Natural circulation split tube-and-shell type waste heat boiler capable of optimizing flow field arrangement

A natural circulation and waste heat boiler technology, applied in water tube steam boilers, steam boilers, steam boiler accessories, etc., can solve the problems of shortening the service life of heat exchange tubes, cracking and leakage of tube plates, and large heat flux density, etc., to reduce fluctuations , solve the effect of flow stagnation or even backflow, and avoid obstruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in further detail below in conjunction with the accompanying drawings.

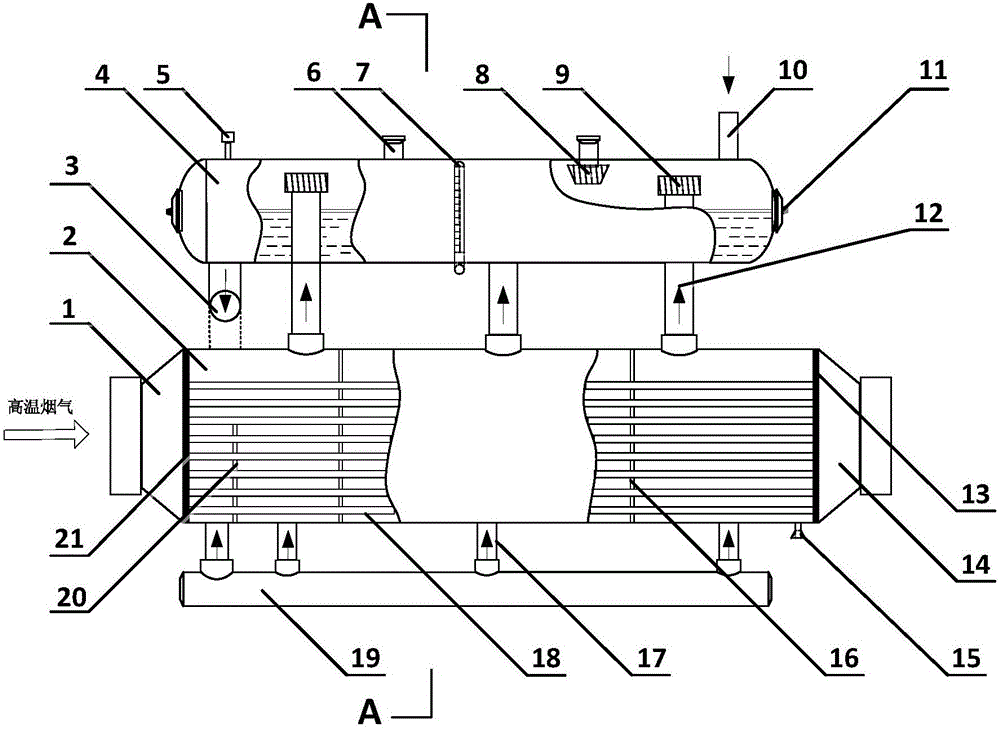

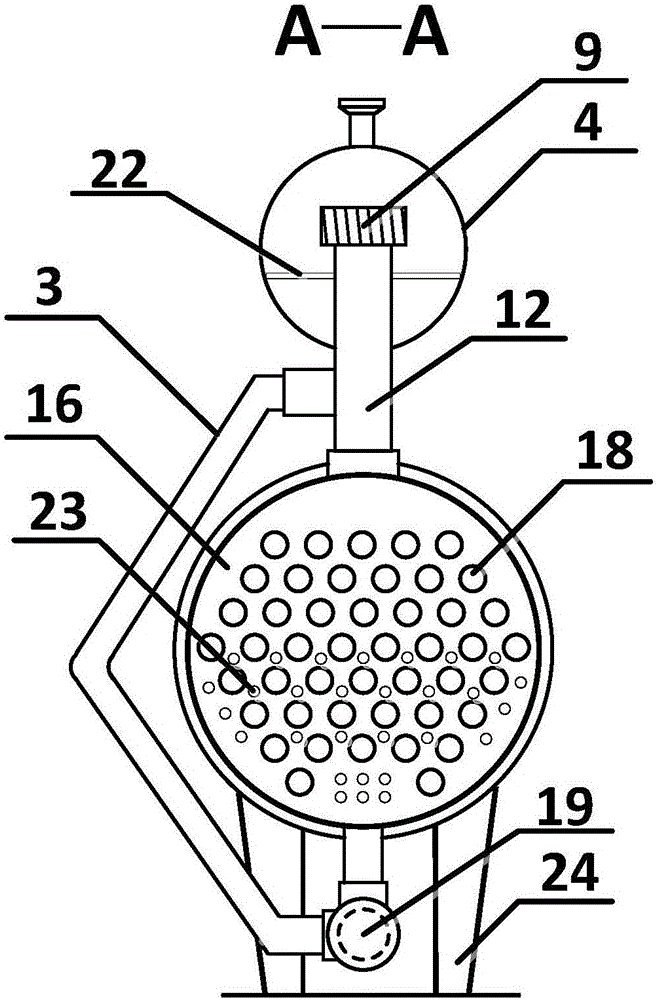

[0042] see figure 1 with figure 2, the present invention includes a drum 2 and a steam drum 4 arranged sequentially from bottom to top, and the drum 2 is installed on a boiler support 24; wherein the drum 2 includes a shell, and a vertical front tube plate 21 and a rear tube plate 21 are installed in the shell. The tube sheet 13 , the front tube sheet 21 and the rear tube sheet 13 divide the interior of the shell into a flue gas inlet 1 , a heat exchange chamber and a flue gas outlet 14 in sequence.

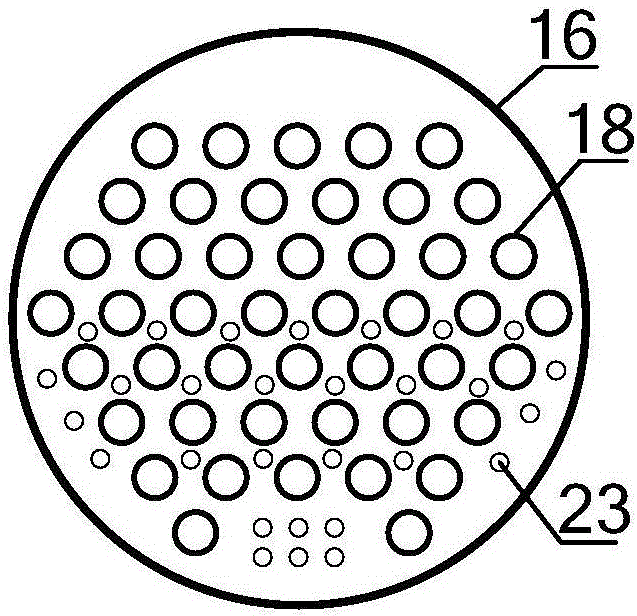

[0043] The lower side of the heat exchange chamber is connected to the water collection pipe 19 through several first water distribution pipes 17 arranged side by side; a heat exchange tube bundle is arranged in the heat exchange chamber, and the two ends of the heat exchange tube bundle are respectively expanded and welded with the front tube plate 21 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com