Boiler combustion method of biochemical industry alcohol waste liquid

A biochemical and boiler combustion technology, which is applied in the direction of combustion methods, combustion control, and combustion equipment, can solve the problems of inapplicability of biochemical alcohol factories, inability to fully recover waste liquid, and high operating costs, so as to facilitate the adjustment of boiler load, The effect of increasing furnace temperature and improving operation level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

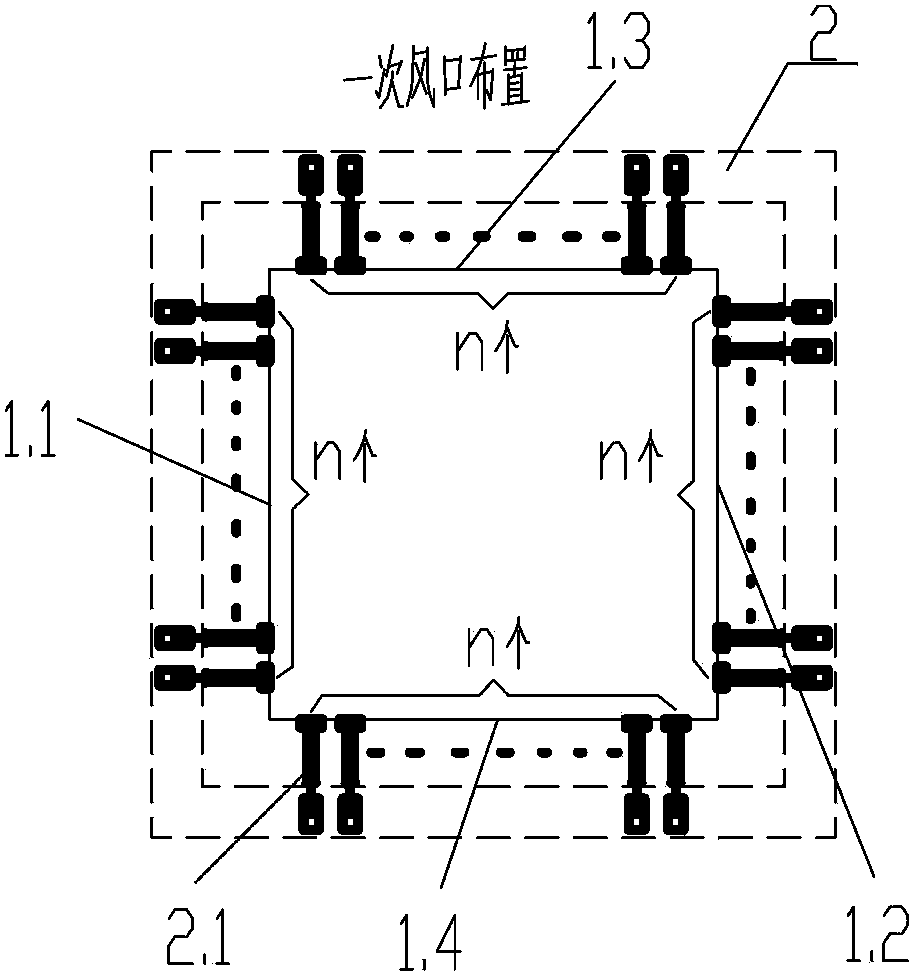

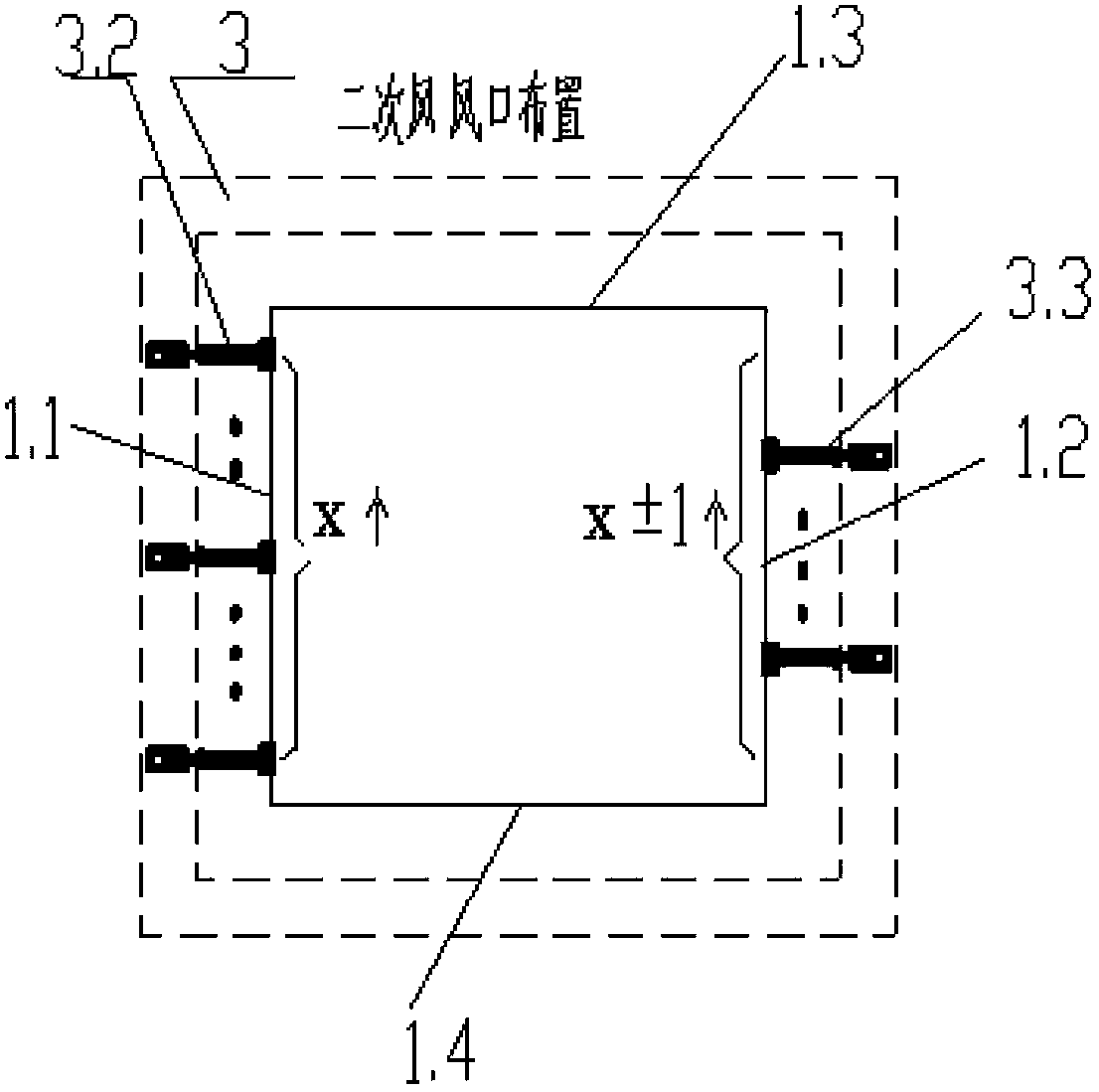

[0028] The combustion air distribution of chemical alcohol waste liquid combustion boiler adopts graded air supply. The waste liquid combustion boiler adopts at least two levels of air supply, namely primary air and secondary air, and the configuration of the tertiary air is determined according to the layout of the waste liquid burner. If the waste liquid burner is arranged between the primary air and the secondary air, the tertiary air is optional; if the waste liquid burner is arranged above the secondary air, the tertiary air must be arranged above the waste liquid burner.

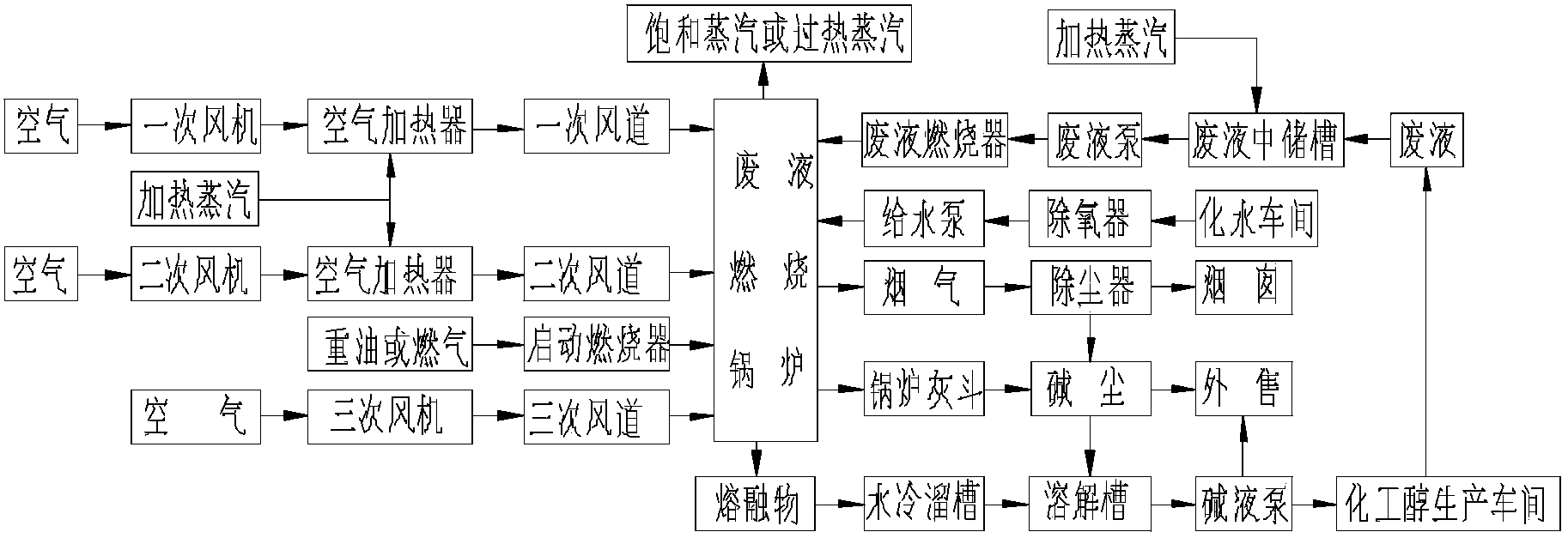

[0029] Such as figure 1 As shown, the waste liquid from the chemical alcohol production workshop is sent to the waste liquid medium storage tank, and the steam heating coil is arranged in the medium storage tank to ensure that the temperature of the waste liquid reaches 100°C to 150°C. Start the primary fan and the secondary fan, open the air heater to heat the steam regulating valve, and make the tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com