Electric glass melting furnace work simulating method and application thereof

A technology of glass electromelting and simulation methods, applied in special data processing applications, electrical digital data processing, instruments, etc., can solve the problems of small application range, troublesome software training, high cost, etc., to reduce the difficulty of process control and improve energy Utilization rate, the effect of saving production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with specific examples, but not as a limitation of the present invention. In the following description, different "one embodiment" or "embodiment" do not necessarily refer to the same embodiment. Furthermore, the particular features, structures, or characteristics of one or more embodiments may be combined in any suitable manner.

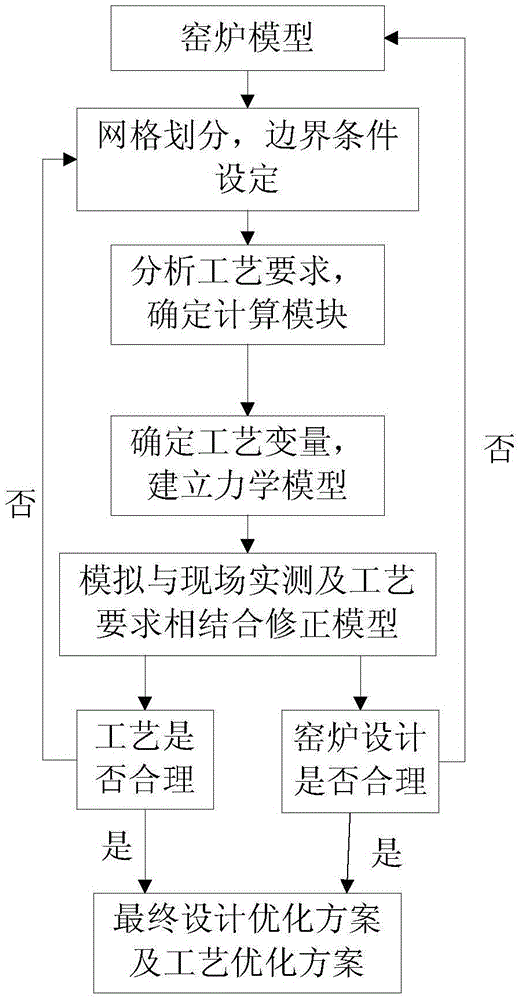

[0037] figure 1 It is a schematic flow chart of the working simulation method of the glass electric melting furnace and its application according to the embodiment of the present invention. see figure 1 , the working simulation method of glass electric melting furnace, the simulation method is based on fluent software, including the following steps:

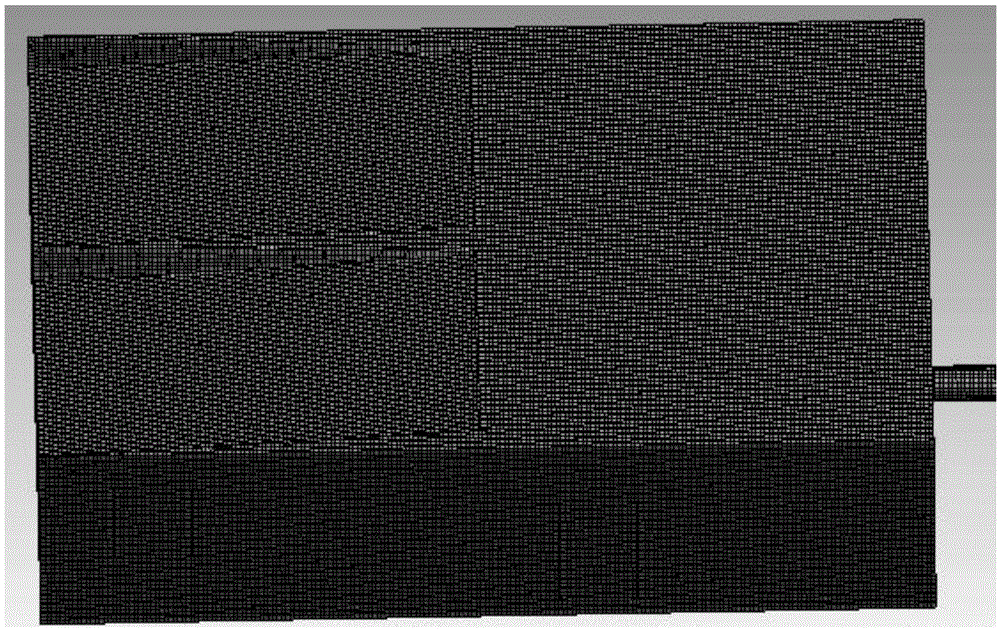

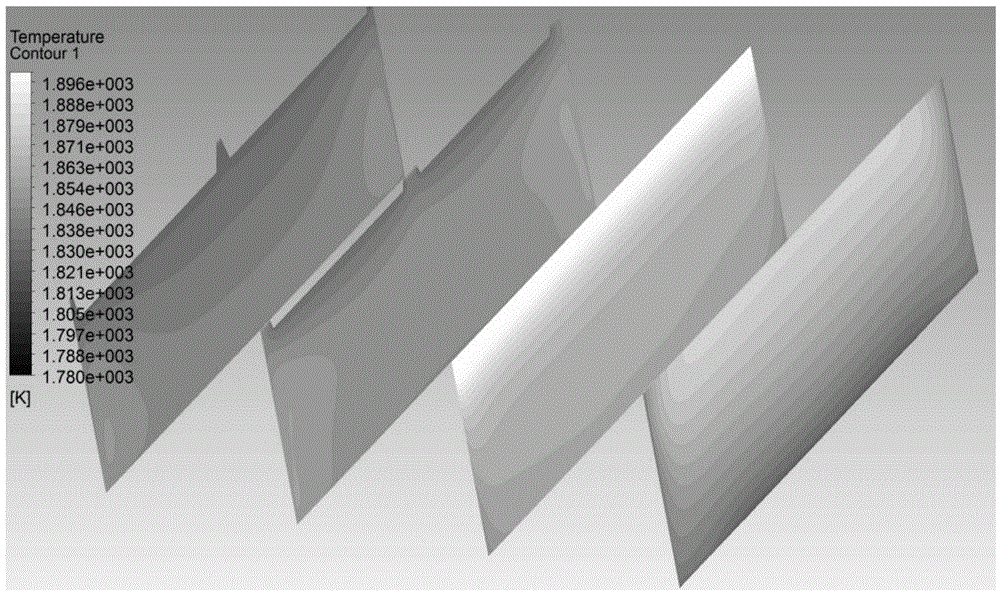

[0038] Establish a geometric model of the molten glass based on the glass thermal furnace, and divide the grid. In the model and grid, the electrode surface and the adjacent insulating refractory material area are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com