Air-cooled high-temperature alloy carbon black reaction furnace and carbon black preparation method

A high-temperature alloy and air-cooled technology, which is applied in the field of air-cooled superalloy carbon black reactor and carbon black preparation, can solve the problems of affecting the quality of carbon black production and insufficient cooling methods of carbon black reactor, so as to reduce manpower and material resources Cost, air film integrity, reduced maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

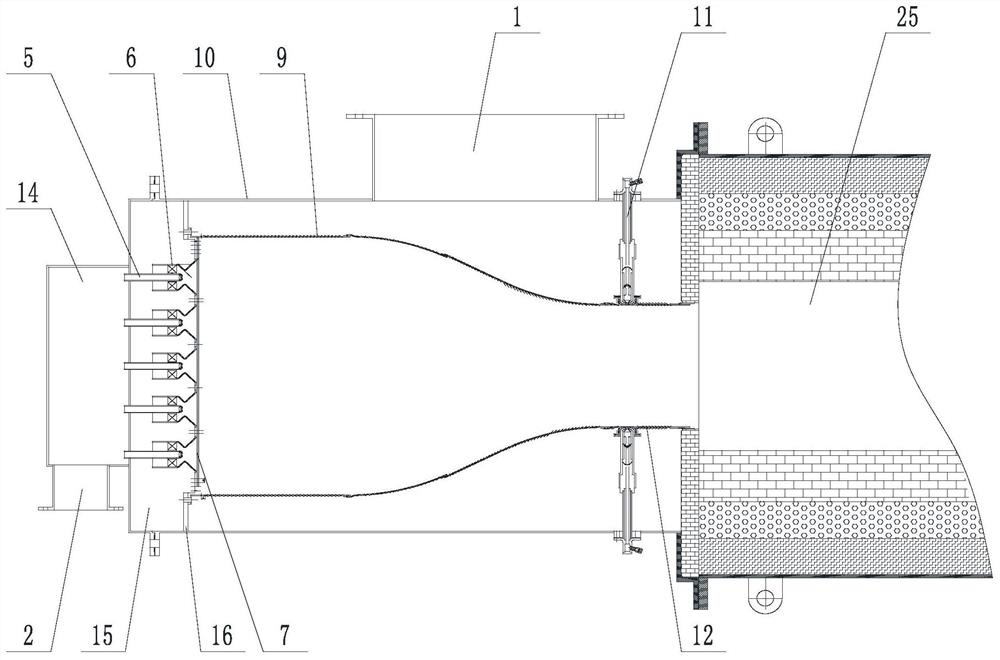

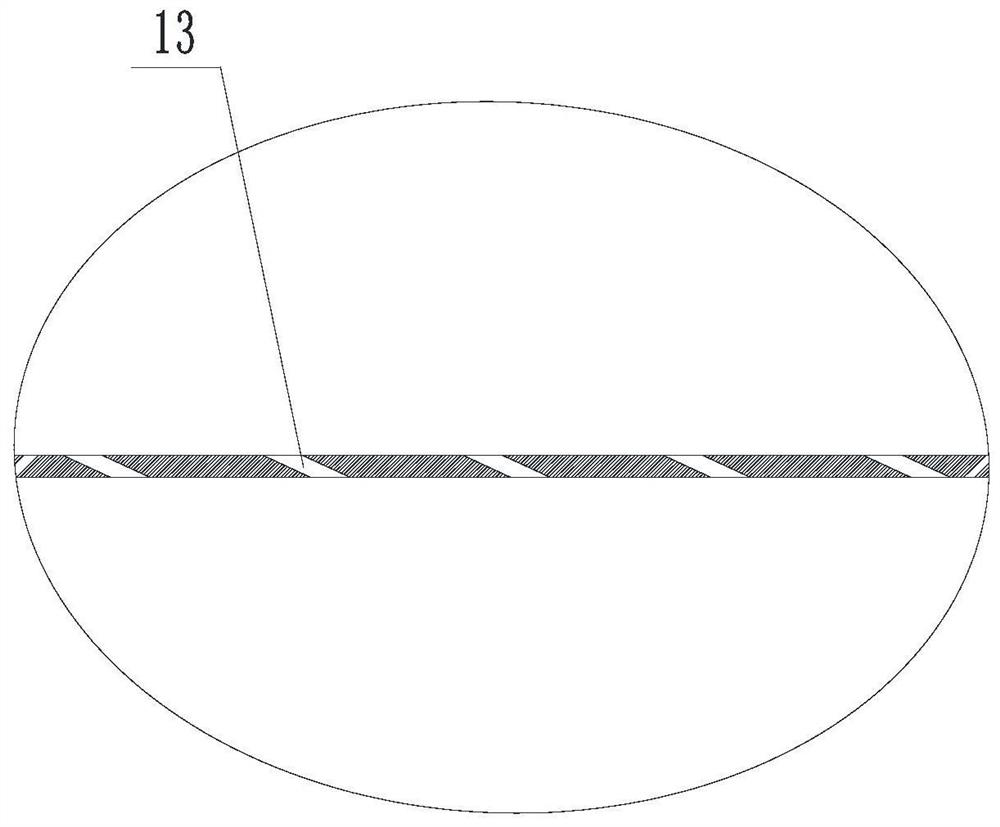

[0042]Such asfigure 1 versusfigure 2 The air-cooled superalloy carbon black reactor shown includes a casing 10, an air intake assembly 1 located on the casing 10, a gas fuel intake assembly 2, and a combustion chamber arranged in the casing 10, The combustion chamber has a throat section 12 on which a feed oil nozzle 11 is arranged. The combustion chamber includes a flame tube 9 on which a number of cooling holes 13 are arranged. The axis of the cooling hole 13 is determined by Inclined from outside to inside to the downstream direction. Wherein, the gas fuel intake assembly 2 is connected to the first gas collection cavity 14, and the air intake assembly 1 is connected to the second gas collection cavity 15; the gas fuel enters the flame tube 9 through the first gas collection cavity 14, and the air It enters the flame tube 9 through the cooling hole 13 and the second gas collecting cavity 15. In this embodiment, the flame tube 9 is made of high-temperature alloy material.

[0043]Pre...

Embodiment 2

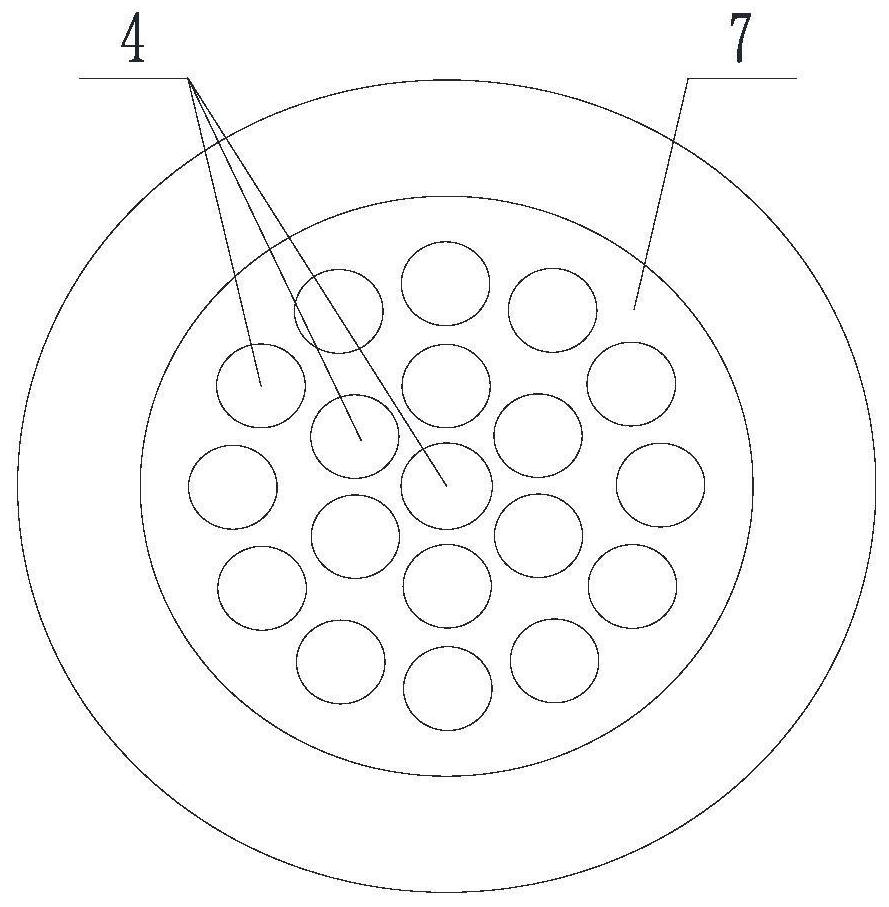

[0047]An air-cooled superalloy carbon black reactor, based on Example 1, asFigure 1 to Figure 5As shown, the flame tube 9 is connected to the inside of the receiver 10 through the receiver flange 16, and air can enter the second air collecting cavity 15 through the receiver flange 16; the second air collecting cavity 15 is located between the flame tube 9 and Between the first gas collection cavity 14. The head of the flame tube 9 is connected to the adapter plate 7, and the side of the adapter plate 7 away from the flame tube 9 is the second gas collecting cavity 15; the adapter plate 7 is provided with a number of through holes, and each through hole is The swirler 6 is installed correspondingly, each swirler 6 is inserted with a gas fuel nozzle 5; the inlet end of the swirler 6 is located in the second gas collecting cavity 15, and the inlet end of the gas fuel nozzle 5 is located in the first A collection cavity 14 in. Three circles of through hole groups are distributed on the ...

Embodiment 3

[0059]An air-cooled superalloy carbon black reactor. On the basis of Example 2, the cyclone in this example is asFigure 4 As shown, it includes a straight section 601, a reduced-diameter section 602, and an enlarged-diameter section 603 which are successively connected; the straight section 601 is provided with a swirling vane 604, and the swirling vane 604 is provided with a nozzle mounting hole 605, and the gas The fuel nozzle 5 passes through the nozzle installation hole 605.

[0060]The gas fuel nozzle 5 is in clearance fit with the nozzle mounting hole 605. The inlet end of the gas fuel nozzle 5 is in communication with the inlet end of the gas fuel. Such asFigure 5 As shown, the outlet end of the gas fuel nozzle 5 is located in the reduced diameter section 602.

[0061]A more preferred embodiment is that the cyclone 6 is welded or bolted to the adapter plate 7 and corresponds to the through holes 4 one-to-one; the adapter plate 7 is made of a high-temperature alloy material or a cer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com