Centre spinning cold gas, fog cooling system and method

A technology of centrifugal casting and cooling system, which is applied in the mist cooling system and the air field of the centrifugal casting process, which can solve the problems of uneven structure of the outer layer of the roll, uneven erosion of the upper and lower thickness, and decline in the performance of the roll, so as to reduce the pressure of the upper and lower parts. Uneven thickness, low mold weight, and improved mold rigidity

Active Publication Date: 2009-04-08

中国冶金科工股份有限公司

View PDF0 Cites 12 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

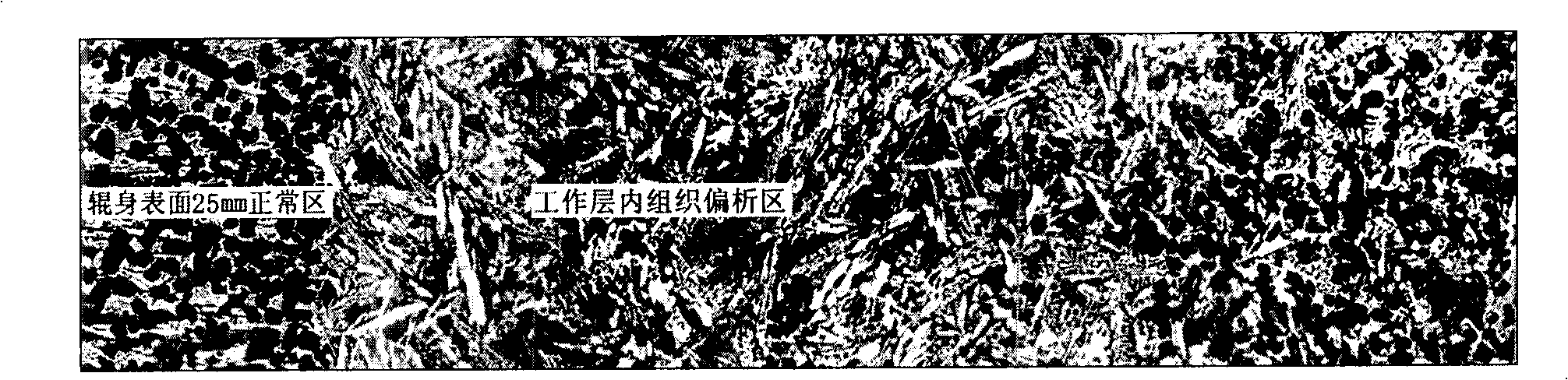

[0003] Due to the centrifugal roll casting, especially the centrifugal casting of high-alloy cast iron rolls containing graphite and carbide, the control of its structure is mainly realized by the quenching of the mold, and the cooling capacity of the mold varies with the heat storage and time of the mold. Therefore, the structure of the outer layer of the roll in the traditional process method inevitably has unevenness, and the structure of the outer layer gradually becomes coarser inward, resulting in a significant decline in the performance of the roll in the middle and late stages of use; moreover, due to the centrifugal roll core filling The composite

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Surface temperature | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses an air fog cooling system and an air fog cooling method for a centrifugal casting cold mold. The cooling system comprises a water collecting pipe, an air header and a plurality of groups of air fog cooling nozzles, wherein the water collecting pipe and the air header are arranged parallel to the axial line of a centrifugal machine, each group of air fog cooling nozzles are provided with a water inlet connected with the water collecting pipe, an air intake connected with the air header and an air fog mixing spray head respectively, the air fog mixing spray heads are arranged towards a centrifugal casting mold to mix compressed air entering the air intake and high pressure water entering the water inlet according to the adjusted proportion into fog and then spray the fog to corresponding outer surfaces of the cold mold from nozzle mouths. The system and the method realize the adjustment of a temperature field during the centrifugal casting, realize the effective control of structural segregation and open grain during the solidification, and have functions of slowing the structural segregation and the open grain of a working layer, can realize the effective control of the upper and lower corrosion amount and the quality of a bonding layer during the vertical core-filling, and have functions of reducing the thickness difference of the working layer and improving the quality of the bonding layer at both ends of a roller.

Description

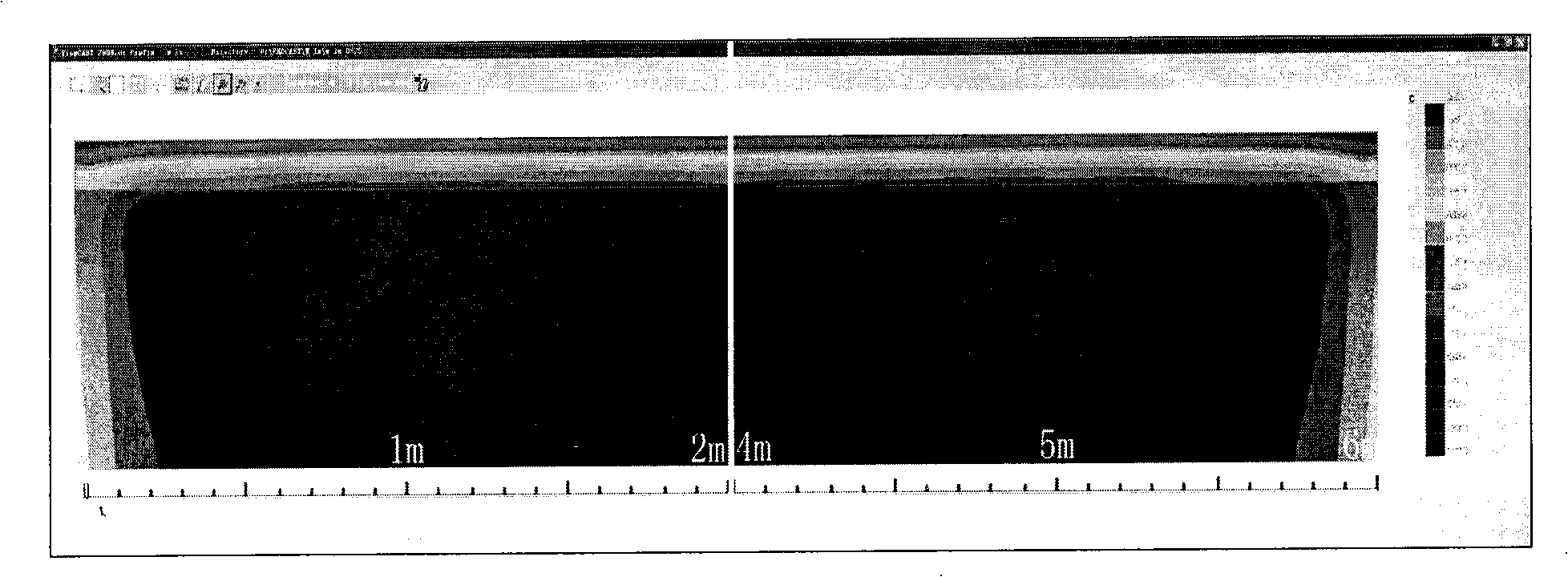

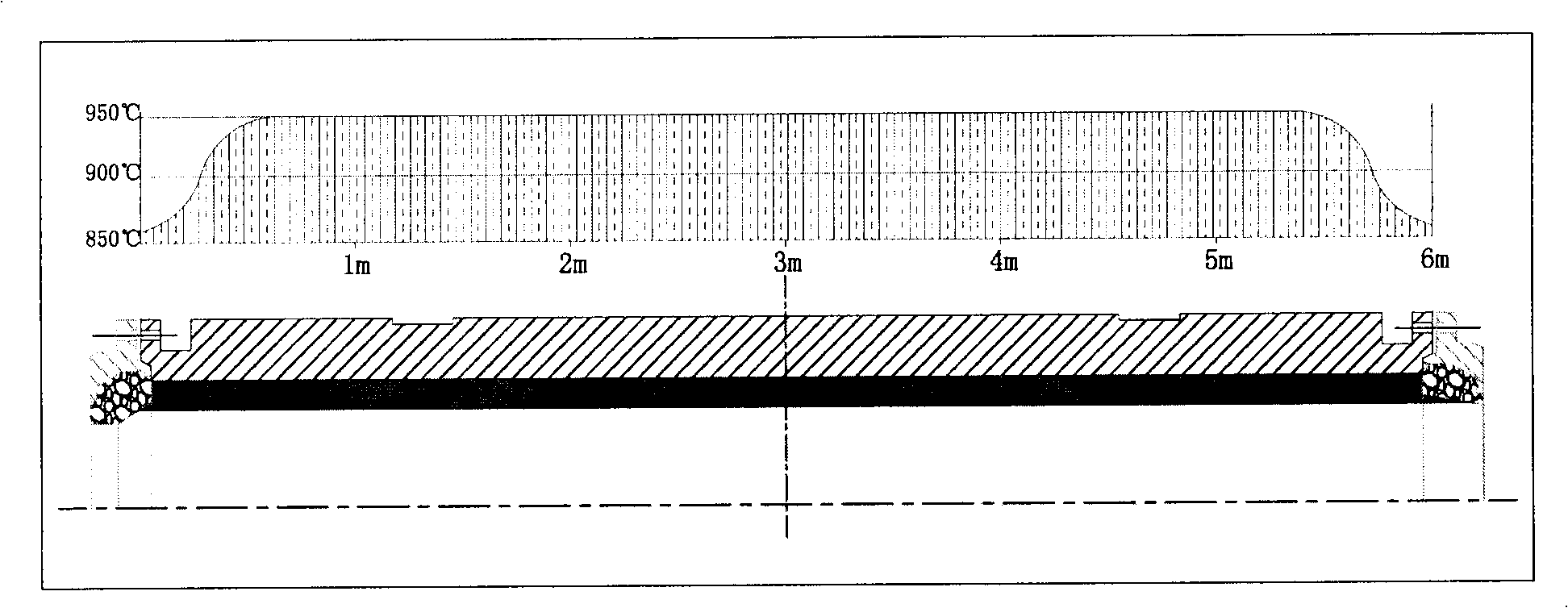

technical field [0001] The invention relates to the field of centrifugal manufacturing, in particular to a gas and mist cooling system and method for centrifugal casting process cooling. Background technique [0002] As everyone knows, the existing centrifugal casting roll cooling method is that the rotating mold is naturally cooled in the air, and there is no control ability. Taking the pouring and cooling of Φ1250×5000 roll as an example, the wall thickness of the traditionally designed cold form is about 300mm, and the weight of the cold form is 73000Kg. Taking the cast ICDP roll as an example, figure 1 , figure 2 They are respectively the cloud diagram of the temperature distribution of Φ1250×5000 roll working layer using traditional centrifugal casting cold mold natural cooling CAE and the corresponding temperature distribution diagram. image 3 shown. [0003] Due to the centrifugal roll casting, especially the centrifugal casting of high-alloy cast iron rolls cont...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B22D13/10

Inventor 周守航韩庆礼黄衍林张西鹏刘艳

Owner 中国冶金科工股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com