Patents

Literature

31results about How to "Efficient Waste Heat Recovery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

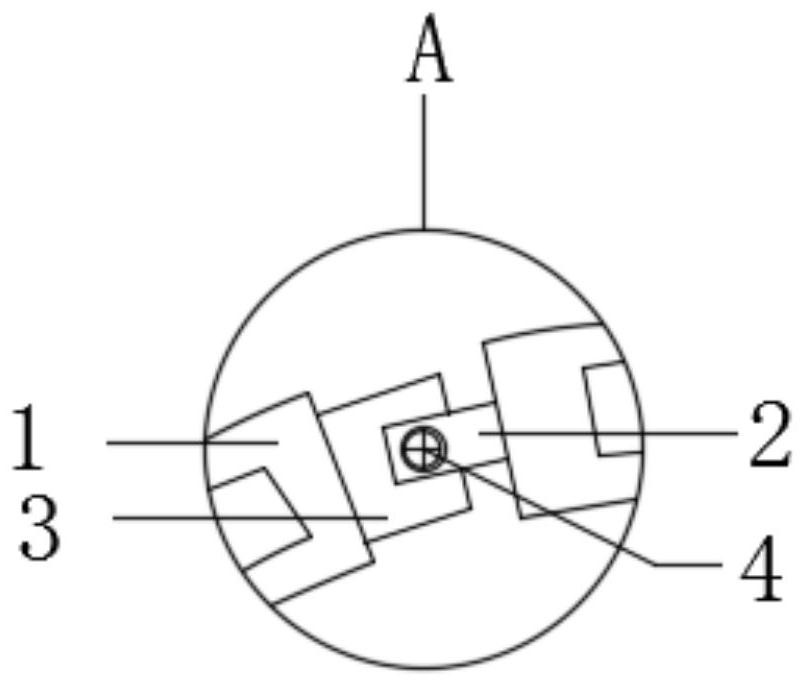

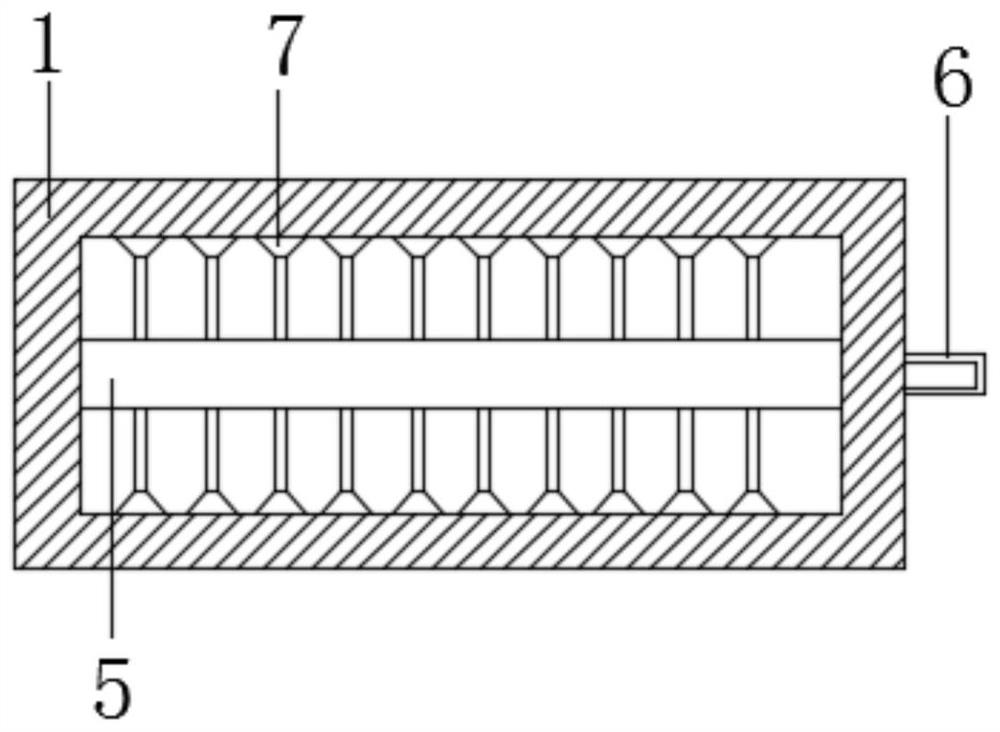

Multifunctional heat pump drying device

ActiveCN107166902APrecisely control the supply air temperatureAdapt to diversityHeat pumpsDrying gas arrangementsMultiple frequencyInverter compressor

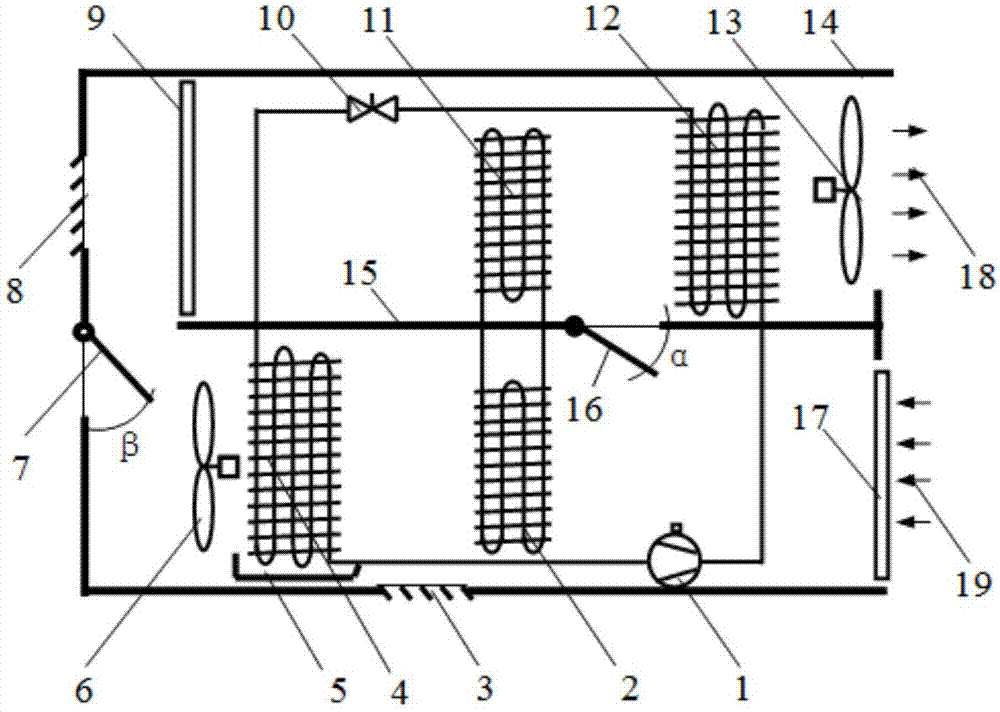

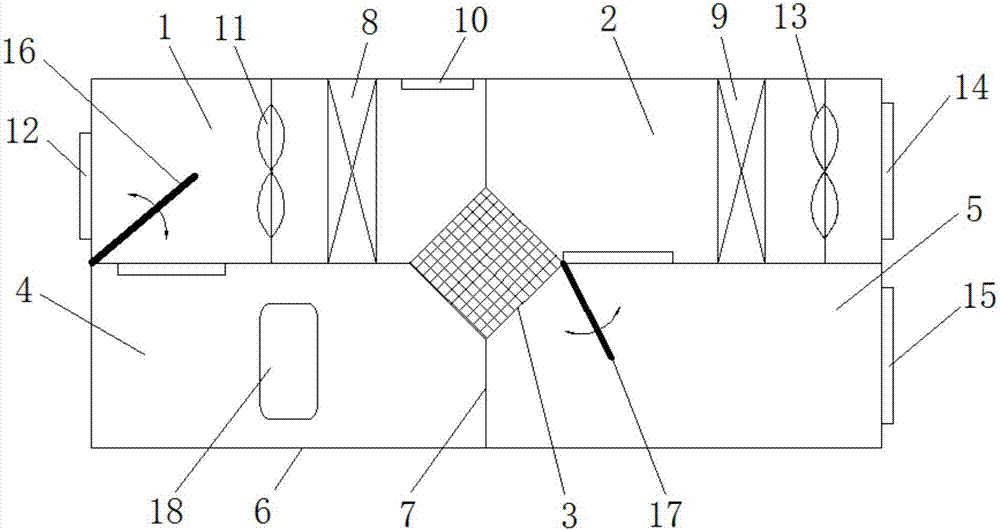

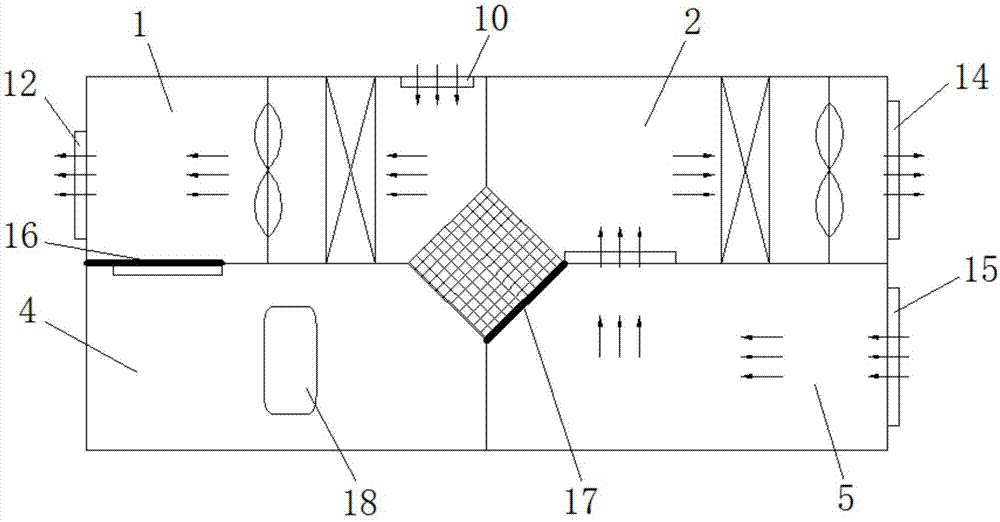

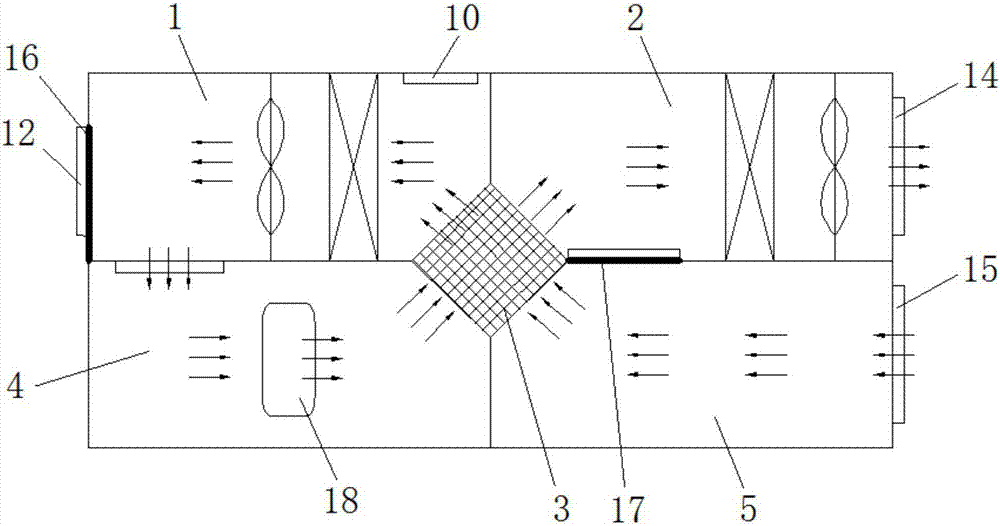

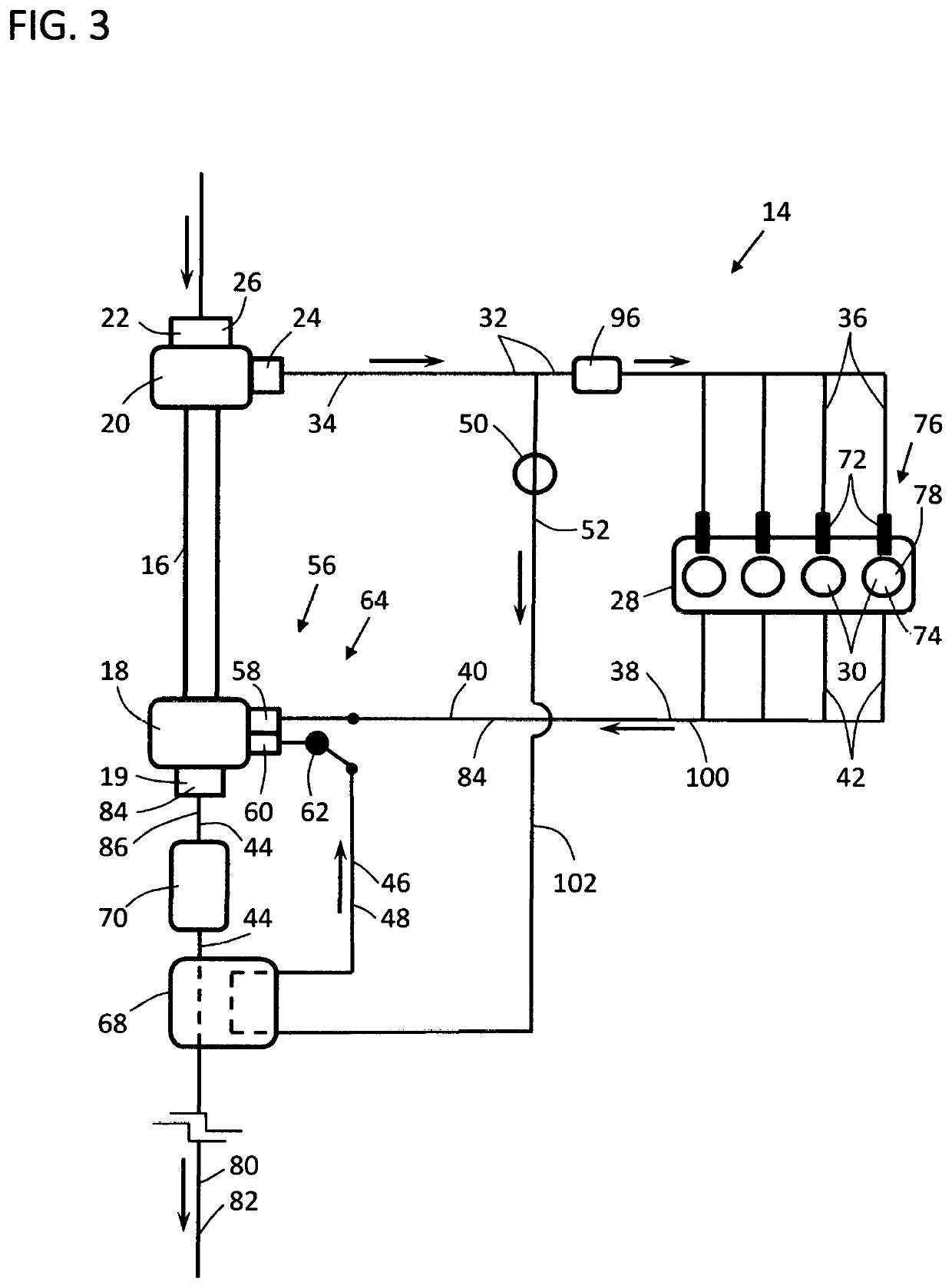

The invention discloses a heat pump drying device with multiple operation modes. The heat pump drying device comprises a heat pump circulating system and a drying medium processing channel; the heat pump circulating system is composed of a compressor, a condenser, an expansion valve and an evaporator, and the compressor is a combination of a single or multiple frequency-conversion compressor bodies; and the drying medium processing channel is subjected to combined control by four ventilation doors to form four change modes, namely a rapidly heating mode, a closed type mode, an open type mode and a semi-open type mode, and four different types of drying modes are formed. The heat pump drying device is high in dehumidification capacity, different operation modes can be provided targeted to different climate conditioners and diversity of drying objects, and the quality of a dried product is effectively improved, and energy is saved.

Owner:ANHUI MELUCK REFRIGERATION EQUIP

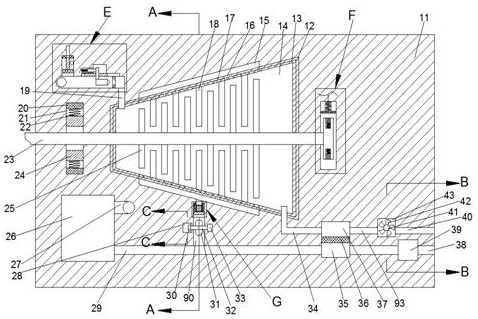

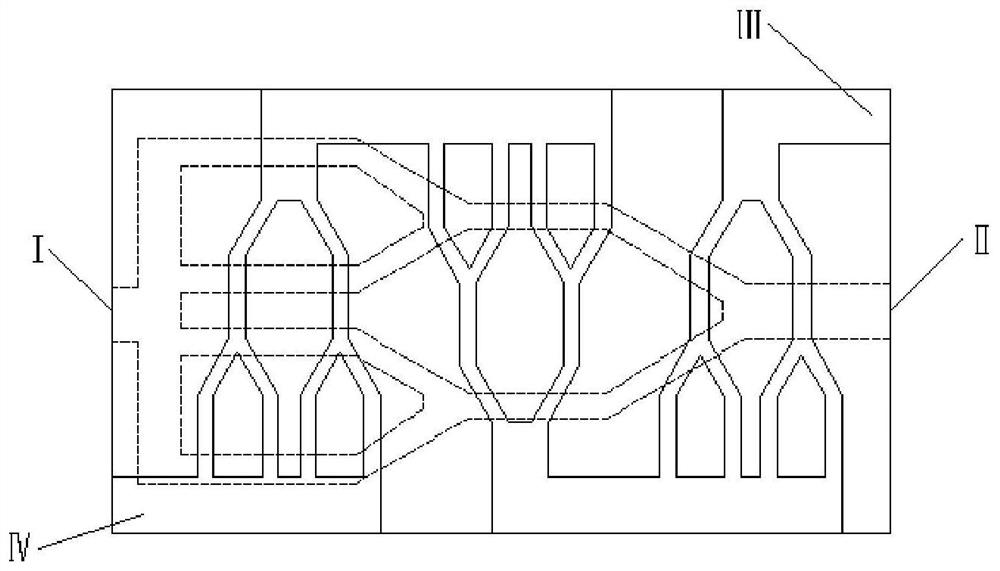

Drying heat pump system adopting air energy open type humidity-eliminating mode and closed type dehumidifying mode

The invention provides a drying heat pump system adopting an air energy open type humidity-eliminating mode and a closed type dehumidifying mode. The drying heat pump system comprises a first heat exchange region with an evaporator, a second heat exchange region with a condenser, a third heat exchange region, a compressor region and an air return region, wherein a first air flue for enabling the compressor region to communicate with the second heat exchange region and a second air flue for enabling the first heat exchange region to communicate with the air return region are arranged in the third heat exchange region; the first heat exchange region is equipped with a fresh air door and an air outlet; a hot air outlet is formed in the second heat exchange region; an air return hole is formed in the air return region; a first switching door capable of opening a channel between the two regions and the air outlet is arranged between the first heat exchange region and the compressor region; and a second switching valve capable of opening a channel between the two regions and the second air flue is arranged between the second heat exchange region and the air return region. With the adoption of the drying heat pump system, switching between the air energy open type humidity-eliminating mode and the closed type dehumidifying mode can be realized at different time quantum for material drying, defects of single-mode drying are avoided; and the drying heat pump system has wider drying process adaptation and realizes efficient energy-saving and drying performances.

Owner:ZHONGSHAN AMITIME ELECTRIC CO LTD

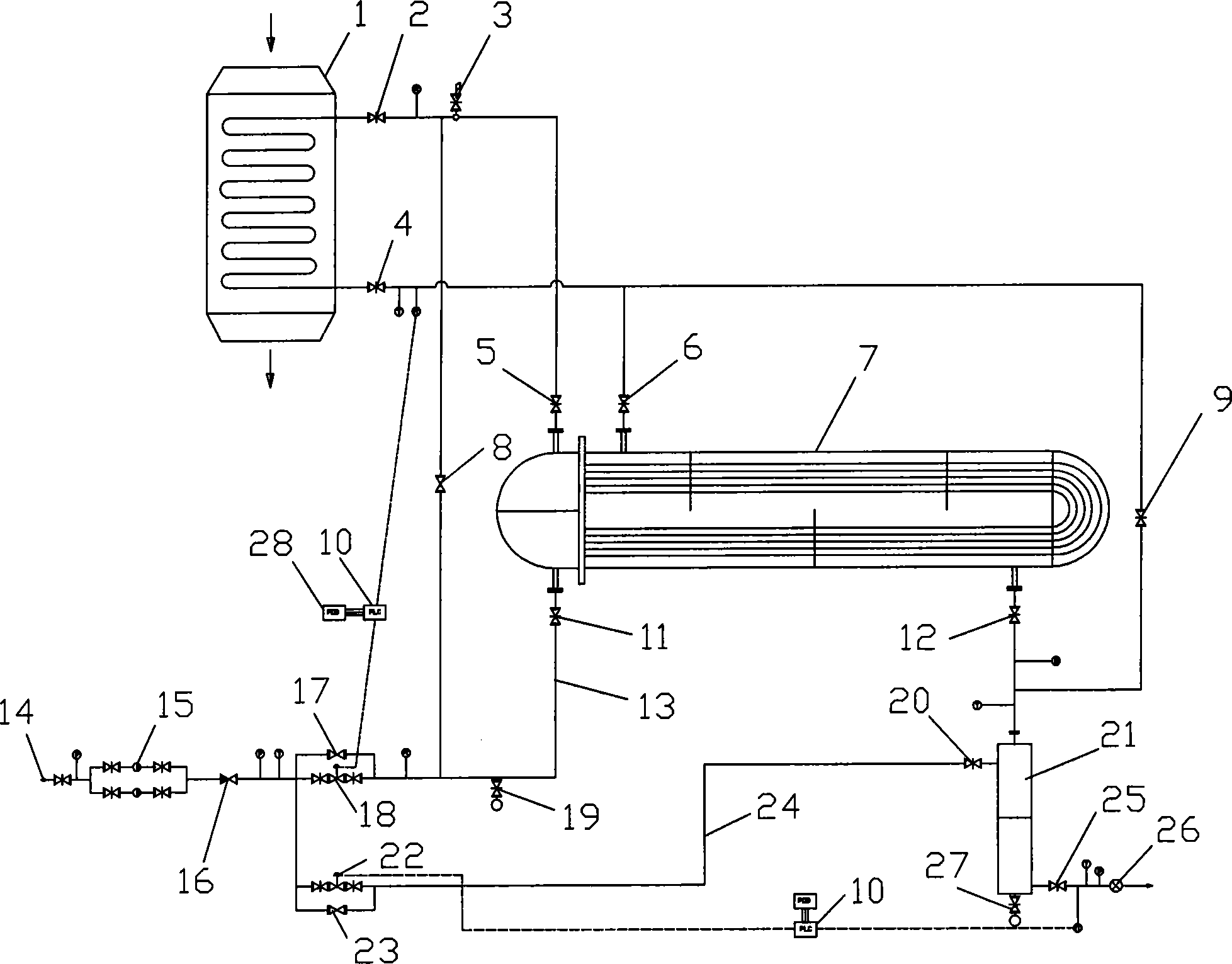

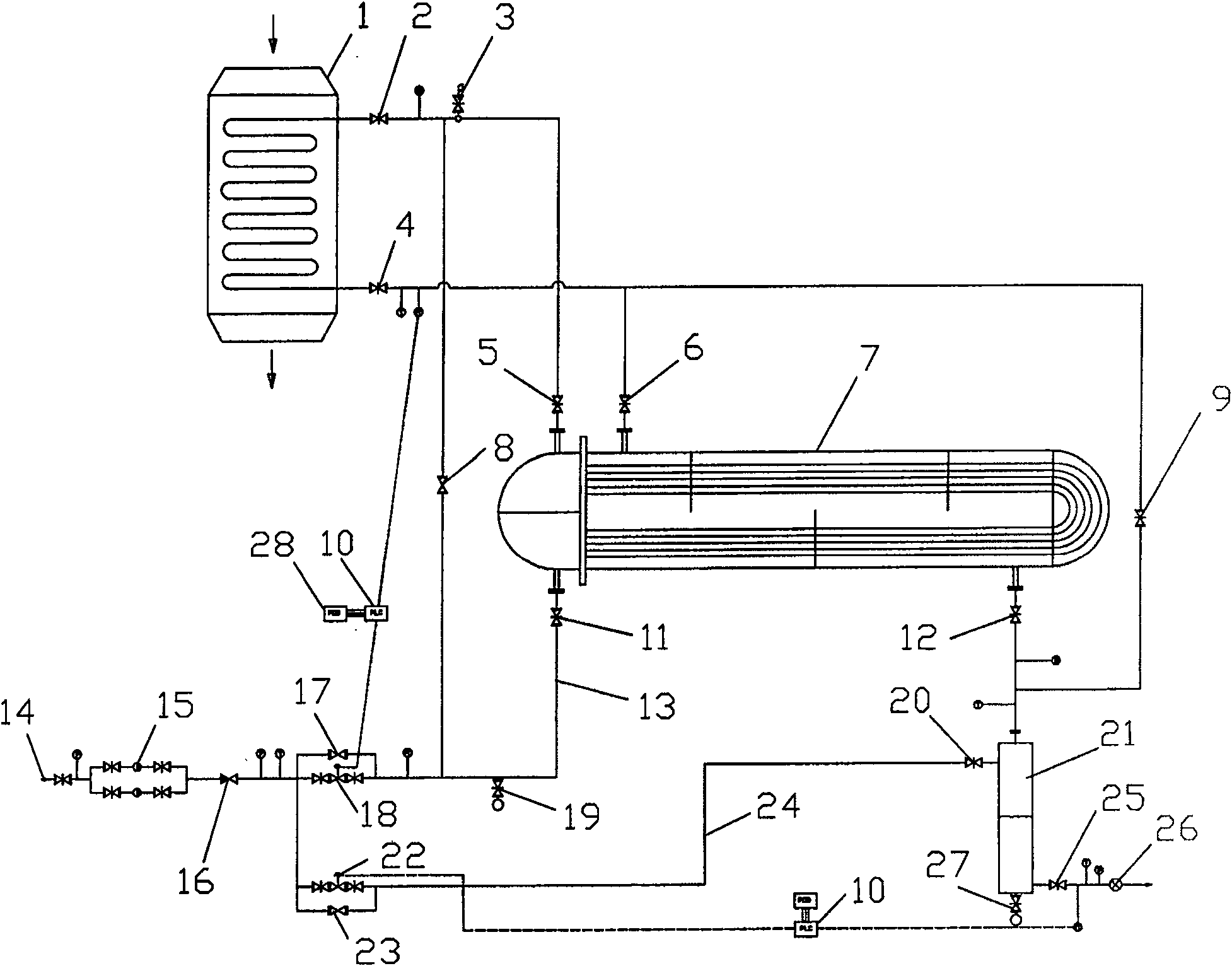

Dew-point corrosion resistant residual heat recovering system

InactiveCN101191700AExtended service lifeEfficient waste heatStationary tubular conduit assembliesWaste heat treatmentFlue gasEngineering

The present invention discloses a dew point corrosion resistant waste head recovery system; a header pipe (14) is connected with a main pneumatic valve (18) and an auxiliary pneumatic valve (22) through the distributary of a booster pump (15); the main pneumatic valve (18) is connected to the heating end inlet of a temperature compensator (7) through a first valve (11); a heating end outlet of the temperature compensator (7) is connected to a heat exchange inlet of a thermotube heat exchanger (1) through a second valve (5) and a third valve (2); a heat exchange outlet of the thermotube heat exchanger (1) is connected with a cooling end inlet of the temperature compensator (7) through a fourth valve (4) and a fifth valve (6); the cooling end outlet of the temperature compensator (7) is connected with a mixer (21) through a seventh valve (12); the auxiliary pneumatic valve (22) is connected with the mixer (21) through an eighth valve (20); an outlet of the mixer (21) is connected with a sixth valve (25). The system has the function of self-temperature compensation of cold fluid and temperature adjustment of the heat exchanger wall, effectively solves the problem of low dew point corrosion of the heat exchanger, prolongs the life-span of the heat exchanger, recovers the waste head of low-temperature flue gas and achieves the effect of energy conservation and emission reduction.

Owner:CENT SOUTH UNIV

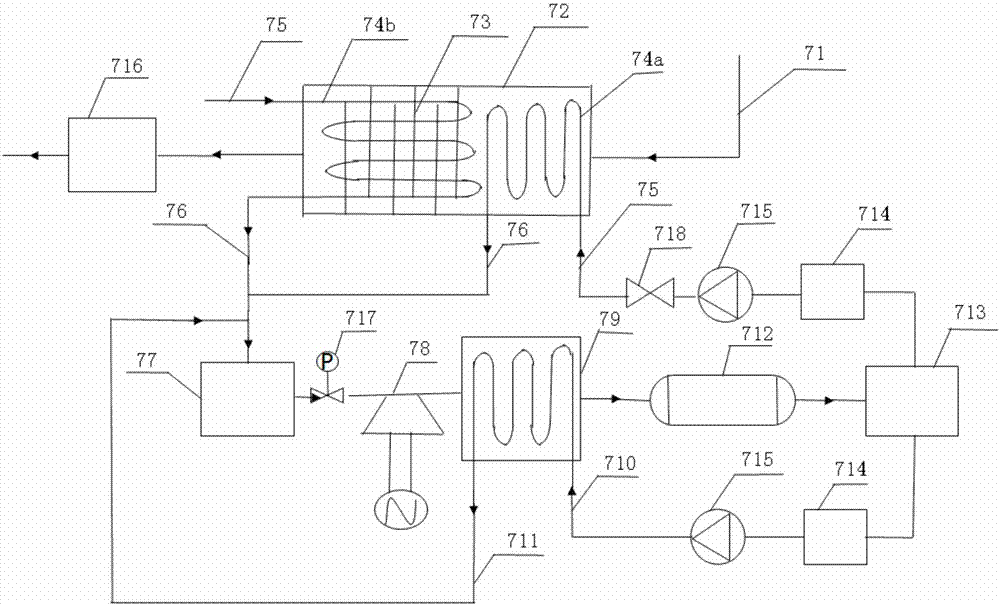

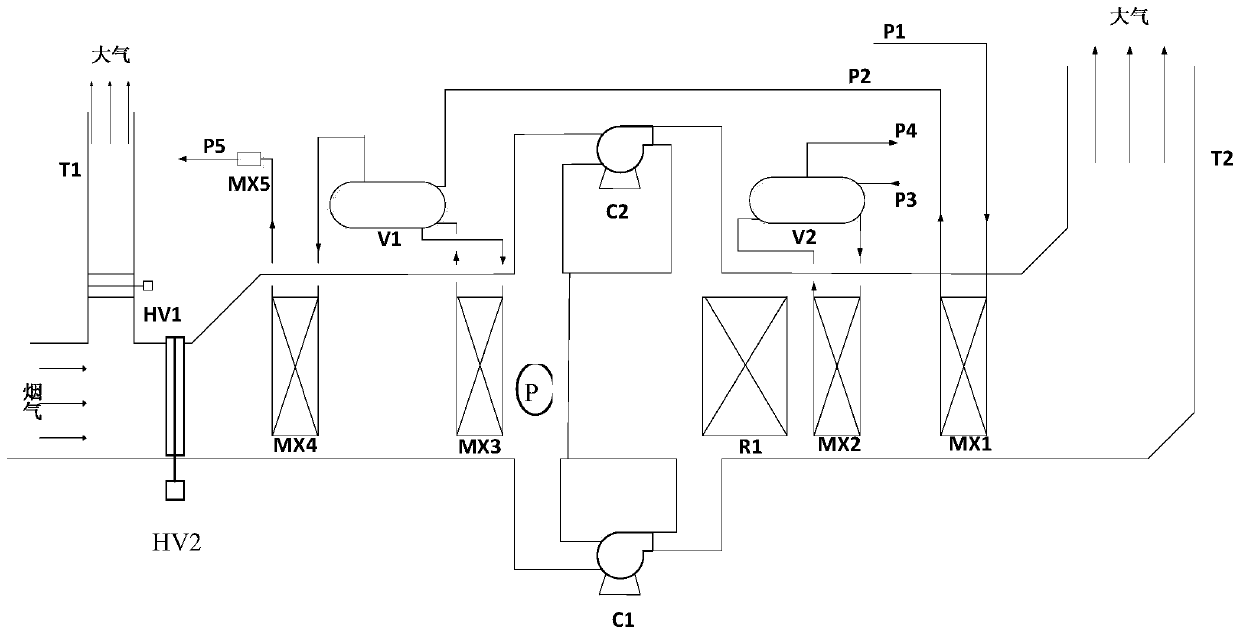

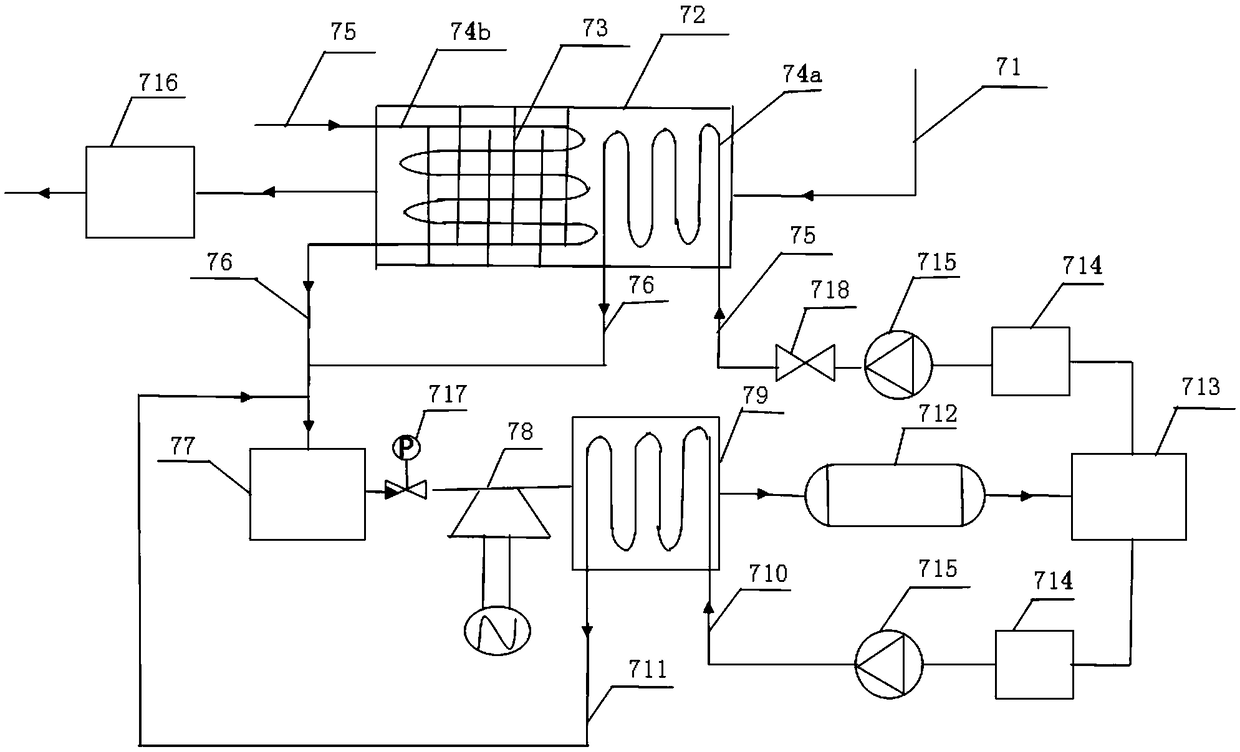

Smoke waste heat recycling system based on film absorption

ActiveCN107631290ALower dew point temperatureSolve the problem of waste heat recovery requiring anti-corrosionFeed water supplyCombustion processFiberAir preheater

The invention belongs to the technical field of gas boiler smoke waste heat recycling and film absorption, and relates to a smoke waste heat recycling system based on film absorption. The system comprises a gas boiler, a vacuum film water recoverer, a film bundle heat exchanger, an indirect heat exchanger, an air preheater, a heat supply pipe net, a chimney and the like. Smoke passes through a vacuum hollow fiber film bundle in the vacuum film water recoverer, water steam in wet smoke is separated from dry smoke, the dry smoke obtained after separation sequentially passes through the indirectheat exchanger and the air preheater, return water and air are heated through waste heat, meanwhile, the separated water steam enters the film bundle heat exchanger, primary heated return water in thewater tightness hollow fiber film bundle is further heated and is sent into the boiler or nearby secondary pipe net users, the water steam obtained after heat exchange is condensed, and water can bedirectly supplemented for the boiler. The system can achieve smoke dry and wet separation, heat energy in the water steam and the dry smoke obtained after separation can be efficiently utilized, waterresources are saved, and the phenomenon of chimney white smoke discharging is reduced.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE

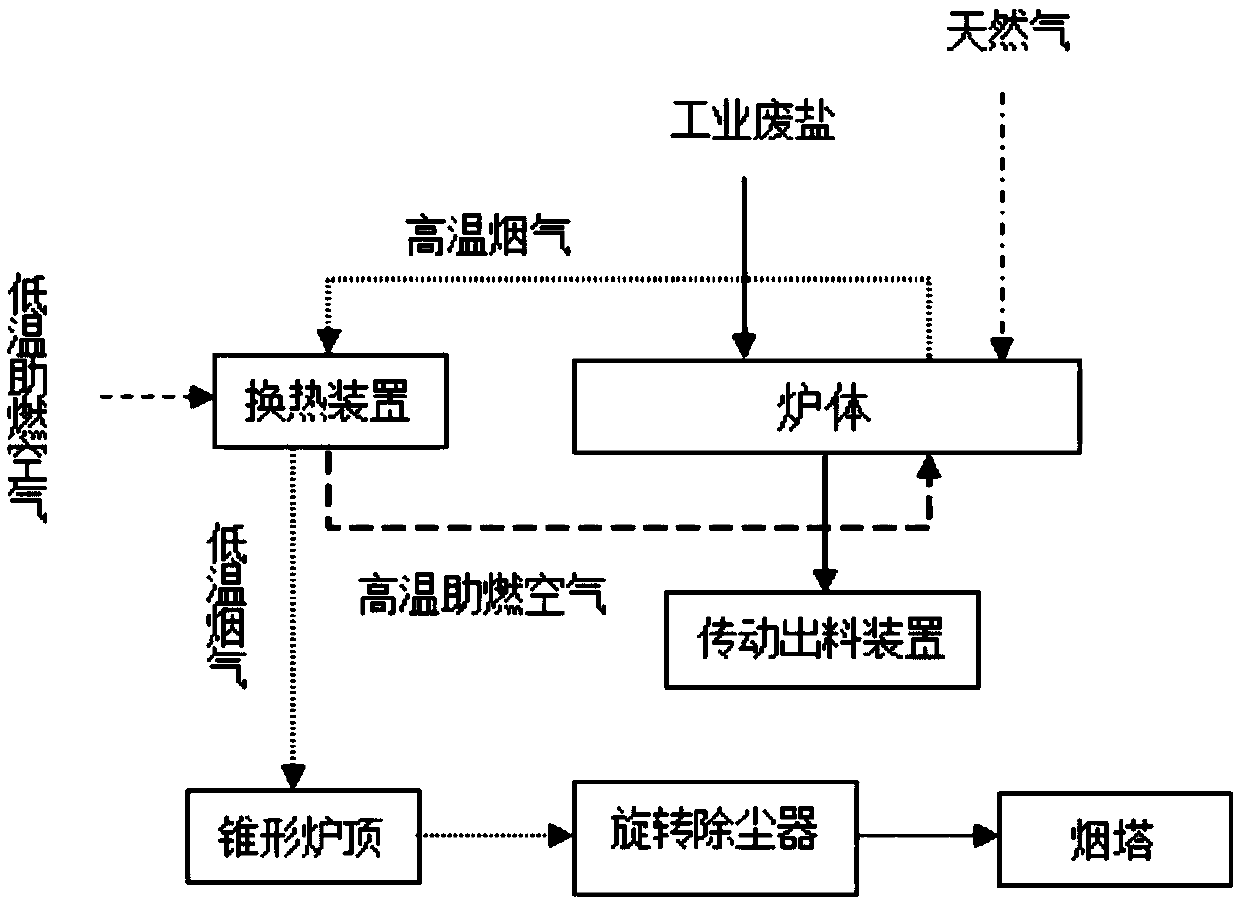

High-efficiency melting and incineration device for industrial waste salt

InactiveCN109579025AEfficient removalAvoid secondary pollutionIncinerator apparatusSimple Organic CompoundsCombustion

The invention belongs to the technical field of environmental protection and industrial waste treatment and particularly relates to a high-efficiency melting and incineration device for industrial waste salt. The high-efficiency melting and incineration device for industrial waste salt comprises a melting incinerator body, a waste heat recovery device, a burner A, a burner B, a combustion air pipeline A, a combustion air pipeline B, a flue gas pipeline, a blower, an induced draft fan, an electric control valve, a lifting feeder, a furnace bottom transmission mechanism and a transmission discharging device. According to the high-efficiency melting and incineration device for industrial waste salt, toxic organic compounds in secondary high-temperature incineration flue gas are utilized, andthe waste heat recovery device is utilized, so that the flue gas temperature is reduced, combustion-supporting air is preheated, and meanwhile the effects of protecting the environment and improving the thermal efficiency of a furnace can be achieved.

Owner:NORTHEASTERN UNIV

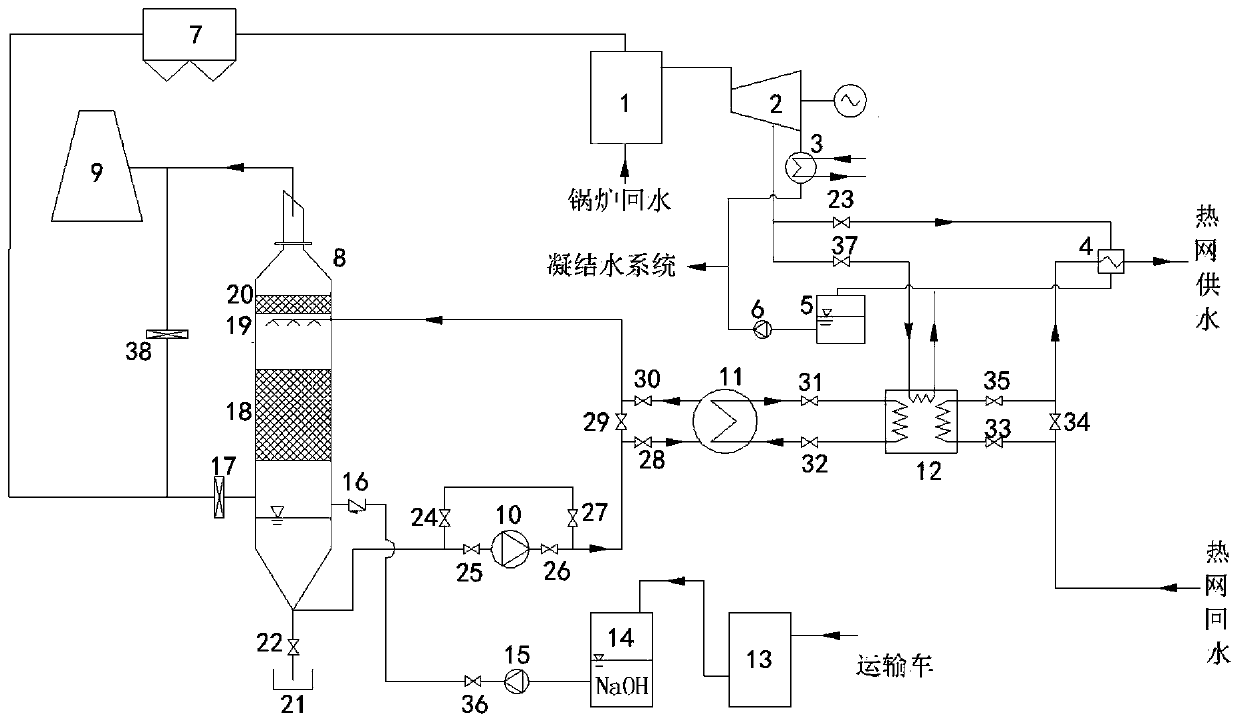

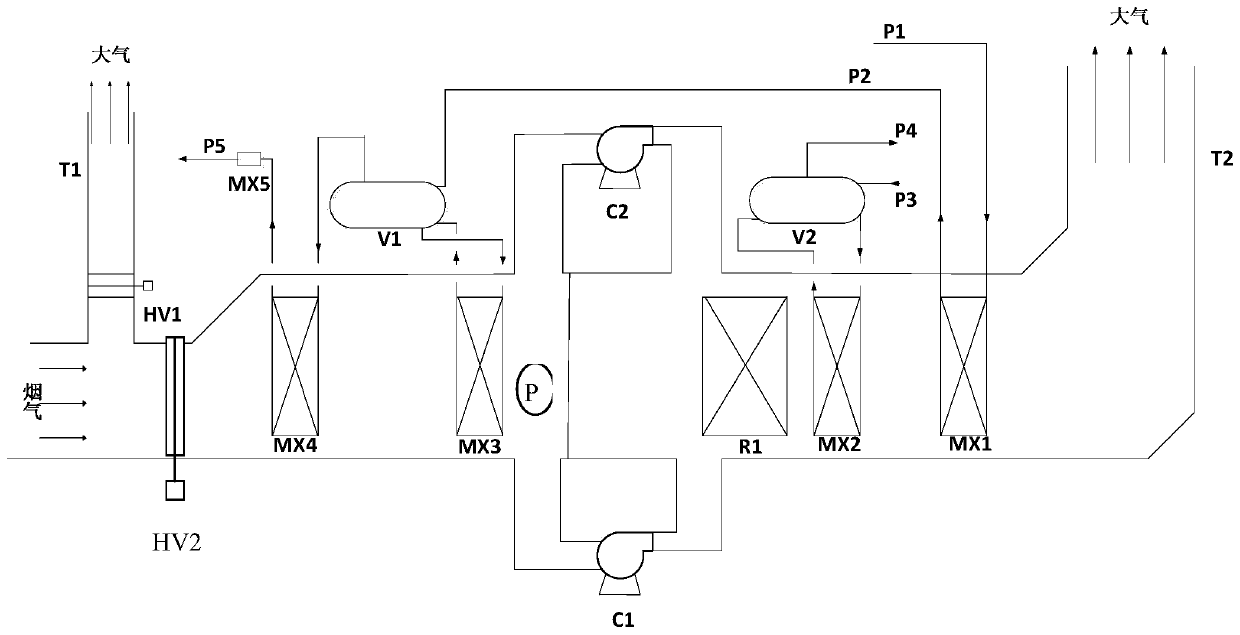

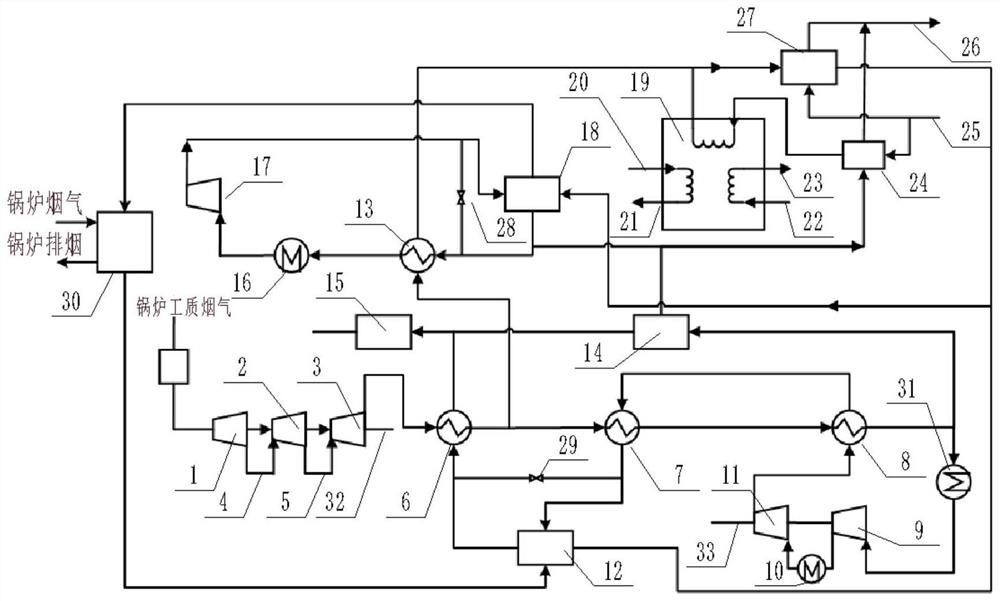

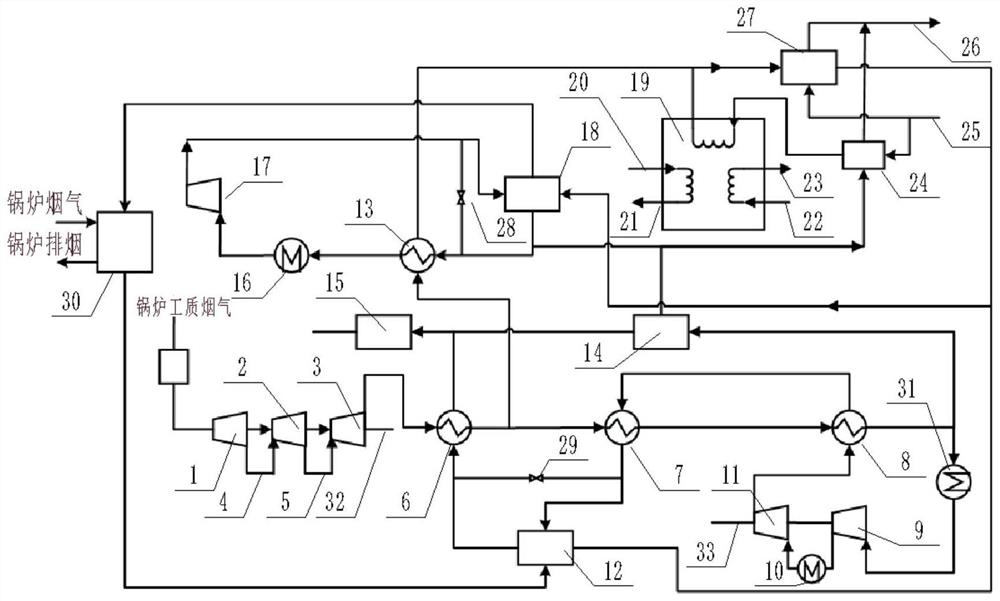

Energy saving system for adopting absorption heat pump to deeply recover smoke waste heat for central heating

PendingCN109945278AImprove work efficiencyEfficient Waste Heat RecoveryFeed water supplyEnergy efficient heating/coolingHeating systemSmoke

Owner:DALIAN UNIV OF TECH

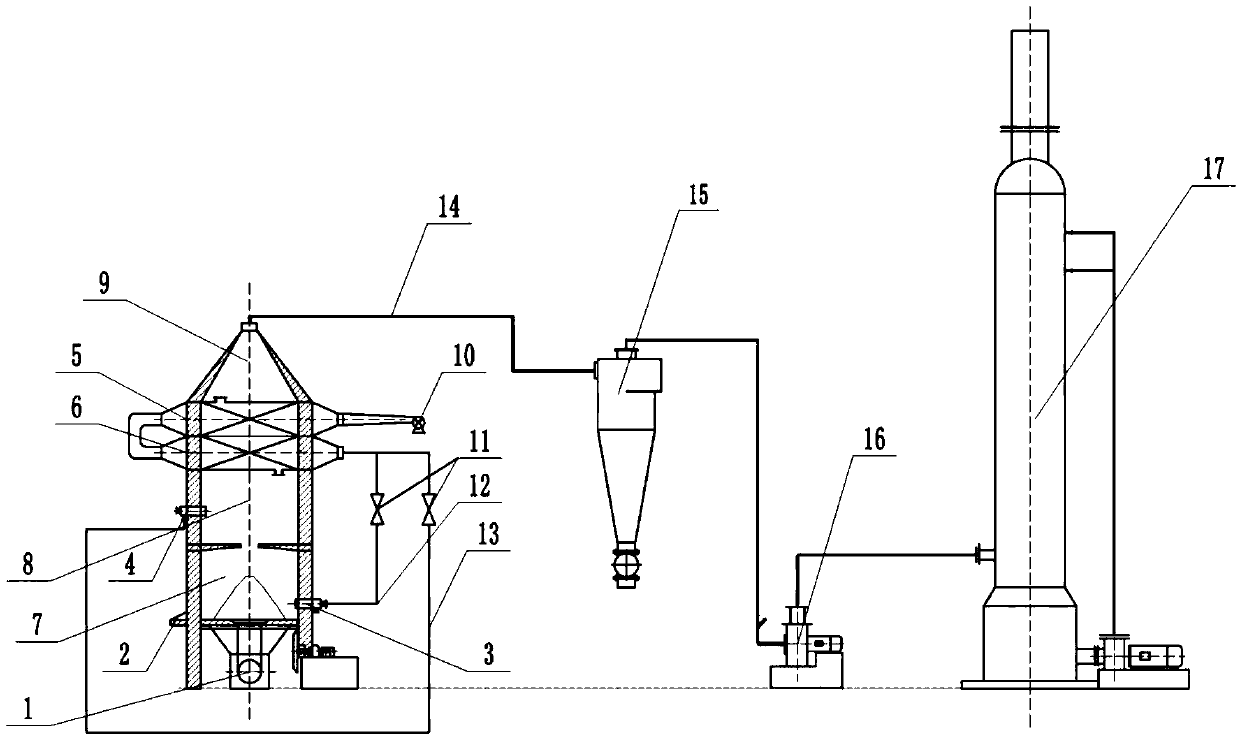

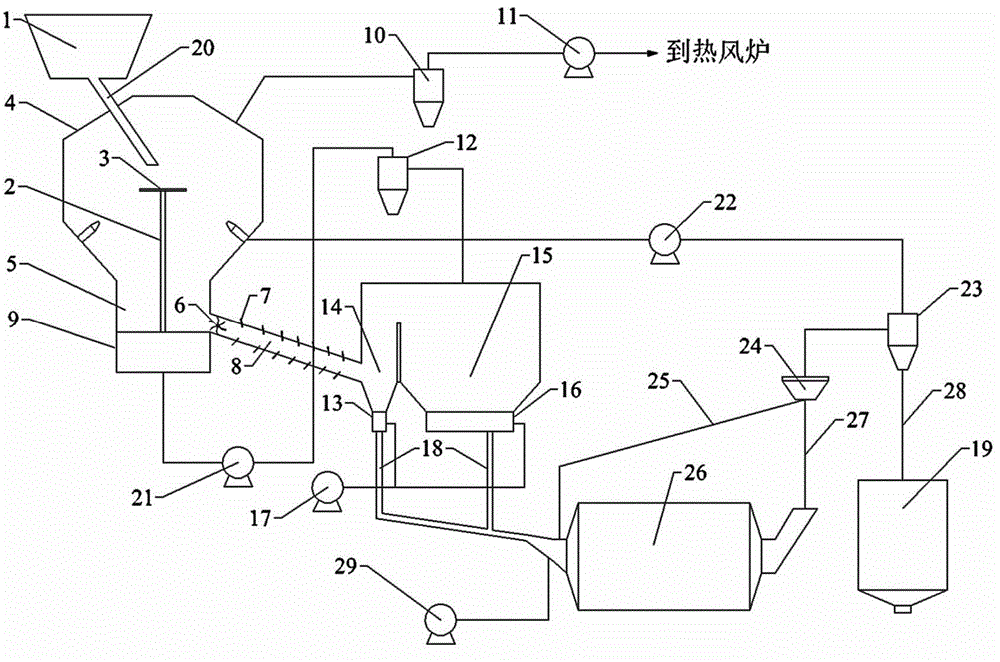

Dry-type granulation treatment waste heat recovery system

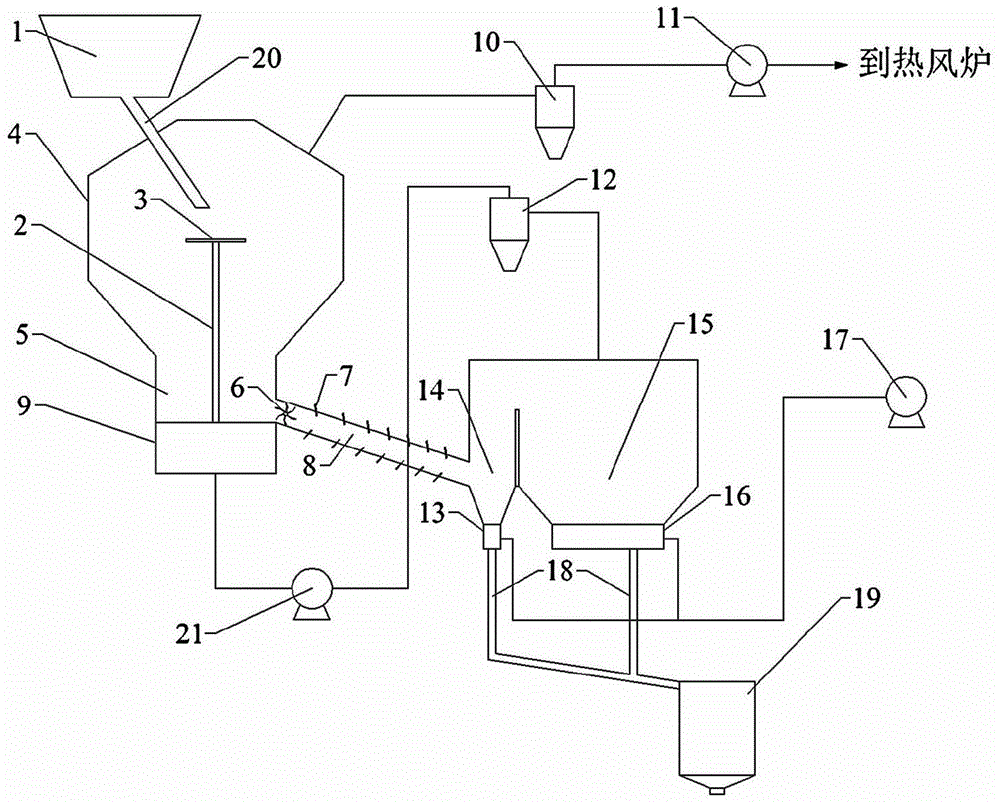

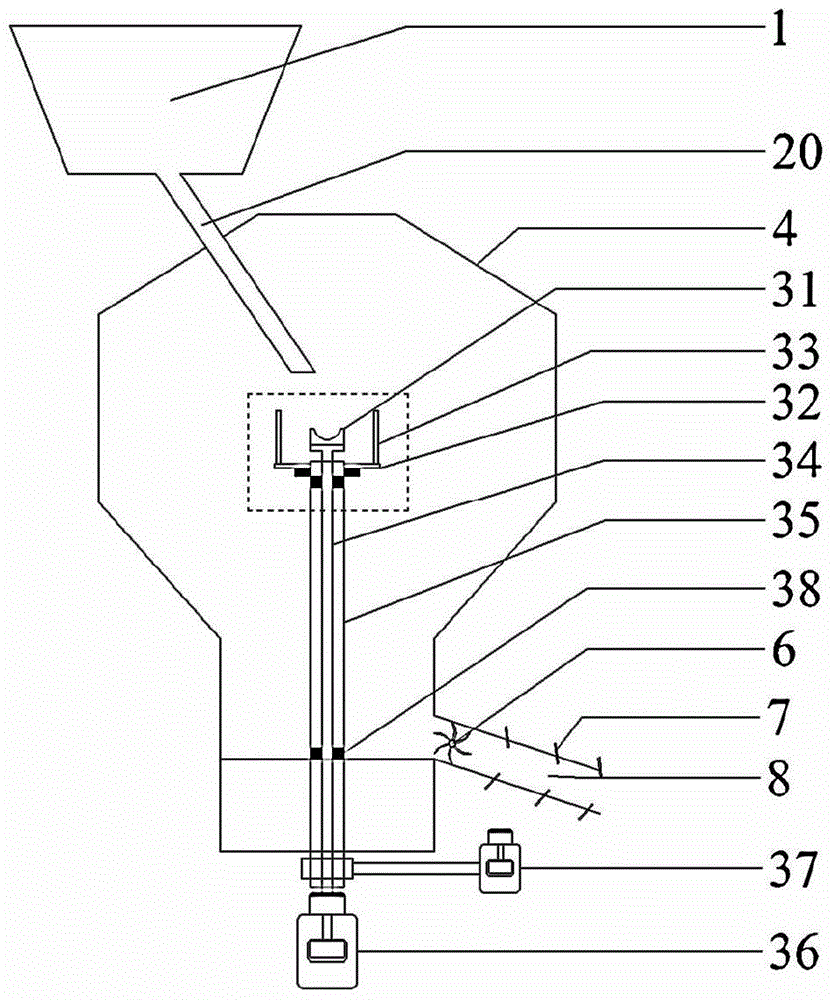

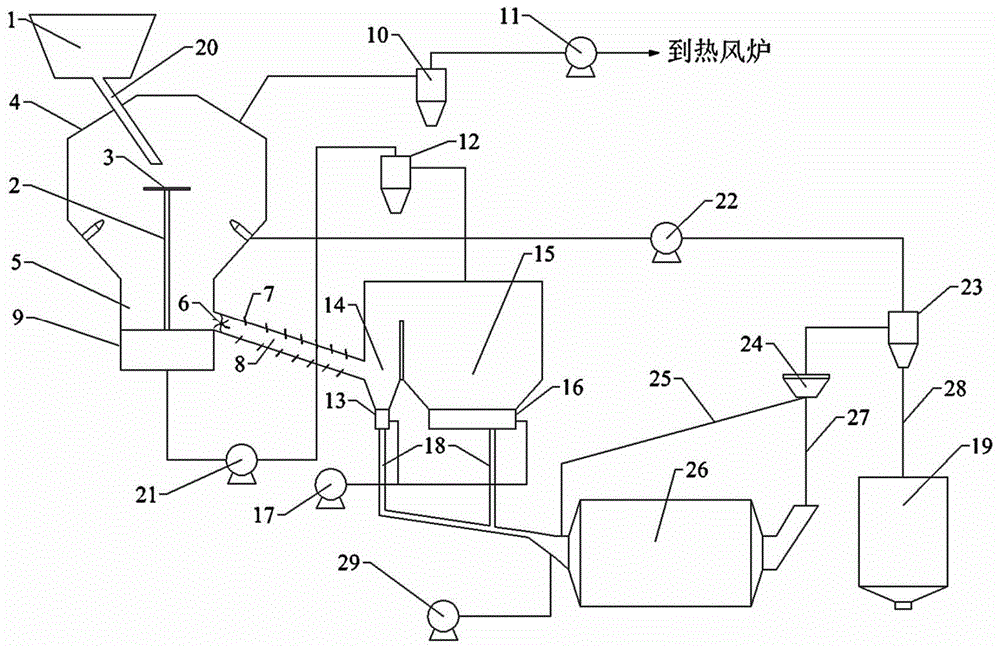

ActiveCN104388611AHigh recovery rateImprove qualityRecycling and recovery technologiesWaste heat treatmentWaste heat recovery unitSlag

The invention discloses a dry-type granulation treatment waste heat recovery system which comprises a slag storage bin, a granulation cooling unit, a primary waste heat recovery unit, a secondary waste heat recovery unit and a tertiary waste heat recovery. The system is characterized in that the top of the granulation cooling unit is provided with a first air outlet; the first air outlet is connected with a high-temperature booster fan through a pipeline; a granulator is arranged in the granulation cooling unit, positioned below a charging pipe and driven by a rotating shaft to rotate; the primary waste heat recovery unit is arranged below the granulation cooling unit; the bottom of the primary waste heat recovery unit is provided with a first fluidized bed and a slag discharge pipe; the slag discharge pipe is communicated with the secondary waste heat recovery unit; the bottom of the secondary waste heat recovery unit is provided with a spray bed; and the upper part of the secondary waste heat recovery unit is communicated with the upper part of the tertiary waste heat recovery unit. The system implements the dry-type granulation function and high-efficiency waste heat recovery, and can be widely used in the fields of steel, metallurgy and the like.

Owner:CHONGQING UNIV

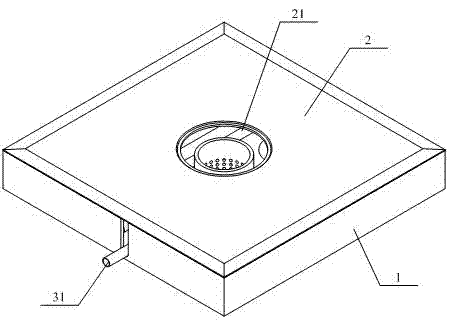

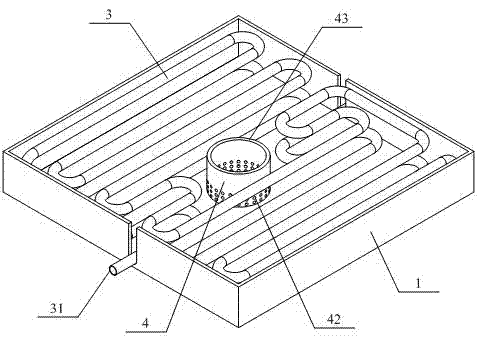

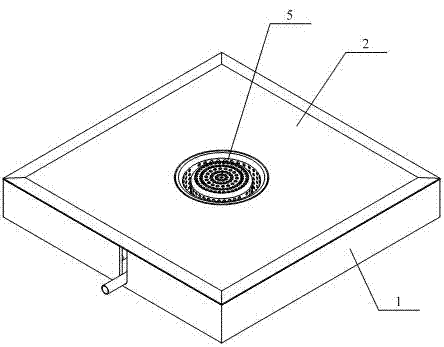

Waste heat recovery energy saving heat exchanger

InactiveCN102927836AIncrease temperatureDoes not take up effective spaceOther heat production devicesStationary conduit assembliesWaste heat recovery unitEngineering

The invention discloses a waste heat recovery energy saving heat exchanger. The waste heat recovery energy saving heat exchanger comprises a box body and a top cover which is arranged on the box body, a sink water port for enabling outside hot water to flow in is disposed on the top cover, a drainage port for discharging water subjected to heat exchange out of the box body is arranged on the box body, and a heat exchange part with a water inlet and a water outlet is disposed in the box body. According to the waste heat recovery energy saving heat exchanger, the energy saving heat exchanger is designed to be an independent device, and the sink water port and the drainage port are arranged on the device, so that concealed setting of the heat exchanger is convenient, and increasing of the use ratio of waste heat recovery is facilitated.

Owner:QINGDAO ECONOMIC & TECHN DEV ZONE HAIER WATER HEATER +1

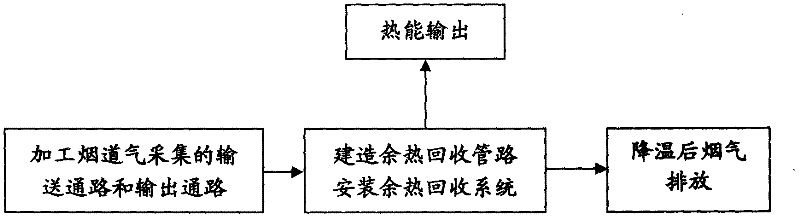

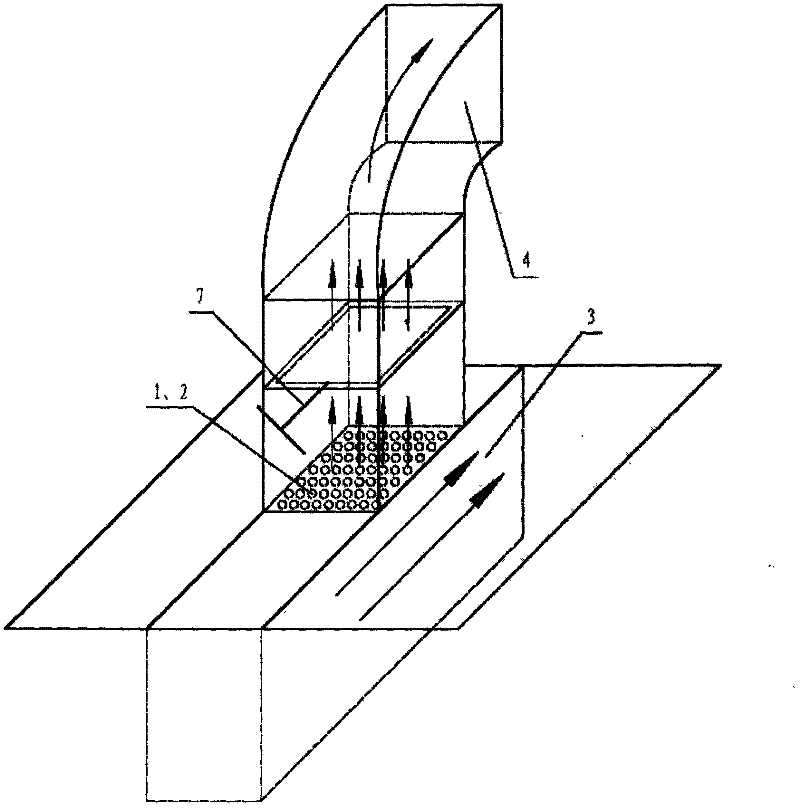

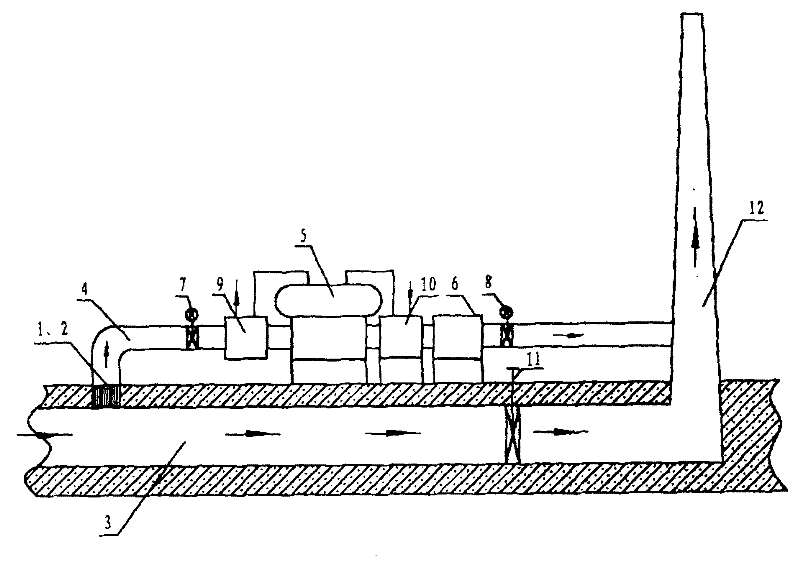

Method for recovering flue gas waste heat of coke oven

InactiveCN102338366AEfficient Waste Heat RecoveryContinuous and reliable operationIncreasing energy efficiencySteam generation using hot heat carriersFlueProcess engineering

The invention relates to a method for recovering flue gas waste heat of a coke oven. The method comprises the following steps of: machining a flue gas acquisition conveying channel and a flue gas output channel on an output flue of the coke oven; constructing a coke oven flue gas waste heat recovery pipeline which is communicated with the flue gas acquisition conveying channel and the flue gas output channel and is positioned between the flue gas acquisition conveying channel and the flue gas output channel, and installing a waste heat recovery system in the waste heat recovery pipeline; and regulating pressure in the waste heat recovery pipeline, performing heat energy conversion by using the waste heat recovery system, outputting heat energy and discharging coke oven flue gas from which the waste heat is recovered along the flue gas output channel. The method is mainly applied to the waste heat recovery of the flue gas of a newly-built or rebuilt coke oven system, and can be matched with the coke oven systems with various structures; and the method is a set of integral independent waste heat recovery system, an integral structure of the coke oven system is not changed, the flue gas waste heat of the coke oven system can be recovered efficiently, and the coke oven system can run stably, reliably and continuously. The method is small in investment and flexibly and conveniently applied, and meets the requirements of the waste heat recovery of the coke oven systems with the various structures, maintenance cost is low, and the integral structure is simple.

Owner:BAODING RUNLI ENERGY SAVING & ENVIRONMENTAL PROTECTION

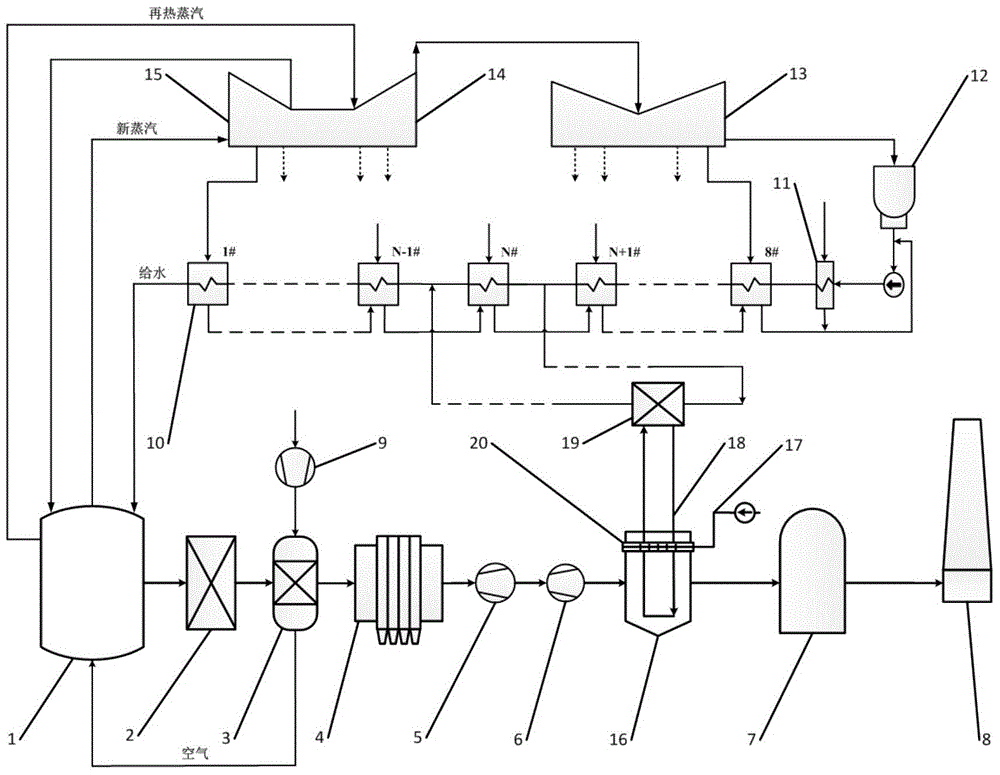

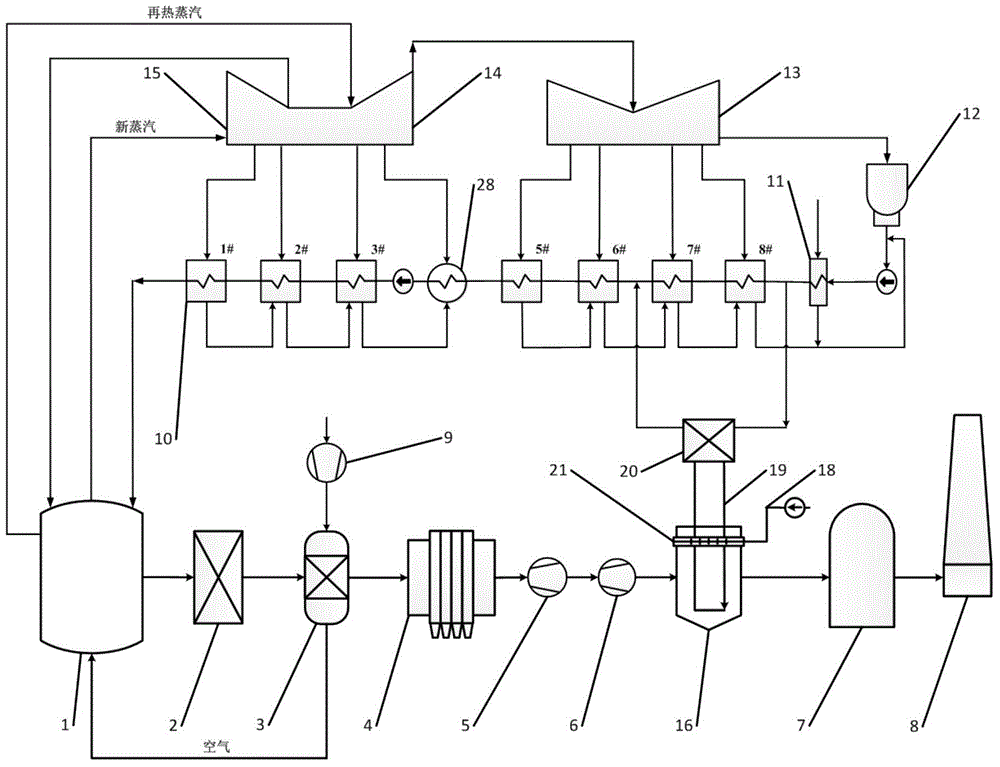

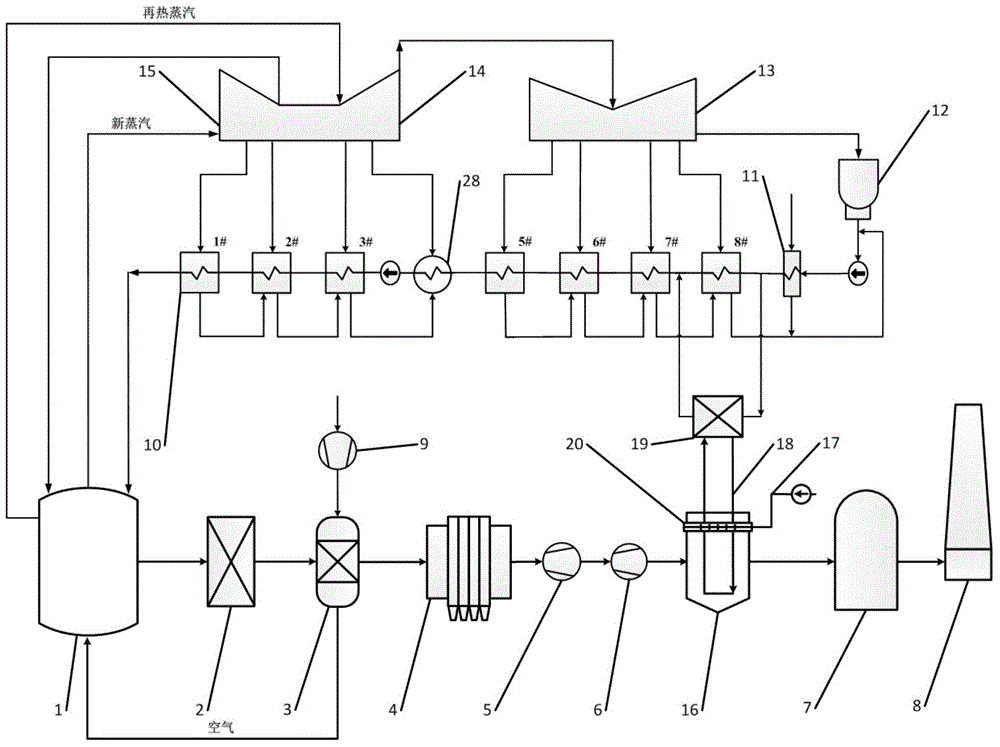

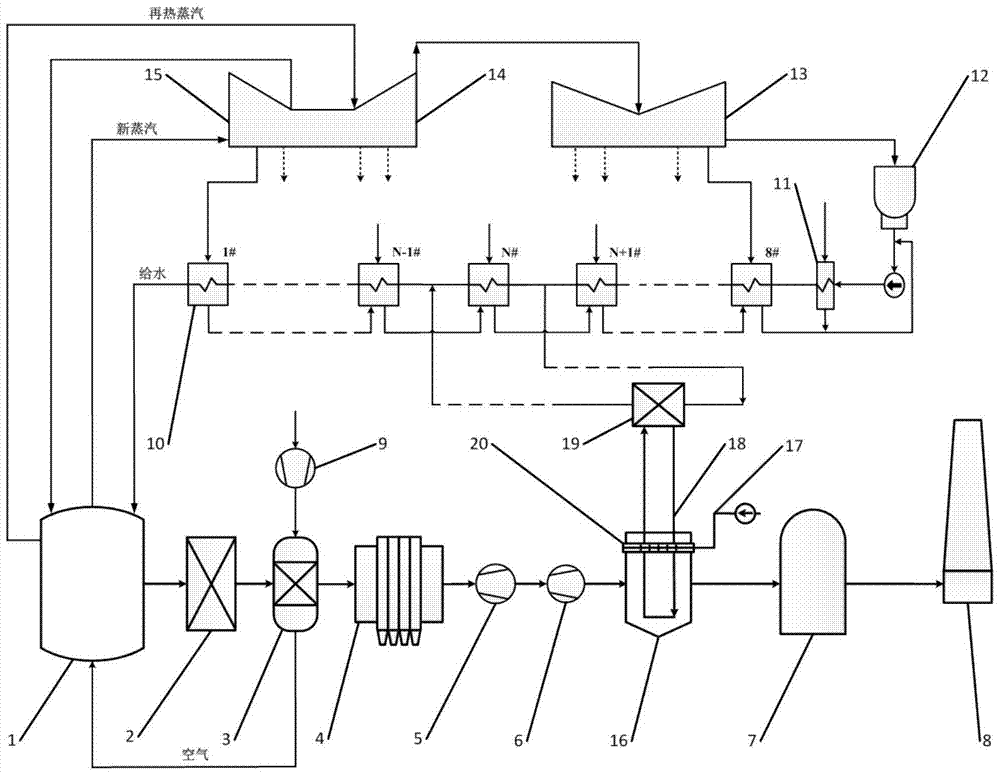

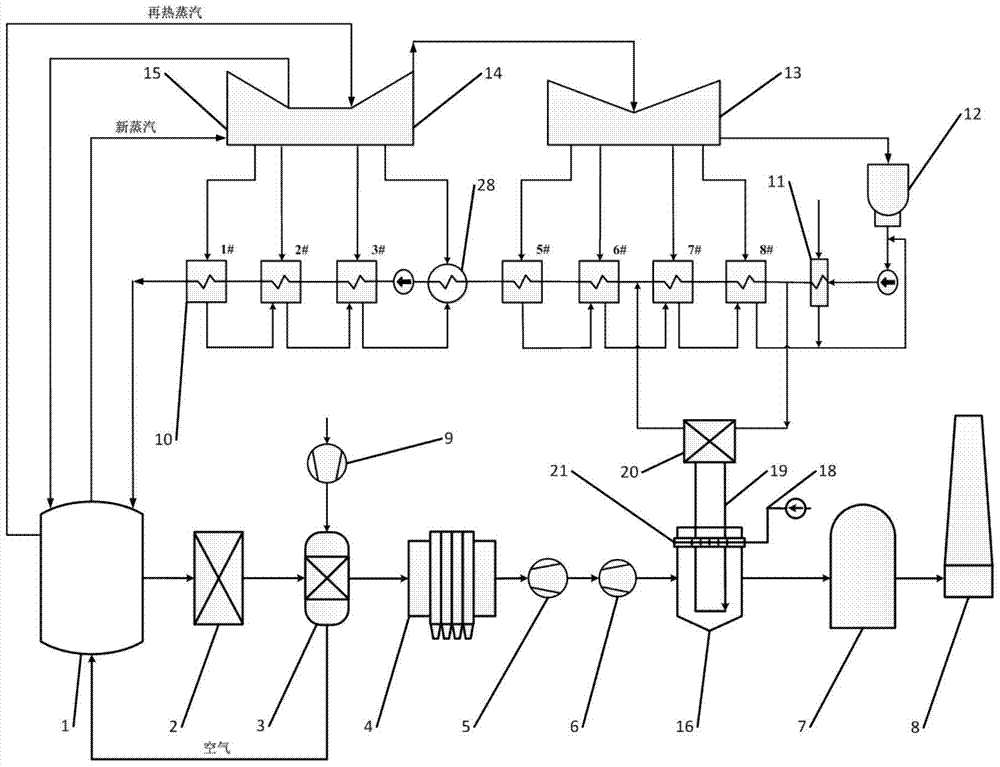

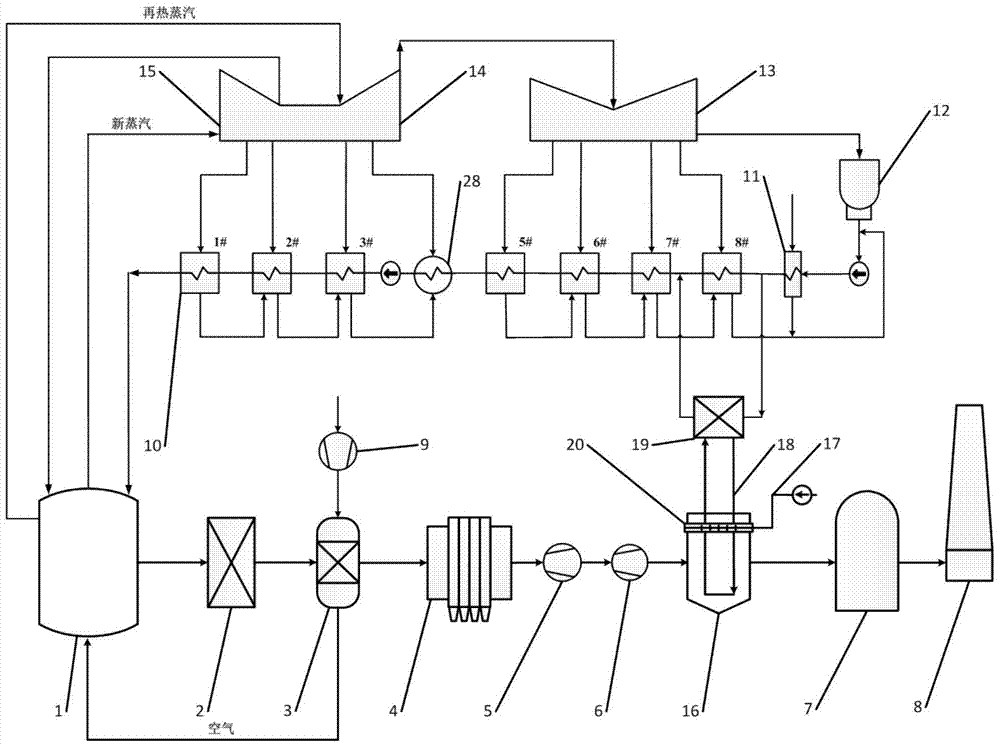

Energy-saving and low-dust emission coal-fired power generation system

ActiveCN104896492AEfficient removalLow costCombustion processIndirect carbon-dioxide mitigationFlue gasProcess engineering

The invention relates to an energy-saving and low-dust emission coal-fired power generation system. The energy-saving and low-dust emission coal-fired power generation system comprises a boiler, a desulfurization tower and an electrostatic dust collector. The energy-saving and low-dust emission coal-fired power generation system is characterized in that a waste heat recovery system is arranged in the upstream direction of the desulfurization tower, and a dedusting system is arranged behind the desulfurization tower; a waste heat recovery system is arranged in the upstream direction of the desulfurization tower; or a dedusting system is arranged behind the desulfurization tower. The waste heat recovery system recovers heat in a high-temperature flue gas at a tail part of the boiler and sends the heat into a steam turbine heater, and comprehensive utilization of flue gas waste heat is achieved through saving of extraction flow of the heater. The invention provides an energy-saving and low-dust emission coal-fired power generation system, clean emission in a true sense is achieved through the waste heat recovery system and the dedusting system, and the energy-saving and low-dust emission coal-fired power generation system is simple, reliable and efficient.

Owner:GUODIAN NEW ENERGY TECH INST

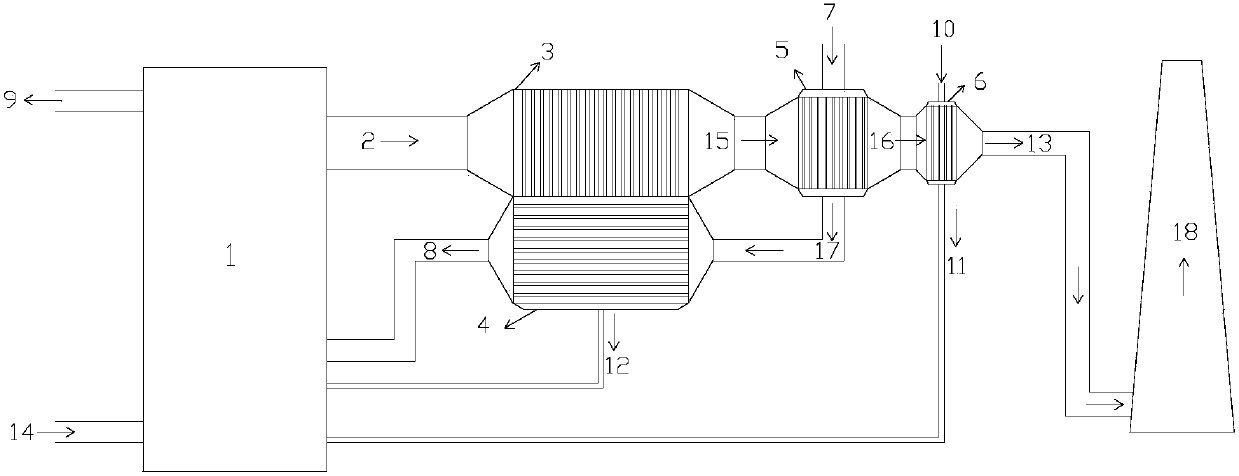

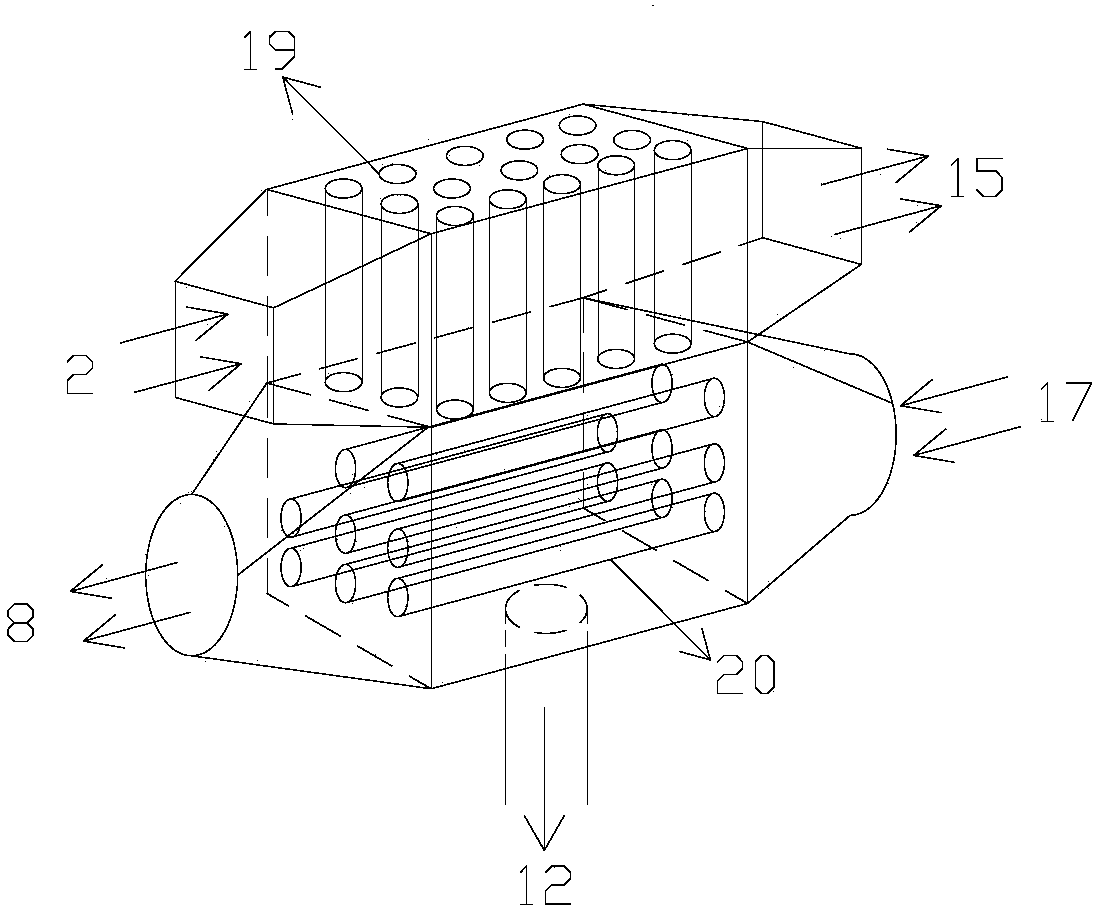

High-temperature flue gas waste heat recovery and advanced purification system

ActiveCN106989607AEfficient recovery of waste heatExtend the distribution pathIncreasing energy efficiencySteam engine plantsOrganic Rankine cycleProcess engineering

The invention discloses a high-temperature flue gas waste heat recovery and advanced purification system. The system comprises a waste heat recovery module, a power generation module, an organic Rankine cycle heat exchanger and a dust removal purification module, wherein the gas inlet end of the waste heat recovery module is connected with a high-temperature flue gas inlet, the gas outlet end of the waste heat recovery module is connected with the dust removal purification module, two sets of tube type heat exchangers in different arrangement directions are arranged in the waste heat recovery module, a heat-exchange medium pipe outlet inside the waste heat recovery module is connected with the power generation module, the power generation module and the organic Rankine cycle heat exchanger are connected in series, and steam output through the organic Rankine cycle heat exchanger is subjected to refluxing through a condenser, passes through a working medium separator and then is connected to the waste heat recovery module and a heat exchange medium pipe inlet of the organic Rankine cycle heat exchanger. According to the high-temperature flue gas waste heat recovery and advanced purification system, a water working medium and an organic working medium are adopted and combined with electrolyzed high-temperature flue gas for three-time heat exchange, the purpose of utilizing heat of high-temperature flue gas to the maximum extent is achieved, the dust removal purification module is adopted for conducting advanced purification on cooled flue gas, energy conservation and emission reduction are achieved, and the economic benefit of enterprise production is improved.

Owner:CENT SOUTH UNIV

Dew-point corrosion resistant residual heat recovering system

InactiveCN100547330CExtended service lifeEfficient waste heatStationary tubular conduit assembliesWaste heat treatmentEffective solutionFlue gas

The invention discloses an anti-dew point corrosion waste heat recovery system. The main pipe (14) is connected with a main pneumatic valve (18) and a secondary pneumatic valve (22) through a booster pump (15). The main pneumatic valve (18) passes through the first The valve (11) is connected to the inlet of the heating end of the temperature compensator (7), and the outlet of the heating end of the temperature compensator (7) is connected to the heat pipe heat exchanger (1) through the second valve (5) and the third valve (2) for heat exchange The inlet, the heat exchange outlet of the heat pipe heat exchanger (1) are connected to the inlet of the cooling end of the temperature compensator (7) through the fourth valve (4) and the fifth valve (6), and the outlet of the cooling end of the temperature compensator (7) passes through the fourth valve (4) and the fifth valve (6). The seven valves (12) are connected with a mixer (21), the auxiliary pneumatic valve (22) is connected with the mixer (21) through the eighth valve (20), and the outlet of the mixer (21) is connected with the sixth valve (25). This system has the functions of cold fluid temperature self-compensation and heat exchanger wall temperature adjustment, which effectively solves the problem of low-temperature dew point corrosion of the heat exchanger, prolongs the service life of the heat exchanger, and can efficiently recover the waste heat of low-temperature flue gas, achieving the effect of energy saving and emission reduction .

Owner:CENT SOUTH UNIV

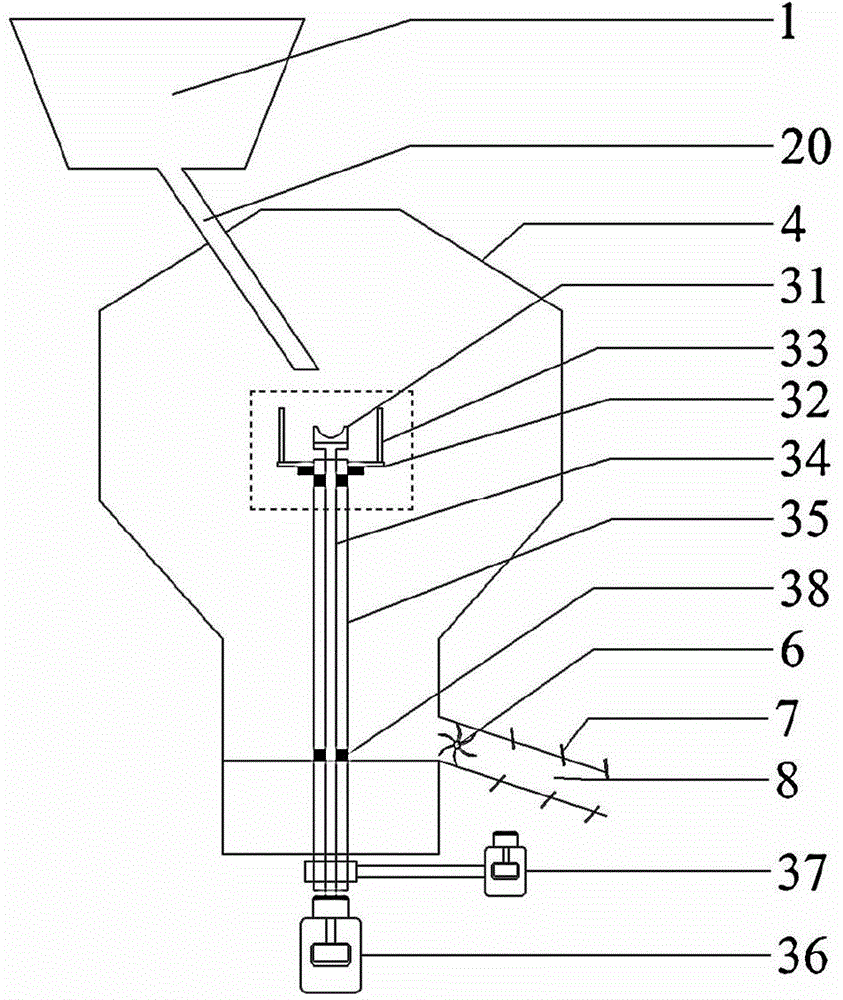

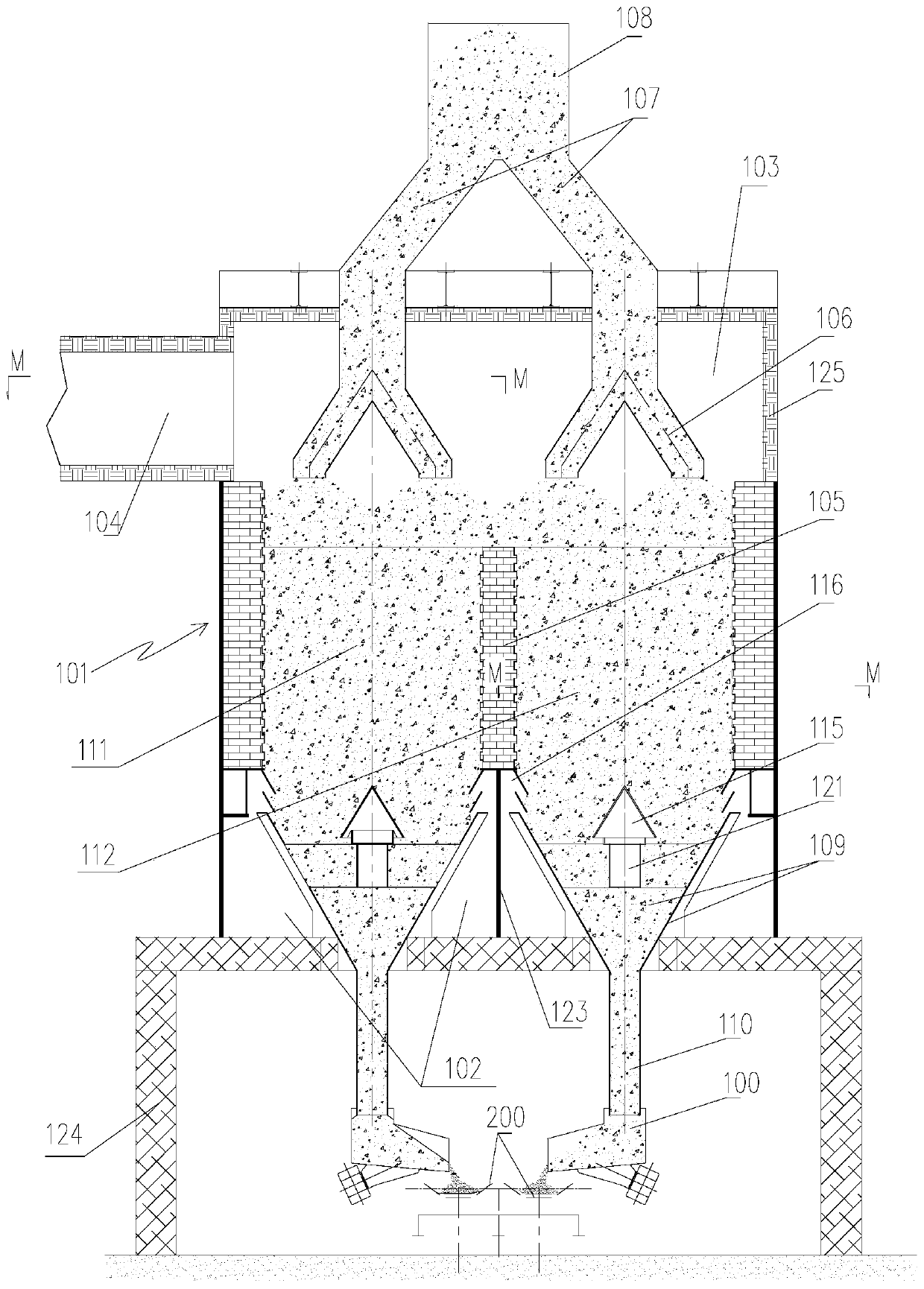

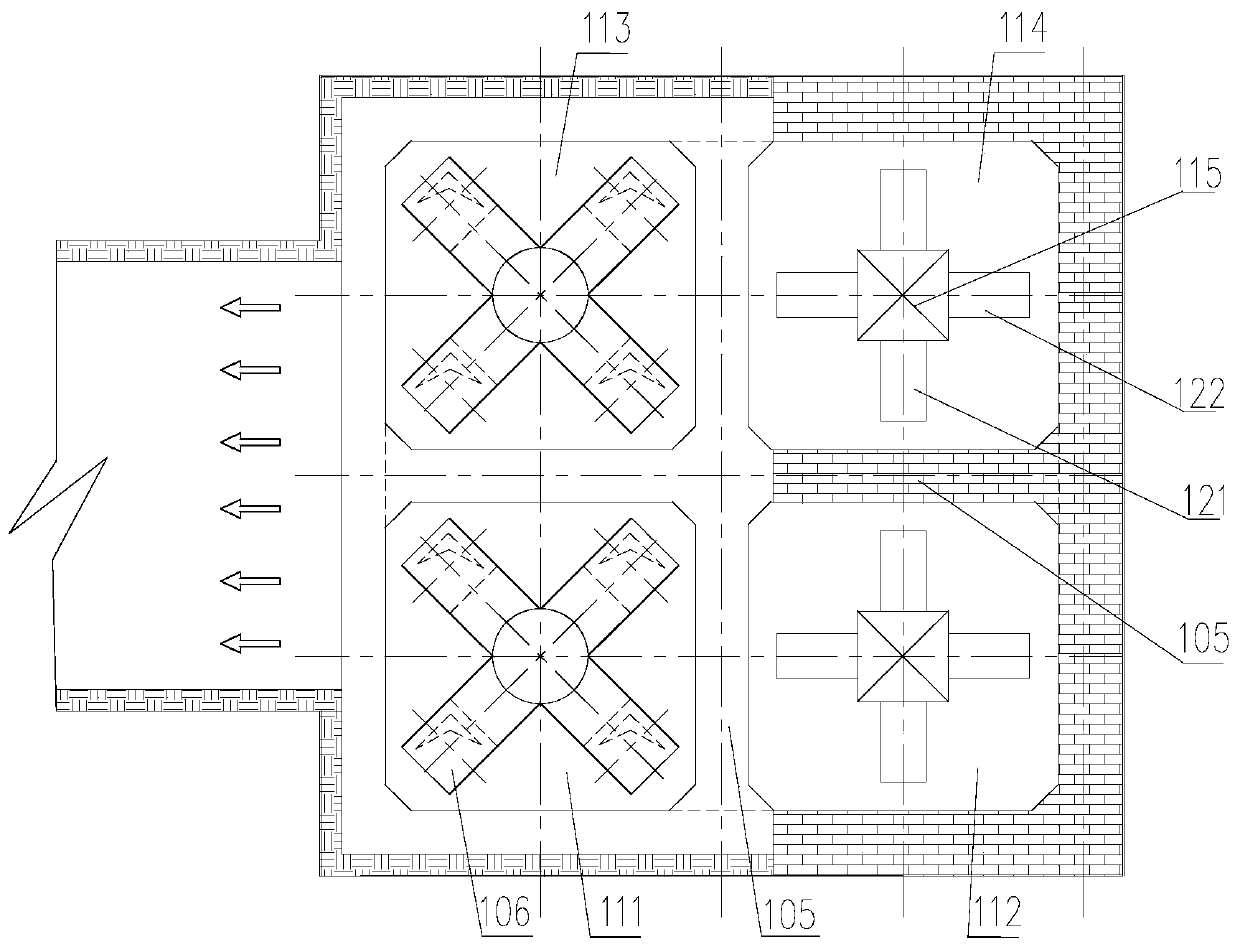

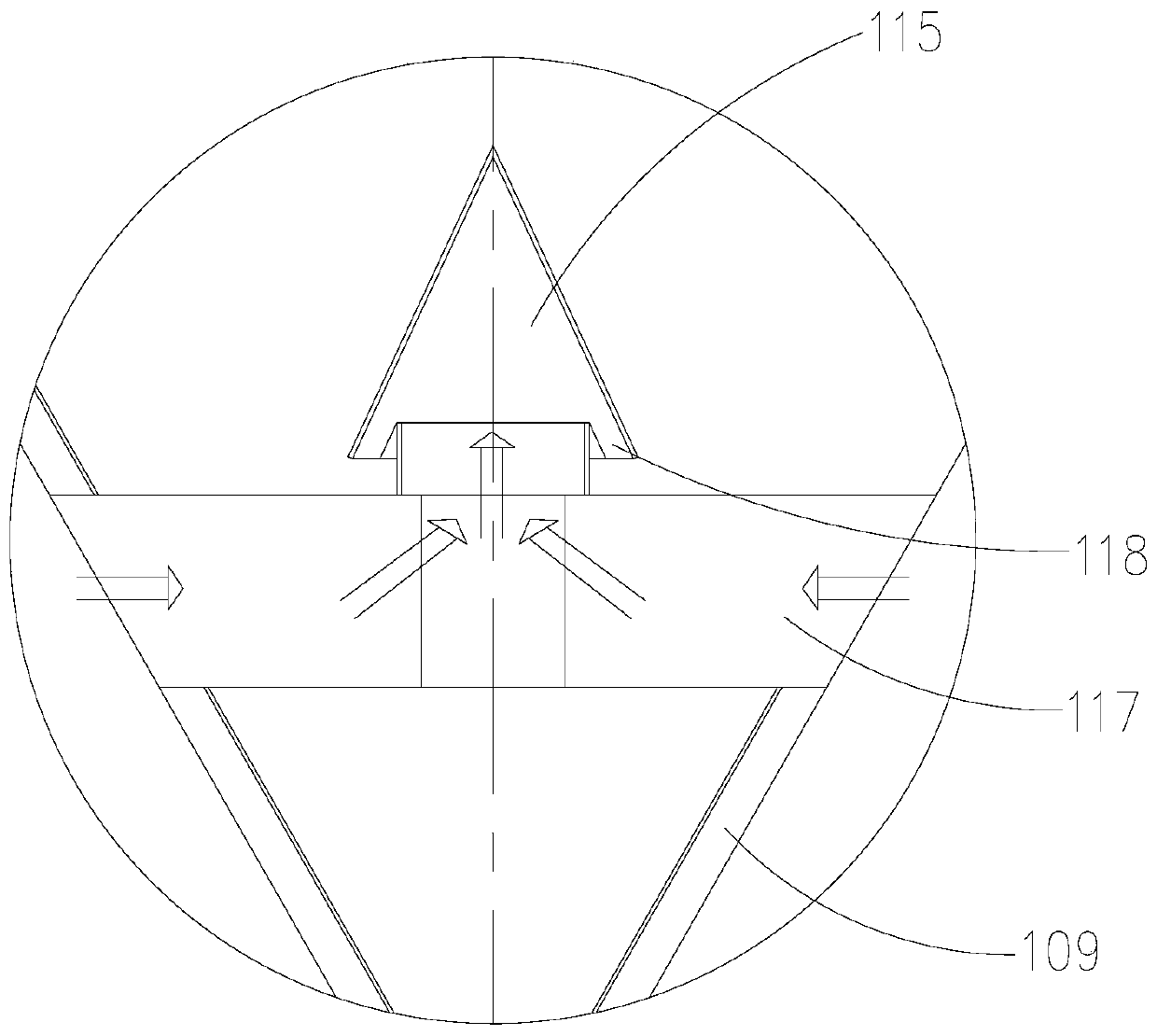

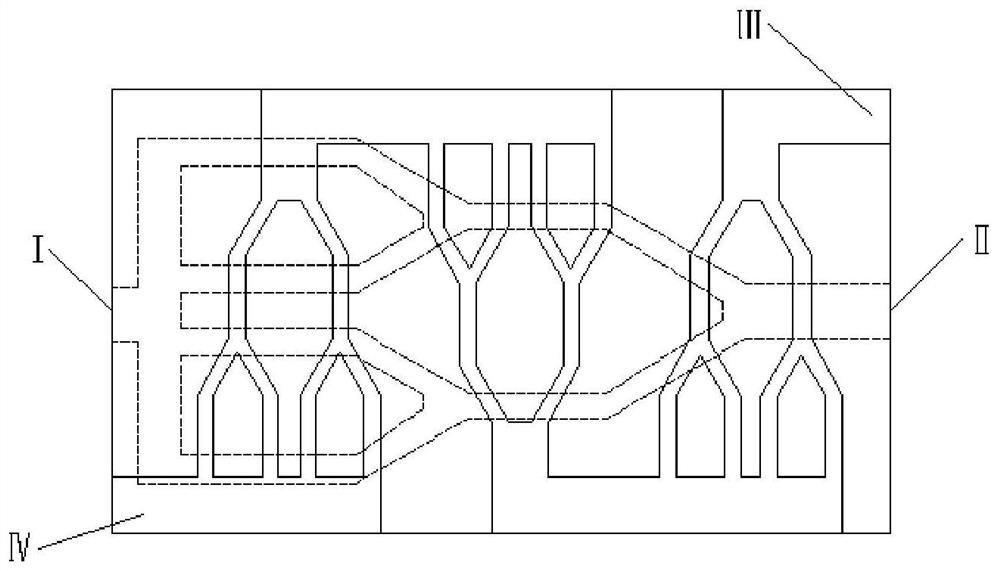

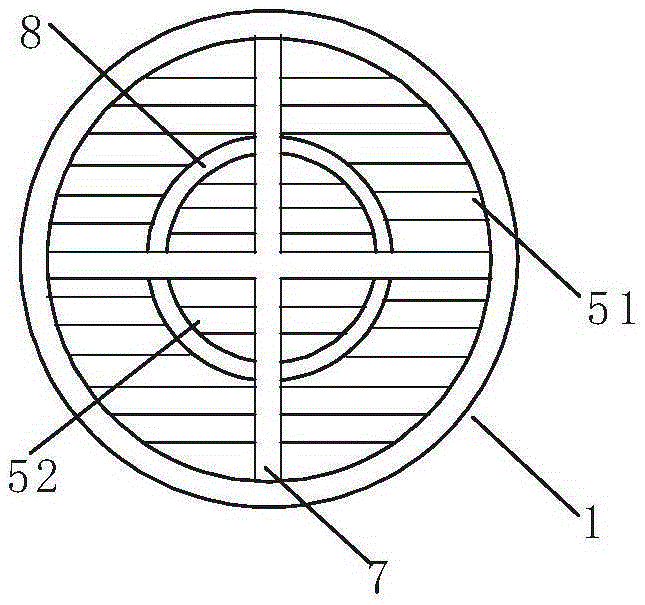

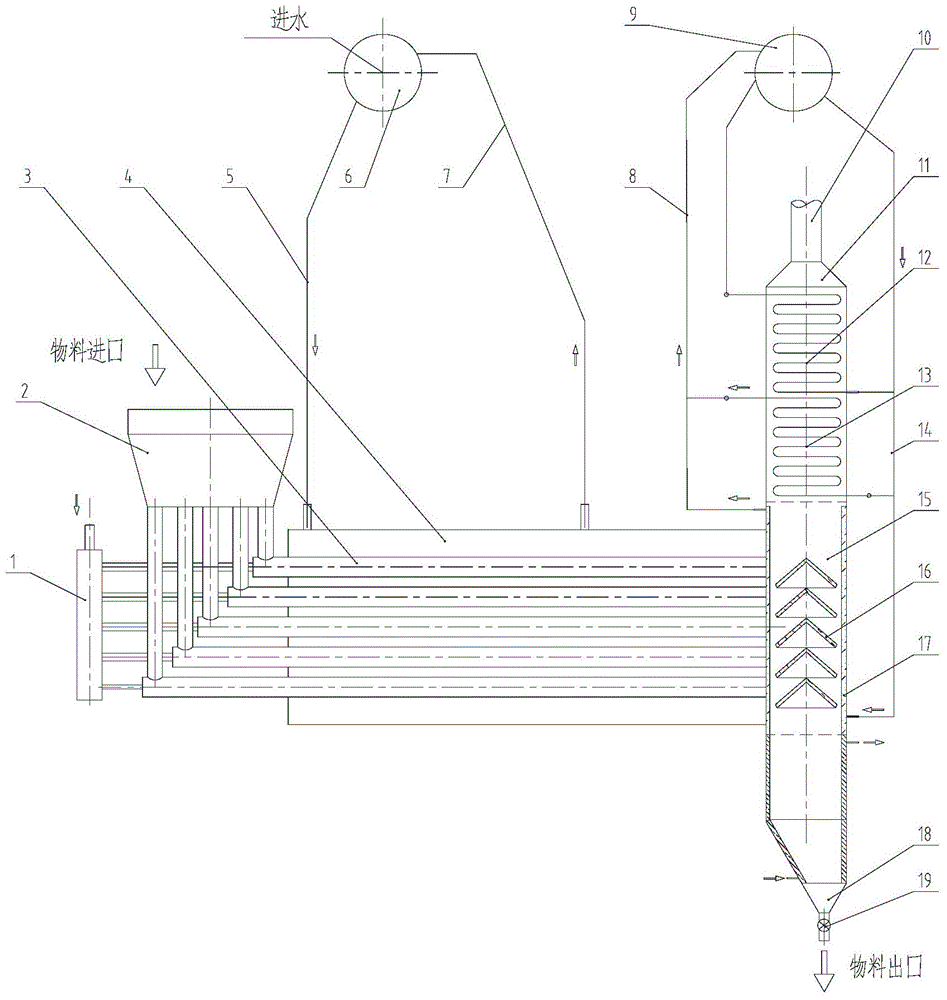

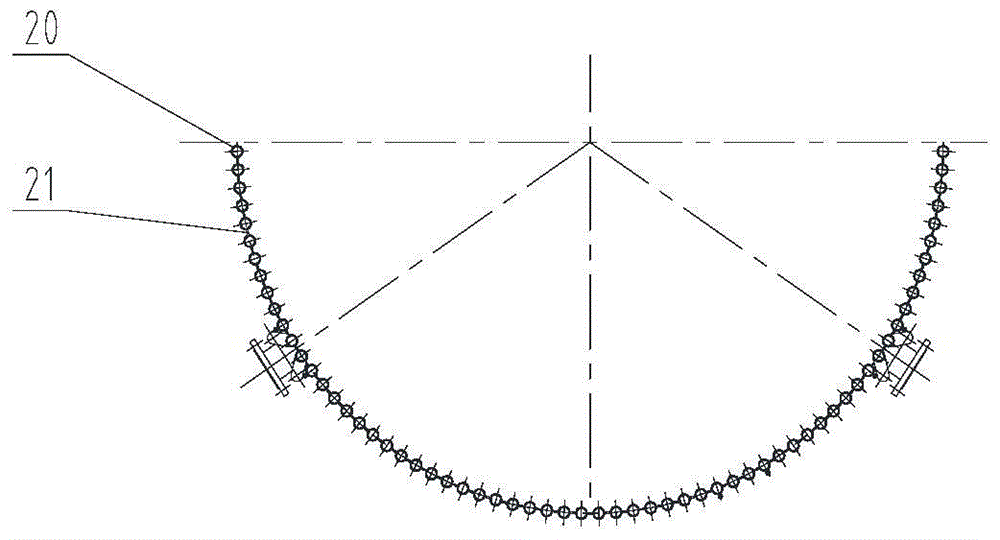

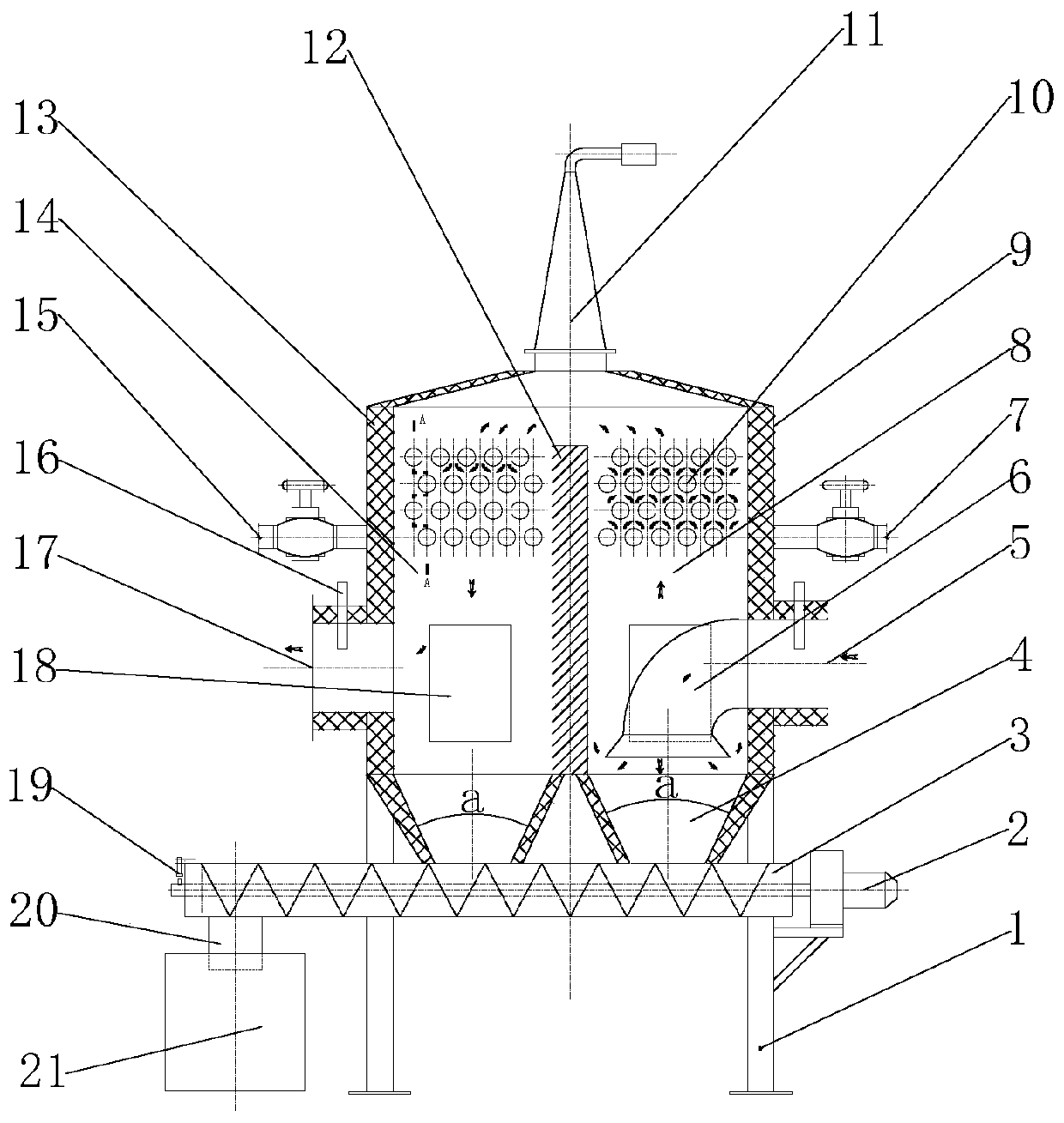

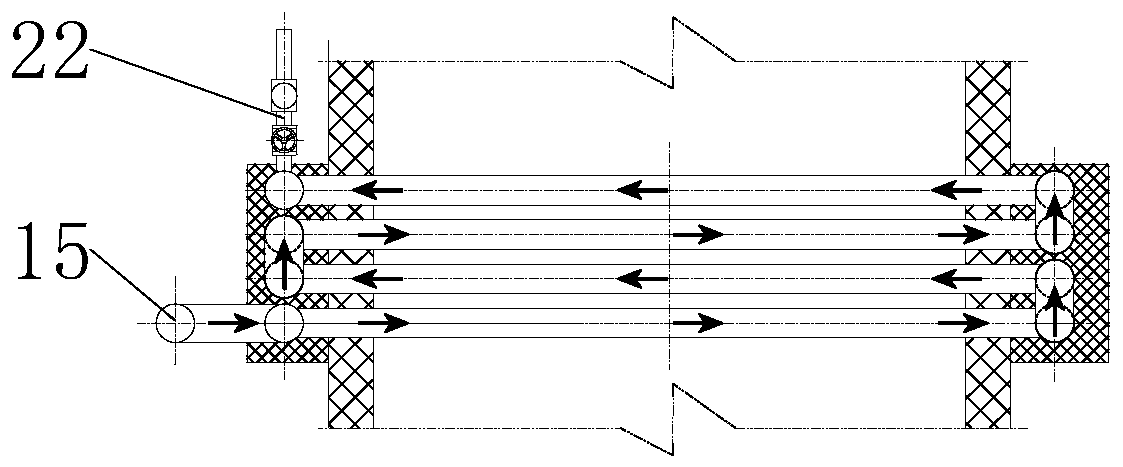

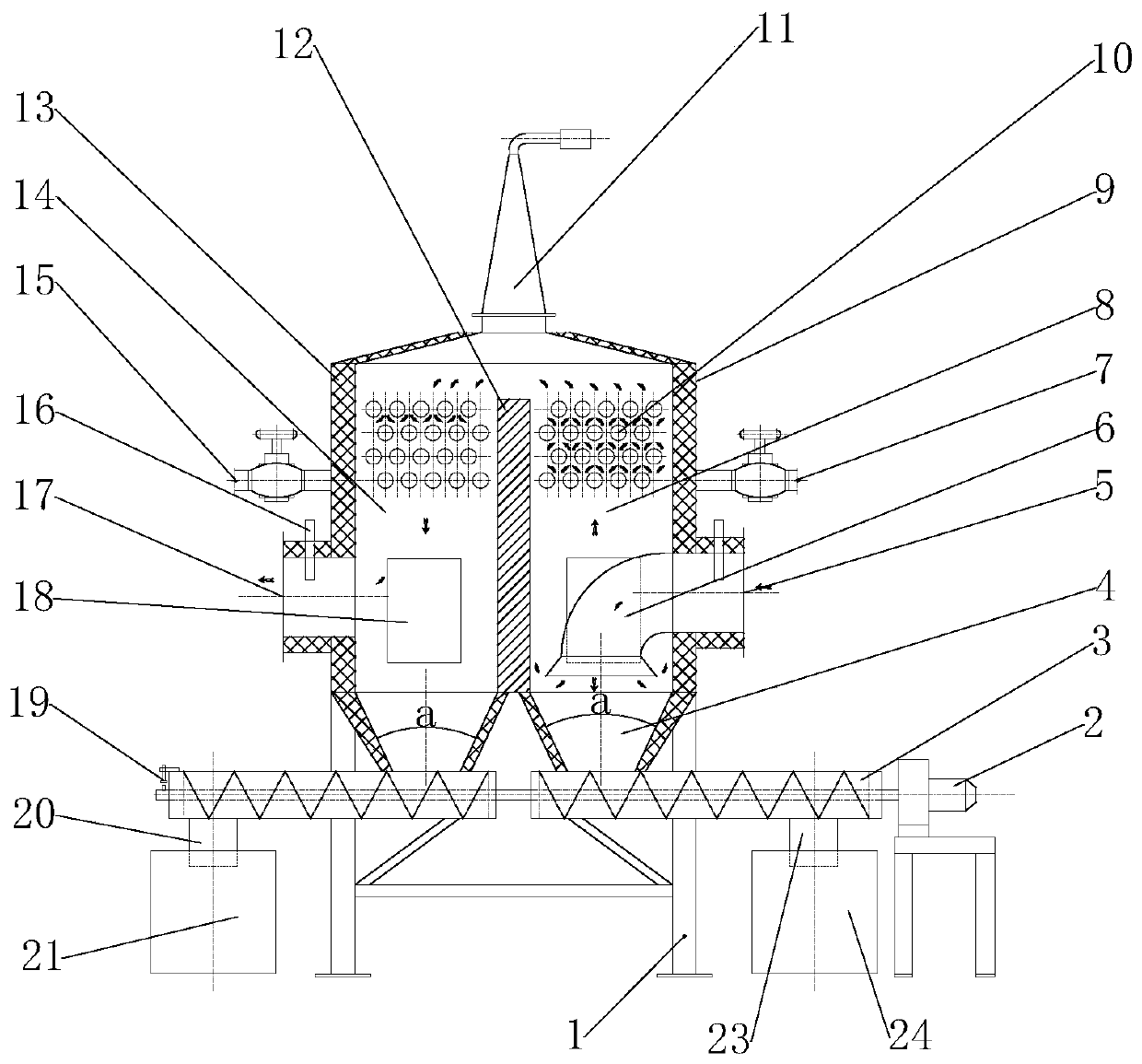

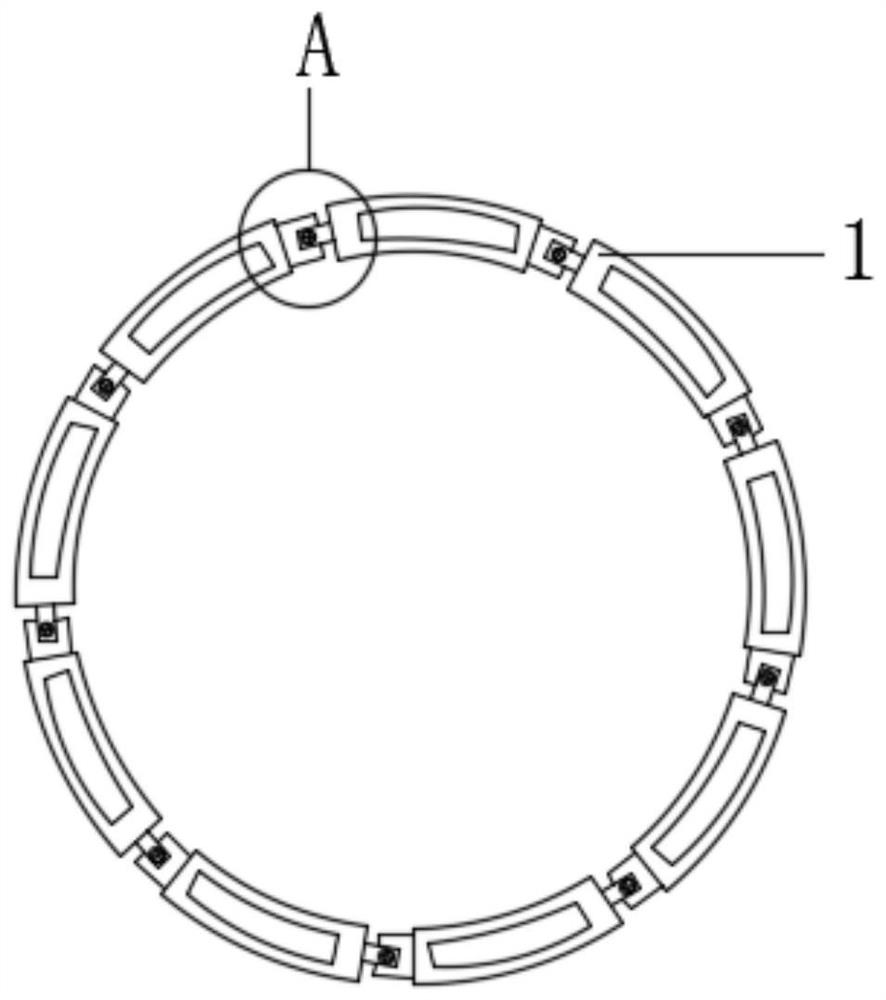

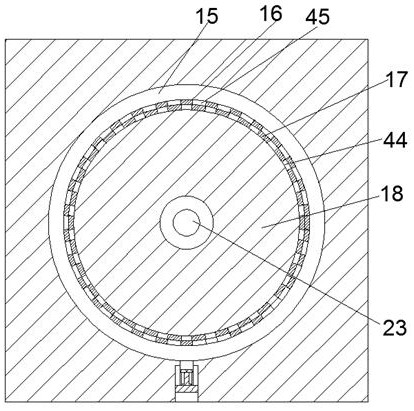

Vertical cooling kiln and mineral aggregate cooling and waste heat recovery method

PendingCN110779323AImprove uniformityRealize countercurrent heat exchangeVertical furnacesWaste heat treatmentThermodynamicsHot blast

The invention relates to the technical field of sinter cooling devices, in particular to a vertical cooling kiln and a mineral aggregate cooling and waste heat recovery method. The vertical cooling kiln comprises a kiln body, an inner ring air supply device, and an outer ring air supply device, wherein a cooling air supply chamber is arranged at the bottom of the kiln body, a hot air concentrationchamber is arranged at the top of the kiln body, and at least one cooling unit chamber is arranged between the cooling air supply chamber and the hot air concentration chamber; the cooling air supplychamber is used for providing cooling air to the cooling unit chambers, and the hot air concentration chamber is used for communicating with a hot air delivery channel; the inner ring air supply device is used for making the cooling air flow to the periphery from the centers of the cooling unit chambers; and an outer ring air inlet of the outer ring air supply device communicates with the coolingair supply chamber, and the outer ring air supply device is used for making the cooling air flow from the periphery of the cooling unit chambers to the centers. According to the vertical cooling kilnand the method, the uniformity of air supply into the cooling unit chambers can be improved, the uniform cooling of a mineral aggregate is realized, and the waste heat recovery efficiency is improved.

Owner:SHEN KAN QINHUANGDAO GENERAL ENG DESIGN & RES INST CORP MCC

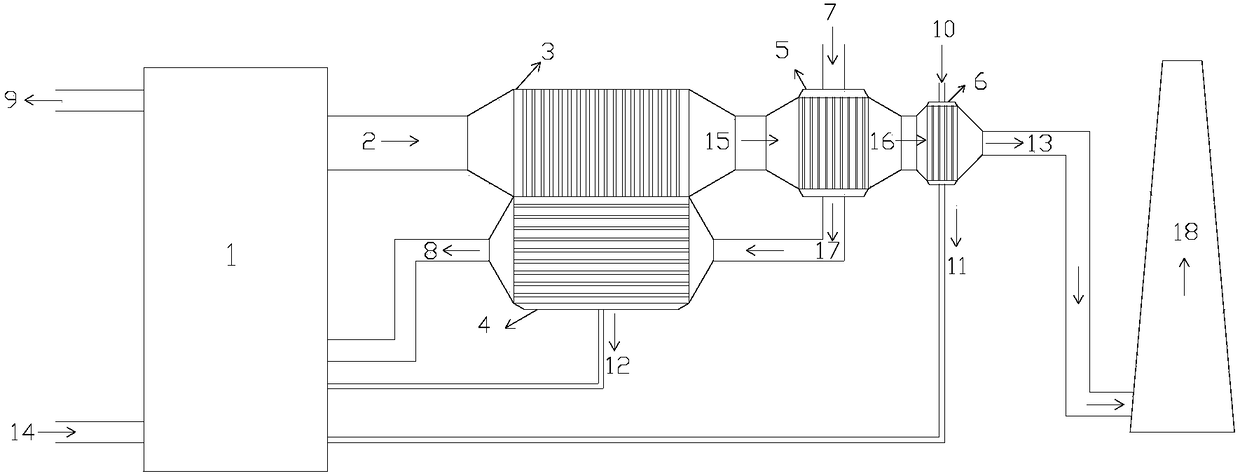

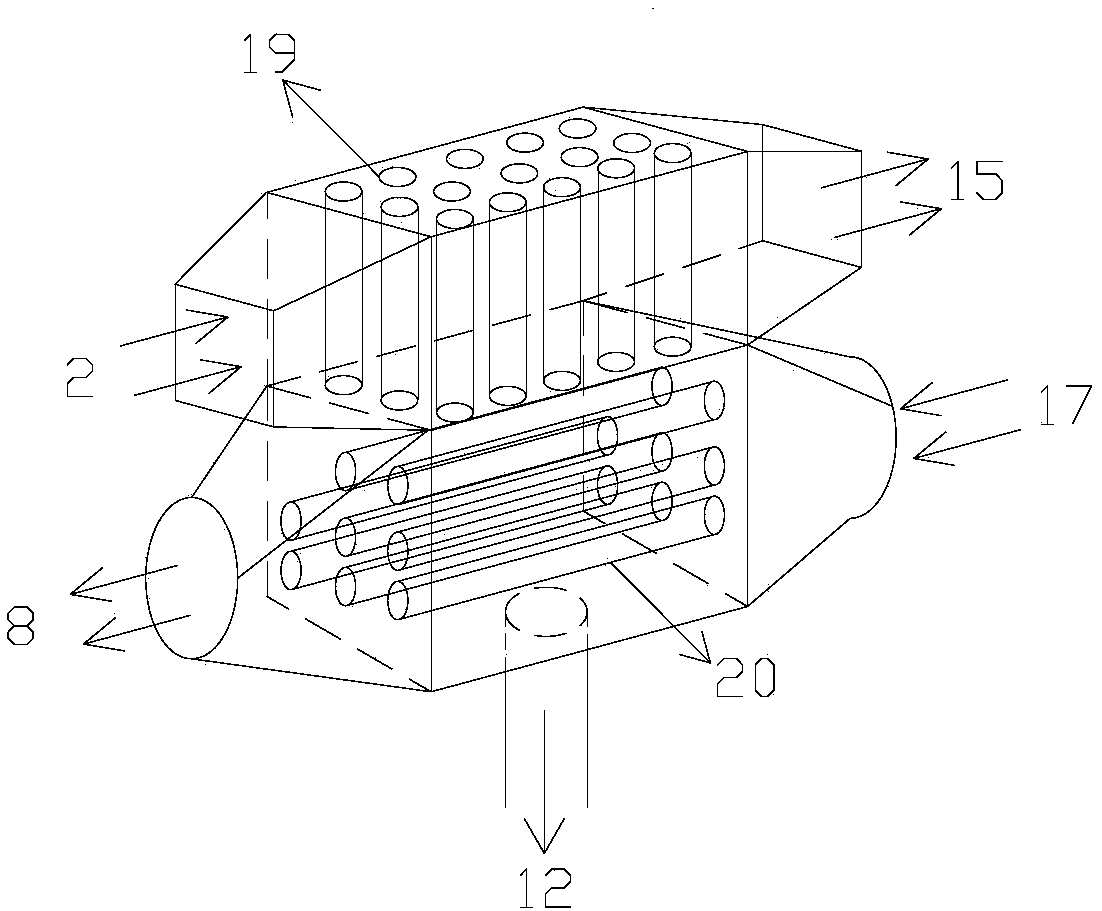

Efficient waste heat recovery and denitration combined technology for gas turbine tail gas

InactiveCN111174189AAvoid the risk of downtimeGuaranteed uptimeDispersed particle separationSteam generation using hot heat carriersPtru catalystFlue gas

The invention provides an efficient waste heat recovery and denitration combined technology for gas turbine tail gas. Flue gas discharged from a gas turbine enters a flue gas denitration system, is subjected to heat exchange with saturated steam from a high-pressure steam drum through a superheating segment of a high-pressure boiler, then is subjected to heat exchange with high-pressure boiler water from the high-pressure steam drum through an evaporation segment of the high-pressure boiler, then enters a denitration reaction bed layer through a fan to make contact with a catalyst for a denitration reaction, then is subjected to heat exchange with low-pressure boiler water from a low-pressure steam drum through an evaporation segment of a low-pressure boiler, and finally is subjected to heat exchange with the high-pressure boiler water at a coal-saving segment of the high-pressure boiler and then is discharged through a chimney. According to the efficient waste heat recovery and denitration combined technology, the high-pressure steam drum and the low-pressure steam drum are subjected to heat exchange with the flue gas to generate high-pressure steam and low-pressure steam, waste heat in the flue gas is recovered maximally, thus the comprehensive utilization rate of the gas turbine is increased and reaches 95% or above, the operation and investment costs are lowered, and the energy saving and environment friendly requirements are met.

Owner:ZHEJIANG SATELLITE ENERGY CO LTD

Multi-stage low-temperature waste heat recovery system based on supercritical carbon dioxide

ActiveCN113280672AEfficient Waste Heat RecoveryImprove waste heat recovery efficiencyRecuperative heat exchangersCombustion processFlue gasProcess engineering

The invention discloses a multi-stage low-temperature waste heat recovery system based on supercritical carbon dioxide. The multi-stage low-temperature waste heat recovery system comprises a supercritical carbon dioxide multi-stage waste heat recovery circulating system and a novel heat exchange system for providing a cold source for the whole system; and the novel heat exchange system comprises a first-stage novel heat exchanger, carbon dioxide of a low-temperature heat exchanger exchanges heat with a circulating cooling working medium through the first-stage novel heat exchanger, and carbon dioxide discharged from the first-stage novel heat exchanger enters a second-stage novel heat exchanger through a large-temperature-difference heat exchange unit and exchanges heat with circulating cooling liquid, and finally the low-temperature carbon dioxide working medium is formed and returns to the low-temperature heat exchanger to be subjected to heat exchange with the low-temperature flue gas for next-stage circulation. According to the low-temperature multi-stage waste heat recovery system with the supercritical carbon dioxide as the working medium, after heat exchange is conducted at the position of a first-stage heat regenerator 6, the high-temperature working medium is divided into two paths, and the waste heat utilization efficiency is improved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

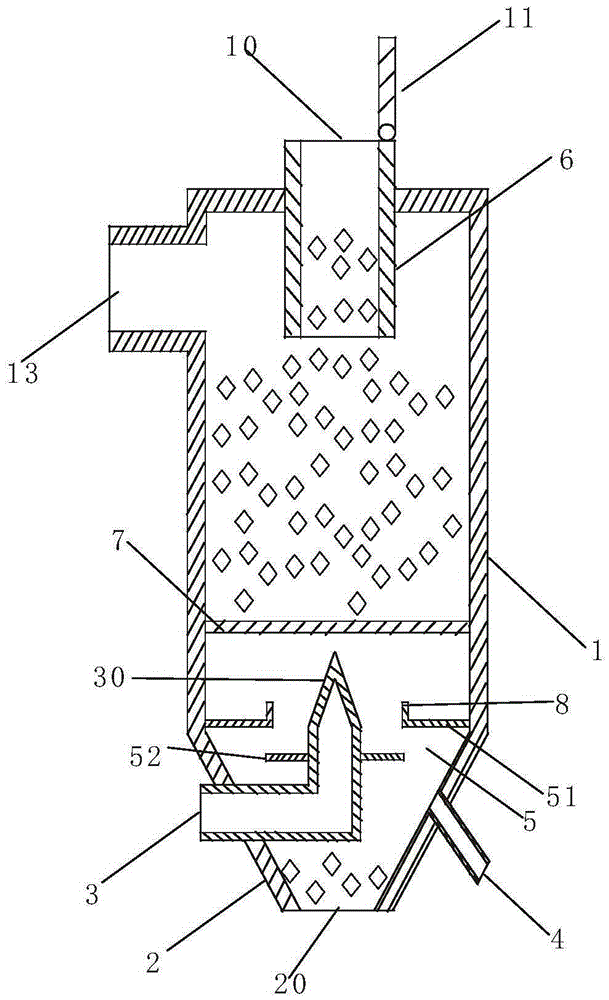

Waste heat recovery furnace

ActiveCN104121786BEfficient recyclingReduce dosageEnergy industryWaste heat treatmentRecovery boilerWaste management

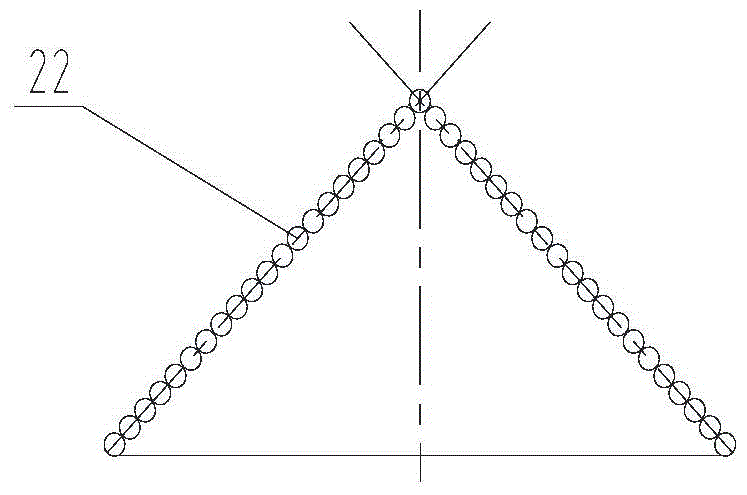

The invention provides a waste heat recycling furnace. According to the waste heat recycling furnace, waste heat of sintered ore can be sufficiently and efficiently recycled. The waste heat recycling furnace comprises a cooling cylinder. A feeding opening is formed in the upper surface of the cooling cylinder, a sealing cover for sealing the feeding opening is arranged on the feeding opening, an air outlet is formed in the upper end of the side wall of the cooling cylinder and connected with an induced draft fan, a conical cold feeder is connected to the lower end of the cooling cylinder, a discharging opening is formed in the lower end of the cold feeder, a vibration discharging machine is installed in the discharging opening, a center cooling air pipe extending to the center of the cooling cylinder is installed on the waste heat recycling furnace, a conical center air cap with the upward top end is connected to the upper end of the center cooling air pipe, a plurality of air holes are formed in the conical wall of the center air cap, one or more peripheral cooling air pipes are formed on the conical wall of the cold feeder in the mode of surrounding the conical wall, a discharging mechanism is arranged between the cooling cylinder and the cold feeder and comprises an upper discharging plate and a lower discharging plate, and the upper discharging plate and the lower discharging plate can be opened and closed and can achieve discharging through reciprocating movement.

Owner:TIANJIN ZHENGYUANHE TECH DEV CO LTD

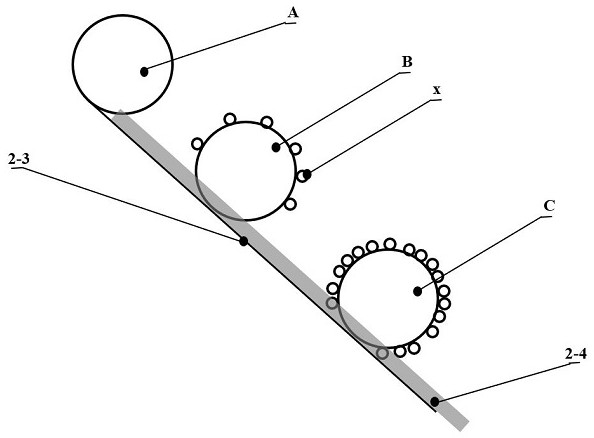

Metallurgical slag granulation-catalyst preparation and modification integrated device system and method

PendingCN113117678AEfficient Waste Heat RecoveryIncrease added valueCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsMetallurgical slagIntegrated devices

The invention discloses a metallurgical slag granulation-catalyst preparation and modification integrated device system and method, the system is mainly composed of four parts of a granulation system, a catalyst modification system, a waste heat recovery system and a separation and circulation system, and the working process of the system is composed of four steps of metallurgical slag granulation, catalyst modification, particle waste heat recovery and screening and recovery. According to the process, catalyst modification powder is directly adhered by utilizing the secondary coagulation characteristic of the surfaces of granulated metallurgical slag particles so that the catalyst particles with high additional value are prepared. The system not only realizes efficient recovery of waste heat of metallurgical slag particles, but also greatly improves the additional value of metallurgical slag products.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

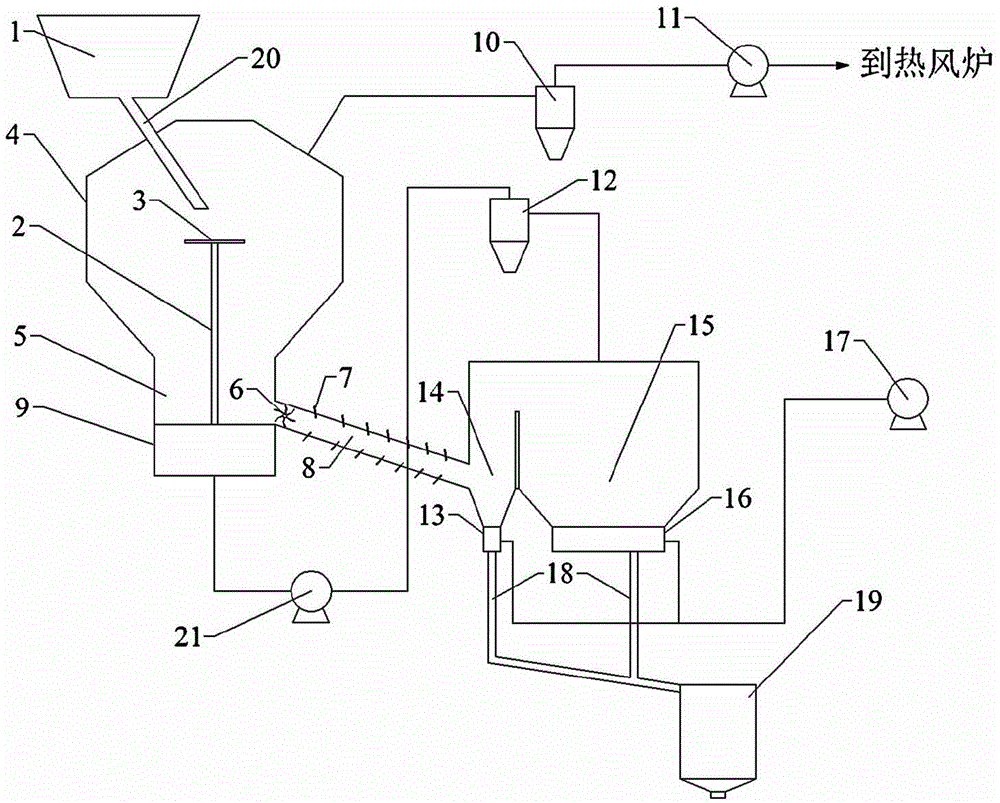

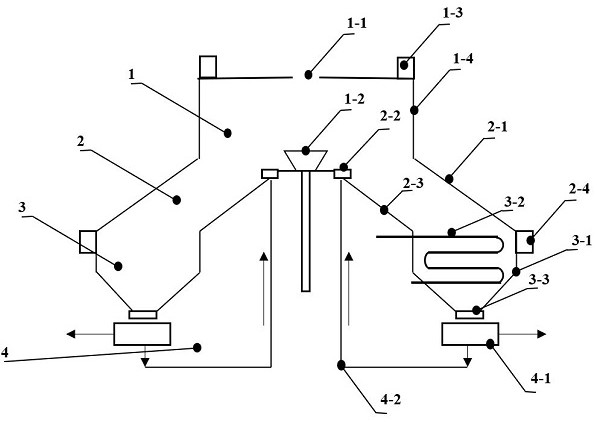

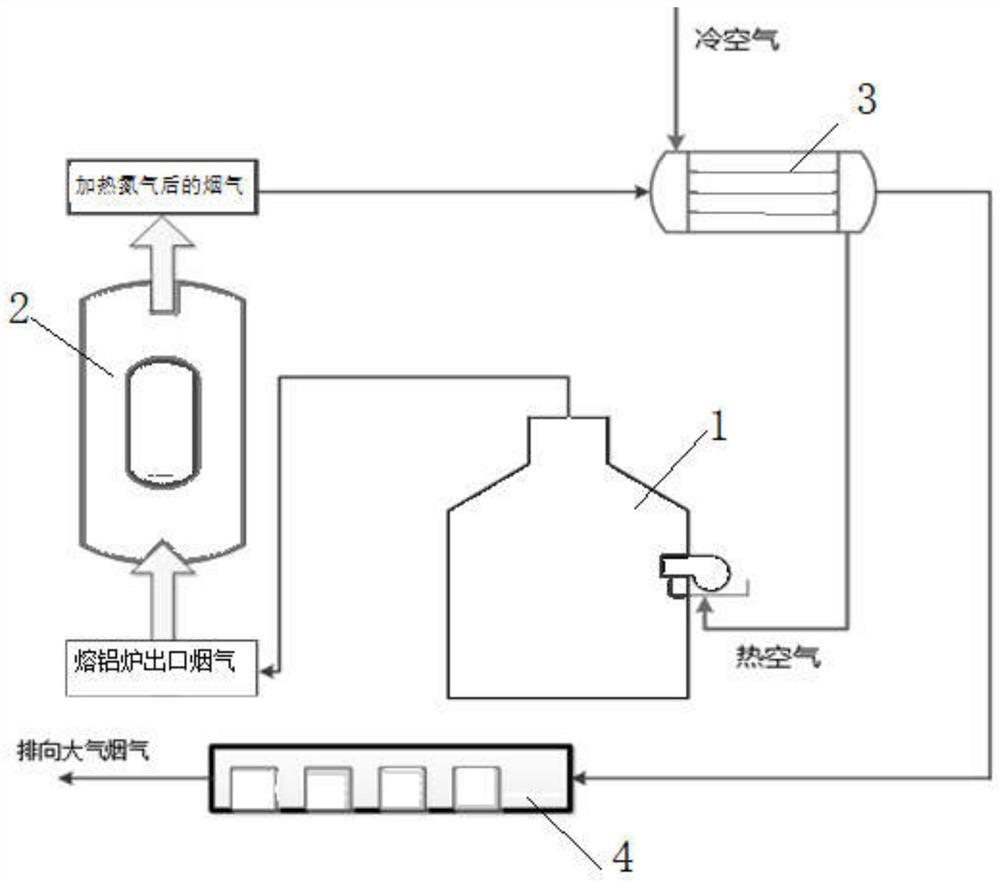

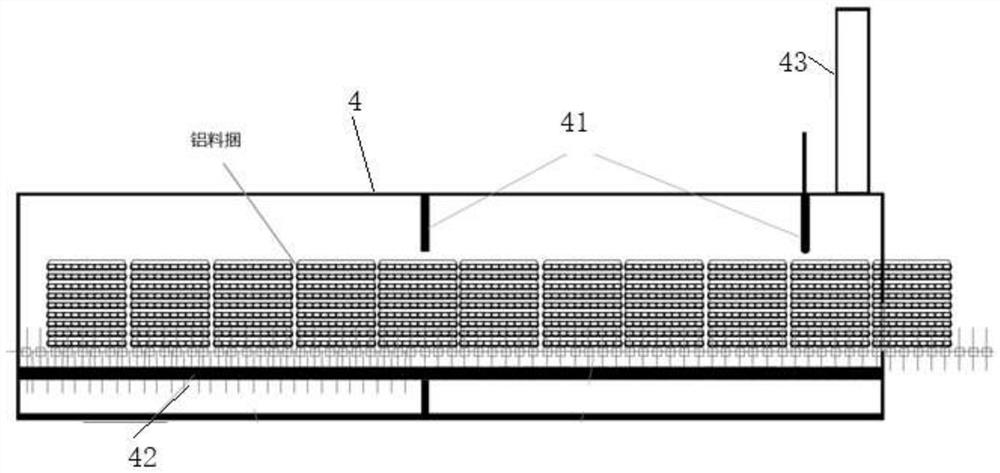

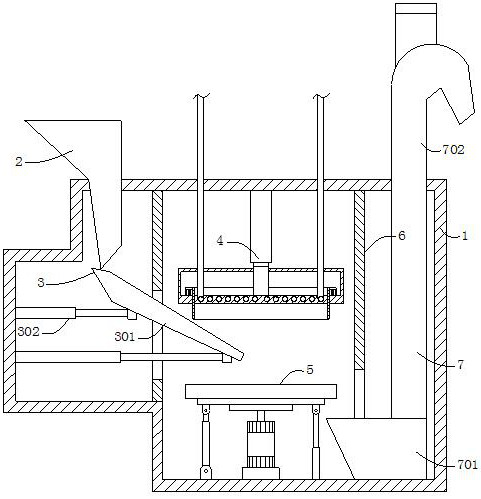

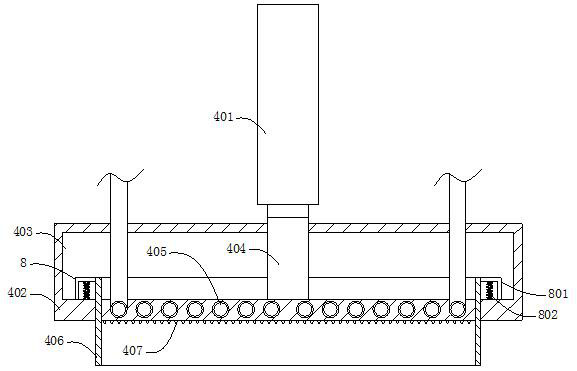

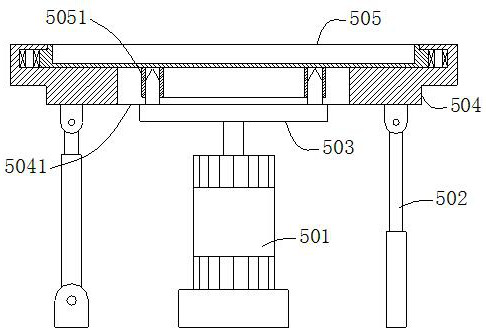

Flue gas waste heat recovery system and recovery method for aluminum melting furnace

InactiveCN114322581AMeet the requirements of smelting processImprove heat transfer efficiencyIncreasing energy efficiencyPreheating chargesNitrogen gasCorrosion

The invention provides a flue gas waste heat recovery system and method for an aluminum melting furnace. A nitrogen heater, a flue gas-air heat exchanger and an aluminum ingot heating chamber are sequentially installed on a flue gas discharge pipeline of the aluminum melting furnace. The flue gas sequentially heats nitrogen in the nitrogen tank, cold air in the flue gas-air heat exchanger and aluminum ingots in the aluminum ingot heating chamber; and the cold air in the flue gas-air heat exchanger is heated to serve as hot air and is connected to the aluminum melting furnace through a pipeline. The heat exchange efficiency of the heat exchanger and the dew point corrosion resistance of equipment are improved, the service life of the heat exchanger is prolonged, low-temperature flue gas waste heat can be efficiently recycled, and the obvious energy-saving and emission-reducing effects are achieved.

Owner:CENT SOUTH UNIV

Blast furnace slag recycling device

ActiveCN114277204AEasy to handleEfficient Waste Heat RecoveryIncreasing energy efficiencyRecycling and recovery technologiesThermodynamicsProcess engineering

The blast furnace slag recycling device comprises a box body, an inner cavity of the box body is sequentially divided into a first area, a second area and a third area through two vertically-arranged partition plates, a feeding hopper is fixedly embedded in the top of the first area, and a material guiding mechanism used for guiding slag is arranged in the middle of the first area; the top and the bottom of the second area are provided with a waste heat recovery mechanism and a containing and dumping mechanism correspondingly, and the waste heat recovery mechanism and the containing and dumping mechanism are oppositely arranged. According to the invention, the waste heat recovery mechanism is matched with the accommodating and dumping mechanism to crush the slag, and waste heat recovery is carried out on the crushed slag; the slag is crushed and is uniformly laid in the placing disc, so that on one hand, efficient waste heat recovery is realized, and on the other hand, follow-up procedure treatment on the slag is facilitated; in addition, the mode that the waste heat recovery mechanism serves as a good heat conductor to make contact with the molten slag to achieve waste heat recovery is more efficient compared with the waste heat recovery mode that a conveying belt is adopted and air is spaced.

Owner:中环正奇科技有限公司

A flue gas waste heat recovery system based on membrane absorption

ActiveCN107631290BLower dew point temperatureSolve the problem of waste heat recovery requiring anti-corrosionCombustion processFeed water supplyAir preheaterFiber

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE

A combined waste heat recovery device and waste heat recovery method for high-temperature solid materials

InactiveCN104566317BEfficient Waste Heat RecoverySteam generation using hot heat carriersLiquid wasteRecovery method

Owner:CENT IRON & STEEL RES INST

Boiler

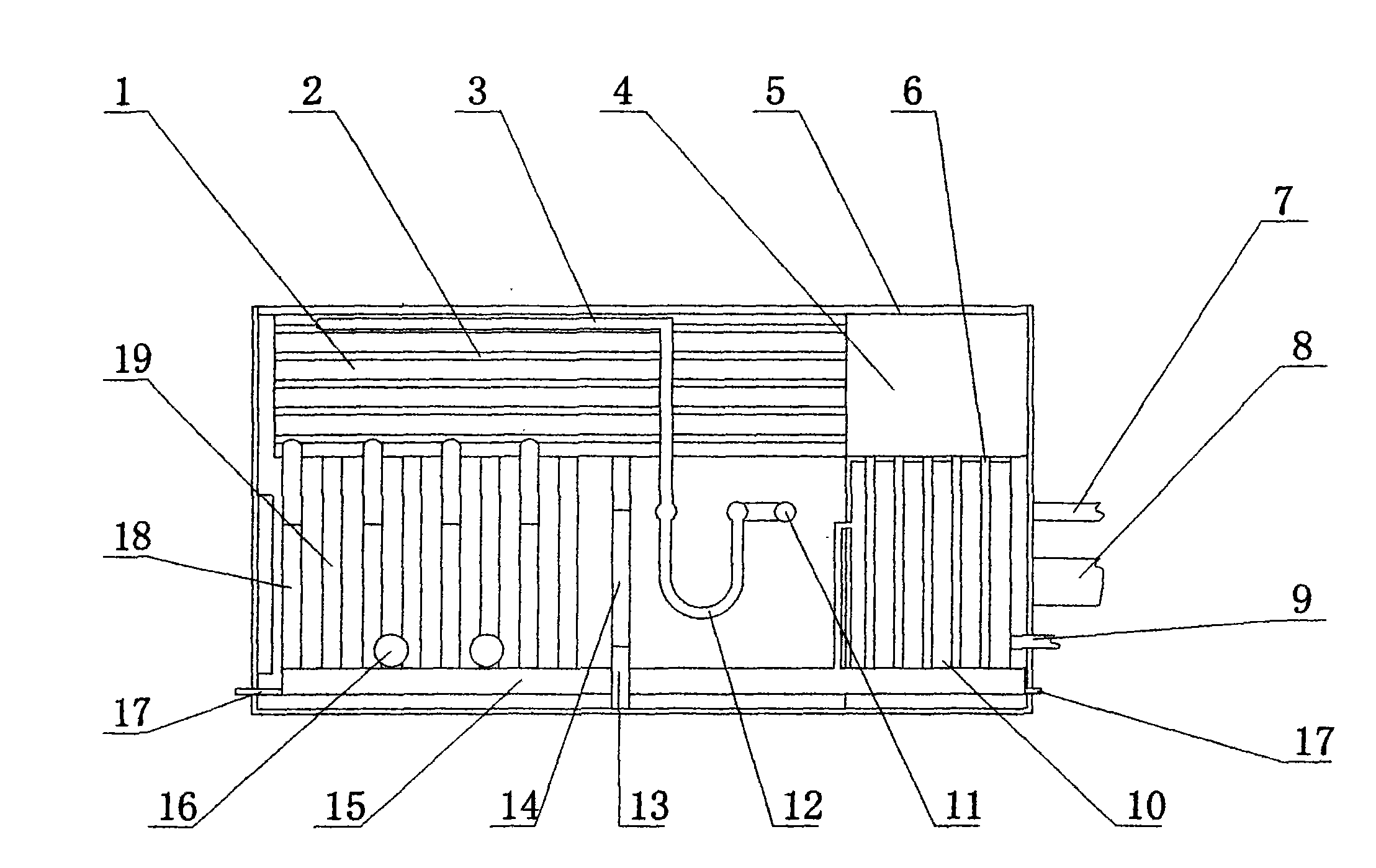

The invention discloses a boiler. The boiler comprises a housing, a burning material inlet, a smoke outlet and a water outlet, and is characterized in that a partition wall with an opening in the middle is arranged at the internal middle part of the housing; an afterheat recovery box is arranged at the rear part of the housing; a water collecting pipe communicated with the afterheat recovery box is arranged at the lower part of the housing; a boiler barrel is arranged at the upper part of the burning box; an ascending water pipe and a descending water pipe are arranged between the boiler barrel and the water collecting pipe; smoke pipes are arranged in the boiler barrel and the afterheat recovery box, and the rear end of the boiler barrel is in sealing connection with the upper end of the afterheat recovery box; a water outlet pipe is communicated to the front end of the boiler barrel; and an U-shaped pipe array is arranged in front of the opening. According to the boiler, the afterheat in the smoke is efficiently absorbed, the utilization efficiency of the heat is improved better, and the amount of inlet oxygen is greatly increased due to the long-distance smoke channel, so that burning efficiency of the fuel is increased; and the waste is avoided, and the energy consumption is reduced.

Owner:侯艳坤

Twin Scroll Turbocharger with Waste Heat Recovery

InactiveUS20200284187A1Preventing compressor surgeMaximizing engine torqueInternal combustion piston enginesExhaust apparatusEngine efficiencyTurbocharger

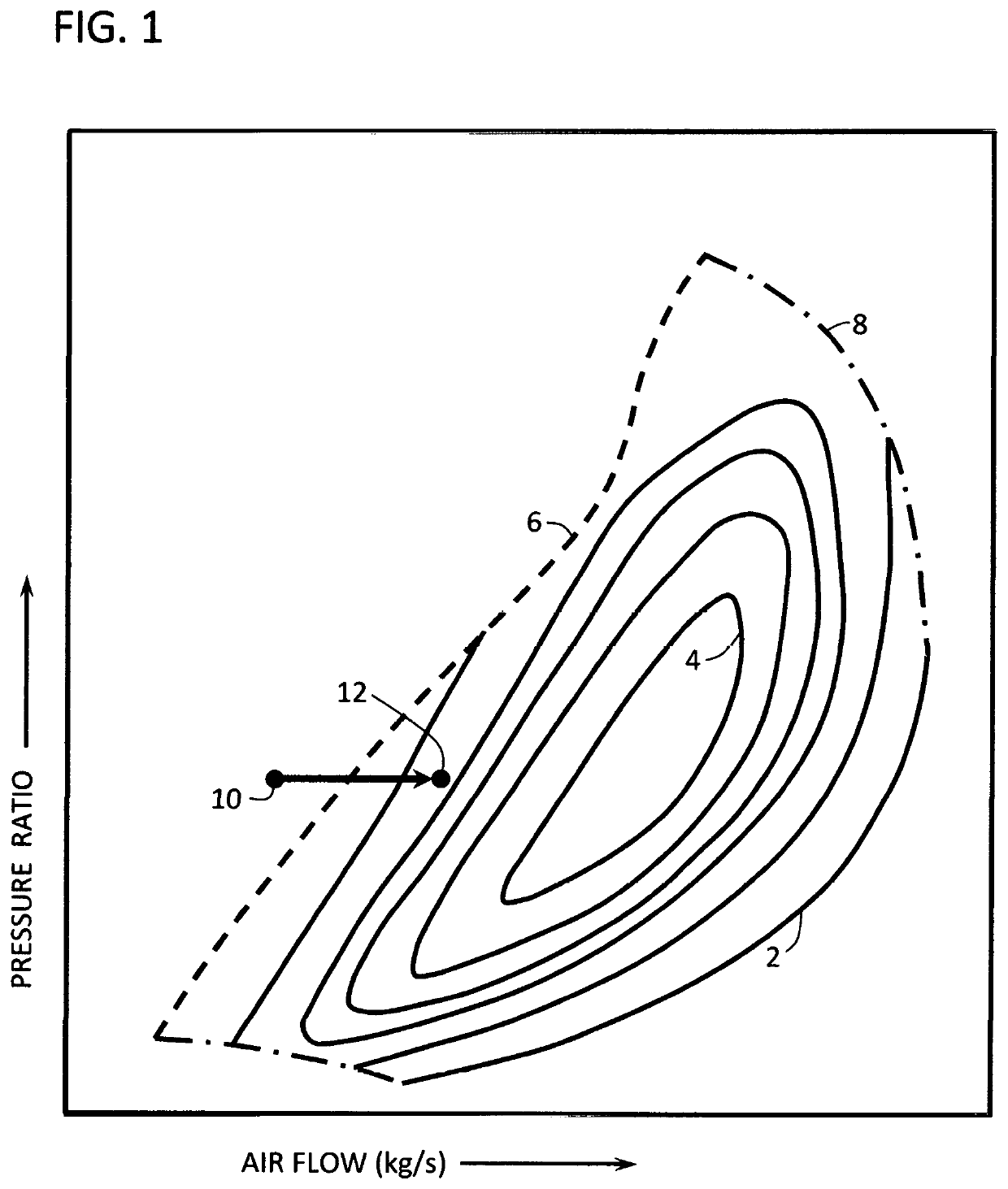

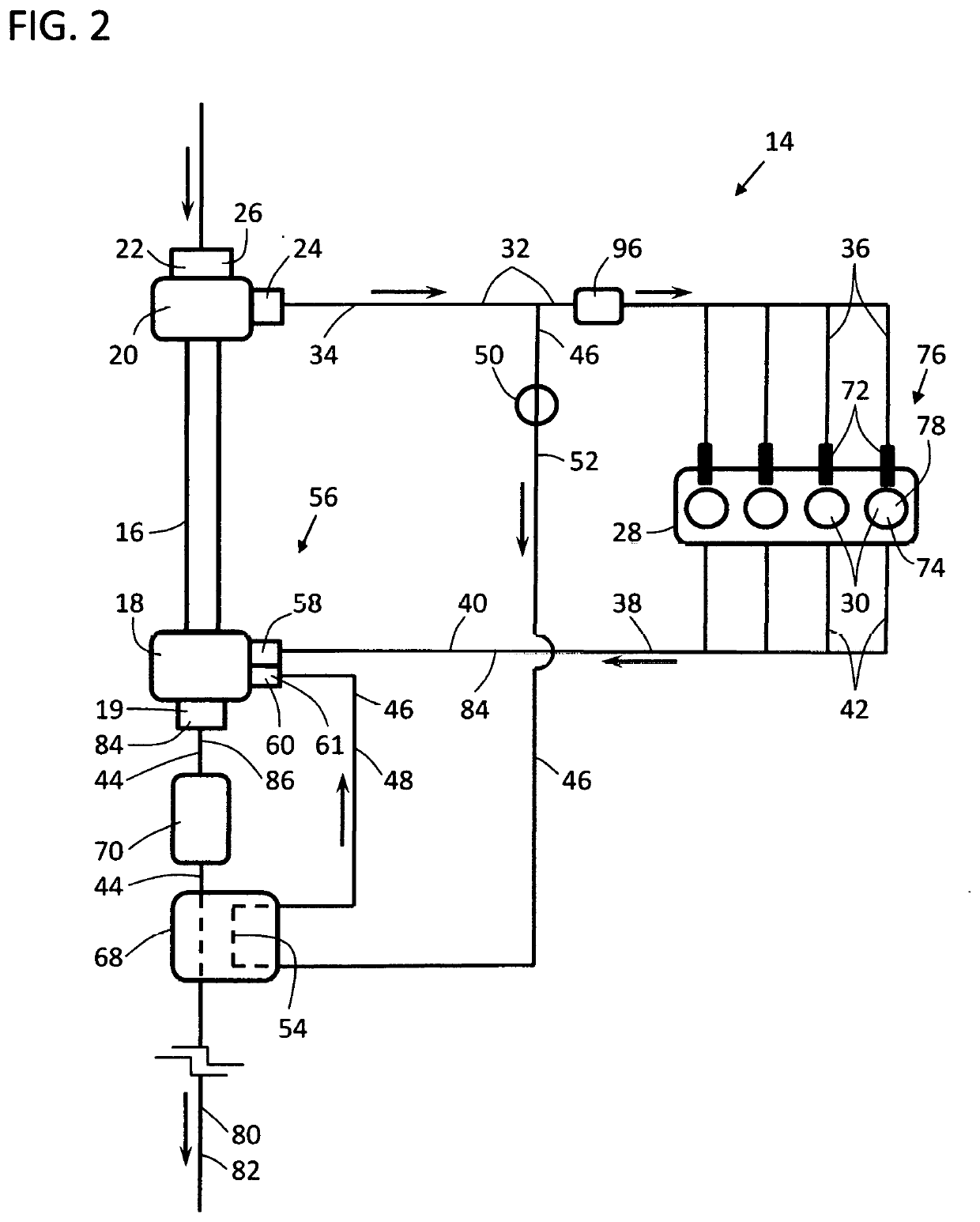

Bypass air from downstream of the compressor is directed into a heat exchanger that draws heat from the exhaust gas of the engine. The bypass air does not include fuel, and instead is heated by the exhaust gas in the heat exchanger. The bypass duct enables air mass flow through the compressor to be increased, thereby preventing compressor surge at low engine speeds. The turbocharger turbine includes a dual entry scroll. The bypass air is fed into the first scroll after being heated in the heat exchanger, and the engine' exhaust gas is fed into the second scroll. Use of two scrolls enables the blowdown impulse energy of the exhaust gas to be retained within the exhaust manifold prior to entry into the turbine, thereby providing improved turbocharger response and preventing backflow of exhaust gas into the bypass duct. Using the exhaust energy to heat the bypass air instead of combusting additional fuel leads to increased engine efficiency.

Owner:MENDLER EDWARD CHARLES

Dry granulation waste heat recovery system

ActiveCN104388611BHigh recovery rateImprove qualityRecycling and recovery technologiesWaste heat treatmentWaste heat recovery unitSlag

The invention discloses a dry-type granulation treatment waste heat recovery system which comprises a slag storage bin, a granulation cooling unit, a primary waste heat recovery unit, a secondary waste heat recovery unit and a tertiary waste heat recovery. The system is characterized in that the top of the granulation cooling unit is provided with a first air outlet; the first air outlet is connected with a high-temperature booster fan through a pipeline; a granulator is arranged in the granulation cooling unit, positioned below a charging pipe and driven by a rotating shaft to rotate; the primary waste heat recovery unit is arranged below the granulation cooling unit; the bottom of the primary waste heat recovery unit is provided with a first fluidized bed and a slag discharge pipe; the slag discharge pipe is communicated with the secondary waste heat recovery unit; the bottom of the secondary waste heat recovery unit is provided with a spray bed; and the upper part of the secondary waste heat recovery unit is communicated with the upper part of the tertiary waste heat recovery unit. The system implements the dry-type granulation function and high-efficiency waste heat recovery, and can be widely used in the fields of steel, metallurgy and the like.

Owner:CHONGQING UNIV

Flue gas waste heat recovery device and method with spark capturing function

PendingCN111412757AImprove resource utilizationTo achieve energy saving needsGas treatmentDispersed particle separationParticulatesThermodynamics

The invention relates to the technical field of high-temperature flue gas treatment in the metal melting process, in particular to a flue gas waste heat recovery device and method with a spark capturing function. The flue gas waste heat recovery device and method solve the problem that a fire is prone to being caused in the flue gas waste heat recovery process, the particulate matter treatment difficulty is lowered, the resource utilization rate is increased, and the cost is reduced. The device adopts the spark capturing and waste heat recovery integrated design and comprises a rack and a boxbody mounted on the rack. A soot blower is mounted at the top of the box body. A partition plate mounted in the box body divides the box body into a left chamber and a right chamber. A flue gas outletand a flue gas inlet are formed in the lower ends of the left side and the right side of the box body and communicate with the left chamber and the right chamber correspondingly. A bent pipe connected with the flue gas inlet is arranged in the right chamber. The left chamber and the right chamber are each provided with a tube nest with the spark capturing function. The tube nests are connected with a water supply pipe and a water drainage pipe on the outer side of the box body correspondingly. Ash discharging hoppers communicating with the left chamber and the right chamber are symmetricallyarranged at the bottom of the box body. The lower ends of the ash discharging hoppers are connected with a conveying device.

Owner:QINHUANGDAO ZHONGQIN BOHAI HUB CO LTD

Pipe cluster waste heat recovery device with expanded heating surface

PendingCN113758344AEfficient Waste Heat RecoveryAchieve the transfer effectRecuperative heat exchangersHeat exchanger casingsMechanical engineeringPhysics

The invention belongs to the technical field of pipelines, and particularly relates to a pipe cluster waste heat recovery device with an expanded heating surface. The cluster waste heat recovery device comprises a binding shell, one end of the binding shell is fixedly connected with a mounting groove block, the other end of the binding shell is fixedly connected with a fixing insertion block, a groove is formed in the surface of the mounting groove block, and a groove in the surface of the mounting groove block is matched with the fixing insertion block. Through holes are formed in the surfaces of the mounting groove block and the fixing insertion block, fixing screws are arranged in the through holes in the surfaces of the mounting groove block and the fixing insertion block, a heat absorption block is arranged in the binding shell, a pull ring is fixedly connected to one end of the heat absorption block, and a heat conduction rod is fixedly connected to the surface of the heat absorption block. According to the pipe cluster waste heat recovery device, the binding shell is arranged, then the fixing insertion block on the binding shell is inserted into the groove of the mounting groove block, and then the fixing screws are inserted into the through holes of the mounting groove block and the fixing insertion block for fixing, so that the efficient waste heat recovery effect is achieved.

Owner:WUXI LAIDA HOT WORKING ENGIN

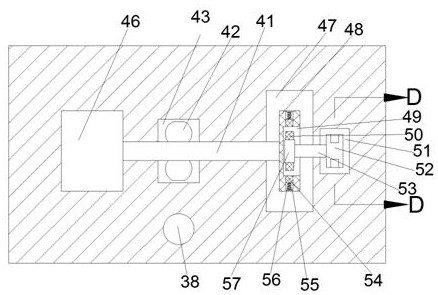

Industrial steam turbine capable of emergently stopping and recovering waste heat for power generation

InactiveCN111894686ASmooth rotationEfficient Waste Heat RecoveryMachines/enginesSafety/regulatory devicesProcess engineeringLeft wall

The invention discloses an industrial steam turbine capable of emergently stopping and recovering waste heat for power generation. The industrial steam turbine comprises a steam turbine body, whereina circular-truncated-cone-shaped supporting plate is arranged inside the steam turbine body, a circular-truncated-cone-shaped shaking supporting plate is arranged inside the supporting plate, a main power shaft is rotationally arranged between the left wall and the right wall inside the shaking supporting plate, and the left end surface of the main power shaft extends to the left side of the steamturbine body, and serves as power to be output other machine equipment. According to the industrial steam turbine, the rotation of the steam turbine is stabler by self-adjusting the rotating speed ofthe steam turbine, the device performs more efficient waste heat recovery, and meanwhile, when the rotating speed of the steam turbine exceeds a critical point, the risk that the steam turbine breaksdown due to the fact that the rotating speed is too large is greatly reduced by reducing the acceleration power of the steam turbine and braking a rotating shaft, and exhausted air is recycled againwhen the rotating speed is too large, so that waste heat recovery of the steam turbine becomes more efficient and stabler.

Owner:深圳市帕灯贸易有限公司

An energy-saving and low-dust emission coal-fired thermal power generation system

ActiveCN104896492BEfficient removalLow costCombustion processIndirect carbon-dioxide mitigationFlue gasProcess engineering

Owner:GUODIAN NEW ENERGY TECH INST

A multi-stage low-temperature waste heat recovery system based on supercritical carbon dioxide

ActiveCN113280672BEfficient Waste Heat RecoveryImprove waste heat recovery efficiencyRecuperative heat exchangersCombustion processFlue gasProcess engineering

The invention discloses a multi-stage low-temperature waste heat recovery system based on supercritical carbon dioxide, including a supercritical carbon dioxide multi-stage waste heat recovery cycle system, and a new heat exchange system that provides cold sources for the entire system; the new heat exchange system includes The first-stage new heat exchanger is installed. The carbon dioxide in the low-temperature heat exchanger exchanges heat with the circulating cooling medium through the first-stage new heat exchanger, and the carbon dioxide from the first-stage new heat exchanger enters through the large temperature difference heat exchange unit. to the second-stage new heat exchanger, and conduct heat exchange with the circulating cooling liquid, and finally form a low-temperature carbon dioxide working fluid and return to the low-temperature heat exchanger for heat exchange with low-temperature flue gas, and carry out the next stage of circulation. The low-low temperature multi-stage waste heat recovery and utilization system with critical carbon dioxide as the working fluid, after heat exchange at 6 places in the first-stage regenerator, the high-temperature working medium is divided into two paths, which improves the efficiency of waste heat utilization.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com