Dew-point corrosion resistant residual heat recovering system

A waste heat recovery system and dew point corrosion technology, applied in waste heat treatment, indirect heat exchangers, heat exchanger types, etc., can solve the problems of high unit energy consumption of enterprise products, short service life of heat exchangers, and increased production costs, etc. Achieve the effect of improving the ability of dew point corrosion resistance, long service life of equipment and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

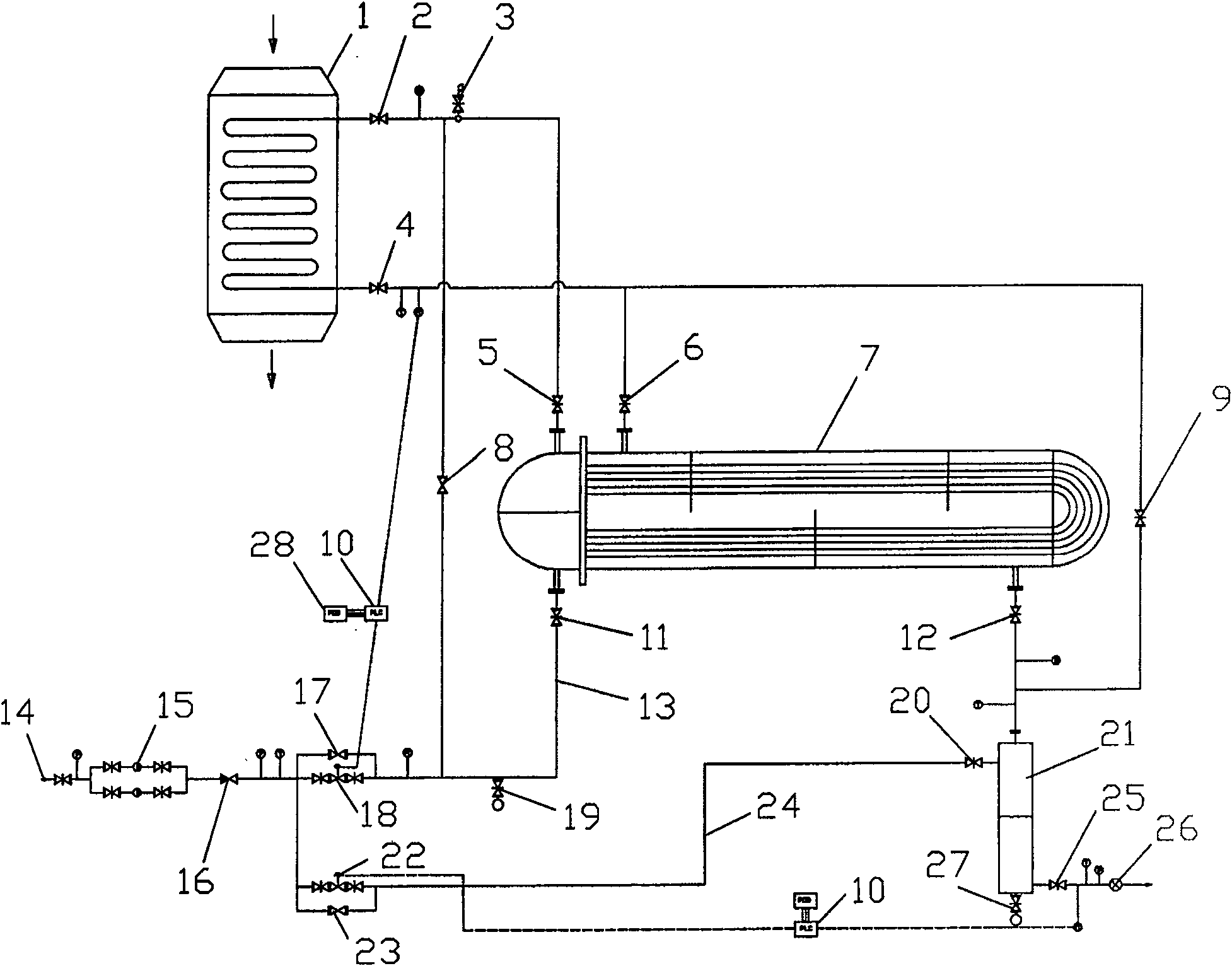

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0017] Referring to the drawings, the main pipe 14 is connected with a main pneumatic valve 18 and a secondary pneumatic valve 22 through a booster pump 15 and a check valve 16. The main pneumatic valve 18 is connected to the heating end inlet of the temperature compensator 7 through the first valve 11, and the temperature compensation The outlet of the heating end of the device 7 is connected to the heat exchange inlet of the heat pipe heat exchanger 1 through the second valve 5 and the third valve 2, and the heat exchange outlet of the heat pipe heat exchanger 1 is connected to the temperature compensator 7 through the fourth valve 4 and the fifth valve 6 The inlet of the cooling end, the outlet of the cooling end of the temperature compensator 7 is connected to the mixer 21 through the seventh valve 12, the auxiliary pneumatic valve 22 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com