Integrated-designed engine cylinder cover

An engine cylinder, integrated design technology, applied in the direction of engine components, machines/engines, cylinder heads, etc., can solve the problems of inconsistent engine lightweight design, inconvenient vehicle layout, no engine cylinder heads, etc., to reduce the number of cooling pipes Advantages of road layout, good fuel economy, lightweight design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

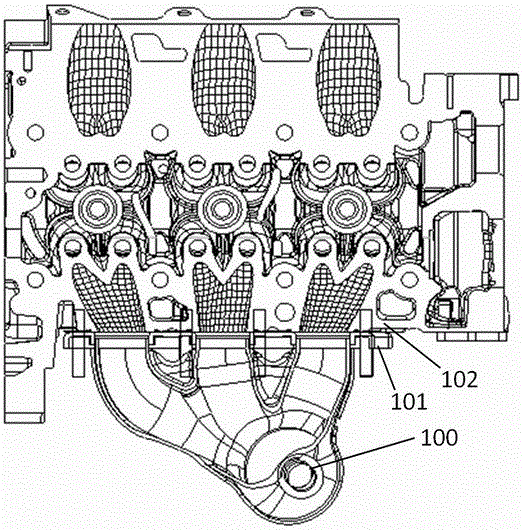

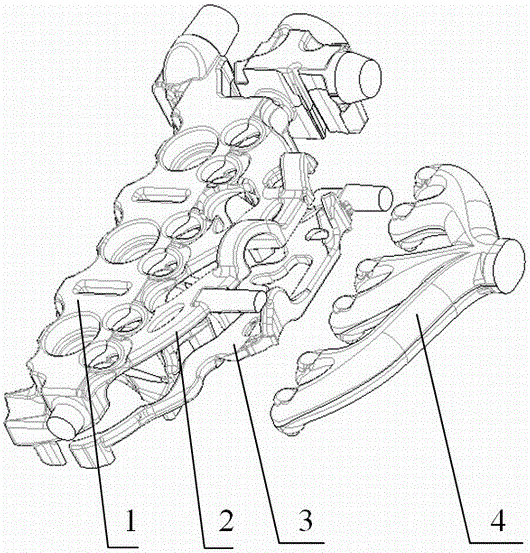

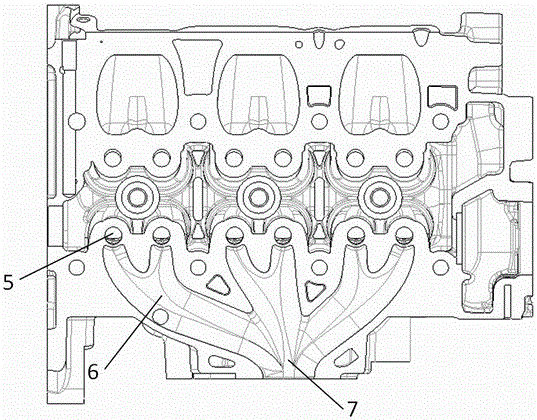

[0036] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can understand the present invention more clearly, but the protection scope of the present invention is not limited thereby.

[0037] The present invention proposes an engine cylinder head integrated with an exhaust manifold, an EGR cooling device and a secondary air channel device, based on the following technical starting points:

[0038] 1) In order to solve the defects of the existing technology that the cylinder head and exhaust manifold are designed separately, which may easily cause air leakage and poor cold start emission effect, the invention innovatively integrates the design of the exhaust manifold on the engine cylinder head;

[0039] 2) The EGR technology needs to be added to the engine technology upgrade, and the EGR gas needs to be cooled. In order to solve the problems of high cost and difficult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com