High temperature self-adaption separated air conditioners

An adaptive, split-type technology, applied in the direction of application, heating method, fluid circulation arrangement, etc., can solve the problems of increasing development costs and material costs, increasing condensers, etc., and achieve simple structure, improved flow coefficient, and preventive protection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

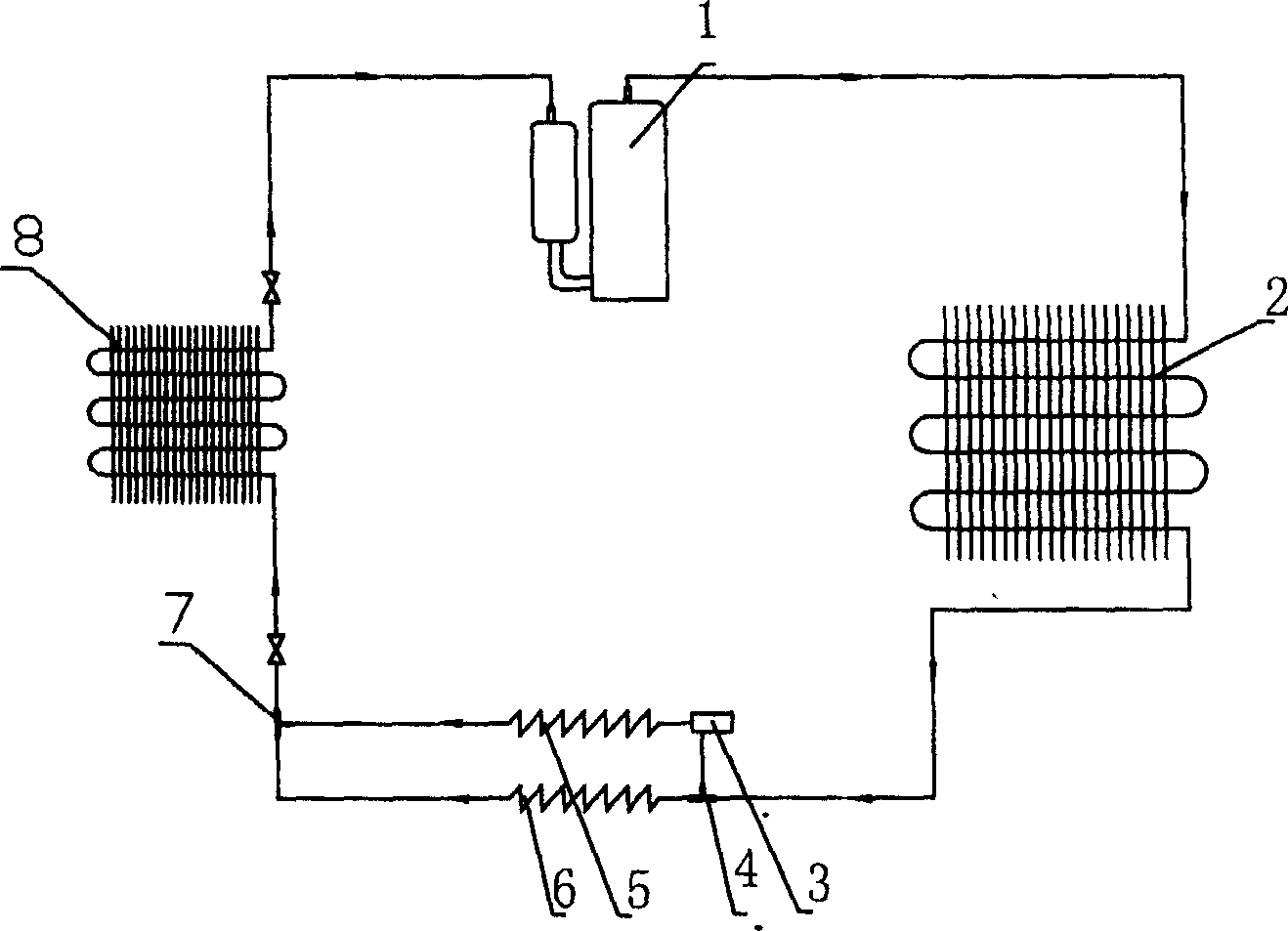

Embodiment 1

[0021] like figure 1 As shown, the refrigeration circuit of Embodiment 1 of the present invention includes: a compressor 1, a condenser 2, an unloading valve 3, a filter 4, an auxiliary capillary 5, a main capillary 6, a tee 7, and an evaporator 8, wherein the filter The inlet of the filter 4 is connected to the outlet of the condenser 2, the two outlets of the filter 4 are respectively connected to the unloading valve 3 and the main capillary 6, and the auxiliary capillary 5 is connected to the inlet liquid supply pipe of the evaporator 8 through the tee 7.

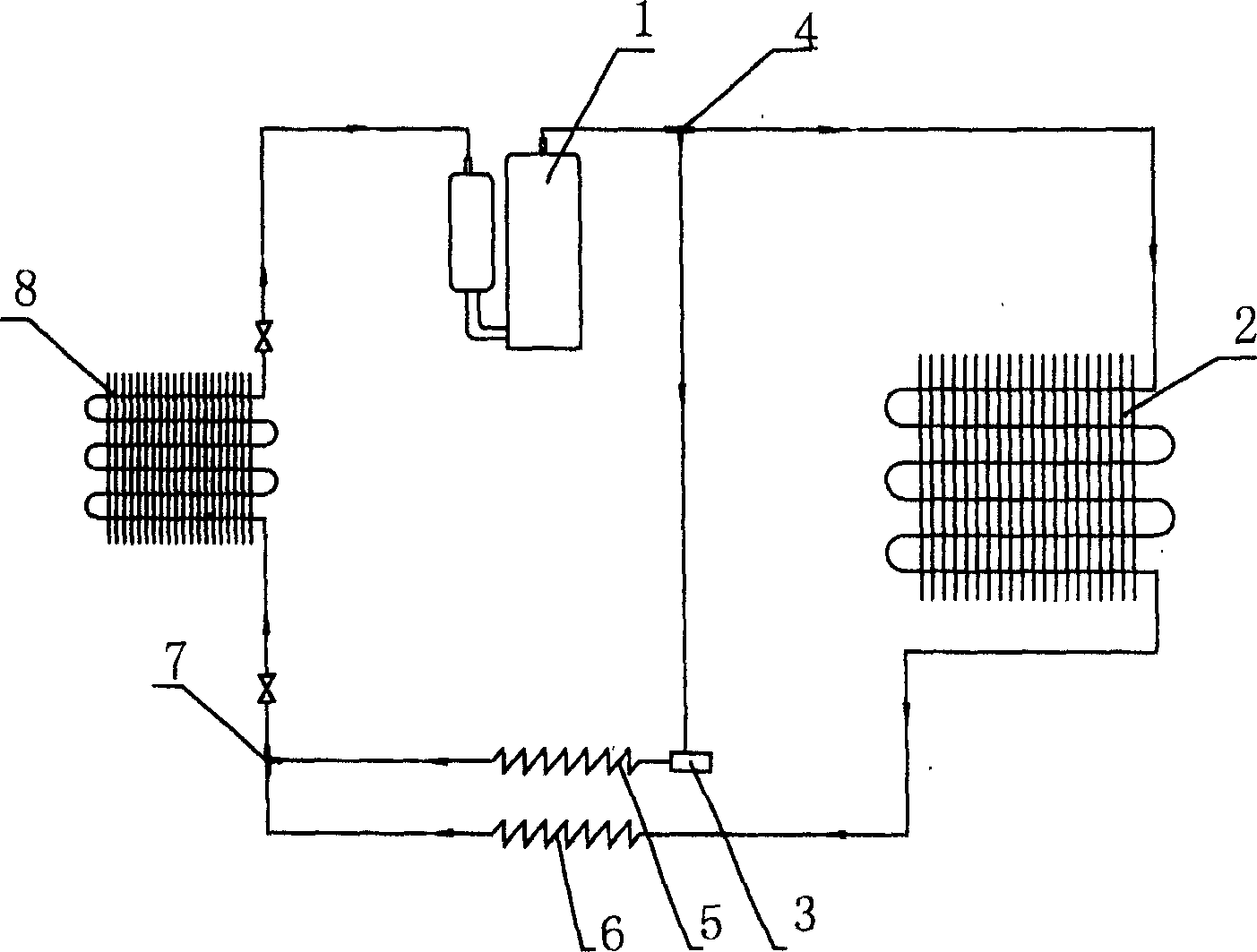

Embodiment 2

[0023] like figure 2 As shown, the refrigeration circuit of the second embodiment of the present invention includes: a compressor 1, a condenser 2, an unloading valve 3, a filter 4, an auxiliary capillary 5, a main capillary 6, a tee 7, and an evaporator 8, wherein the filter The inlet of the filter 4 is connected to the exhaust pipe of the compressor 1, the two outlets of the filter are respectively connected to the unloading valve 3 and the inlet of the condenser 2, and the auxiliary capillary 5 is connected to the inlet liquid supply pipe of the evaporator 8 through the tee 7.

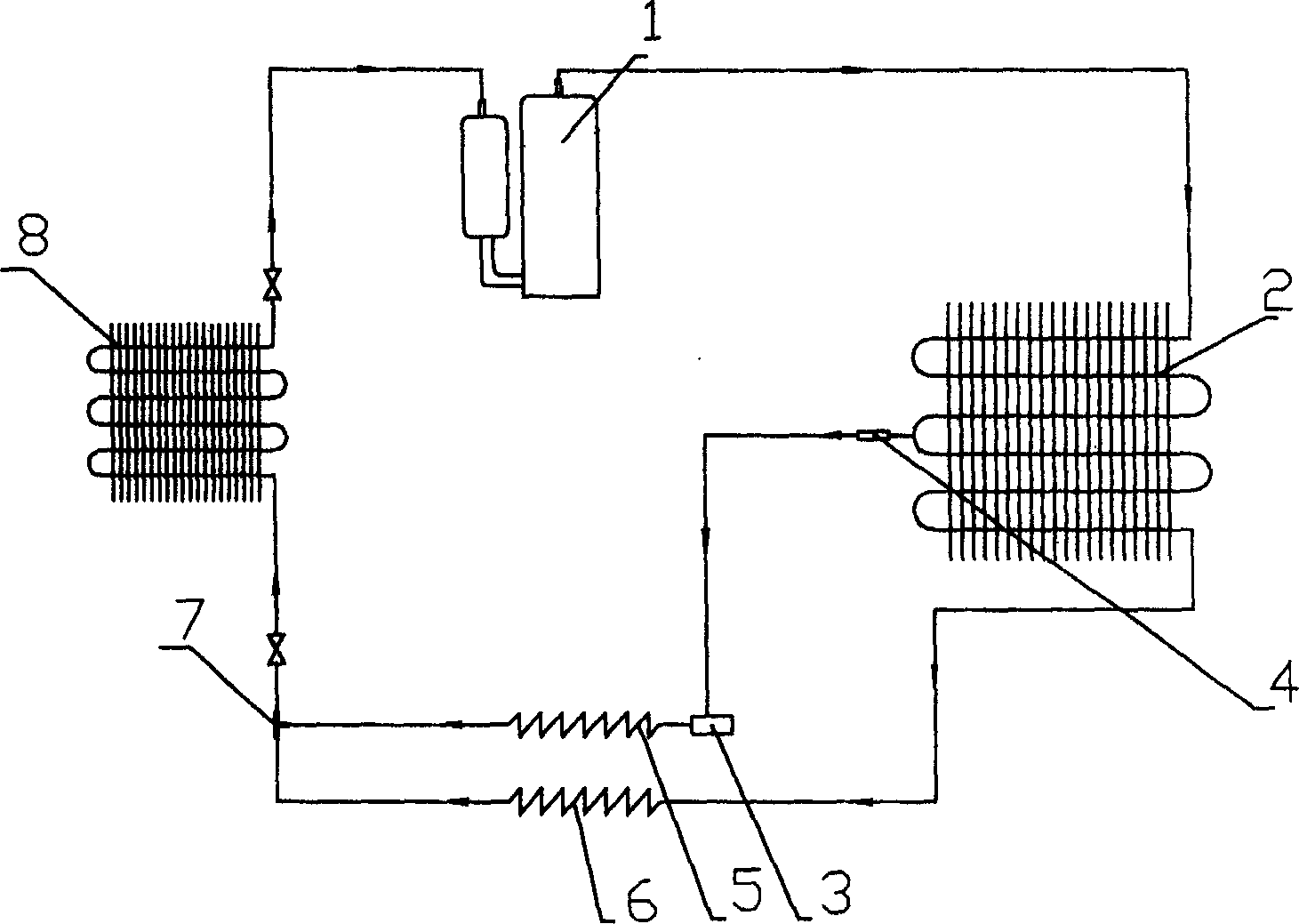

Embodiment 3

[0025] like image 3 As shown, the refrigeration circuit of the third embodiment of the present invention includes: a compressor 1, a condenser 2, an unloading valve 3, a filter 4, an auxiliary capillary 5, a main capillary 6, a tee 7, and an evaporator 8, wherein the filter The inlet of the filter 4 is connected to the middle of the condenser 2, the outlet of the filter is connected to the unloading valve 3, and the auxiliary capillary 5 is connected to the liquid supply pipe at the inlet of the evaporator 8 through the tee 7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com