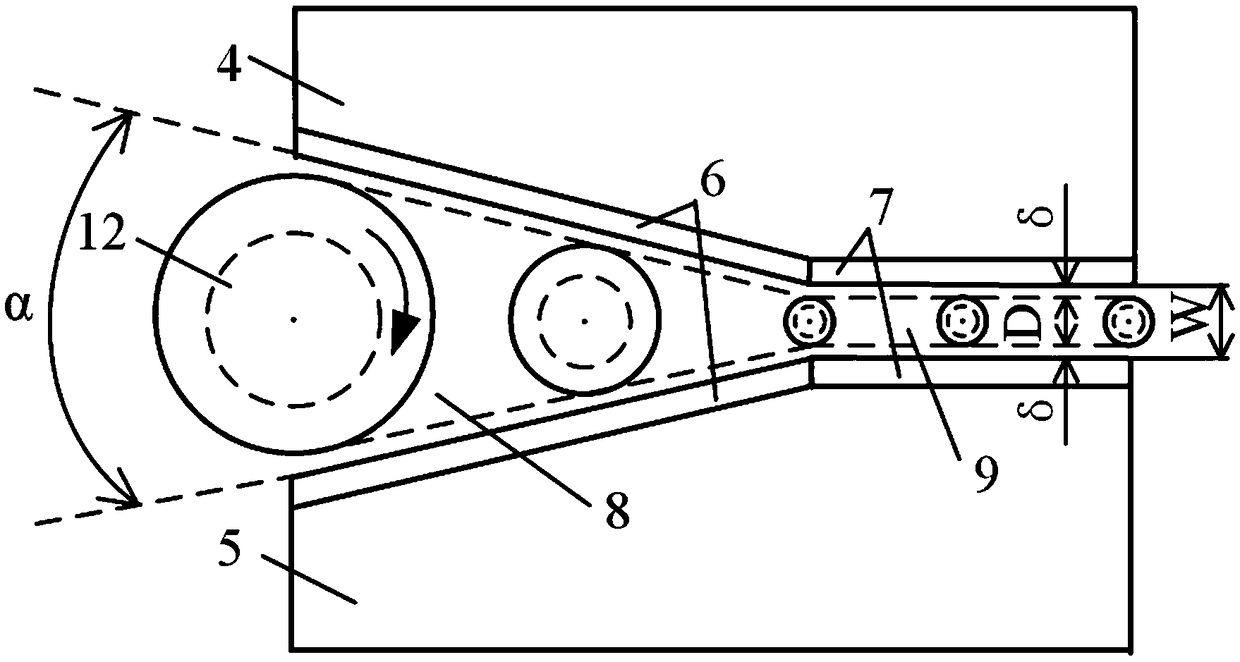

Bike saddle structure in which the oscillation angle and height of a bike saddle are adjustable, and exercise bicycle comprising same

ActiveUS20130123074A1Vibration minimizationWide range of exercise rangeVehicle seatsCycle saddlesPhysical medicine and rehabilitationWhole body

The present invention relates to a bike saddle structure in which the oscillation angle and height of a bike saddle are adjustable, and to an exercise bicycle comprising same. Vibrations in the bike saddle are minimized and the stability thereof is ensured during the left and right oscillation of the bike saddle, thus enabling a rider to exercise his / her whole body including the legs, pelvis, spine, abdomen, etc. over a long period of time. The forward and backward direction and height of the bike saddle are adjustable by the rider, thus providing a wide range of exercise.

Owner:JUN WOO SICK

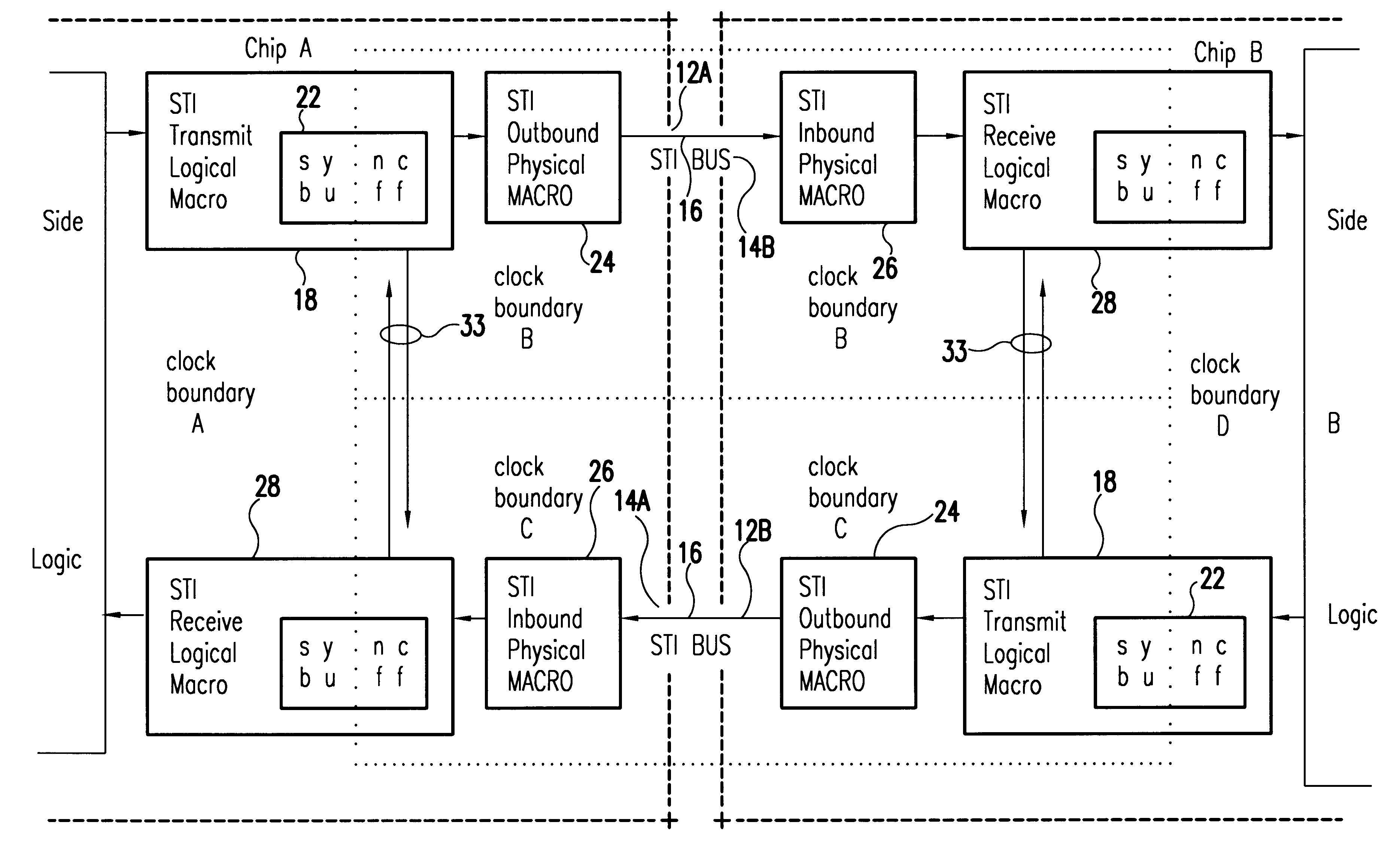

Synchronous interface for transmitting data in a system of massively parallel processors

InactiveUS6185693B1Low costImprove performanceError detection/correctionData resettingDigital dataClock rate

A massively parallel system has a self-timed interface (STI) in which a clock signal clocks bit serial data onto a parallel, electrically conductive bus and the clock signal is transmitted on a separate line of the bus. The received data on each line of the bus is individually phase aligned with the clock signal. Digital data is transmitted at high speeds via the parallel bus to provide a scalable communications network for parallel processing systems while eliminating precise bus length and system clock rates as a critical or limiting factor.

Owner:IBM CORP

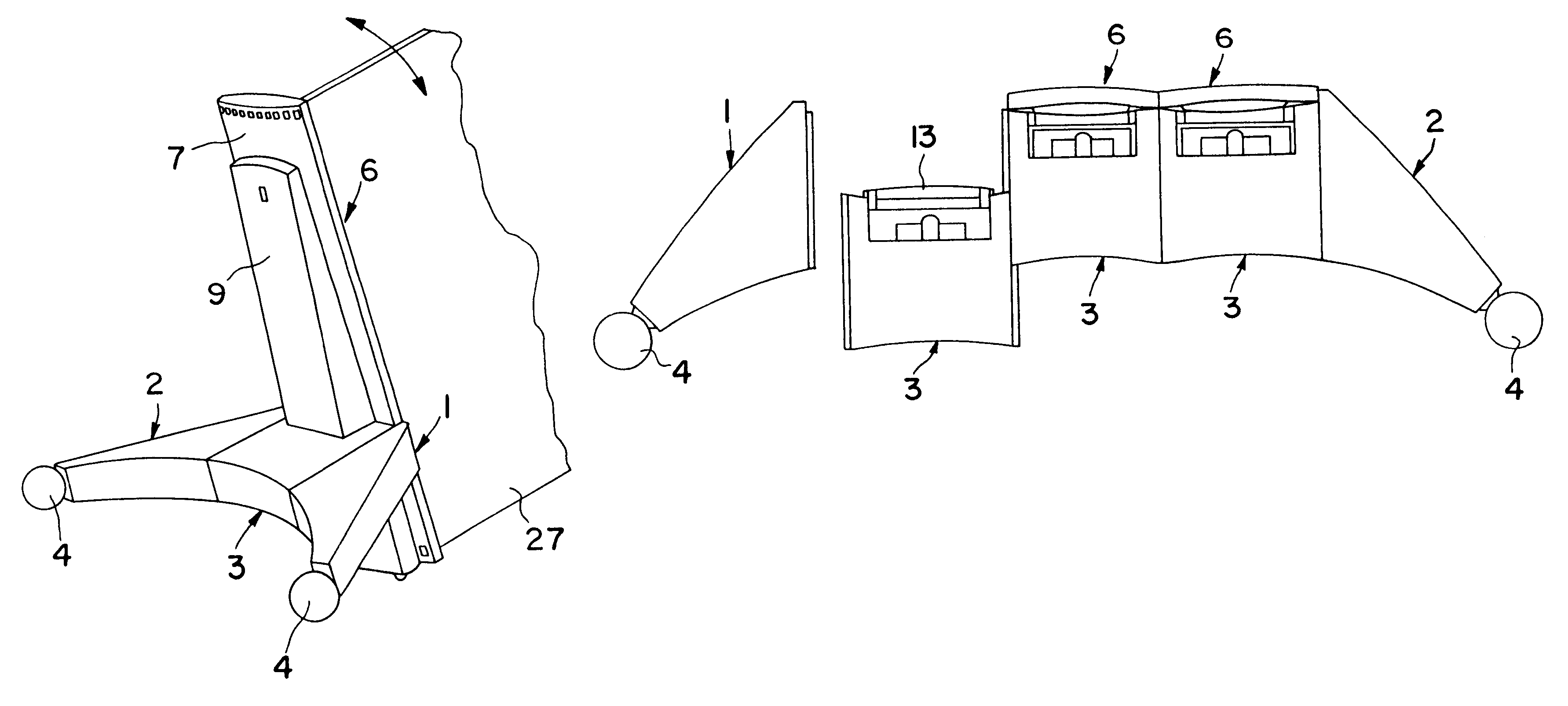

Bike saddle structure having adjustable oscillation angle and height

ActiveUS9061174B2Vibration minimizationEasy widthVehicle seatsCycle saddlesPhysical medicine and rehabilitationWhole body

The present invention relates to a bike saddle structure in which the oscillation angle and height of a bike saddle are adjustable, and to an exercise bicycle comprising same. Vibrations in the bike saddle are minimized and the stability thereof is ensured during the left and right oscillation of the bike saddle, thus enabling a rider to exercise his / her whole body including the legs, pelvis, spine, abdomen, etc. over a long period of time. The forward and backward direction and height of the bike saddle are adjustable by the rider, thus providing a wide range of exercise.

Owner:JUN WOO SICK

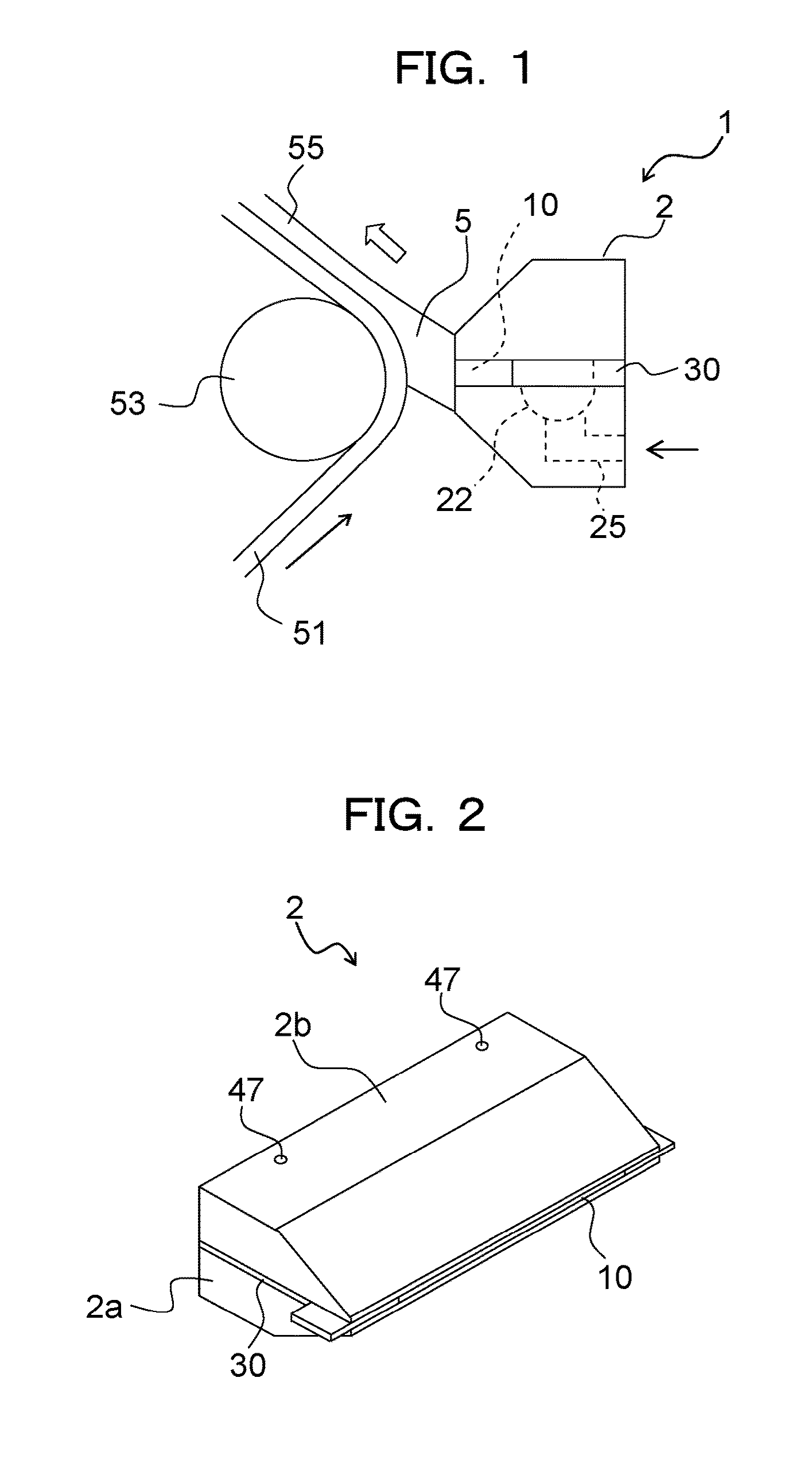

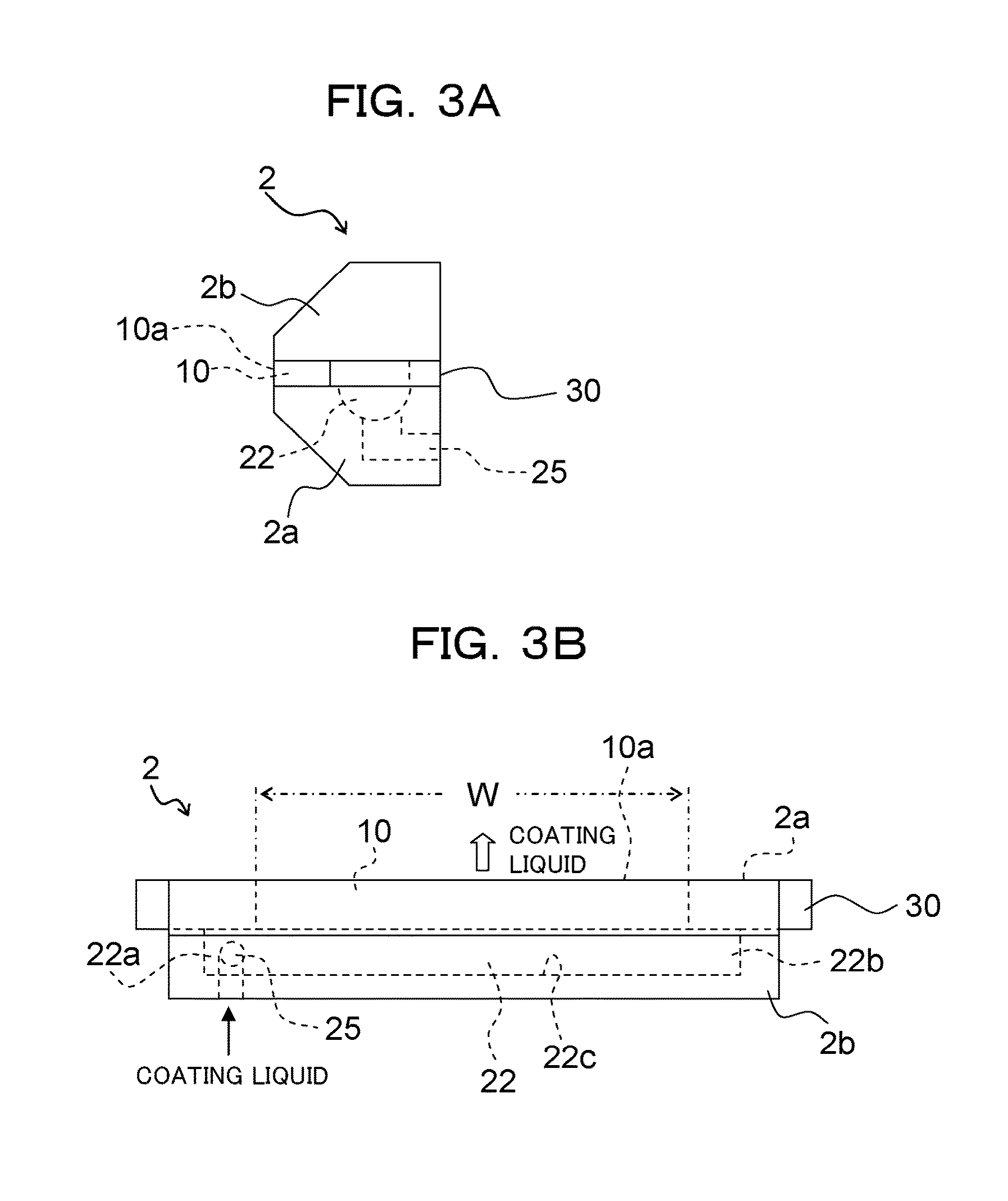

Shim member, die coater, and method for producing coating film

InactiveUS20130236651A1Easy to changeFacilitate the coating width of the die coater to be changedLiquid surface applicatorsLiquid spraying apparatusEngineeringGasket

Provided is a shim member which is sandwiched between two die blocks provided in a the coater, and has the U shape formed by a base end portion which is arranged so as to extend in a longitudinal direction of the slot, and a pair of extending portions which extend toward a nose portion of the die from both ends in a longitudinal direction of the base end portion, wherein a first portion which is a nose portion of at least one extending portion or the whole of at least the one extending portion, out of the pair of the extending portions, and a second portion which is the remaining portion including at least the base end portion, are structured so as to be separable from each other.

Owner:NITTO DENKO CORP

Supporting stand for swivel elements

Display panel systems make it possible to access a wide range of information. Such systems have a stand and a support for swivel panels upon which information carriers can be placed. The present invention provides display panel systems by which information-carrying capacity of the system can be adjusted, as required. The stand is modular and has two side parts which can be combined with a variable number of intermediate parts, each of which having a support for swivel panels.

Owner:DURABLE HUNKE & JOCHHEIM GMBH & CO KG

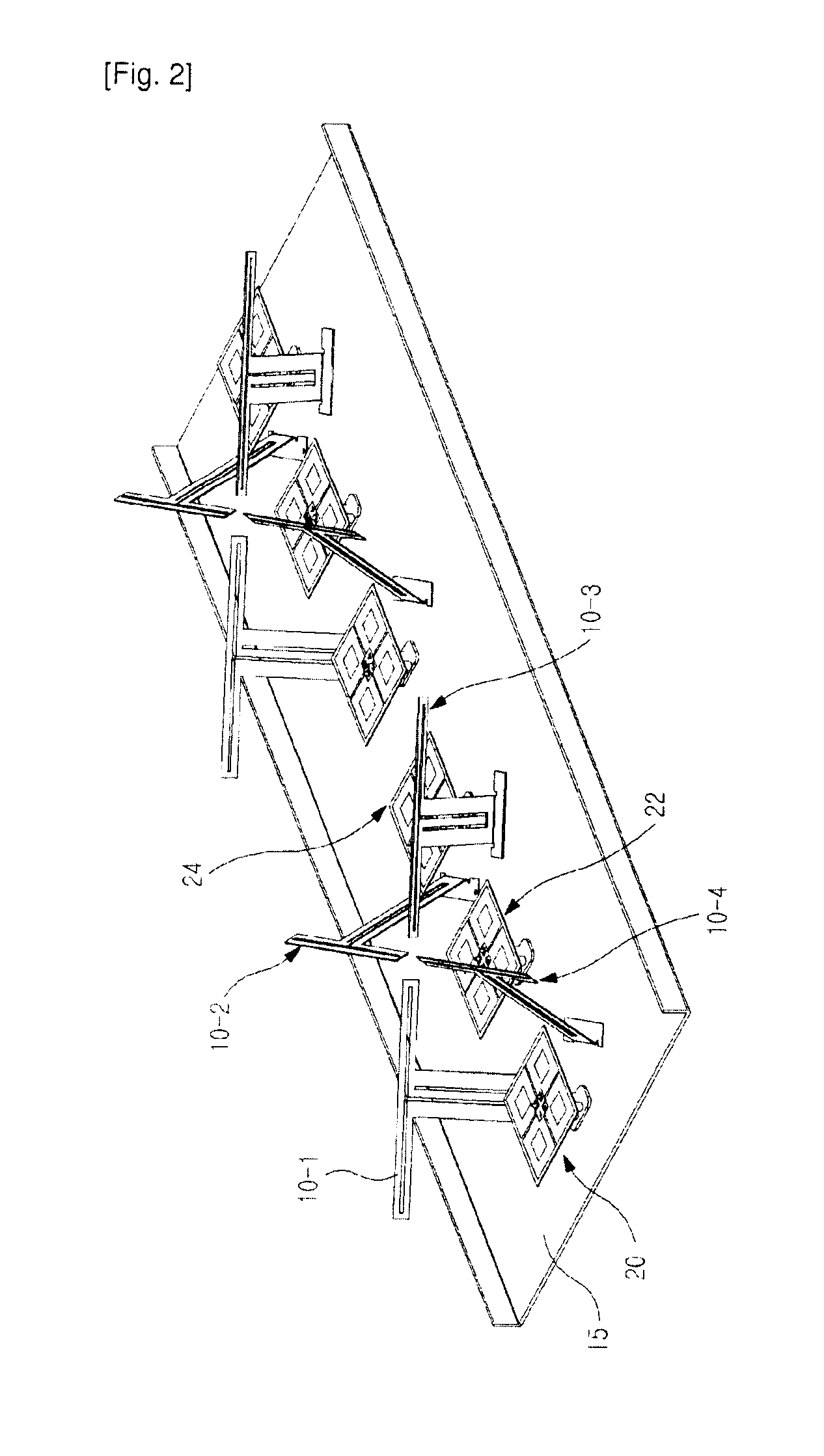

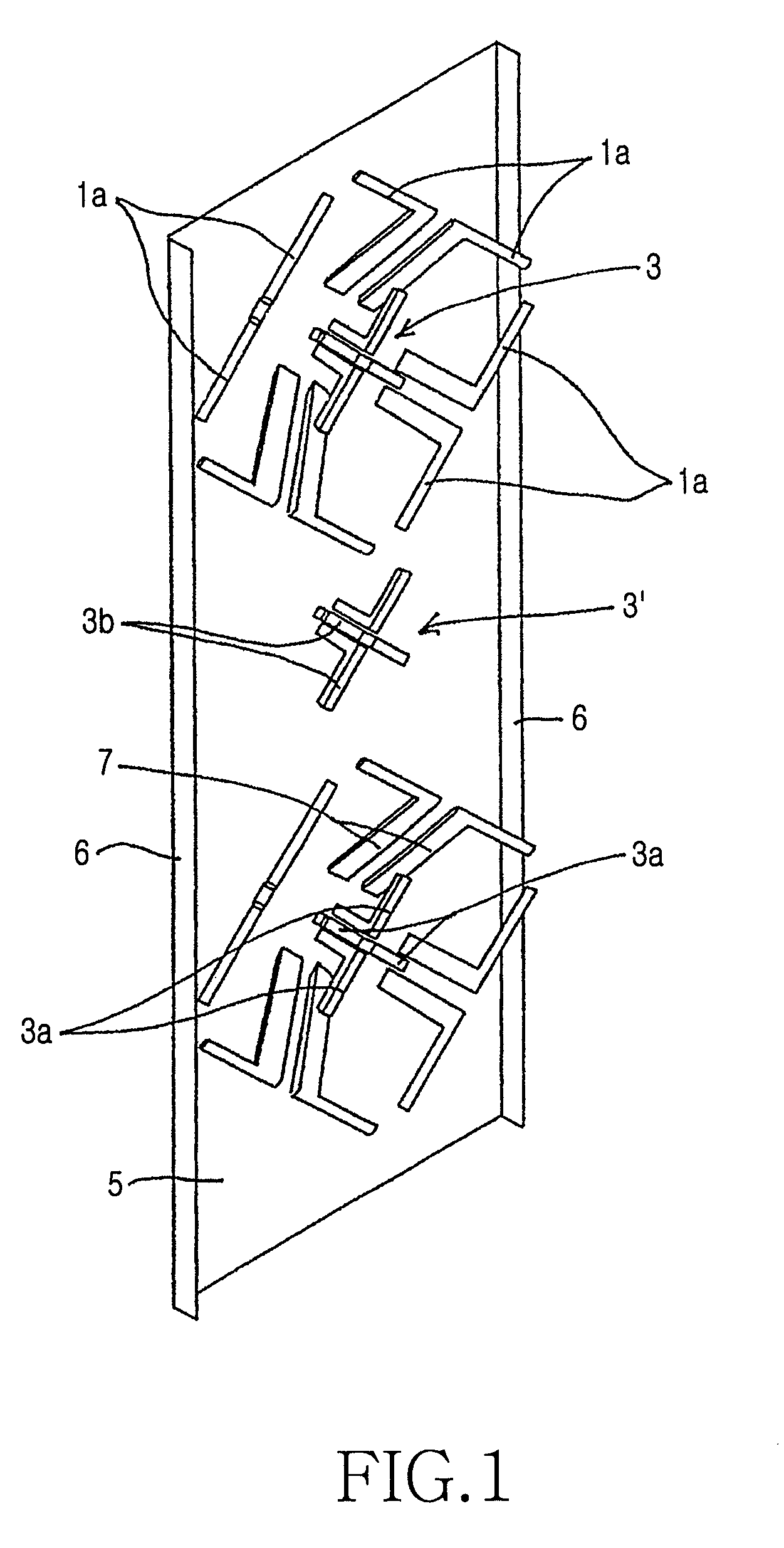

Multi-band, multi-polarized wireless communication antenna

ActiveUS20160248166A1Simple structureStable radiation characteristicsSimultaneous aerial operationsAntenna supports/mountingsMulti bandRadiating element

The present invention relates to a multi-band, multi-polarized wireless communication antenna, which comprises: a reflector; at least one first radiation module of a first band which is installed on the reflector; and at least one second or third radiation module of a second band or a third band installed on the reflector, wherein the first radiation module comprises first to fourth radiating elements having a dipole structure, the first to fourth radiating elements are configured such that every two radiating arms thereof are connected in the shape of letter “”, one of the two radiating arms is configured to be placed side by side along side of the reflector, and the second or third radiation module is installed to be included within an installation range of the first radiation module.

Owner:KMW INC

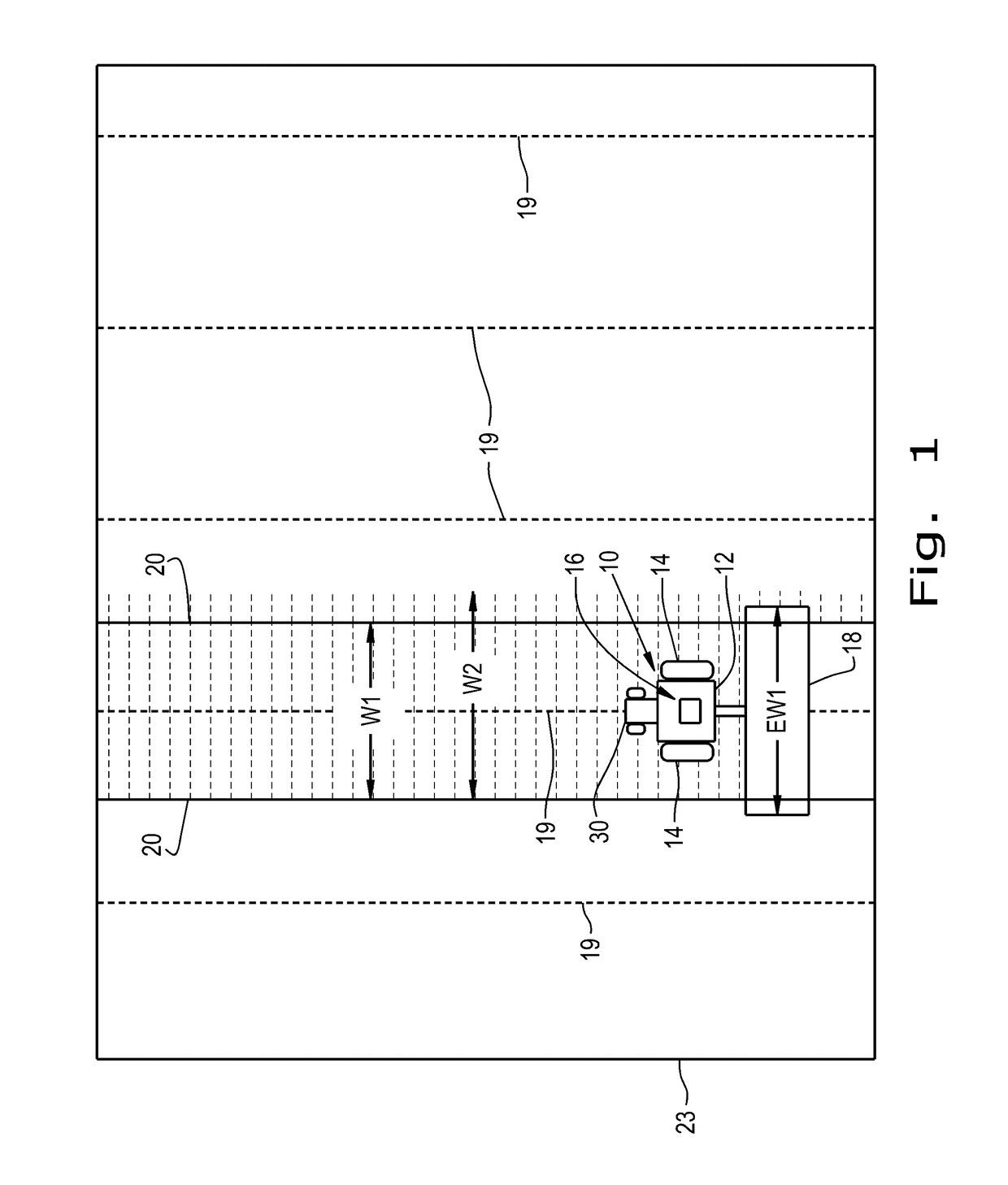

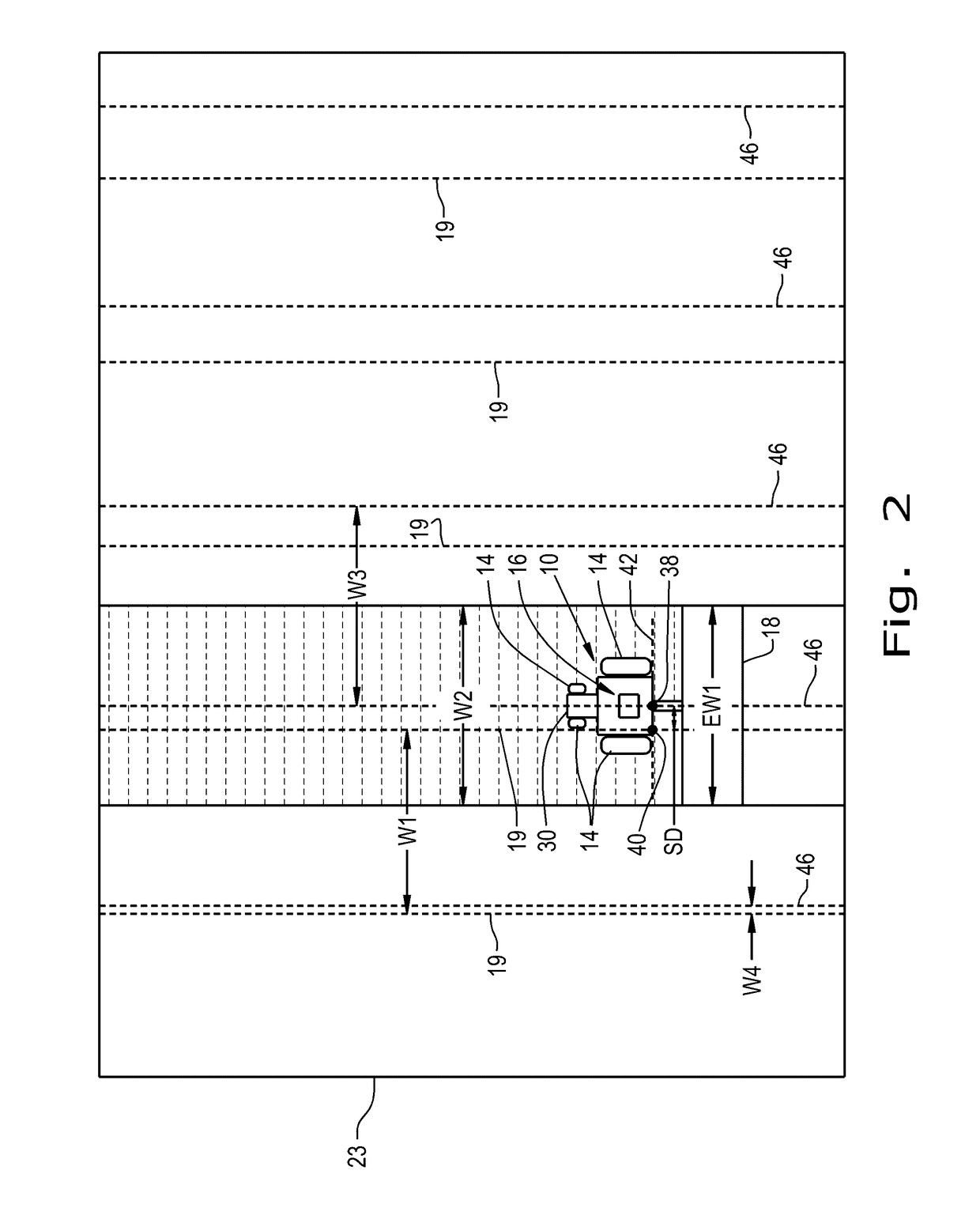

Device and method for guiding agricultural vehicles

ActiveUS20170112045A1Swath width is easyEasy to adjustInstruments for road network navigationGuiding agricultural machinesGeolocationEngineering

Owner:BLUE LEAF I P INC

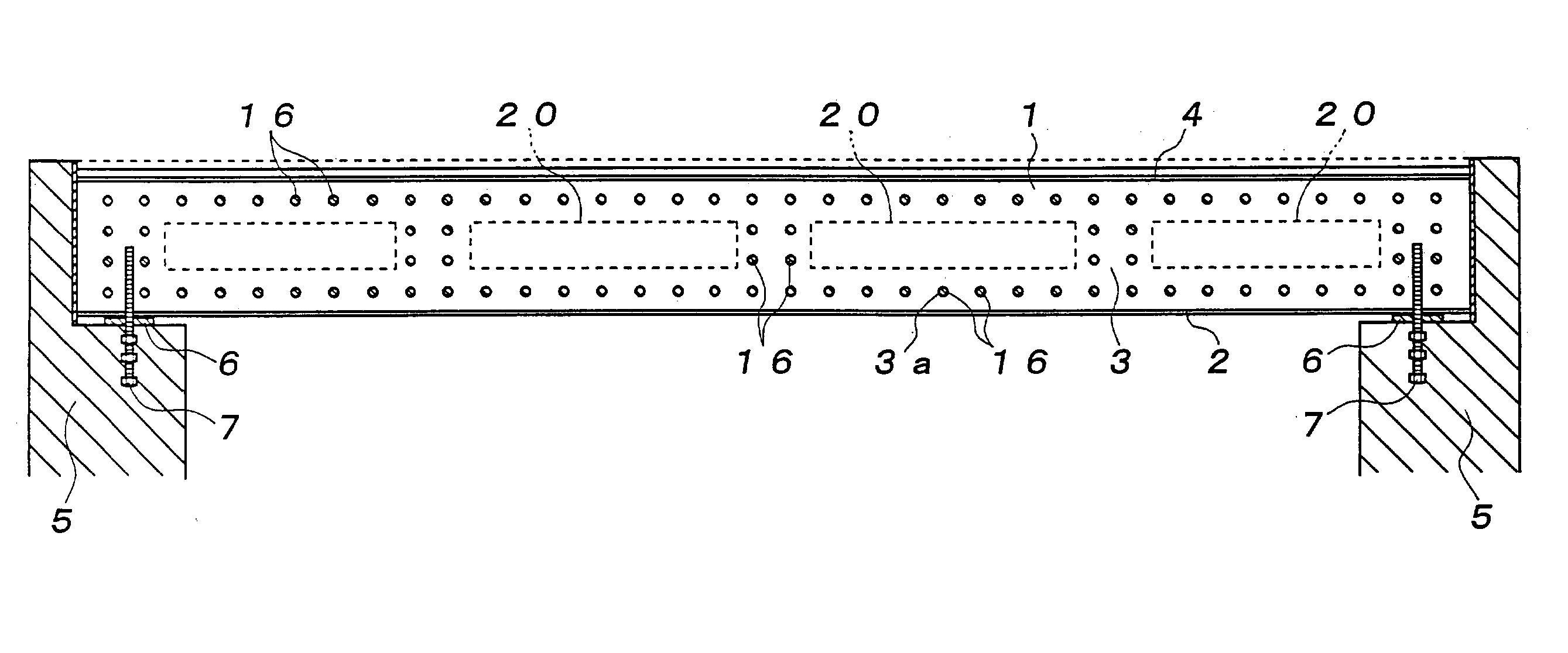

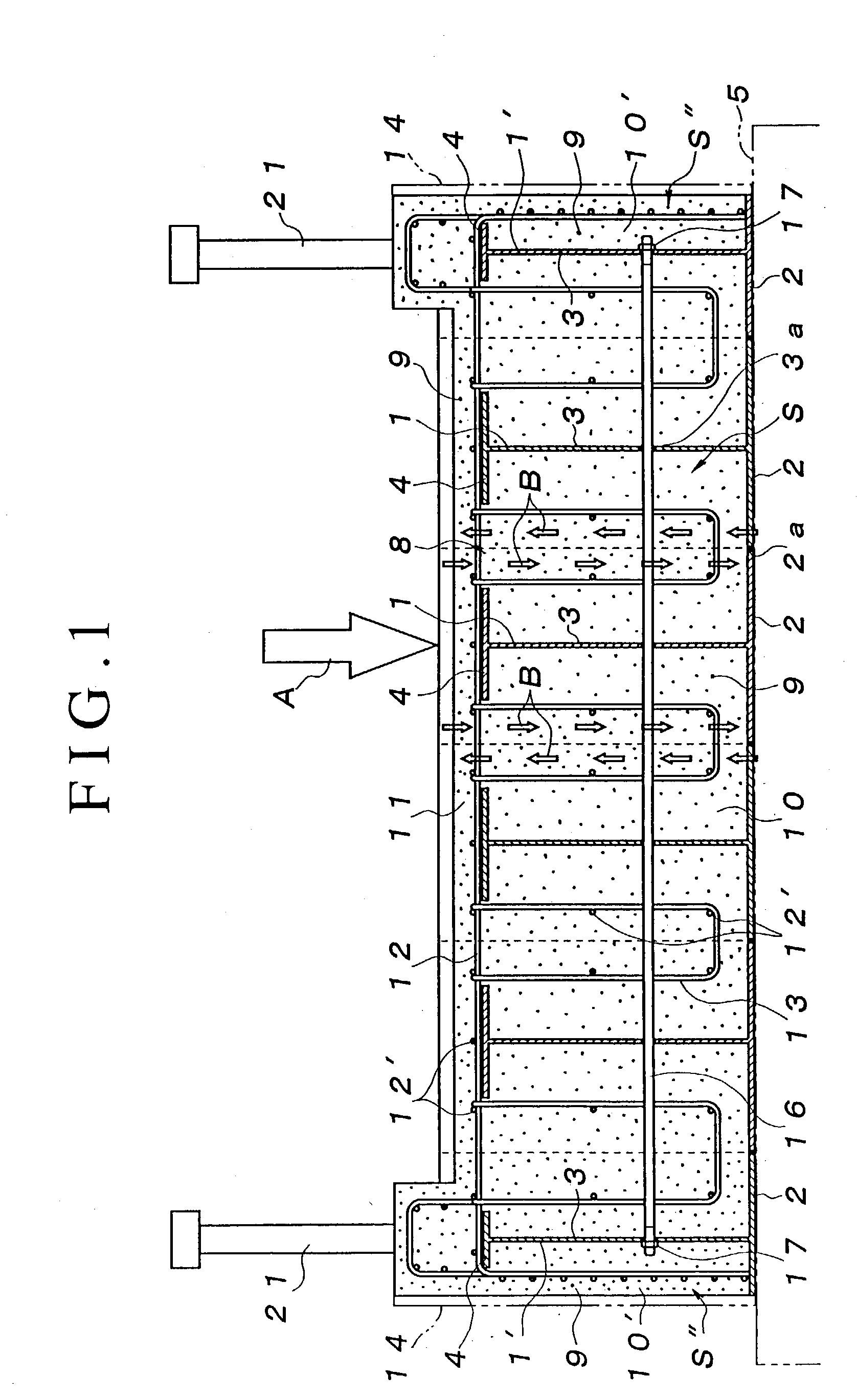

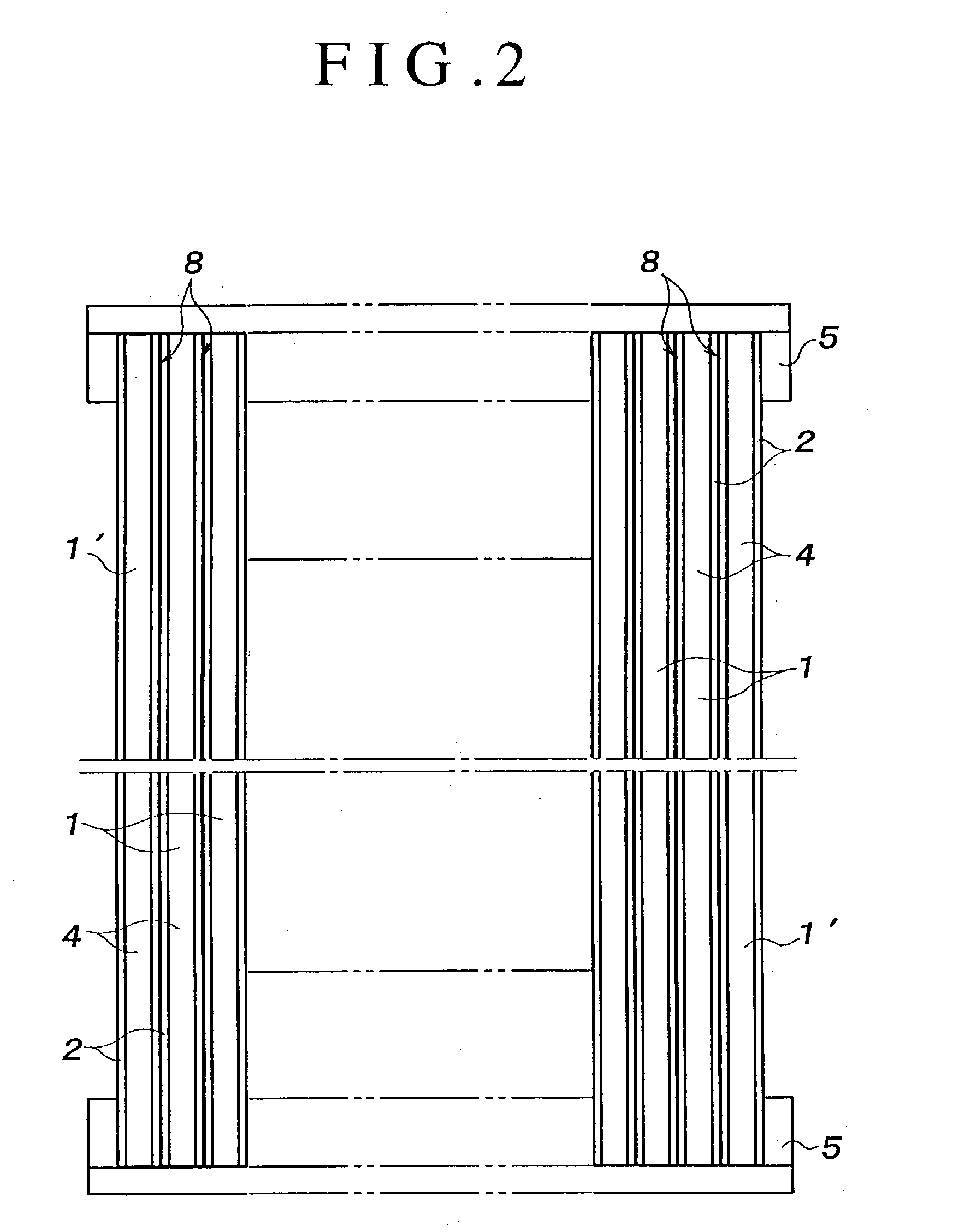

Structure of floor slab bridge

InactiveUS20040074022A1Forming accuratelyLow costBridge structural detailsBuilding constructionsSheet steelFloor slab

To properly construct a floor slab bridge by forming a main girder structure of the floor slab bridge in a bridge using commercially available columnar H-shaped steels and then applying concrete thereto. A construction of the floor slab bridge comprises a plurality of columnar H-shaped steels 1 each disposed between adjacent bridge legs 5, 5 and arranged in side-by-side relation with an end face 2a of a lower flange 2 abutted with a corresponding end face 2a of the adjacent columnar H-shaped steel 1, a lower concrete layer 10 formed by placing concrete in space S defined between the upper and lower flanges 4 and 2 and between the adjacent web plates 3 through a concrete inlet port 8 formed between the adjacent upper flanges 2, an upper concrete layer 11 formed by placing concrete 9 on the upper flange 4, an iron reinforcement 12 is horizontally disposed on the upper flanges 4, an iron reinforcement 13 being suspended in the space S from the horizontal iron reinforcement 12 through the concrete inlet port 8, and the horizontal iron reinforcement 12 being embedded in the upper concrete layer 11 and the suspending iron reinforcement 13 being embedded in the lower concrete layer 10.

Owner:ASAHI ENG CO LTD +1

Method for forming pattern and a wired board

ActiveUS20110185566A1Easy widthFacilitate conductionPrinted circuit aspectsSolid-state devicesEngineering

Owner:BROTHER KOGYO KK

Supporting stand for swivel elements

Display panel systems make it possible to access a wide range of information. Such systems have a stand and a support for swivel panels upon which information carriers can be placed. The stand is modular and has two side parts which can be combined with a variable number of intermediate parts, each of which has a support for swivel panels.

Owner:DURABLE HUNKE & JOCHHEIM GMBH & CO KG

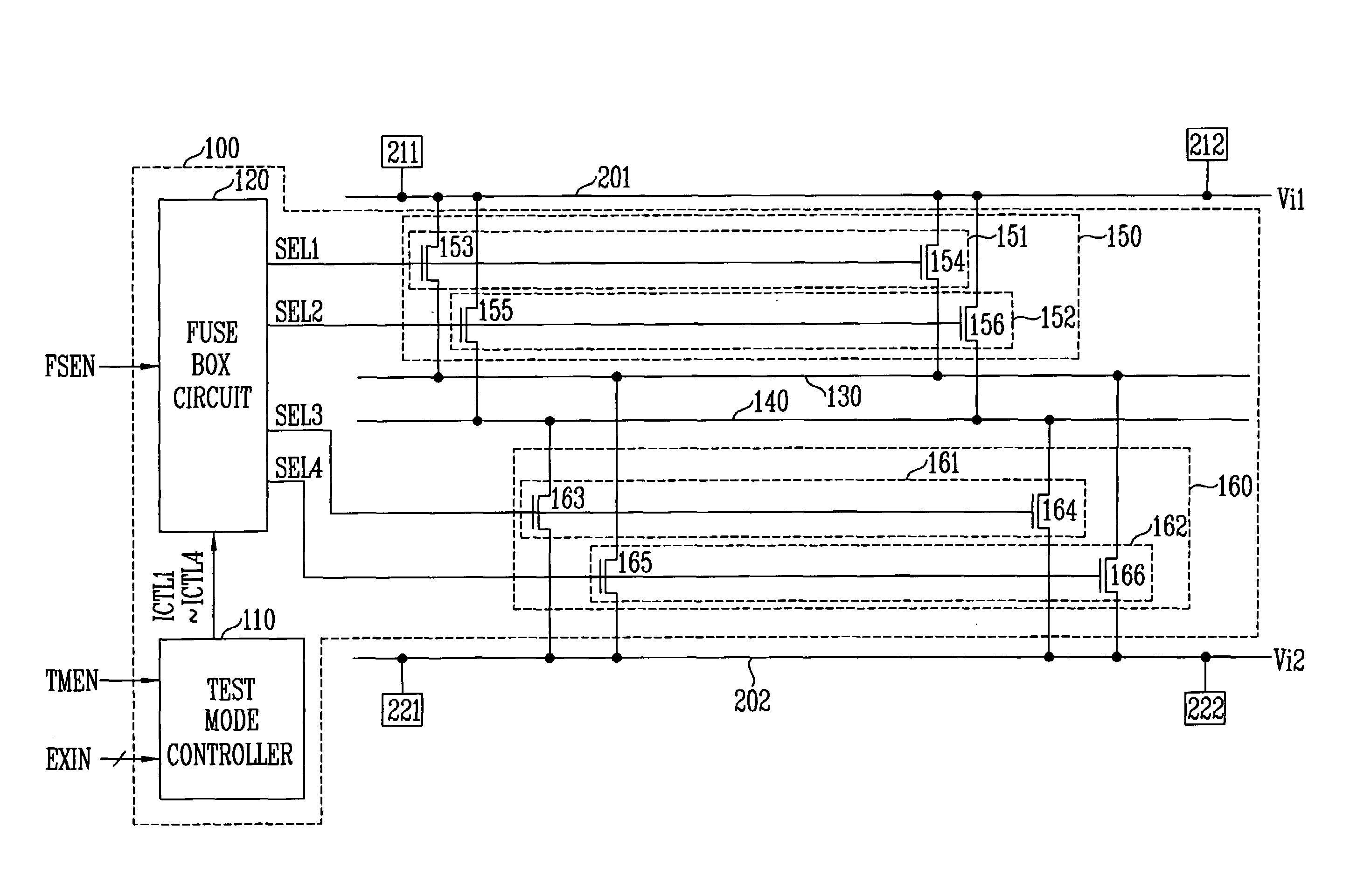

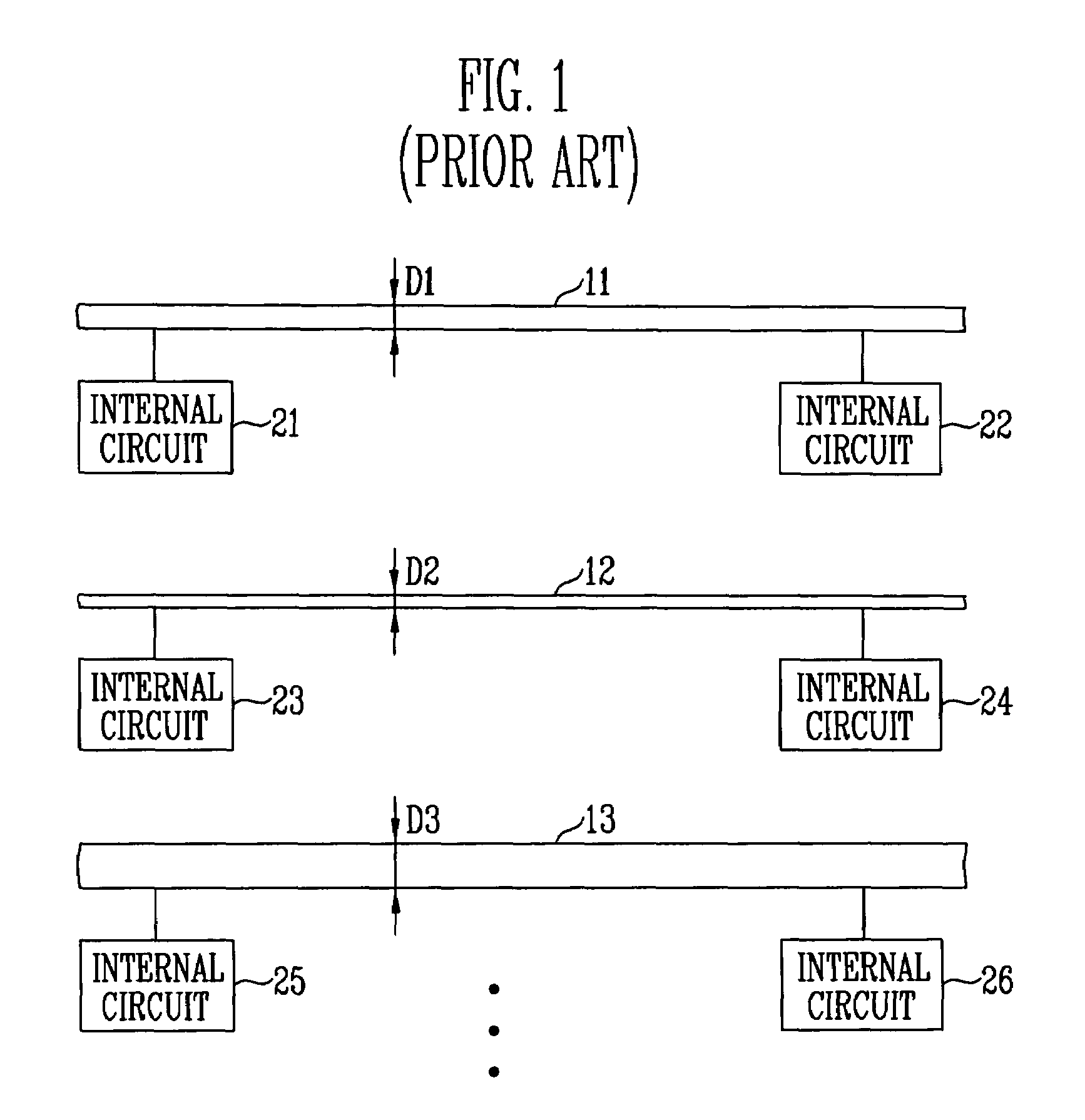

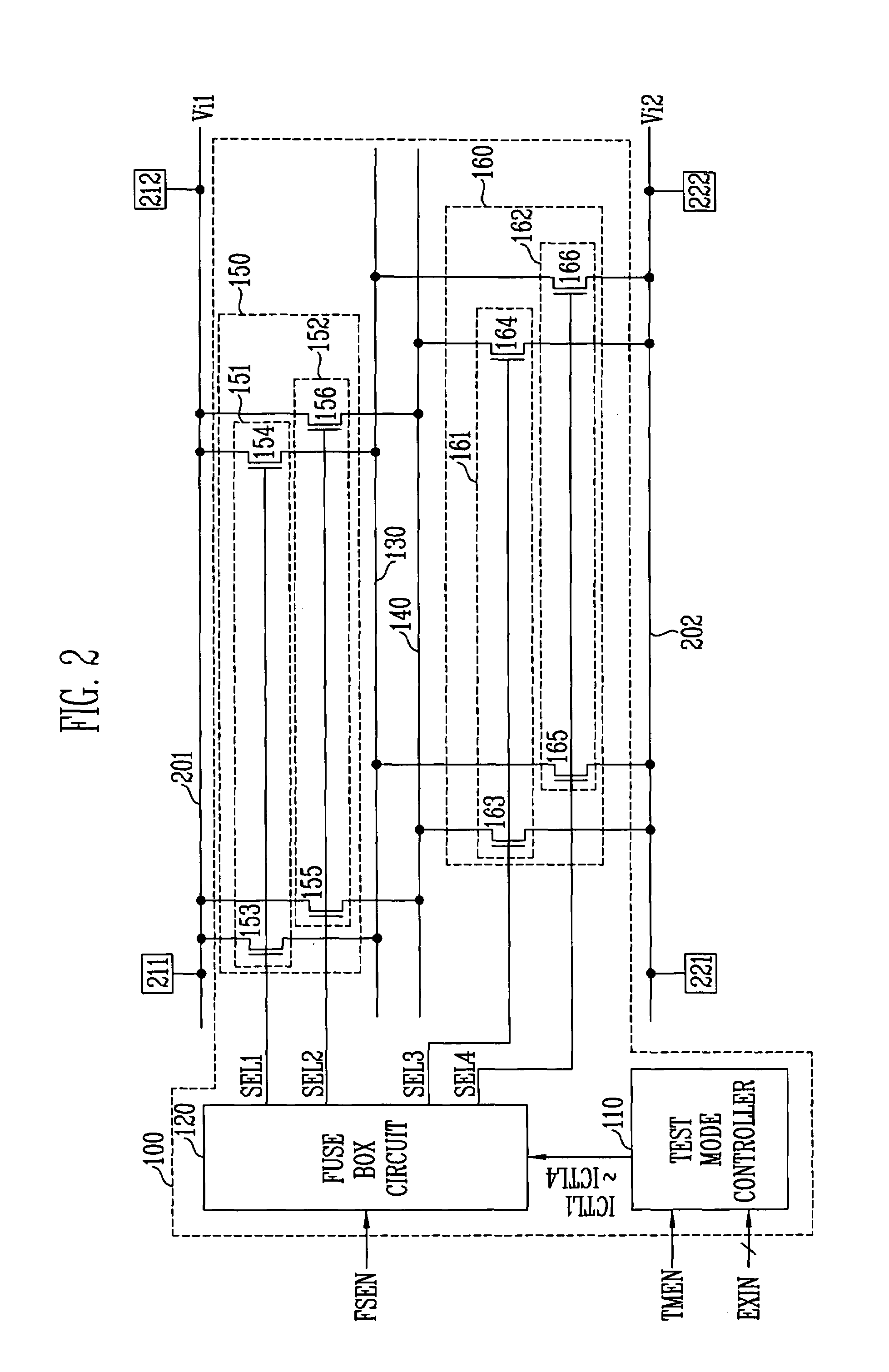

Power line control circuit of semiconductor device

InactiveUS7336089B2Easy to changeLow costSemiconductor/solid-state device detailsSolid-state devicesPower semiconductor deviceManufacturing cost reduction

A power line control circuit of a semiconductor device in which a width of a power line can be selectively controlled. The power line control circuit of the semiconductor device according to the present invention can selectively control the width of the power line employing the dummy power line. It is therefore possible to easily change the width of the power lines and to reduce the manufacturing cost and the manufacturing time depending on the formation of the power lines. Furthermore, the power line control circuit of the semiconductor device according to the present invention can selectively control the width of the power lines, if appropriate. Accordingly, mesh of optimized power lines can be provided. Furthermore, more stabilized product characteristics can be secured and the yield of semiconductor memory devices can be enhanced. In addition, the power line control circuit of the semiconductor device according to the present invention can selectively change power mesh corresponding to a power line method or operation mode of a product.

Owner:SK HYNIX INC

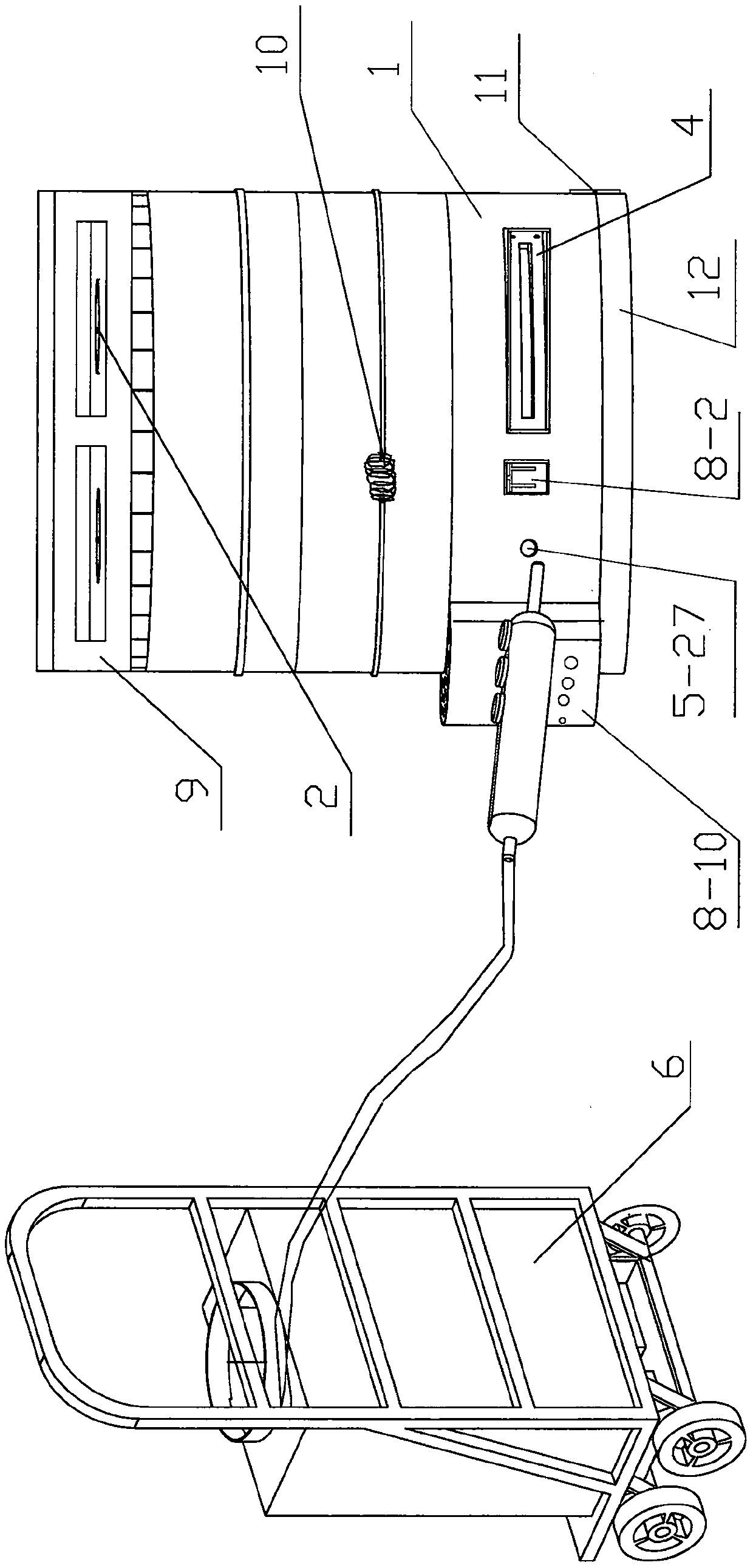

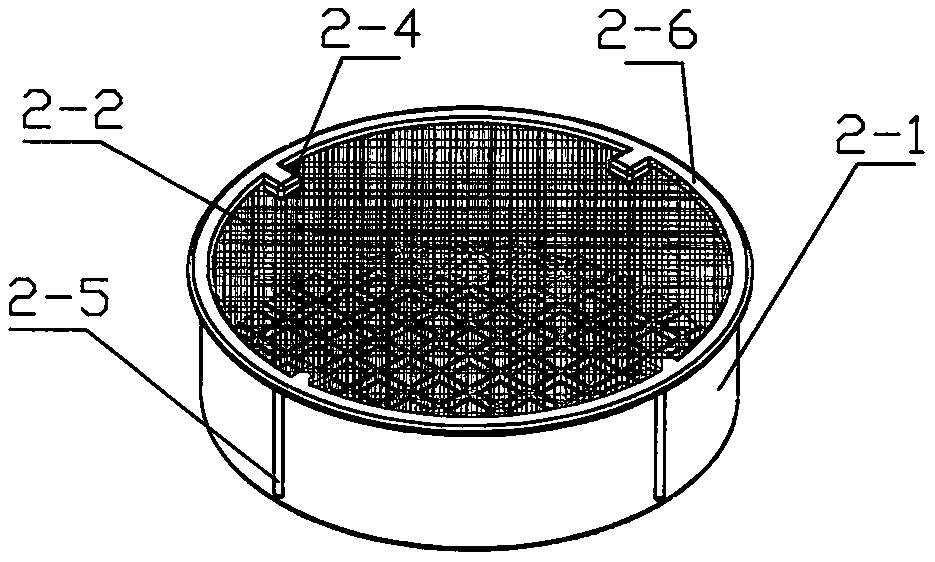

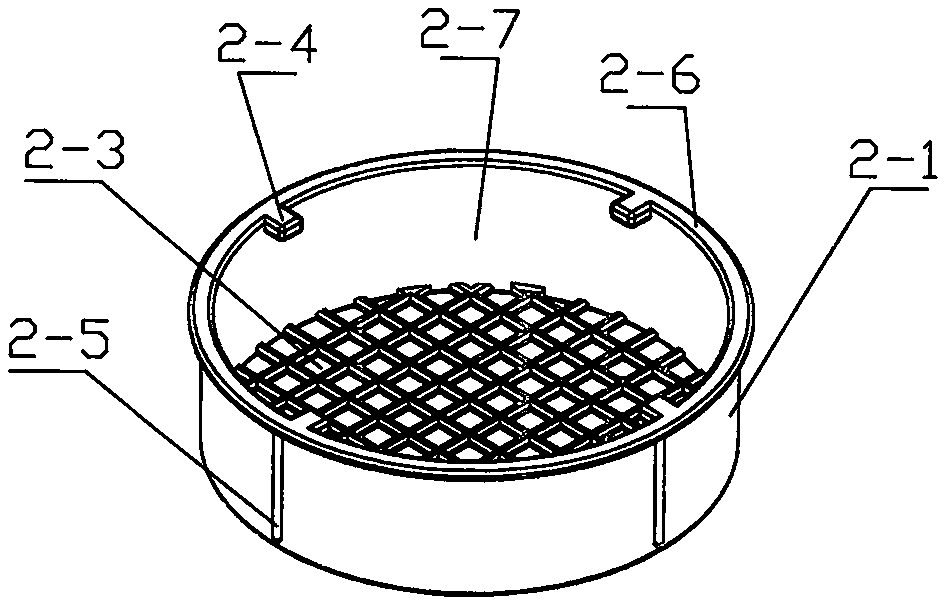

Bee box and auxiliary equipment

The invention discloses bee box and auxiliary equipment. Ventilation ports are formed in a box body or a box cover and is used for ventilation instead of light transmission, a frame can clamp combs, damage to a sealed brood is reduced, the quantity of bees can be adjusted through a queen bee separation entrance, loss is reduced in cooperation with a queen bee collecting box capable of collecting queen bees and drones, a box is round, the entrance is arc-shaped on the back, a feeding device is arranged in the box, water can be added to the feeding device without opening the box, the width of awater feeding channel is set to be within 37 mm, the water feeding channel only occupies the width of one comb, a main body of the feeding device is arranged to be round or square and used in a grid box or a drum type bee box, a water adder can quantitatively add water to the feeding device, labor is reduced, a cage for introduction of the queen bee is 6-15 mm thick and can be put in a bee way without producing burr combs, the queen bee can eat honey on the combs during introduction of the queen bee, worker bees can go in and out during storage of the queen bee, a wasp collection device induces wasps into a collecting box, the wasps are trapped in the box, double covers are adopted for thermal insulation, arc forging parts are arranged on the box covers when the bee box is round, spring hoops are arranged in the middle of the bee box, a bottom plate and the box body are connected through hinges, and an additional observing port is not required during bee checking.

Owner:陈日宝

Absorbent article for sanitary napkin

An absorbent article worn in the groin area, in which, when a compressive force is received from a lateral direction, a main absorbent region can oppose an excretion area of a wearer's body without twists or wrinkles occurring, and when the compressive force is relaxed, the article easily recovers to its original shape. An absorbent body provided in the absorbent article has a main absorbent region, reinforcing regions, and buffer regions. The bending stiffness of the reinforcing regions and the main absorbent region is larger than that of the buffer regions. When compressive force is received from a wearer's thigh areas in the lateral direction, the reinforcing regions that are positioned to the left and right deform in a curved shape, and the buffer regions that are to the left and right are compressed. The main absorbent region does not easily deform, and maintains a tight fit.

Owner:UNI CHARM CORP

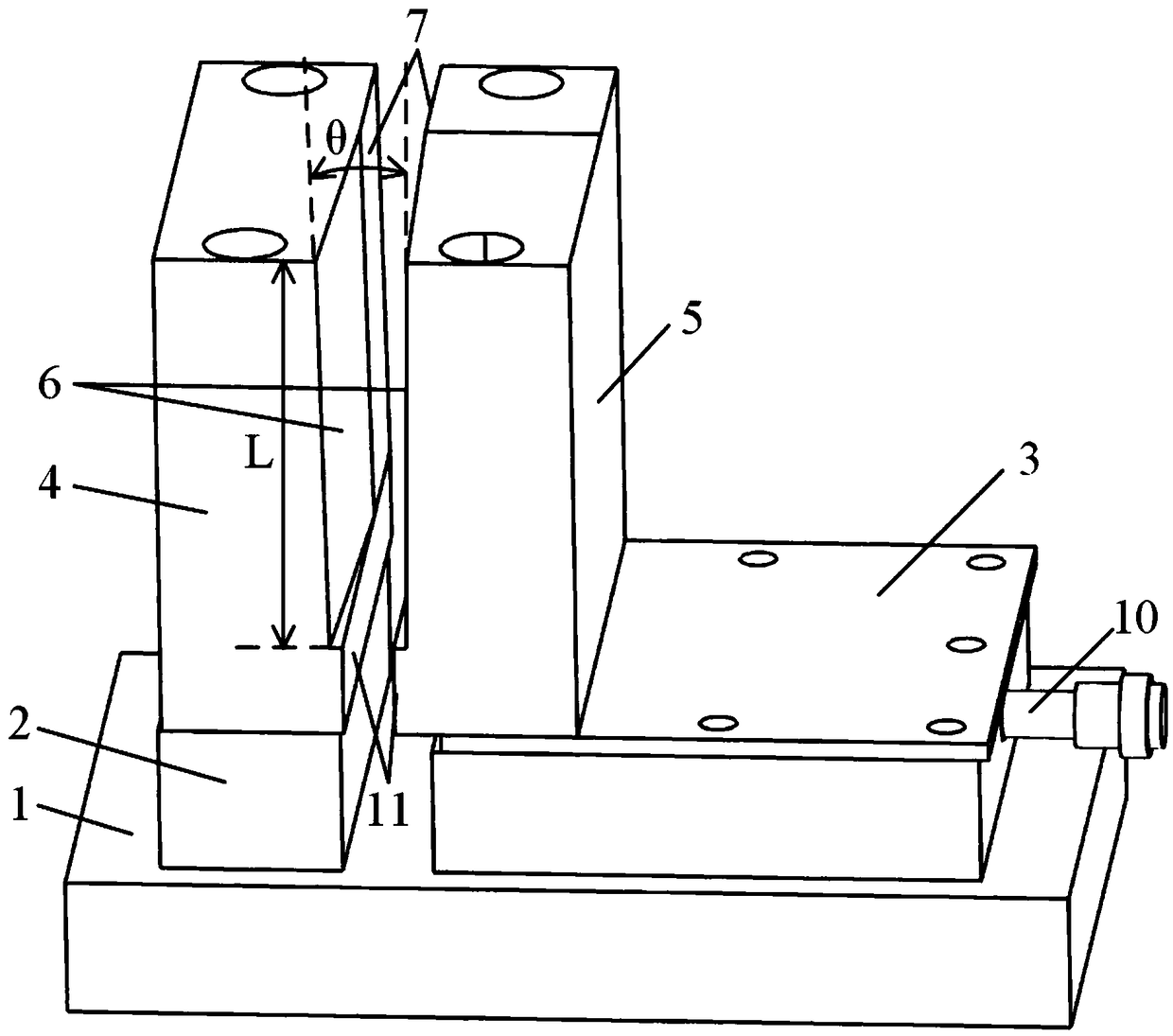

Micro-fine tapered electrode electric spark reverse copying device

PendingCN109108406AGuaranteed machining accuracyEasy widthElectrical-based auxillary apparatusEngineeringMachining process

The invention discloses a micro-fine tapered electrode electric spark reverse copying device. The micro-fine tapered electrode spark reverse copying device comprises an electric spark reverse copyingelectrode, and further comprises a base. The spark reverse copying electrode comprises a first electrode body and a second electrode body, and the first electrode body and the second electrode body are correspondingly connected to the base through one ends of the first electrode body and the second electrode body and are mounted on the base. The first electrode body and the second electrode body are provided with inclined surfaces, the inclined surface on the first electrode body is in directly facing relation with the inclined surface on the second electrode body, and the two inclined surfaces are in a plane symmetry relation. A gap is formed between the two inclined surfaces as a reverse copying channel. The inclined direction of the inclined surfaces is inclined from the end, away fromthe base, of the first electrode body or the second electrode body to the end where the base is located, and the inclined surfaces are inclined relative to symmetry planes for forming the plane symmetry relation of the two inclined surfaces. The reverse copying device can be used for micro-fine tapered electrode machining, does not need expensive online detection equipment in the machining process, and meanwhile, the micro-fine tapered electrode spark reverse copying device is easy to operate during use.

Owner:INST OF MACHINERY MFG TECH CHINA ACAD OF ENG PHYSICS

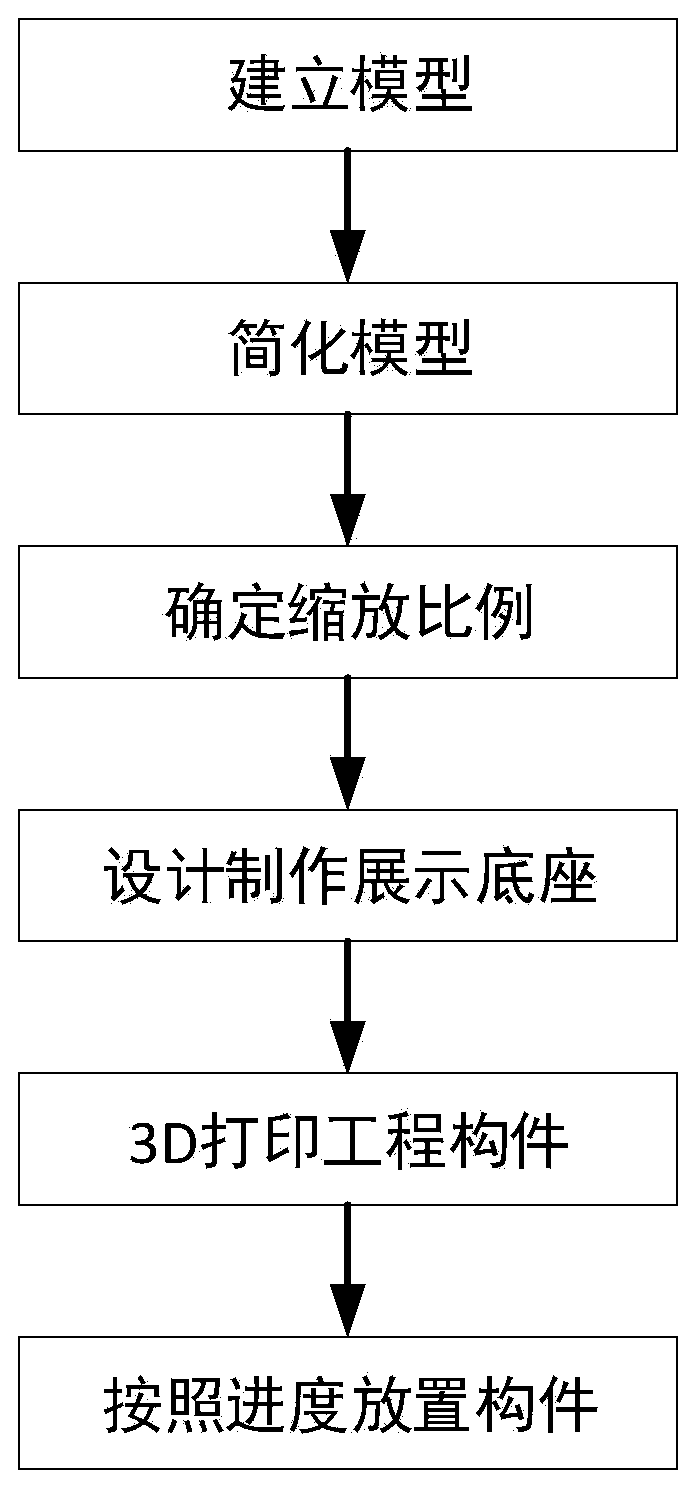

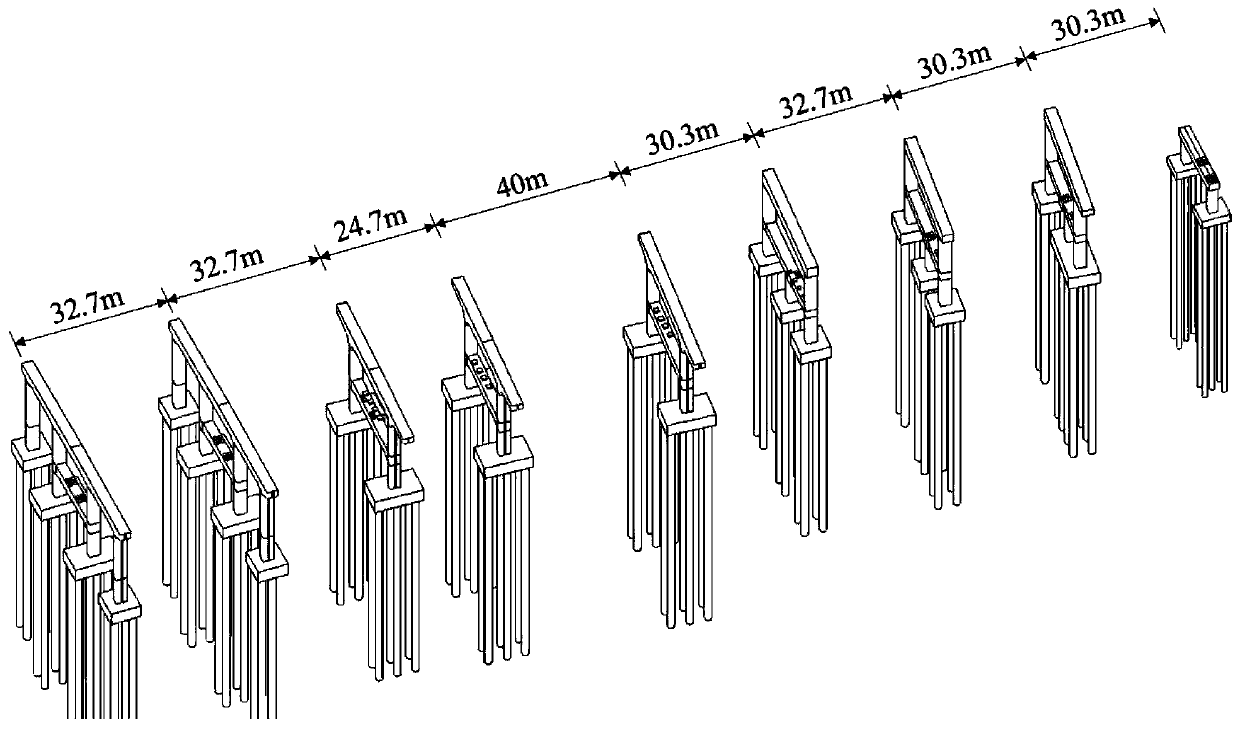

3D printing schedule display method for bridge engineering

ActiveCN109703007ASolve the problem that it is difficult to fully display the progress of the image of the bridge projectHigh precisionAdditive manufacturing apparatusAdditive manufacturing processesBridge engineeringDisplay device

The invention provides a 3D printing schedule display method for bridge engineering and relates to the field of bridge engineering. The method is used for synchronizing the engineering actual schedule, the visual schedule of engineering is displayed indoors, construction management personnel can grasp the overall schedule of the engineering conveniently, rapidly and accurately, and precise and efficient schedule decision making is achieved. According to the flow of the method, (1), an engineering three-dimensional model is set up according to sub-step and sub-item engineering division of an engineering drawing and a construction plan; (2), a bridge structure is simplified to form a simplified three-dimensional model; (3), the scaling proportion is selected; (4), according to the selected scaling proportion and the simplified three-dimensional model, the length of a display device, the number of middle sections, the length of an end section, the width of a base, holing of a top plate, shaft number marking and the distance between a base plate and the top plate are designed; (5), according to the simplified three-dimensional model and the sub-step and the sub-item division, all components of bridge engineering are printed in a 3D manner; and (6), the engineering actual schedule is synchronized, and the components, printed in a 3D manner, of bridge engineering are arranged in thedisplay device.

Owner:BEIJING MUNICIPAL ROAD & BRIDGE

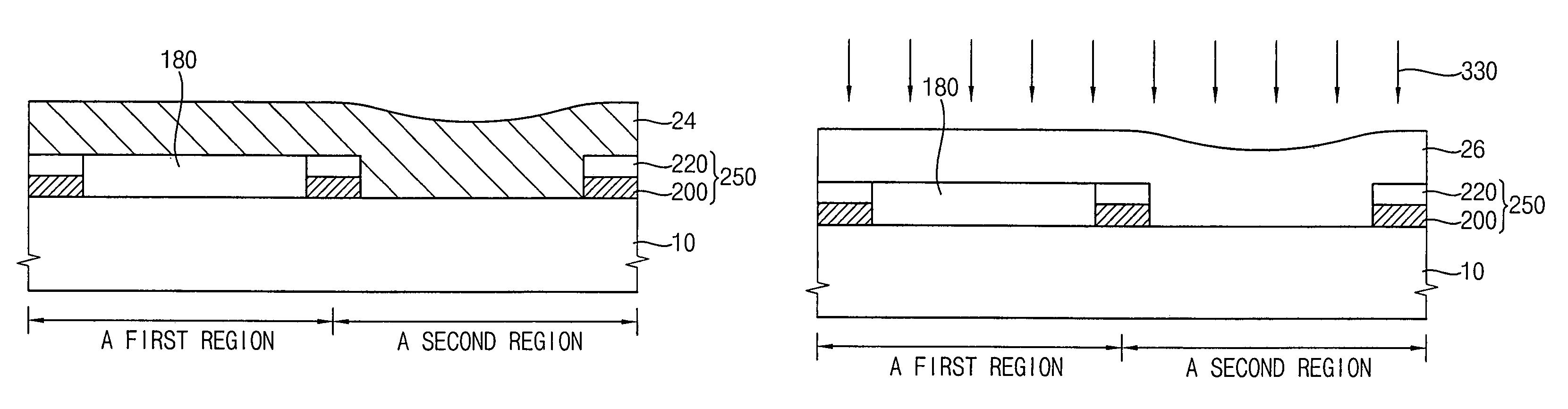

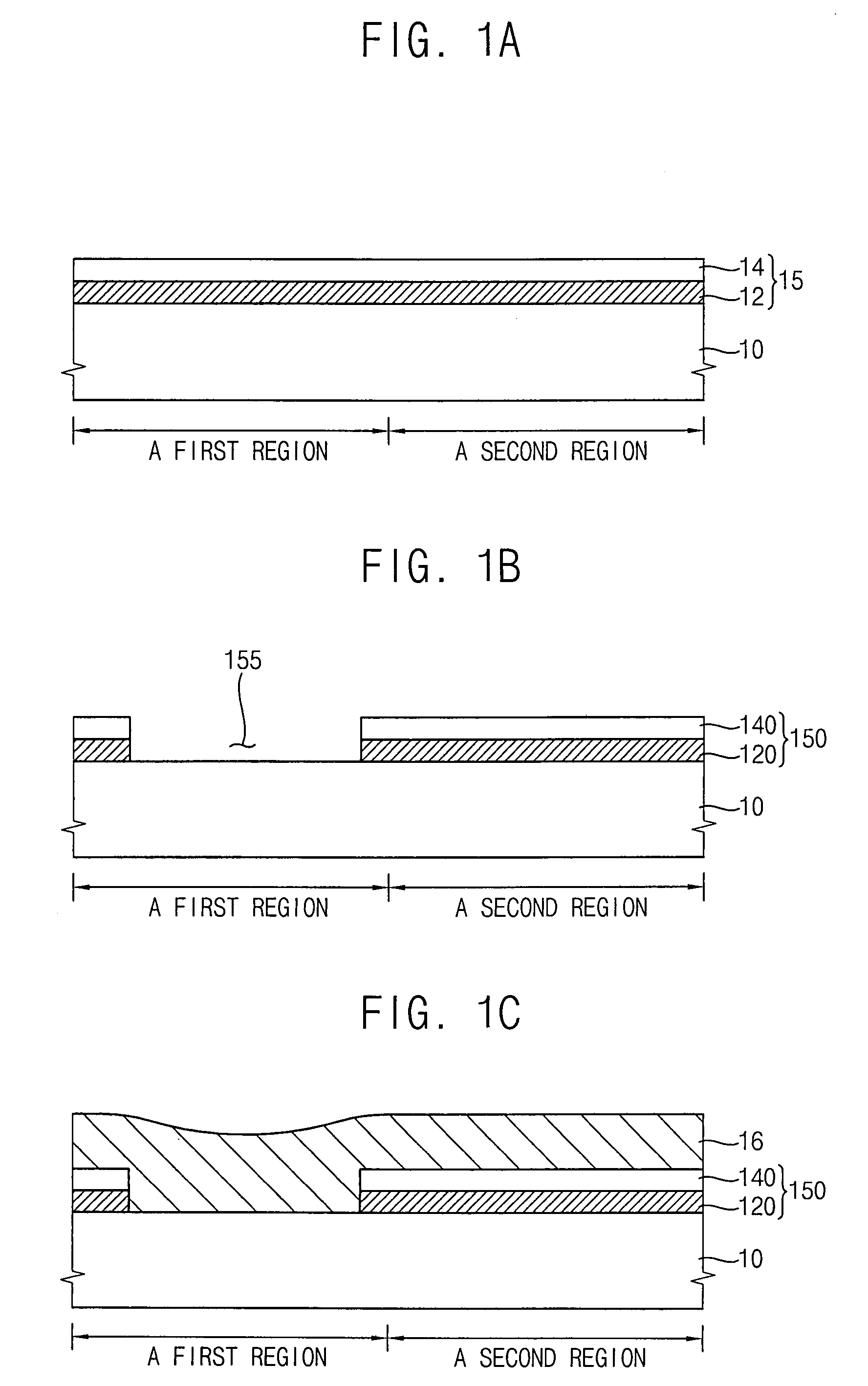

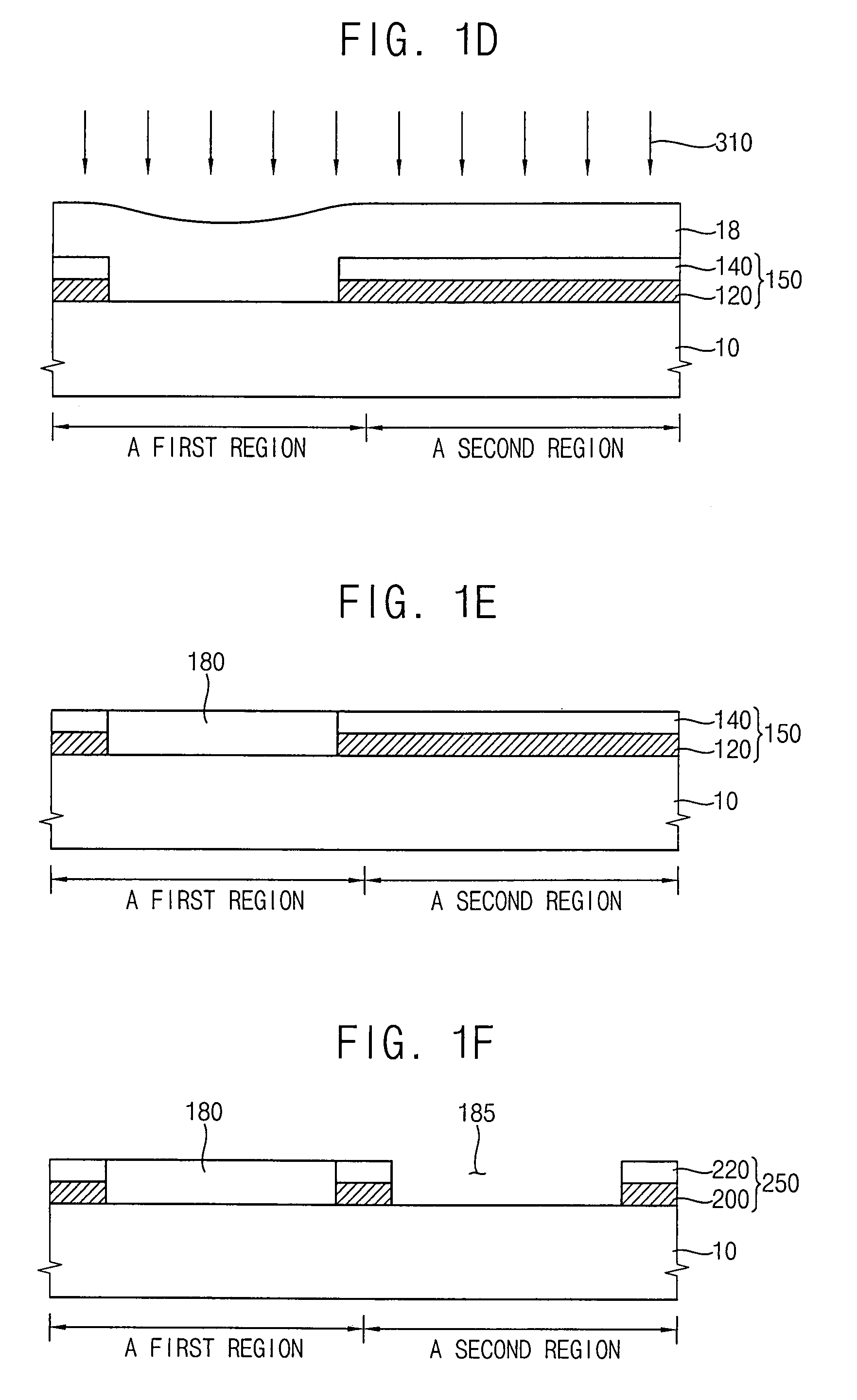

Method for fabricating a semiconductor device

ActiveUS7560319B2Easy to makeEasy widthSemiconductor/solid-state device manufacturingInsulation layerCrystalline silicon

A method of fabricating a semiconductor device includes forming an insulation layer structure on a single-crystalline silicon substrate, forming a first insulation layer structure pattern comprising a first opening by etching a portion of the insulation layer structure, filling the first opening with a non-single-crystalline silicon layer, and forming a single-crystalline silicon pattern by irradiating a first laser beam onto the non-single-crystalline silicon layer. The method also includes forming a second insulation layer structure pattern comprising a second opening by etching a portion of the first insulation layer structure, filling the second opening with a non-single-crystalline silicon-germanium layer, and forming a single-crystalline silicon-germanium pattern by irradiating a second laser beam onto the non-single-crystalline silicon-germanium layer.

Owner:SAMSUNG ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com