3D printing schedule display method for bridge engineering

A technology of 3D printing and bridge engineering, applied in the direction of processing and manufacturing, additive processing, etc., can solve the problems of large linear engineering length, unfavorable formation of schedule decisions, and limitations, and achieve the effect of improving accuracy and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

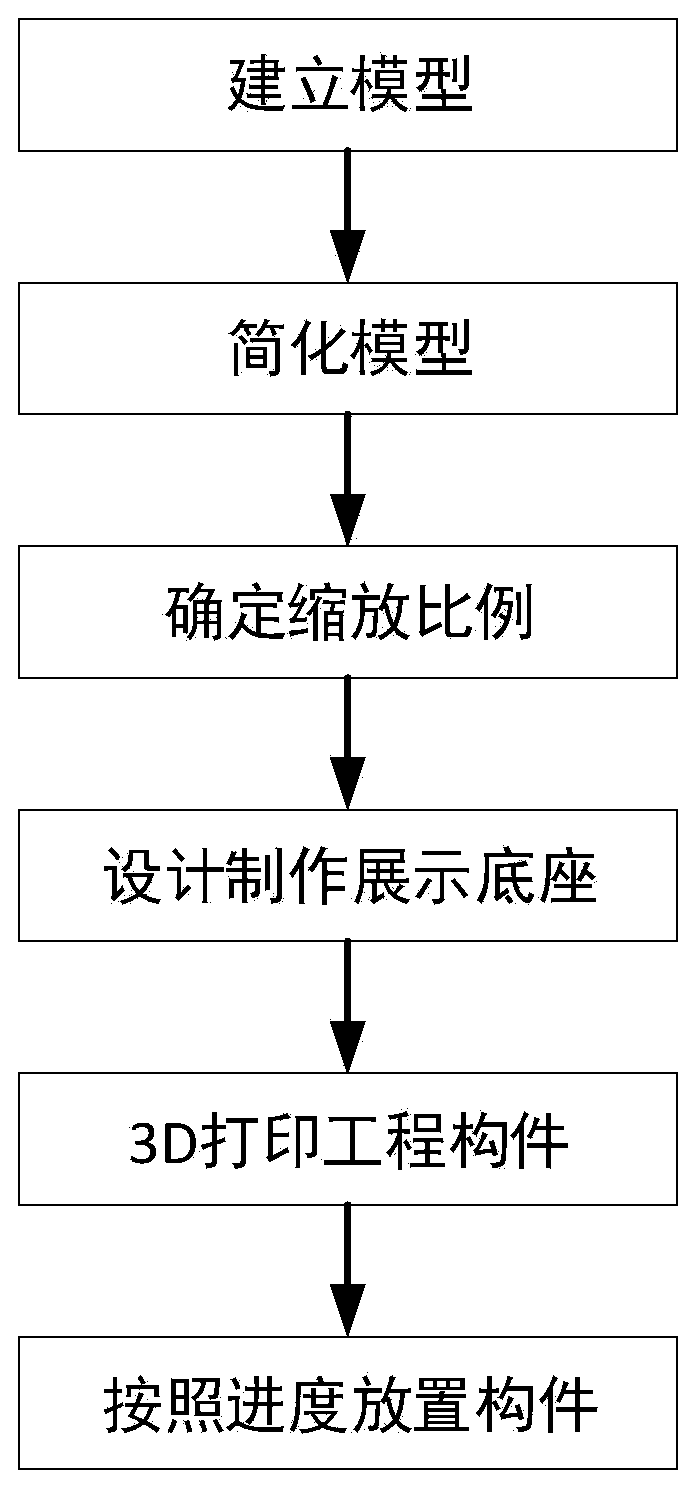

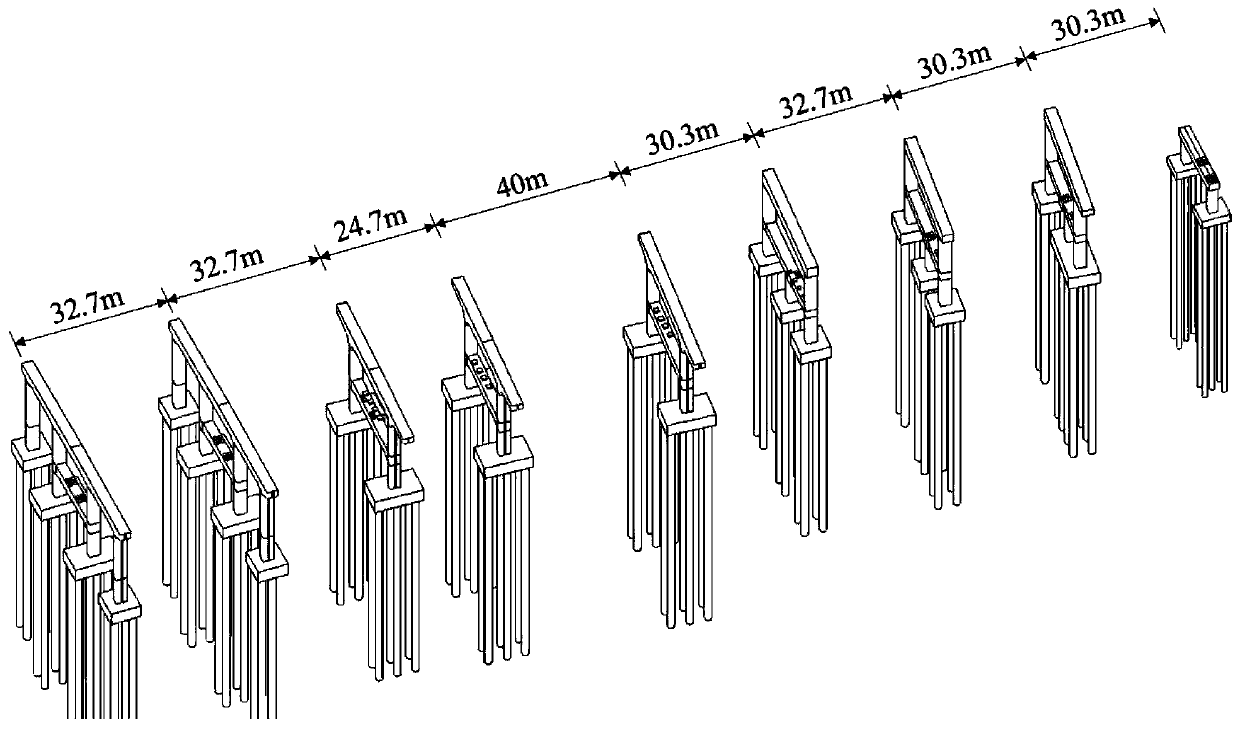

[0036] (1) According to the drawings, use the BIM software Revit to build a 3D model of the entire line structure, and the distance between the lower structures of each axis is different, such as figure 2 , image 3 shown.

[0037] (2) The bridge structure is simplified in Revit software, the height h from the bottom of the cap to the top of the lower structure is 25 meters, and the length of the pile foundation along the whole line is l 1 Unified as 0.6h, that is, 15 meters, the distance between the lower structures of the whole line is l 2 Unify 0.8h, that is, 20 meters, and the flat curve is simplified to a straight line. Get the mileage length L of the simplified model on the straight line 1 1820 meters, the maximum width D 1 is 50 meters. Such as Figure 4 , Figure 5 shown.

[0038] (3) The conference table of the project department can be used to display the length L of the device 2 6.2 meters, width D 2 is 0.6 meters. i 1 =L 2 / (L 1 +2l 2 )=1 / 300, i2=D ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com