A Method for Automatic Elimination of Temperature Difference Drift by Ultrasonic Propagation

An ultrasonic and temperature difference technology, applied in the field of touch screen, can solve the problems of ultrasonic propagation speed change, touch coordinate drift and touch accuracy, and achieve the effect of eliminating temperature difference drift, high accuracy and simple algorithm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

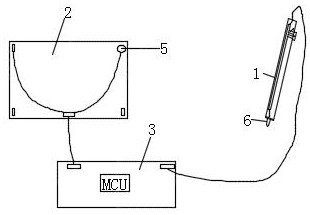

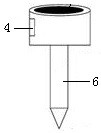

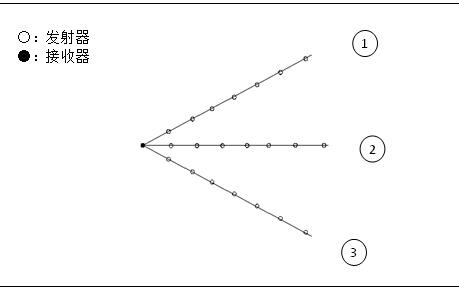

[0025] A method for ultrasonic transmission to automatically eliminate temperature difference drift. First, set the initial velocity of ultrasonic wave as V0, the initial temperature of ultrasonic pen 1 as T0, the real-time temperature of ultrasonic pen 1 as T0', the initial temperature of touch screen body 2 as T1, and the real-time temperature of touch screen body 2. The temperature is T1'. Wherein, the initial velocity V0 of the ultrasonic wave, the initial temperature T0 of the ultrasonic pen 1 and the initial temperature T1 of the touch screen body 2 are stored in the non-volatile memory module of the controller 3 .

[0026] When writing, when the controller 3 detects that the temperature difference between the real-time temperature T0' of the ultrasonic pen 1 and the initial temperature T0 of the ultrasonic pen 1 is greater than the set threshold, the controller 3 corrects the initial ultrasonic velocity V0 to the real-time propagation velocity V1, the The real-time prop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com