A working method of an active temperature-controlled LED high-power drive circuit

A technology of driving circuit and working method, which is applied in the direction of electric lamp circuit arrangement, electric light source, lighting device, etc., to achieve the effect of cooling control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

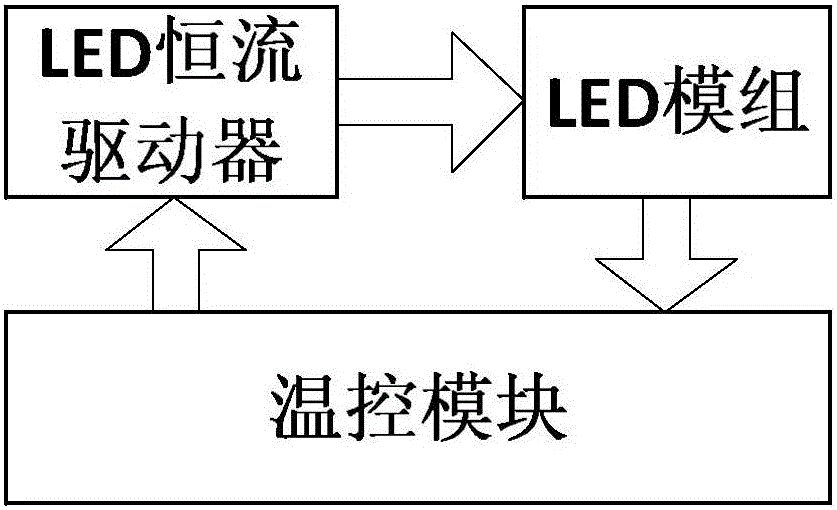

[0026] Such as figure 1 As shown, an active temperature-controlled LED high-power drive circuit includes: an LED constant current driver, an LED module connected to the output end of the LED constant current driver, and an LED operating temperature suitable for collecting from the LED module end to control The temperature control module of the current reference voltage of the LED constant current driver.

Embodiment approach

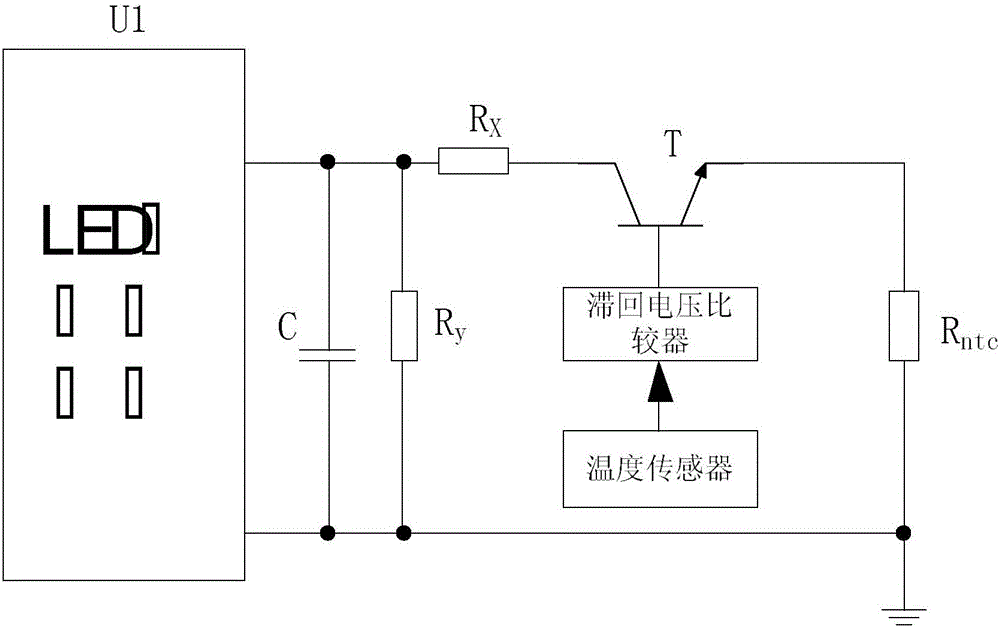

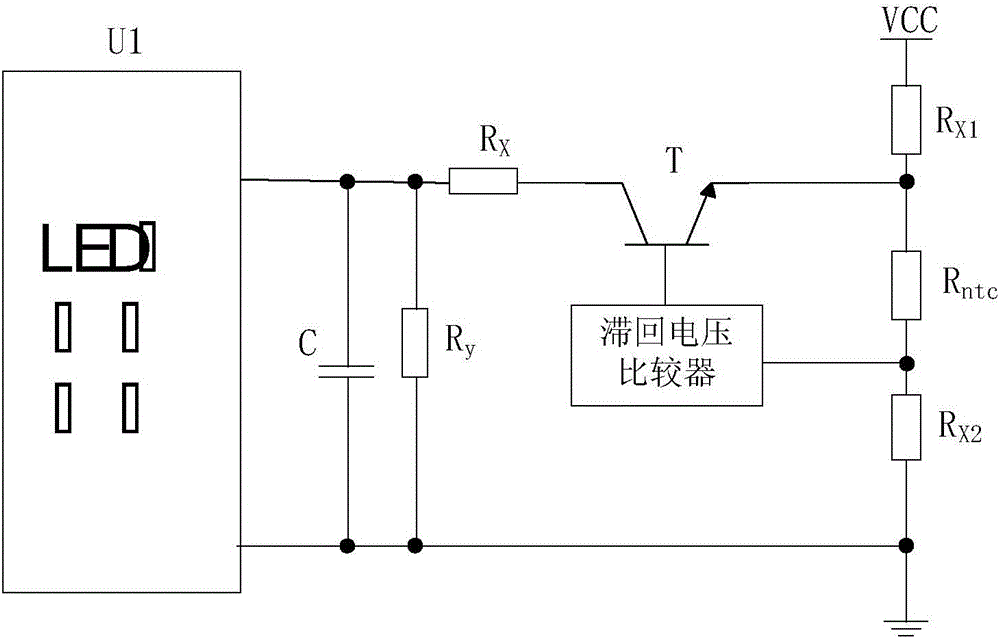

[0027] Such as figure 2 with image 3 As shown, two implementations of the temperature control module include:

Embodiment approach 1

[0029] The temperature control module includes: a temperature sensor, a thermistor located at the end of the LED module, the thermistor is connected to the current reference voltage terminal of the LED constant current driver through a switch tube; the analog signal output terminal of the temperature sensor It is connected to the non-inverting input terminal of a hysteresis voltage comparator, and the inverting input terminal of the hysteresis voltage comparator is connected to a reference voltage U R , the output terminal of the hysteresis voltage comparator is connected to the control terminal of the switching tube T.

[0030] The current reference voltage terminal may also be referred to as a feedback control terminal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com