Integral spinning forming method of shock-absorbing shell with cooling fins

A technology of spin forming and heat sink, applied in the field of shock absorbing shell processing, can solve the problems of poor heat dissipation effect of shock absorbing shell and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

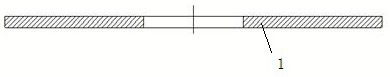

[0038] Example 1, a method for integral spinning of a shock-absorbing shell with cooling fins, the steps are as follows: S1: Laser blanking: use 8-10 mm thick hot-rolled thick steel plates, and the thickness of hot-rolled thick steel plates varies according to the model used , using different thicknesses, and then laser cutting the sheet to obtain a circular sheet, and then blanking to obtain a center hole to form a circular sheet with a center hole 1, such as figure 1 as shown,

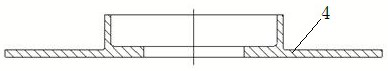

[0039]S2: Shoveling inner cylinder: install the upper and lower molds I and two scooping wheels I2 on the CNC spinning machine, that is, the first scooping wheel and the second scooping wheel, and the edge angle radius of the scooping wheel I2 is preferably 2.0 mm, control the rotation speed of the upper and lower mold I to 300-400rpm, use the first scooping wheel and the second scooping wheel to scoop the circular sheet at the same time, form a boss on the circular sheet 1, and control the scooping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com