Spray reinforcing low-finned tube indirect evaporative cooler

An evaporative cooler, indirect technology, applied in indirect heat exchangers, tubular elements, heat exchanger types, etc., to achieve the effect of improving heat and mass transfer, strengthening heat transfer, and increasing contact time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

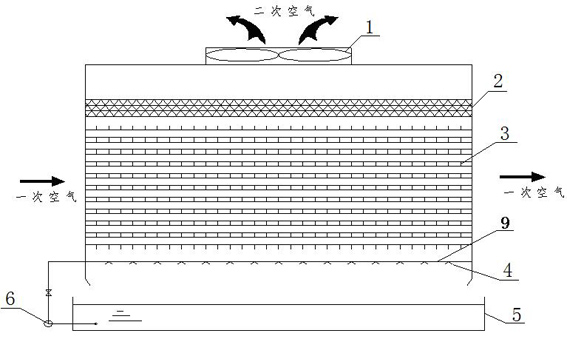

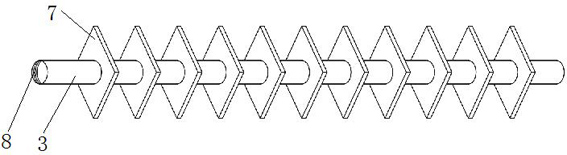

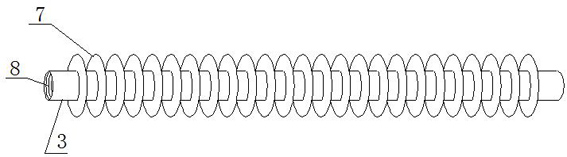

[0026] The structure of the spray-enhanced low-fin tube type indirect evaporative cooler of the present invention is as follows: figure 1 As shown, the secondary fan 1, the water retaining filler 2, the heat exchange tube group composed of multiple heat exchange tubes 3 placed horizontally in multiple rows and rows, the spray water pipe 9 and the water tank 5 are arranged in sequence from top to bottom, and the replacement The radial direction of the heat pipe 3 is consistent with the flow direction of the primary air that enters horizontally, and the air inlet faces of the secondary air are respectively set in four directions between the spray water pipe 9 and the water tank 5, and the air inlet faces are two by two. Symmetrical arrangement. The spraying water pipe 9 is provided with a plurality of downward spraying nozzles 4, and also inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com