Micro-fine tapered electrode electric spark reverse copying device

A technology of electric spark and electrode, which is applied in the field of micro-conical electrode electro-spark counter-copying device, which can solve the problems of breaking under force and easy deformation of micro-electrodes, and achieves the effects of easy operation, elimination of lack of attention, and long length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

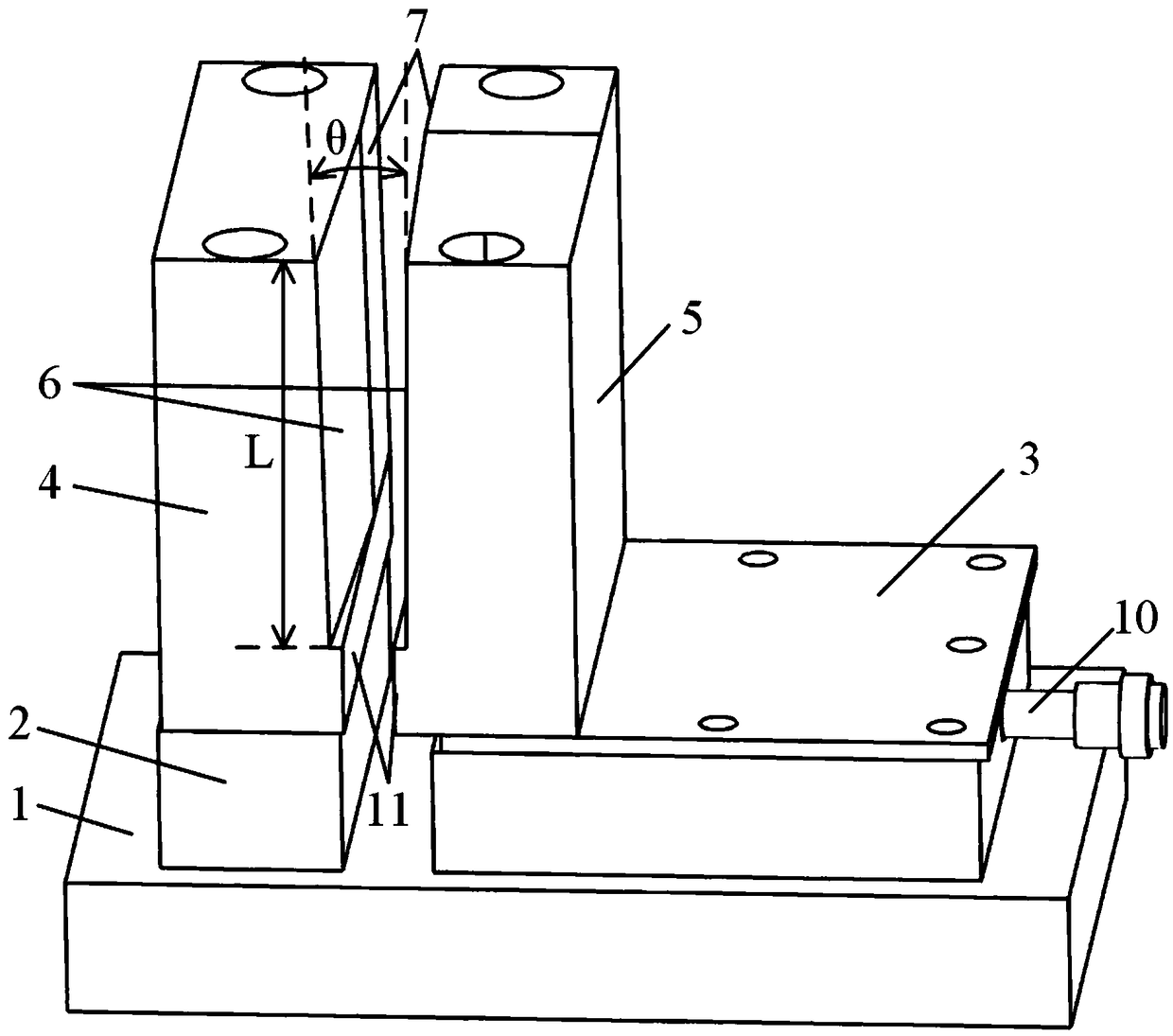

[0044] Such as figure 1 and figure 2 Shown, a kind of fine conical electrode electric spark copying device, comprises electric spark copying electrode, also comprises base 1, and described electric spark copying electrode comprises first electrode 4 and second electrode 5, and described first Both the electrode 4 and the second electrode 5 are installed on the base 1 by connecting one end thereof to the base 1;

[0045] Both the first electrode 4 and the second electrode 5 have slopes, and the slopes on the first electrode 4 and the slopes on the second electrode 5 are in a direct relationship, and the two slopes are in a plane-symmetrical relationship with each other;

[0046] There is a gap between the two slopes as a copy channel;

[0047] The inclination direction of the slope is: from the end of the first electrode 4 or the second electrode 5 away from the base 1 to the end where the base 1 is located;

[0048] The slopes are all inclined relative to a symmetrical pla...

Embodiment 2

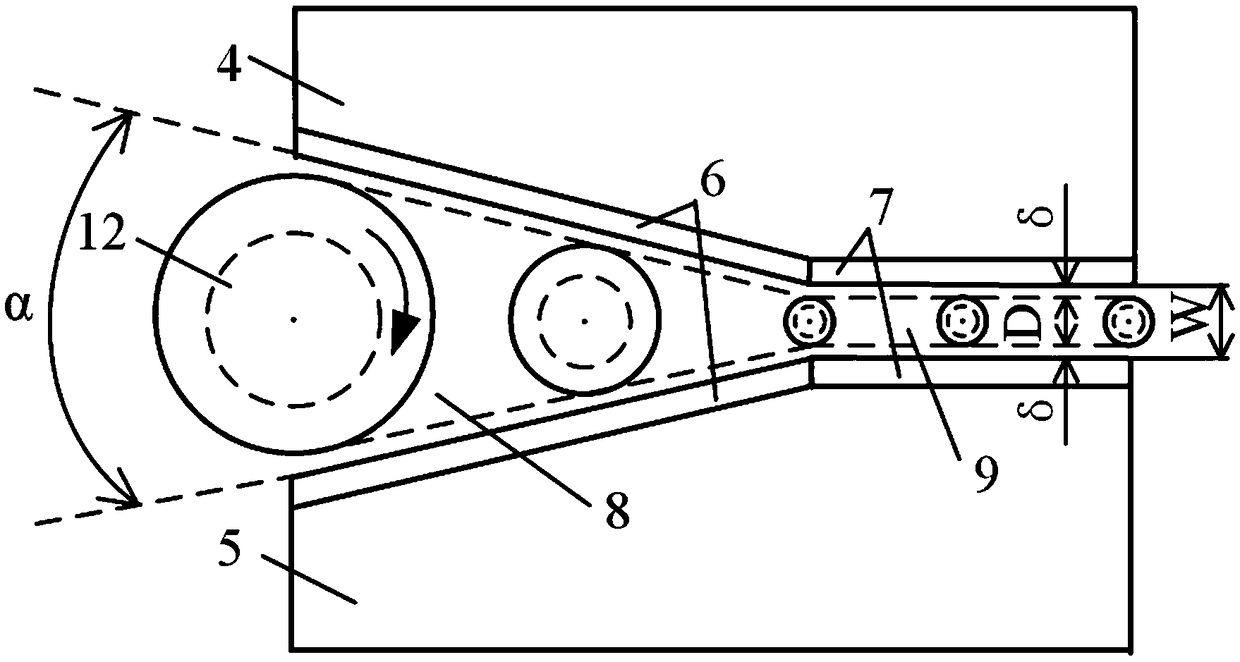

[0058] Such as figure 1 and figure 2 As shown, this embodiment is further limited on the basis of Embodiment 1: the slopes on the first electrode 4 and the second electrode 5 both include a first slope 6 and a second slope 7, and the two first slopes 6 are facing each other. relationship, the two second slopes 7 are in a positive relationship;

[0059] The gap between the two first slopes 6 is the first reverse copy passage 8, the gap between the two second slopes 7 is the second reverse copy passage 9, and the inlet port of the second reverse copy passage 9 is connected to the first reverse copy passage 8. The outlet end of the connection is connected;

[0060] From the inlet end of the first reverse copy passage 8 to the outlet end of the first reverse copy passage 8, the distance between the two first slopes 6 decreases linearly;

[0061] From the inlet end of the second reverse copy passage 9 to the outlet end of the second reverse copy passage 9, the distance between ...

Embodiment 3

[0076] This embodiment provides a specific implementation of a micro-conical electrode 12 electric spark copying device, such as figure 1 and figure 2 As shown, the first electrode 4 and the second electrode 5 are made of red copper, the opening angle α formed by the two first slopes 6 is 0.1°, the angle θ between the two slopes is 5°, and the fine tapered electrode 12 The diameter D of the head is 0.01 mm, and the length of the fine tapered electrode 12 is 10 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com