Slab continuous casting crystallizer flow field control method

A slab continuous casting and control method technology, which is applied in the field of slab continuous casting mold control, can solve problems such as inability to effectively improve the flow field state of the mold, excessive local flow velocity, and partial flow, etc., and achieve an improvement in the flow field of the mold , the effect of improving the quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

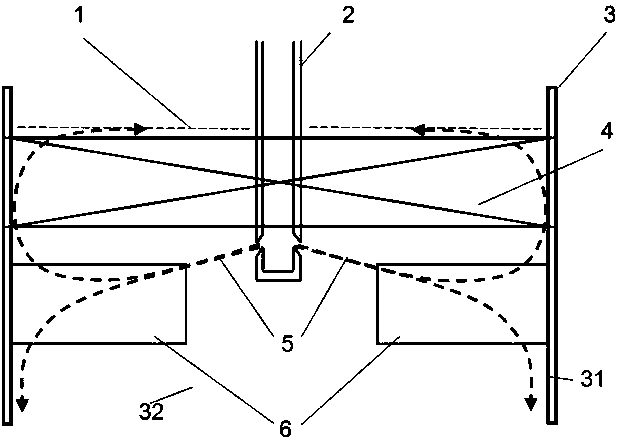

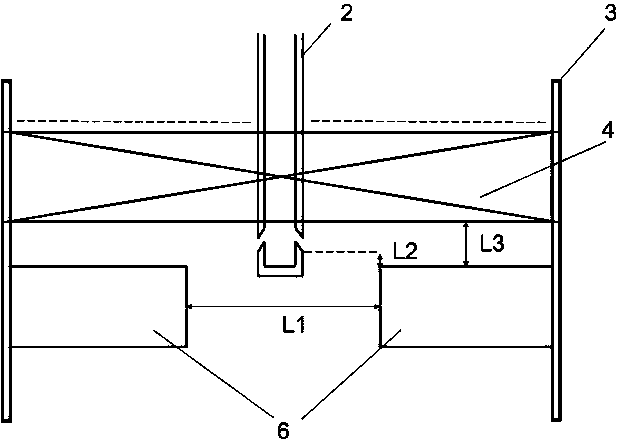

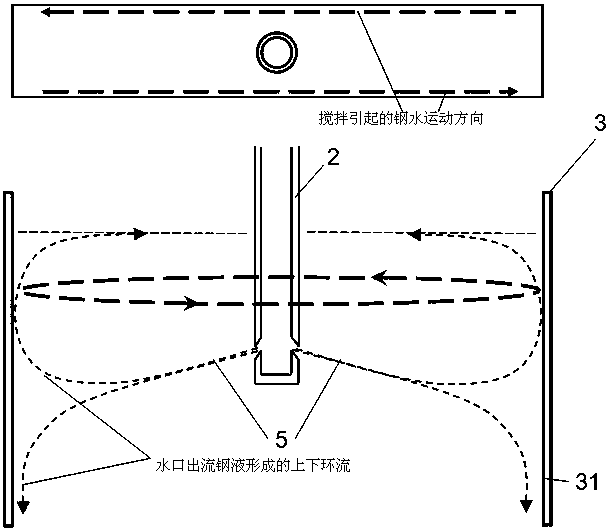

[0029]Production conditions: Production of IF steel plates with a casting speed of 1.6m / s, a width of 1450mm, and a thickness of 230mm. The insertion depth of the nozzle (that is, the distance from the meniscus to the upper edge of the nozzle) is 190mm. For such working conditions, the method of the present invention is used to simultaneously use an electromagnetic stirring device and an electromagnetic braking device, that is, an electromagnetic stirring device is used on the upper part of the crystallizer, and an electromagnetic braking device is used on the lower part.

[0030] On one side of the wide surface of the crystallizer, the iron core height of the electromagnetic stirring device 4 installed on the upper part is 150mm, and the installation position is between the upper edge of the nozzle outlet and the meniscus, and the coverage ratio of the effective stirring area is greater than 0.75. Two electromagnetic brake devices 6 are installed in the lower part as a group, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com