Integral spinning forming method of crankshaft silicon oil shock absorber housing

A technology of spinning forming and shock absorber, which is applied in the field of integral spinning forming of crankshaft silicone oil shock absorber shell, can solve the problems of low material utilization rate, shortage of material defects, low corrosion resistance of parts, etc. Application value and development prospects, guaranteed service life, and excellent overall mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

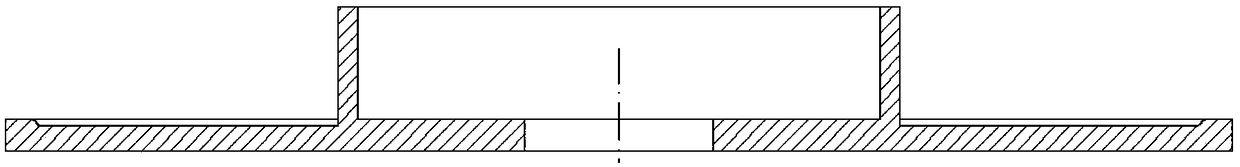

[0042] The technical solutions of the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

[0043] Such as Figure 1-7 As shown, the integral spin forming method of a crankshaft silicon oil shock absorber housing disclosed by the present invention specifically includes the following steps:

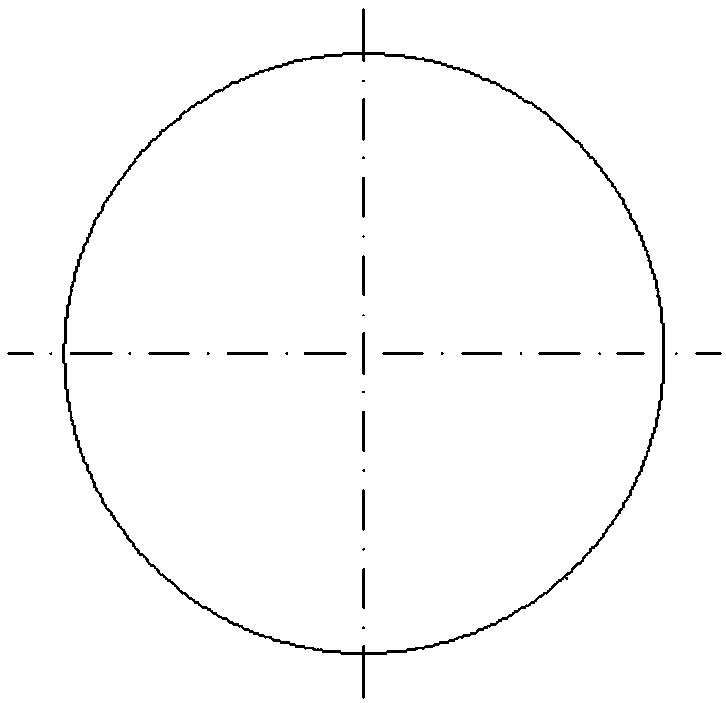

[0044] a. Blanking: use 8-11mm thick hot-rolled thick steel plates to cut and blank the plates to obtain round plates (see figure 1 ).

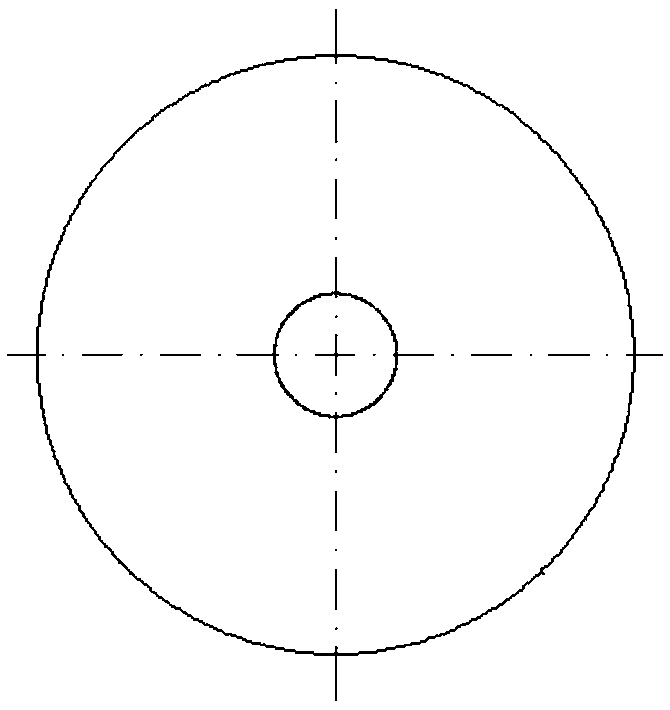

[0045] B, punching the center hole: utilize punching machine to carry out punching center hole to the round plate material that step a obtains, make the circle plate material with center hole (referring to figure 2 ), the role of the middle hole facilitates the fixation and positioning of the subsequent process.

[0046] c. Thickening by shoveling: use two shoveling wheels on the CNC spinning machine to exert pressure on the circular sheet in step b in the axial direction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com