Layered micro-channel reactor with uniformly distributed micro-channel flow velocities

A microchannel reactor, stacked technology, applied in chemical instruments and methods, chemical/physical/physicochemical processes, chemical/physical processes, etc., can solve high manufacturing costs, large flow pressure drop loss, high flow path system Power and other issues, to achieve the effect of improving the uniformity of flow velocity distribution, improving heat and mass transfer performance, and reducing pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

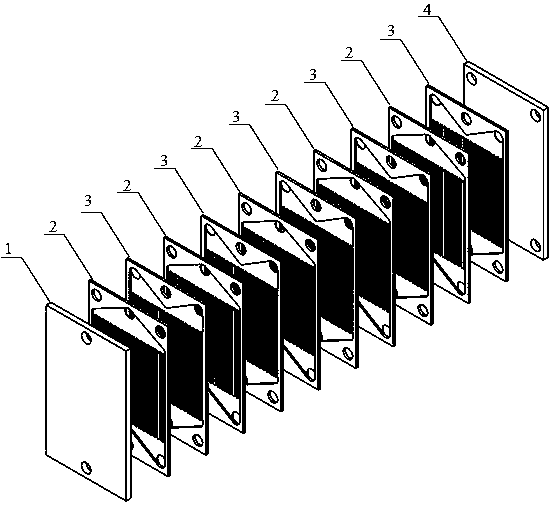

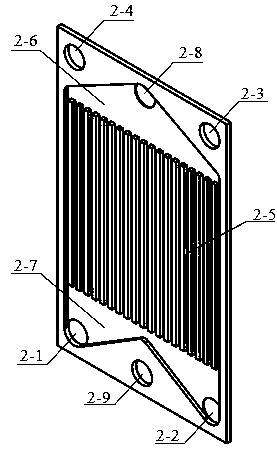

[0038] Figure 6 It is a schematic diagram of the structure of a microchannel reactor for methanol steam autothermal reforming to produce hydrogen. The microchannel reactor is coupled with methanol steam reforming reaction and methanol catalytic combustion reaction. The heat required for methanol steam reforming reaction is provided by the heat released by methanol combustion, mainly including inlet cover plate 1 and two first reaction plates 2. A second reaction plate 3 and an outlet cover plate 4; wherein:

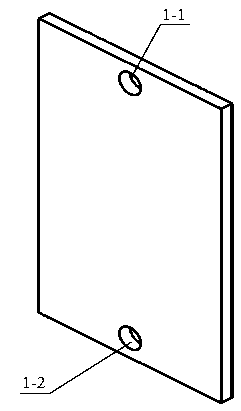

[0039] The inlet cover plate 1 is a rectangular stainless steel plate with a first reaction fluid inlet 1-1 processed in the middle of the top, a second reaction fluid inlet 1-2 in the middle of the bottom of the inlet cover 1, and the first reaction fluid inlet 1-1 through Methanol and water vapor are fed in, which is a channel for methanol steam reforming reaction, and methanol and air are introduced into the second reaction fluid inlet 1-2, which is a channel for met...

Embodiment 2

[0051] The structure of the microchannel reactor of this embodiment is basically the same as that of Example 1, except that the microchannel reactor of this embodiment is used as a heat exchanger. The two working medium fluids entering the microchannel reactor are cold fluid and hot fluid, which enter from one inlet and flow out from two outlets, which can improve the uniformity of the flow velocity distribution of the microchannel array, reduce the temperature gradient, and improve the efficiency of the heat exchanger , The shunt structure is also beneficial to reduce the pressure drop.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com