Patents

Literature

154 results about "Temperature Compensator" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A compensator is used as a temperature compensator and as a pressure compensator too. It offers compensated pressure and temperature readings while the excess oil passes over the relief valve. The compensator is used to unload the pump when the pressure reaches a certain level.

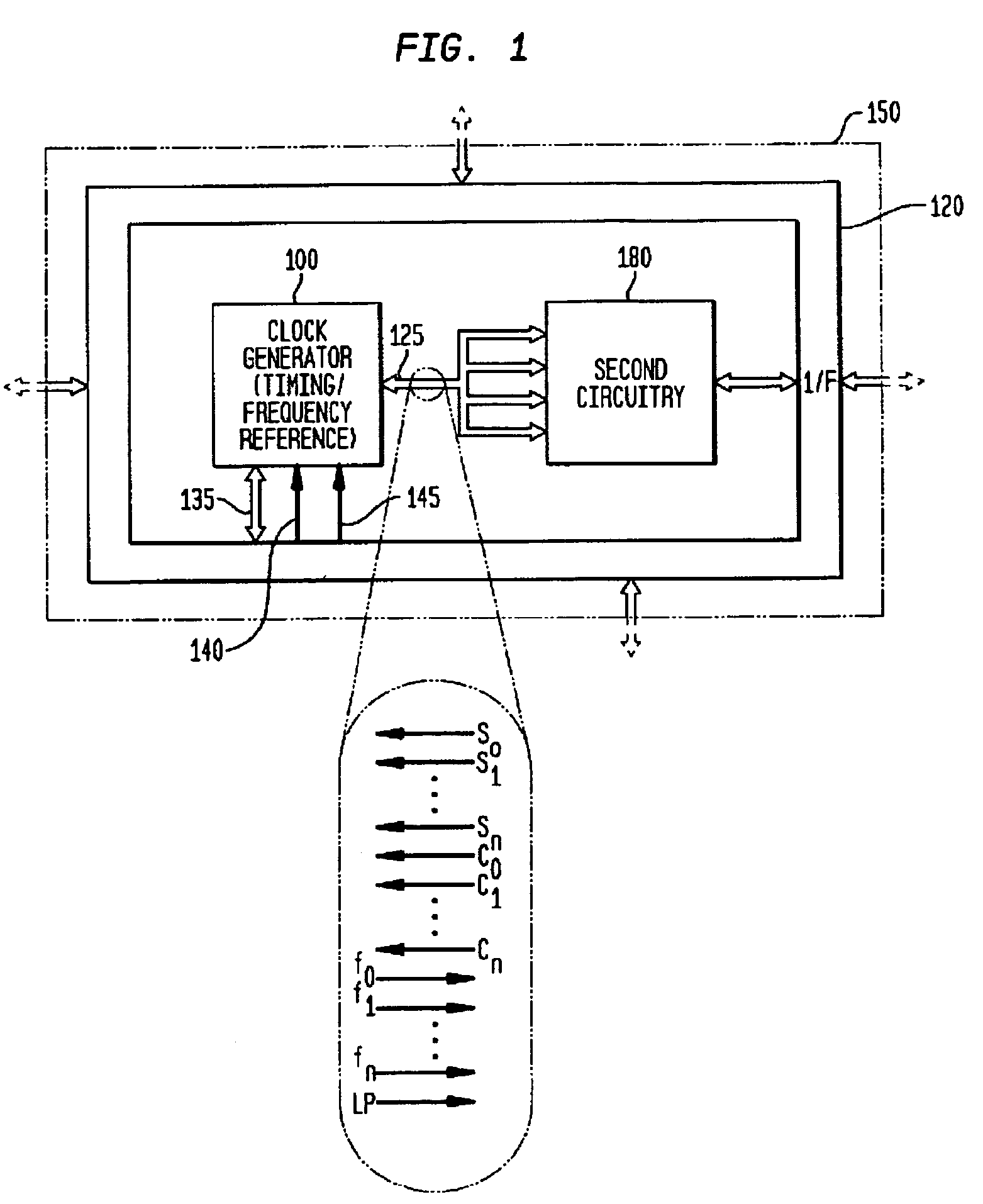

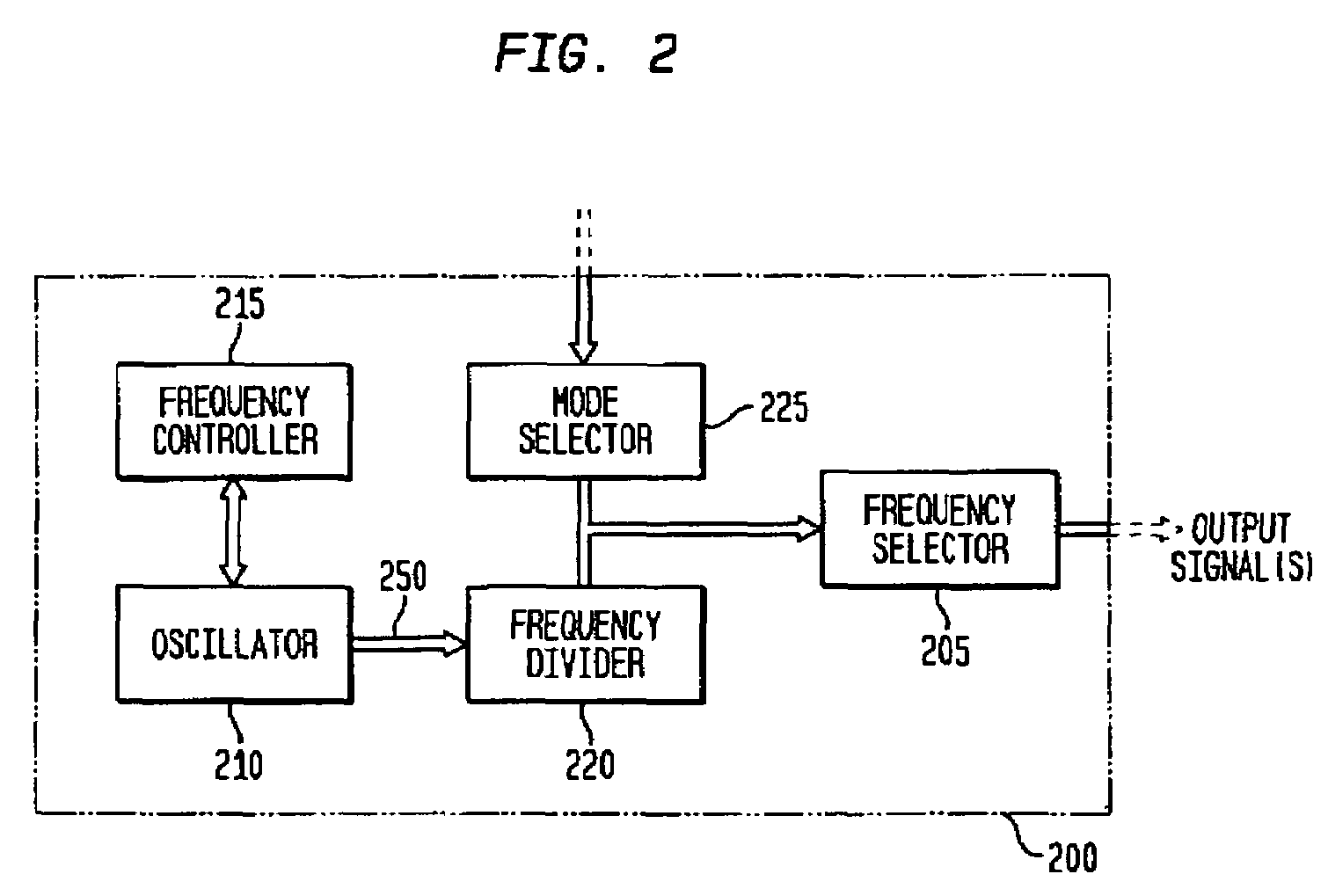

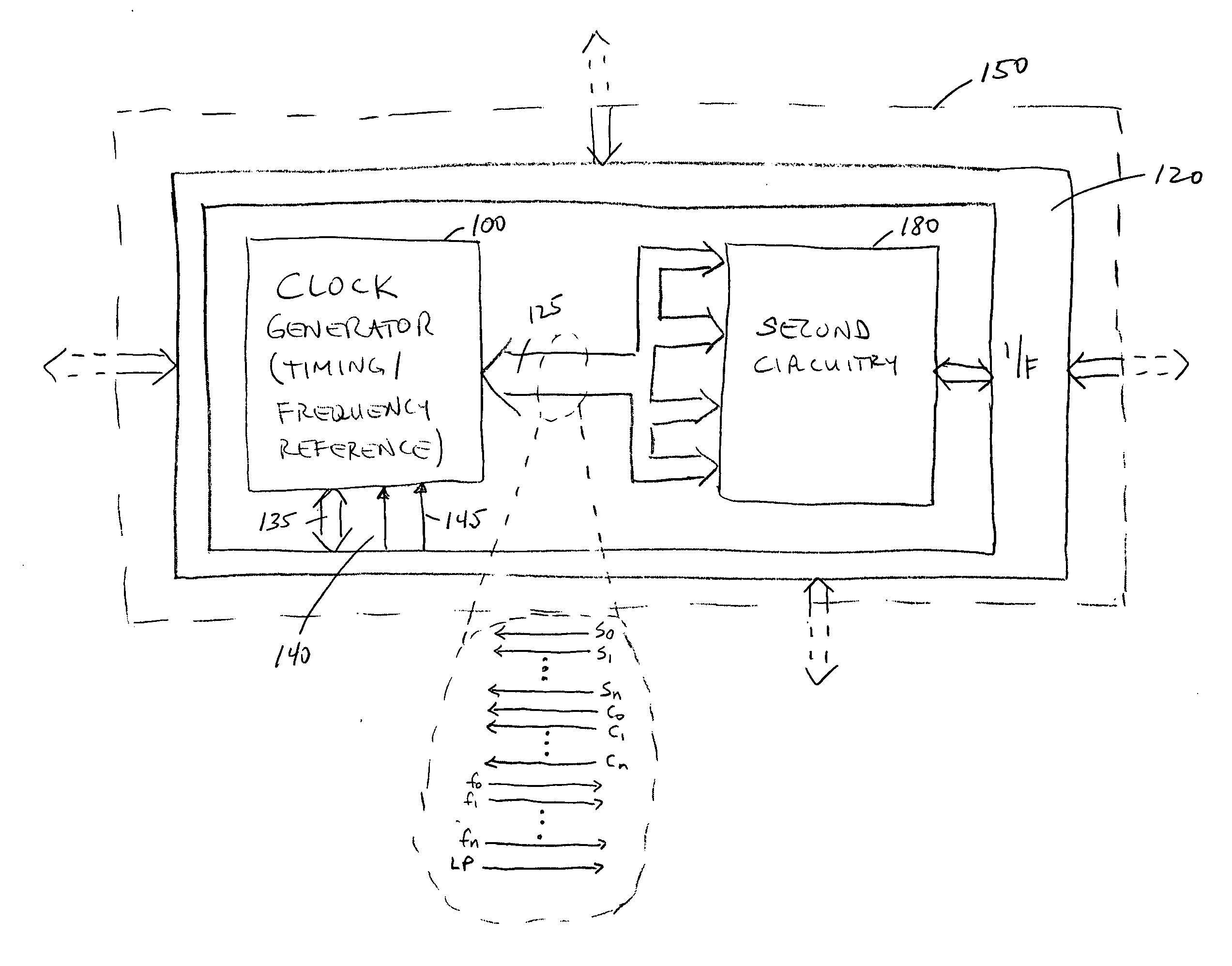

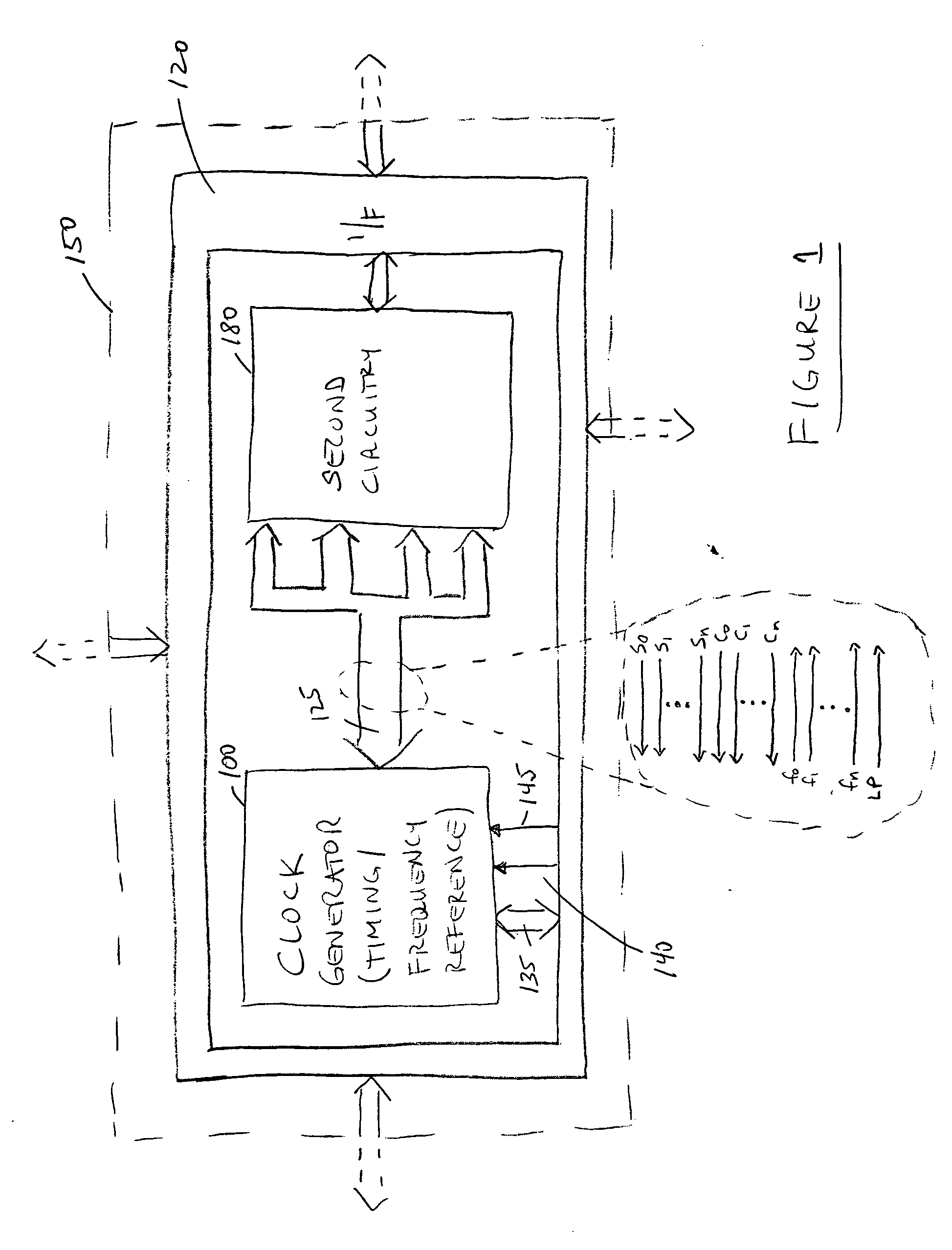

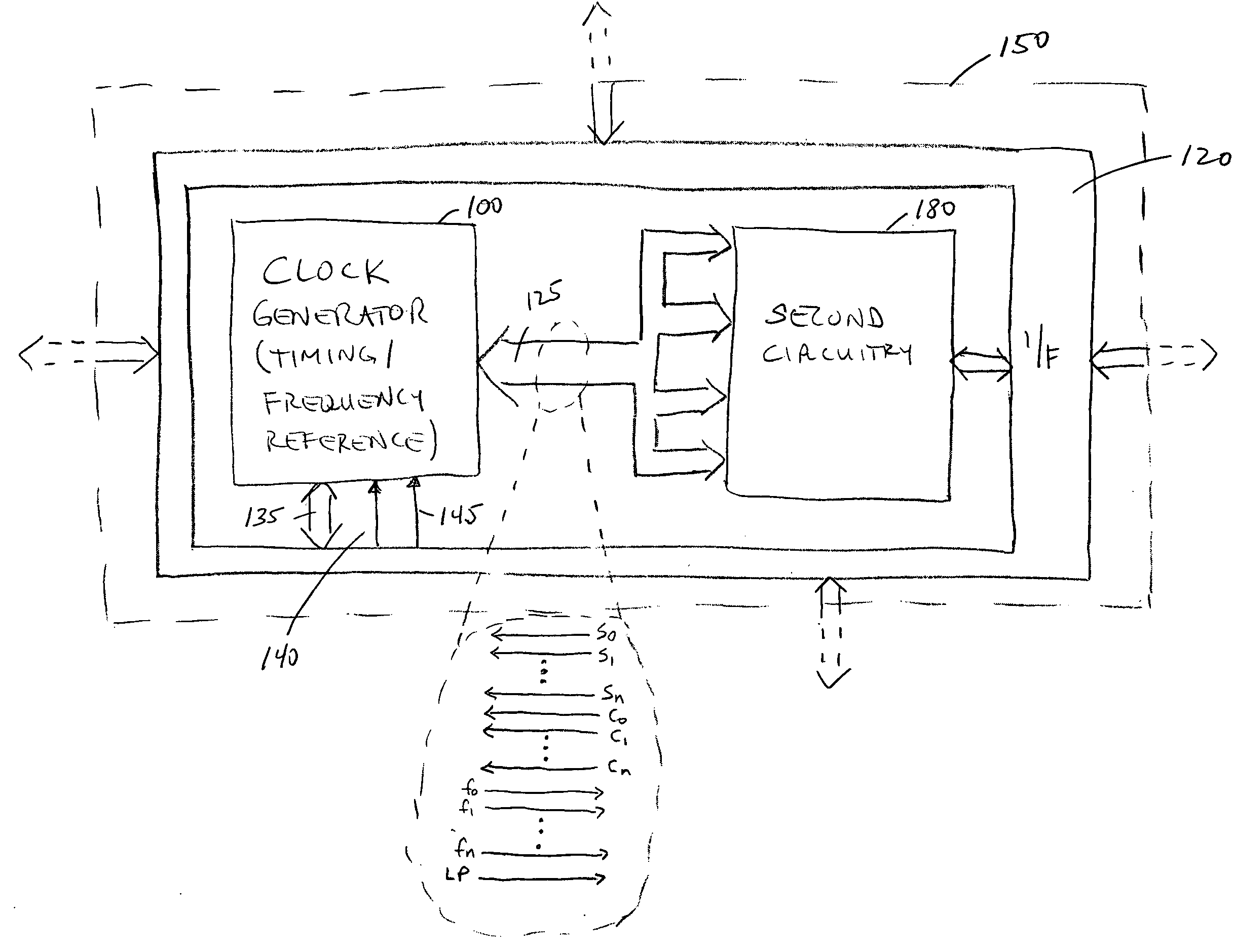

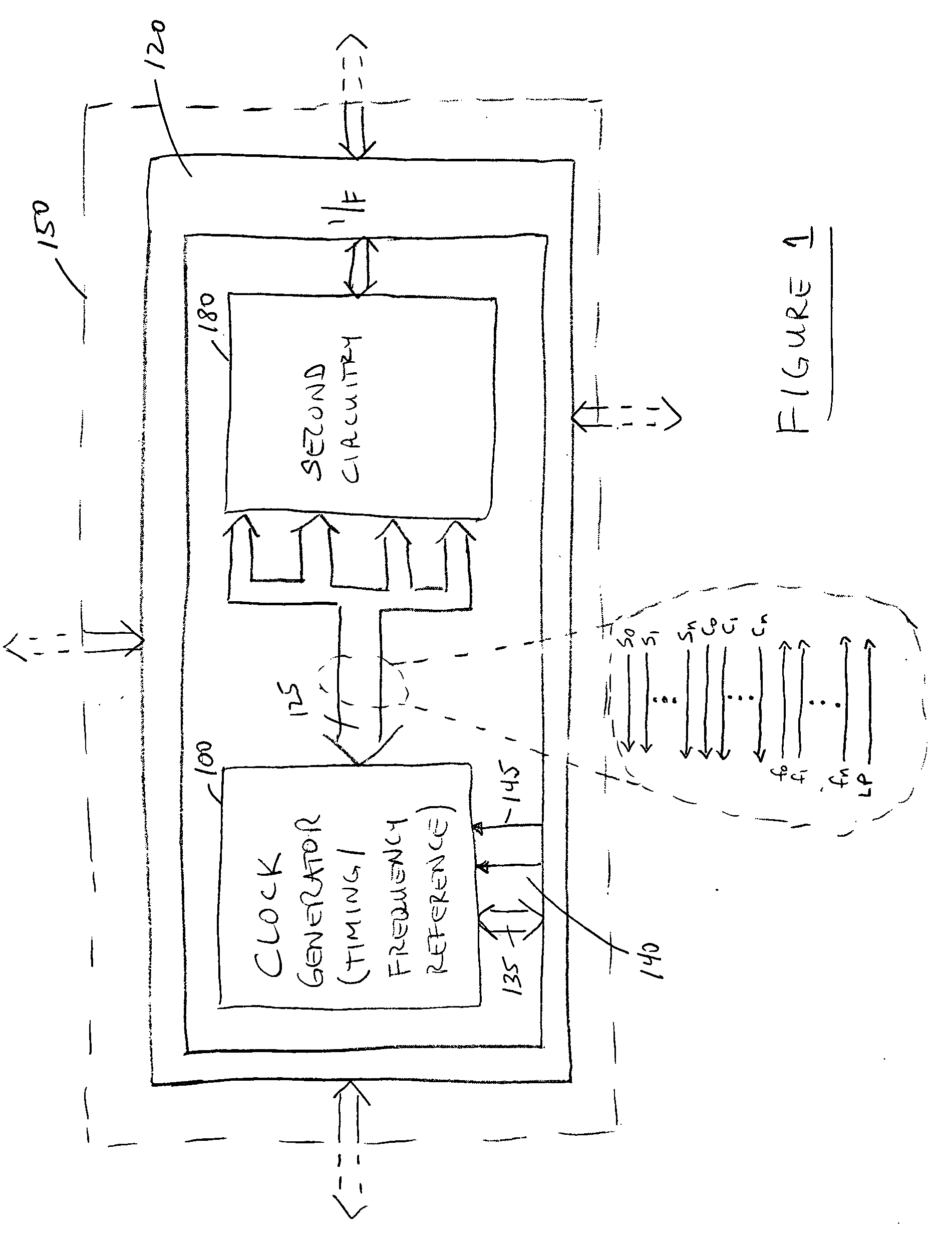

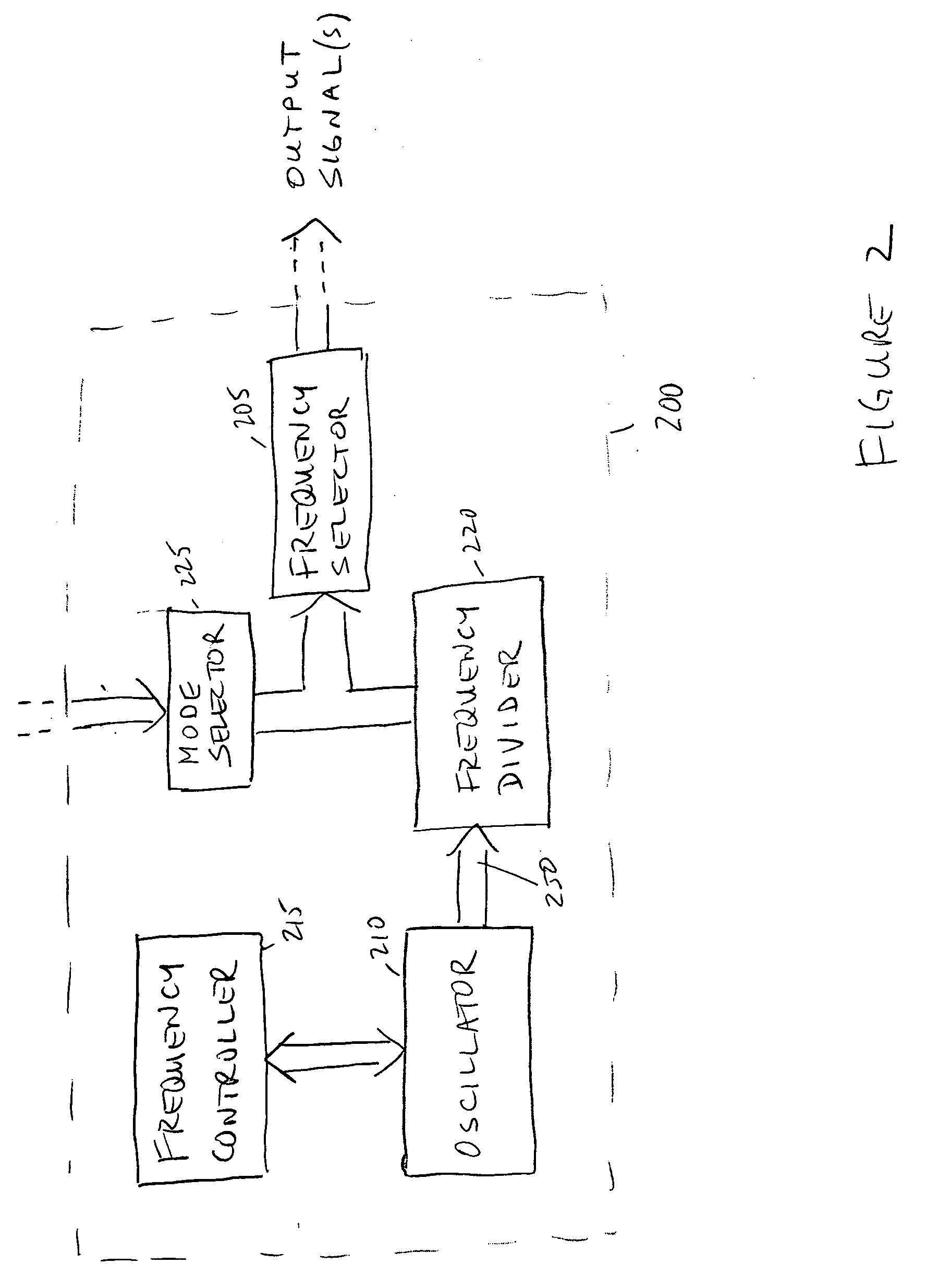

Monolithic clock generator and timing/frequency reference

ActiveUS7227423B2High frequencyLoud noiseResonant circuit tuningPulse automatic controlAudio power amplifierPulsed mode

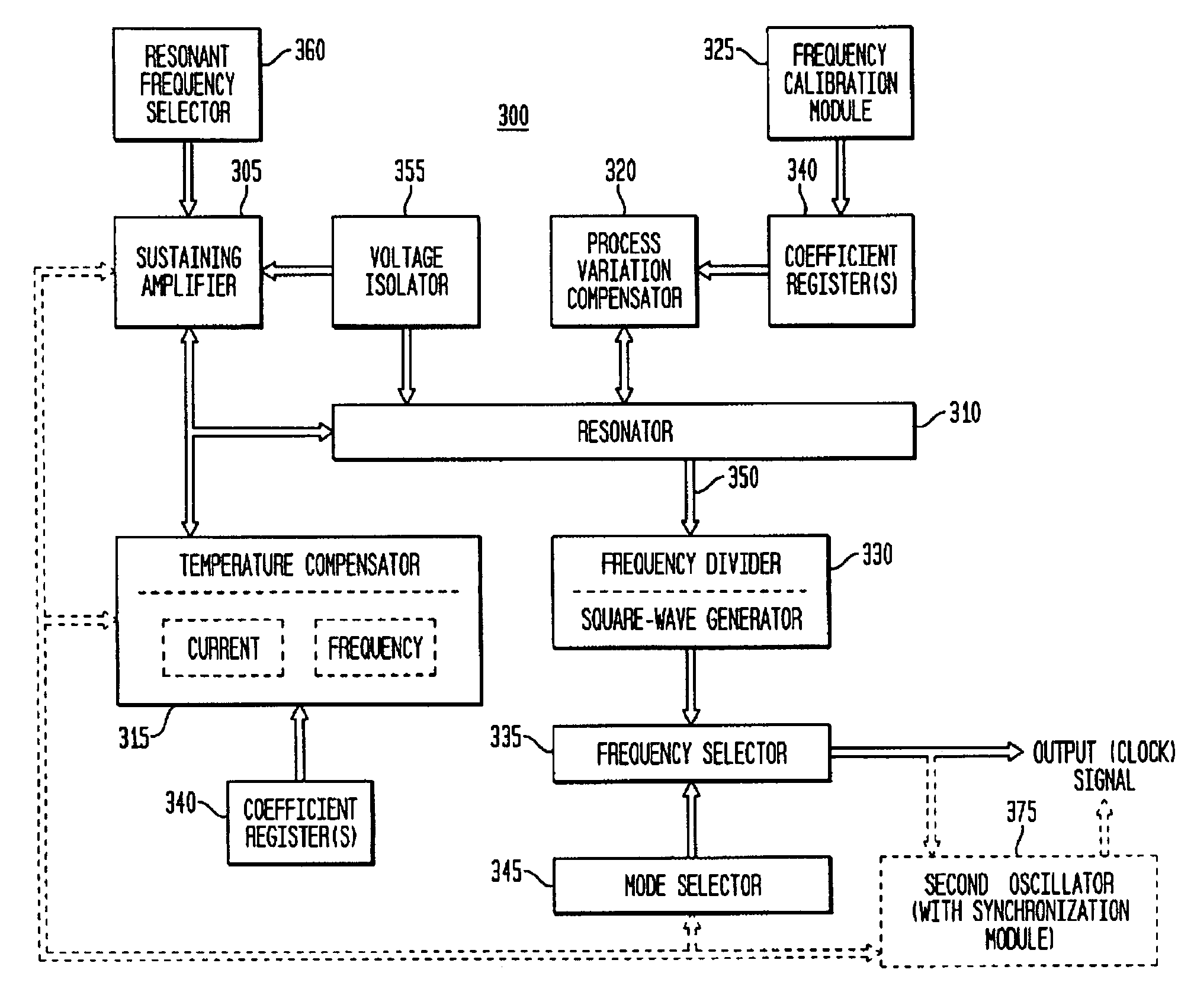

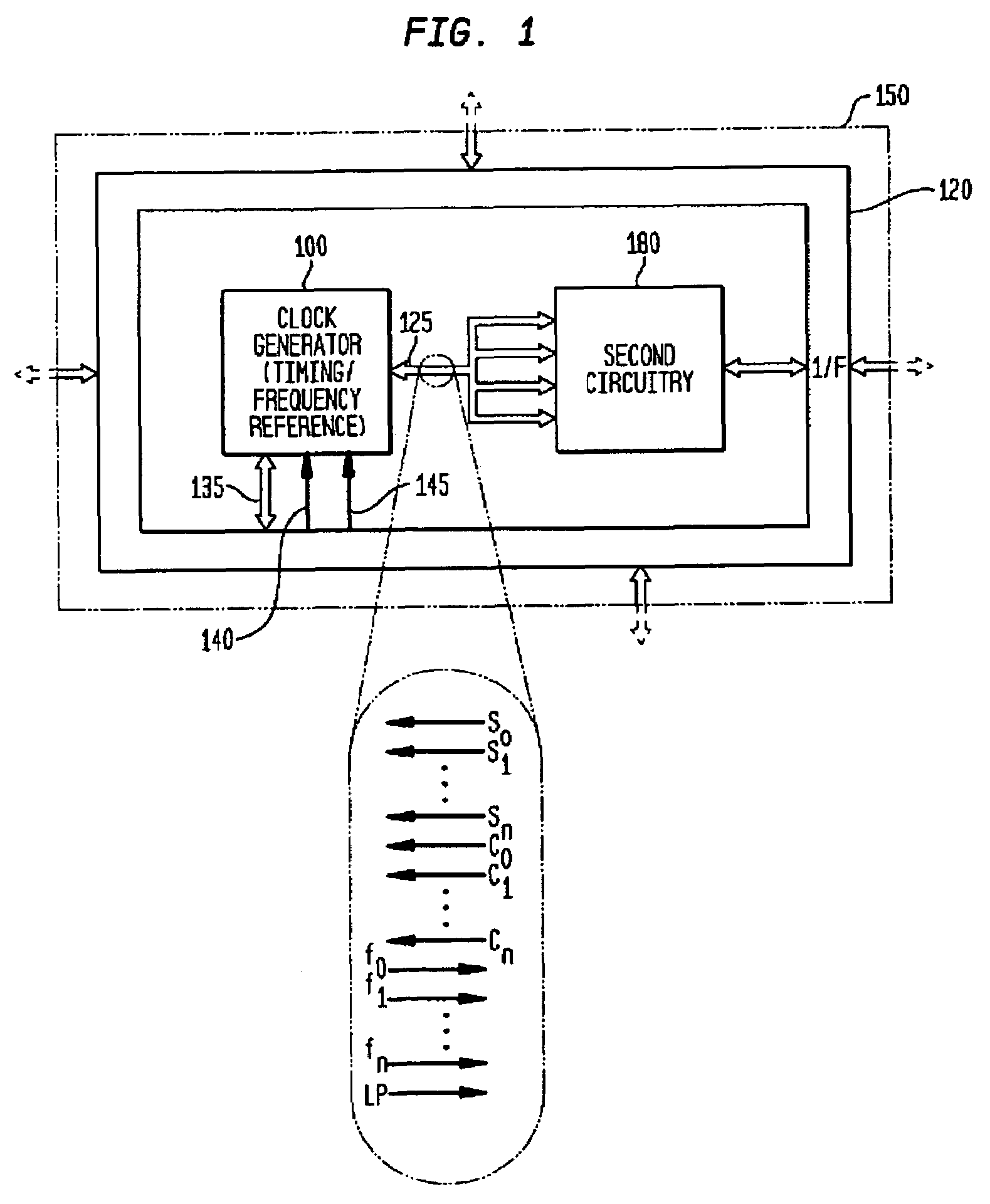

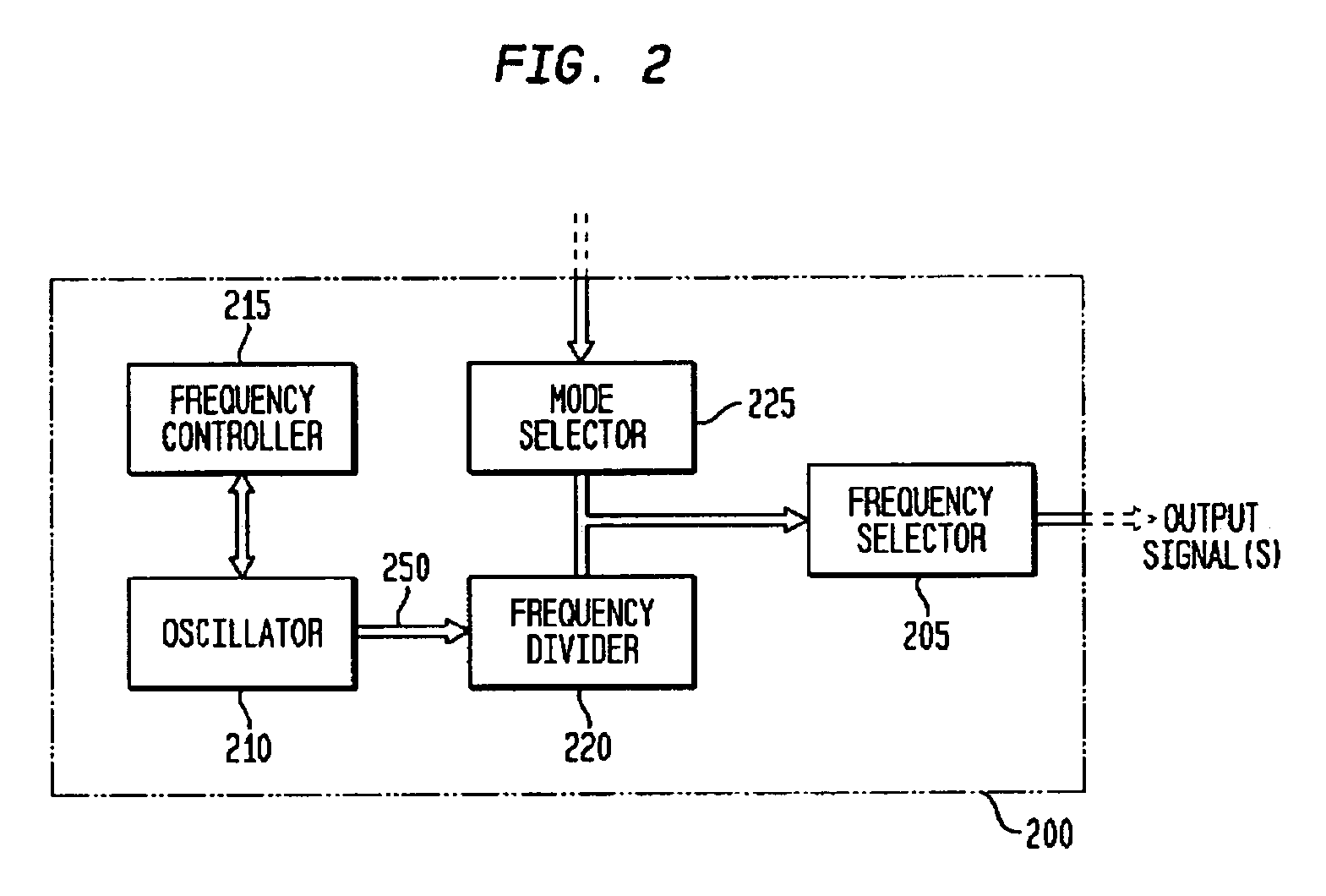

In various embodiments, the invention provides a clock generator and / or a timing and frequency reference, with multiple operating modes, such power conservation, clock, reference, and pulsed modes. The various apparatus embodiments include a resonator adapted to provide a first signal having a resonant frequency; an amplifier; a temperature compensator adapted to modify the resonant frequency in response to temperature; and a process variation compensator adapted to modify the resonant frequency in response to fabrication process variation. In addition, the various embodiments may also include a frequency divider adapted to divide the first signal having the resonant frequency into a plurality of second signals having a corresponding plurality of frequencies substantially equal to or lower than the resonant frequency; and a frequency selector adapted to provide an output signal from the plurality of second signals. The output signal may be provided in any of various forms, such as differential or single-ended, and substantially square-wave or sinusoidal.

Owner:INTEGRATED DEVICE TECH INC

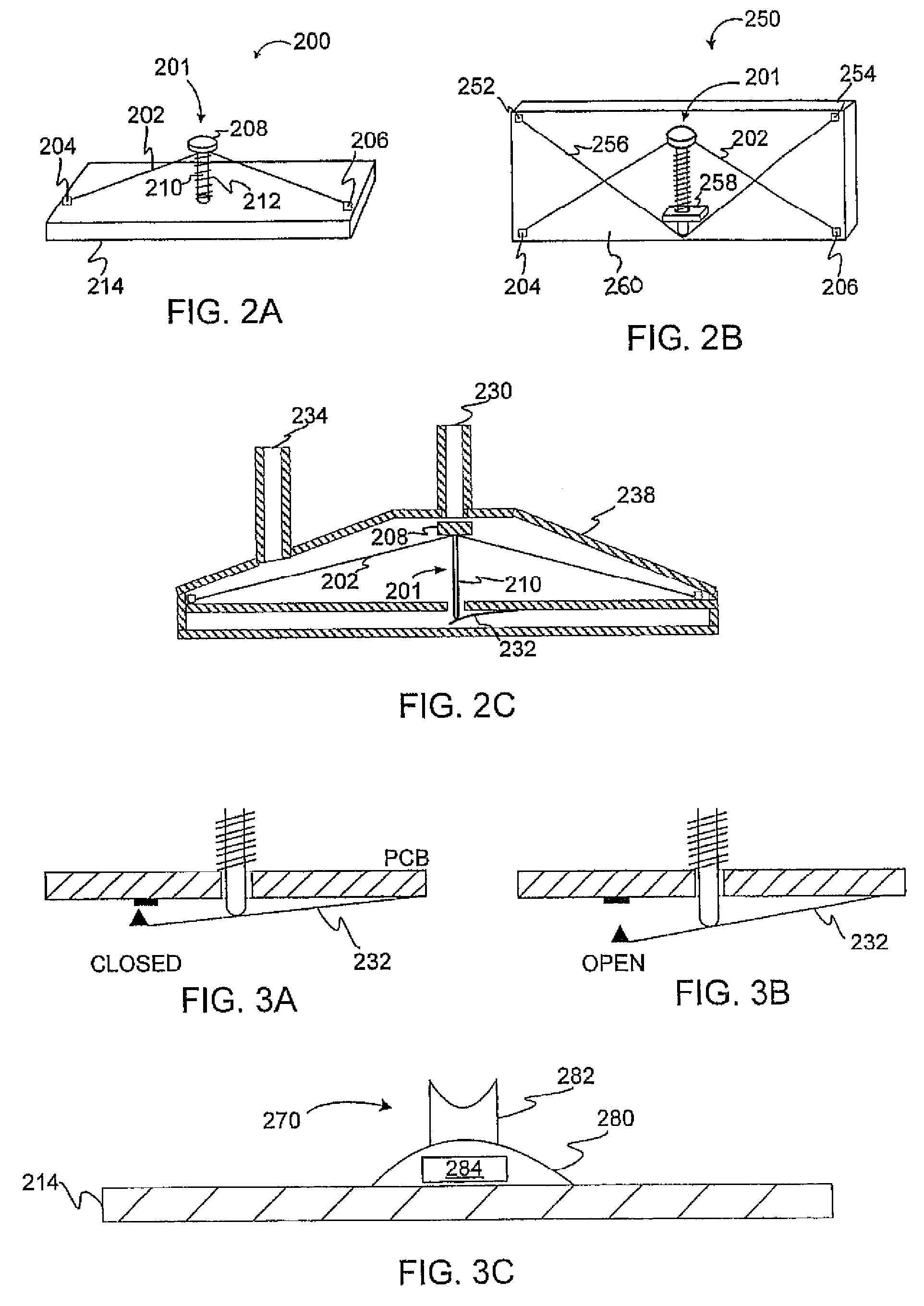

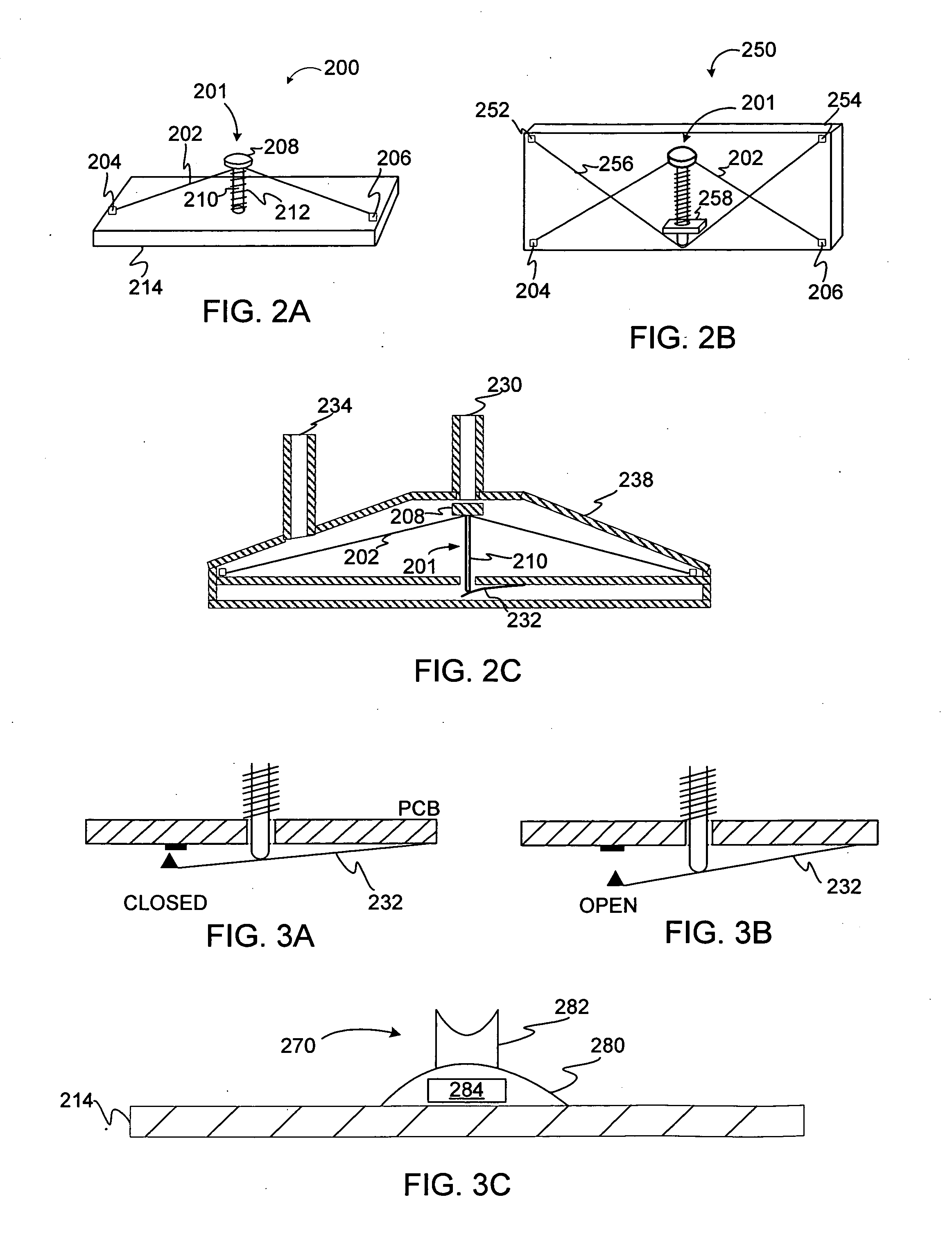

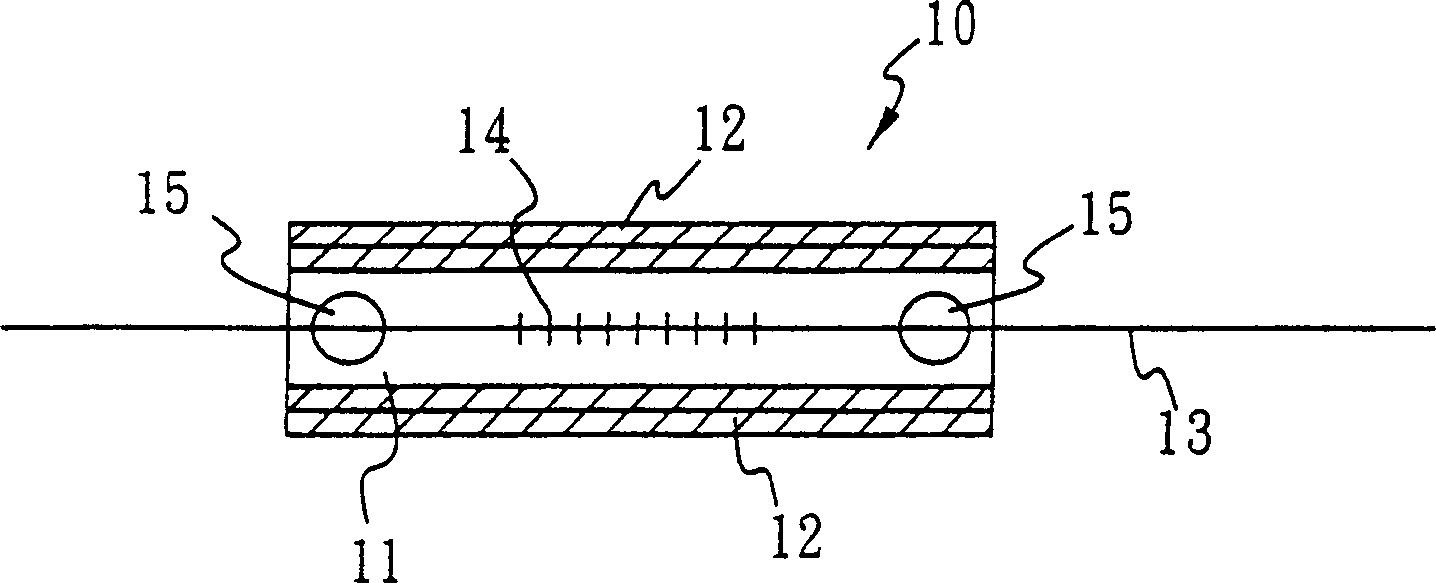

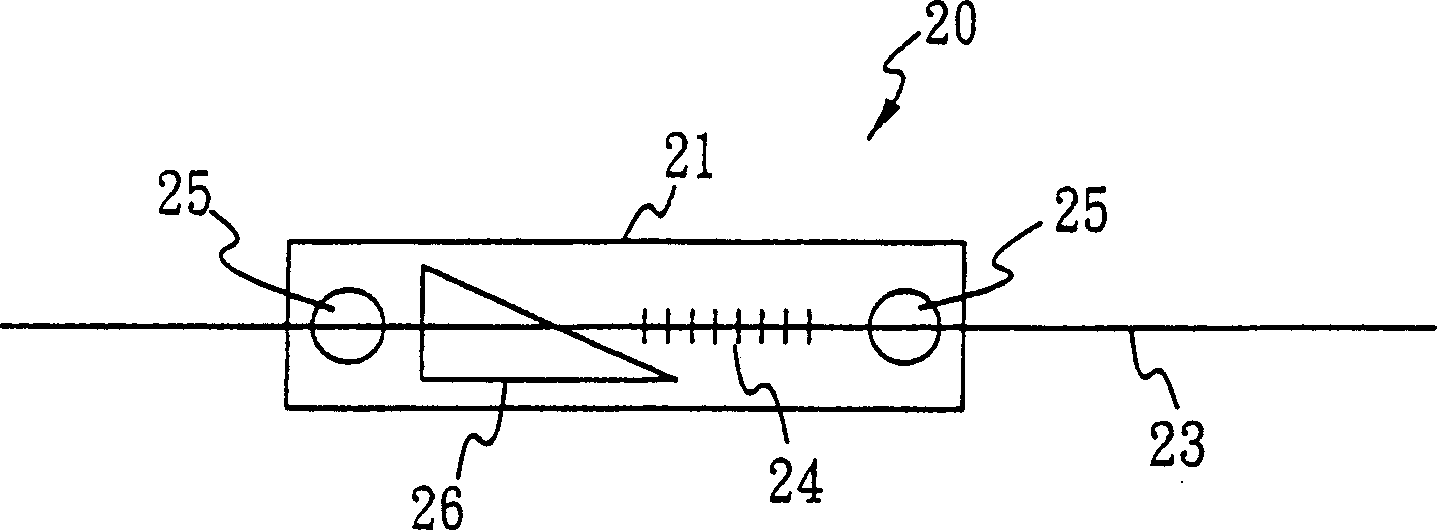

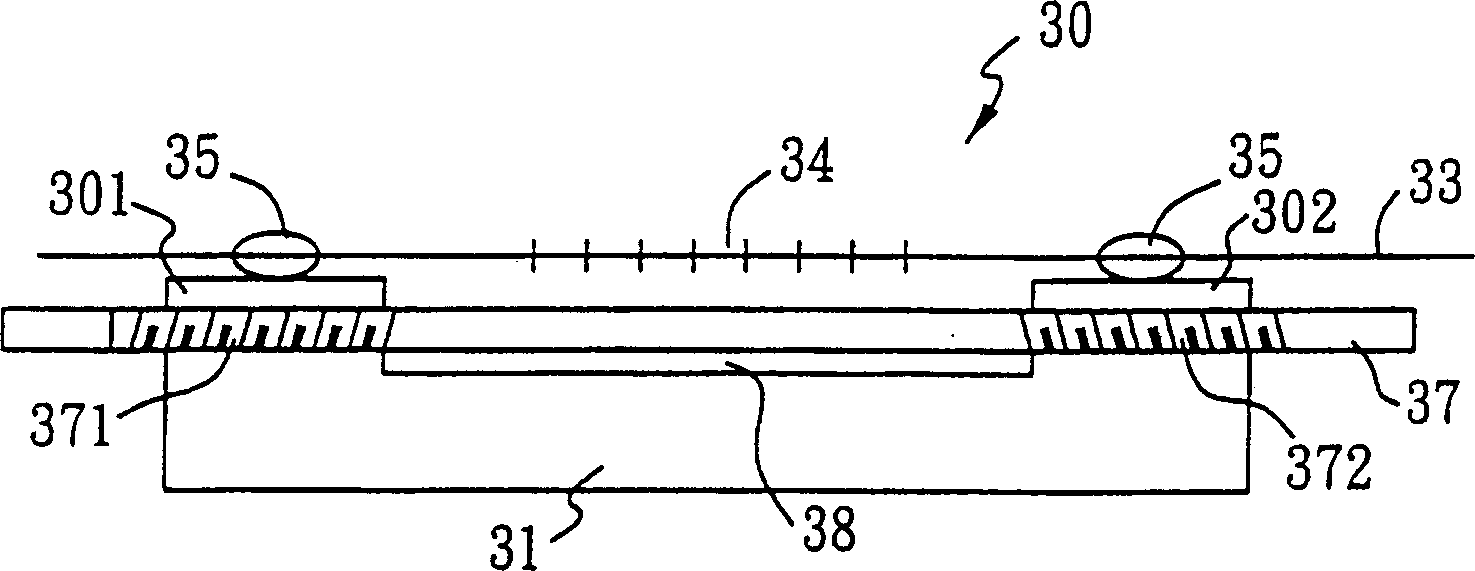

Means and method for mounting electronics

InactiveUS6108205ALow costSimple and low methodSemiconductor/solid-state device detailsPrinted circuit aspectsThin layerEngineering

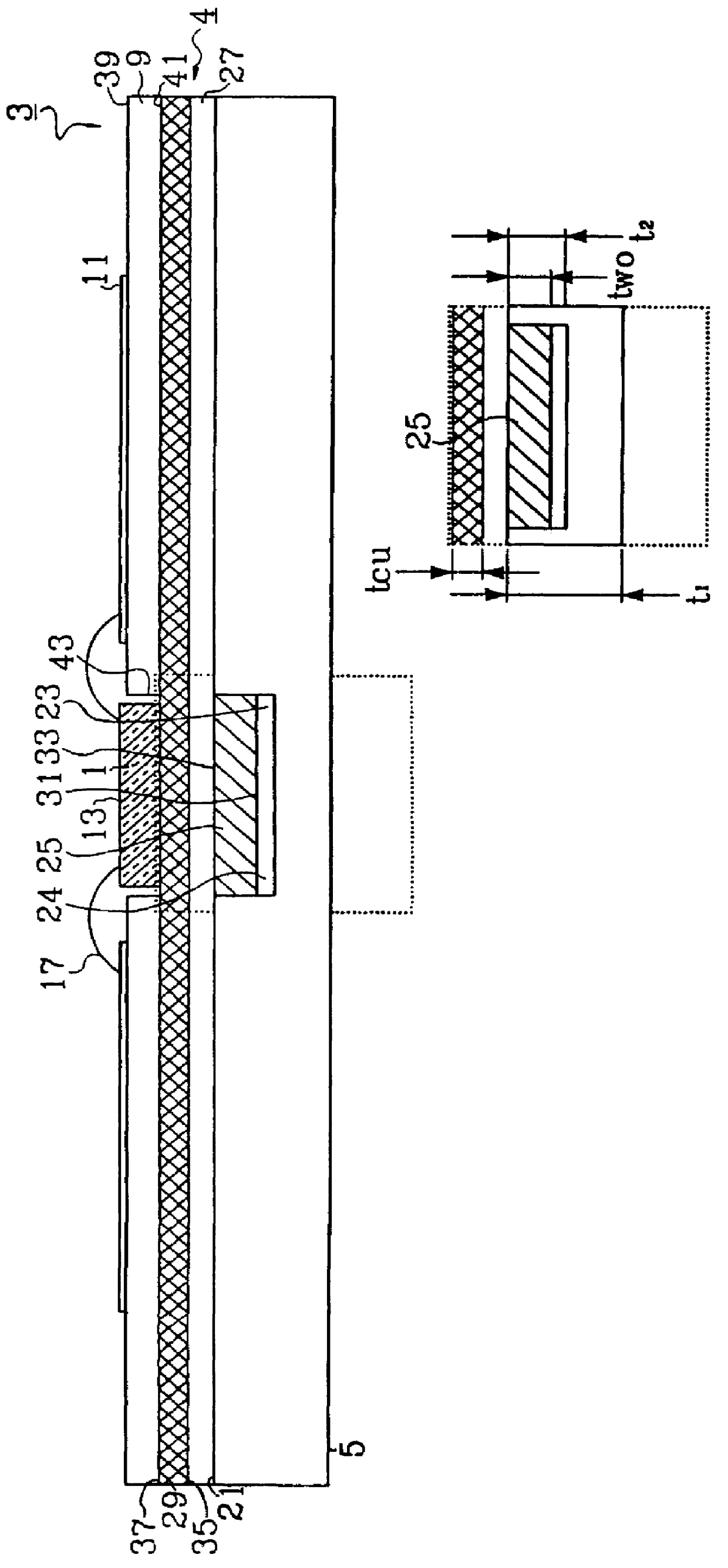

The present invention relates to a method and device for making a temperature-compensated bedding for chips on printed boards, at which a temperature-compensated device is totally or partly recessed in a carrier in the printed board. The chips is placed over the temperature-compensated device. The temperature-compensated device includes a piece of metal recessed in the carrier under the chip. A layer of copper is fixed against the upper side of the carrier and the upper side of the metal piece. The thickness of the copper layer and the thickness of the metal piece are dimensioned so that the resulting coefficient of linear expansion at the upper side of the copper layer is equally big as or a bit bigger than the coefficient of linear expansion of the chip. The temperature-compensated device can as an alternative to the above include a module recessed in the carrier under the chip. A thin layer of dielectric is fixed against the carrier, so that the coefficient of linear expansion of the dielectric layer don't appreciable affect the resulting coefficient of linear expansion of the temperature-compensated device.

Owner:TELEFON AB LM ERICSSON (PUBL)

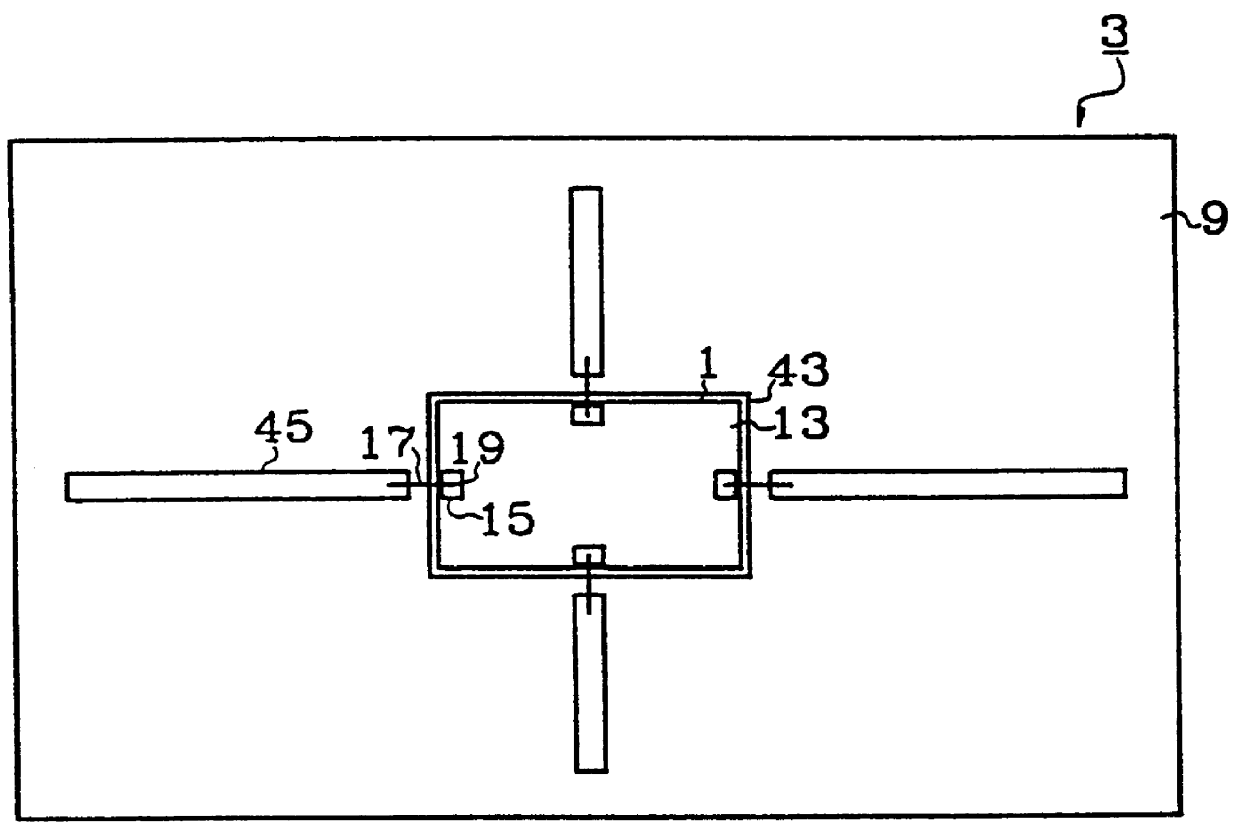

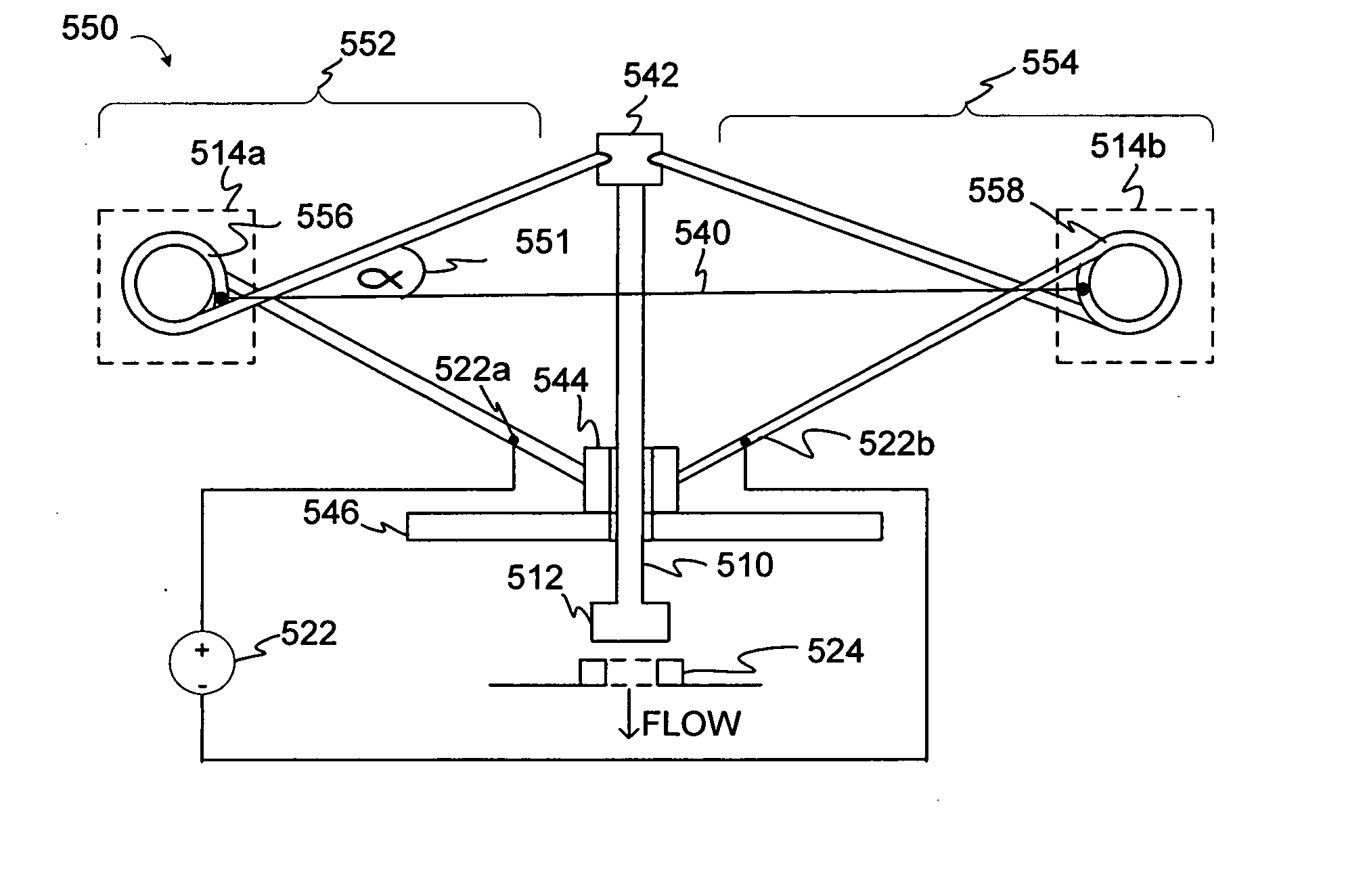

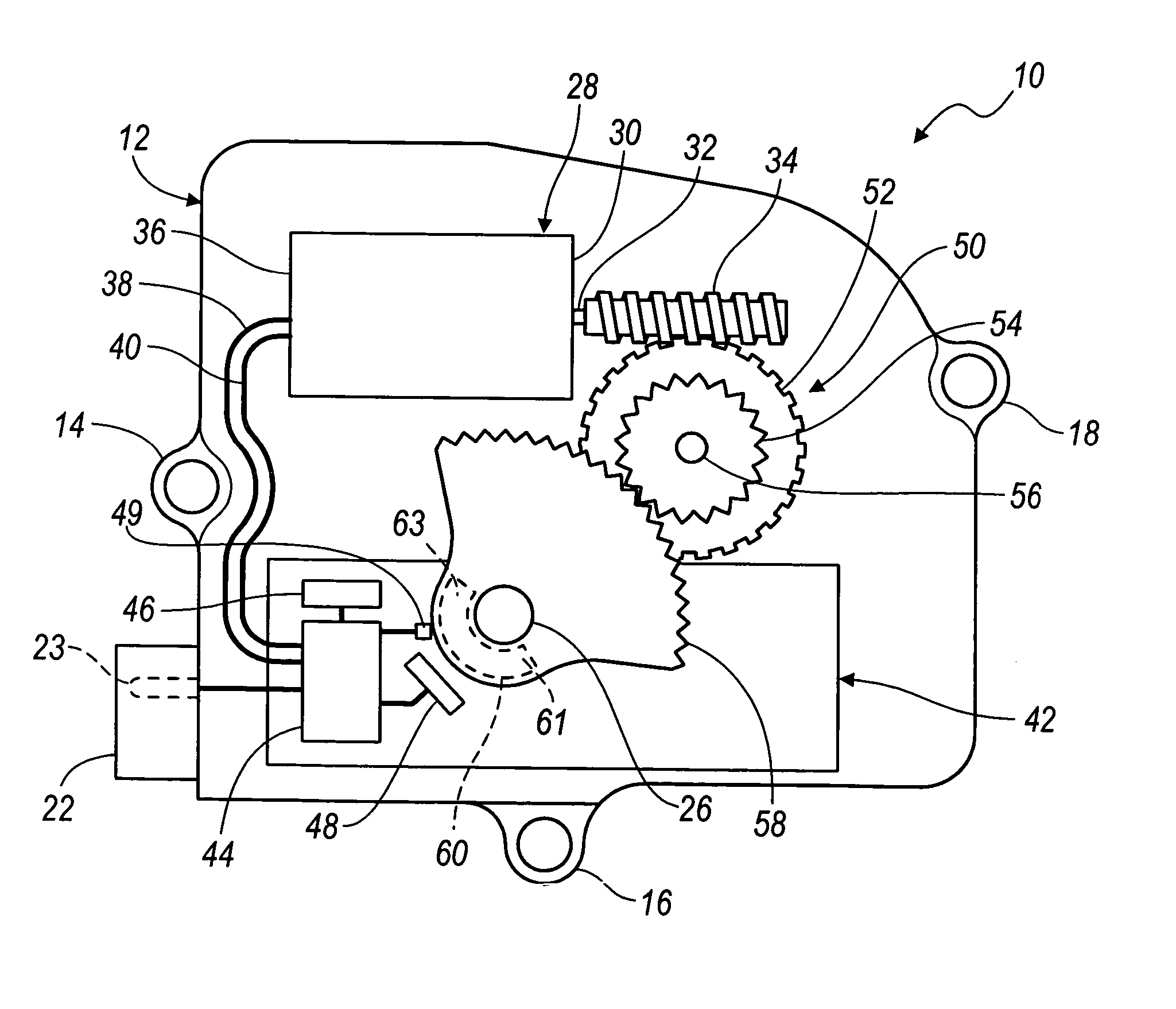

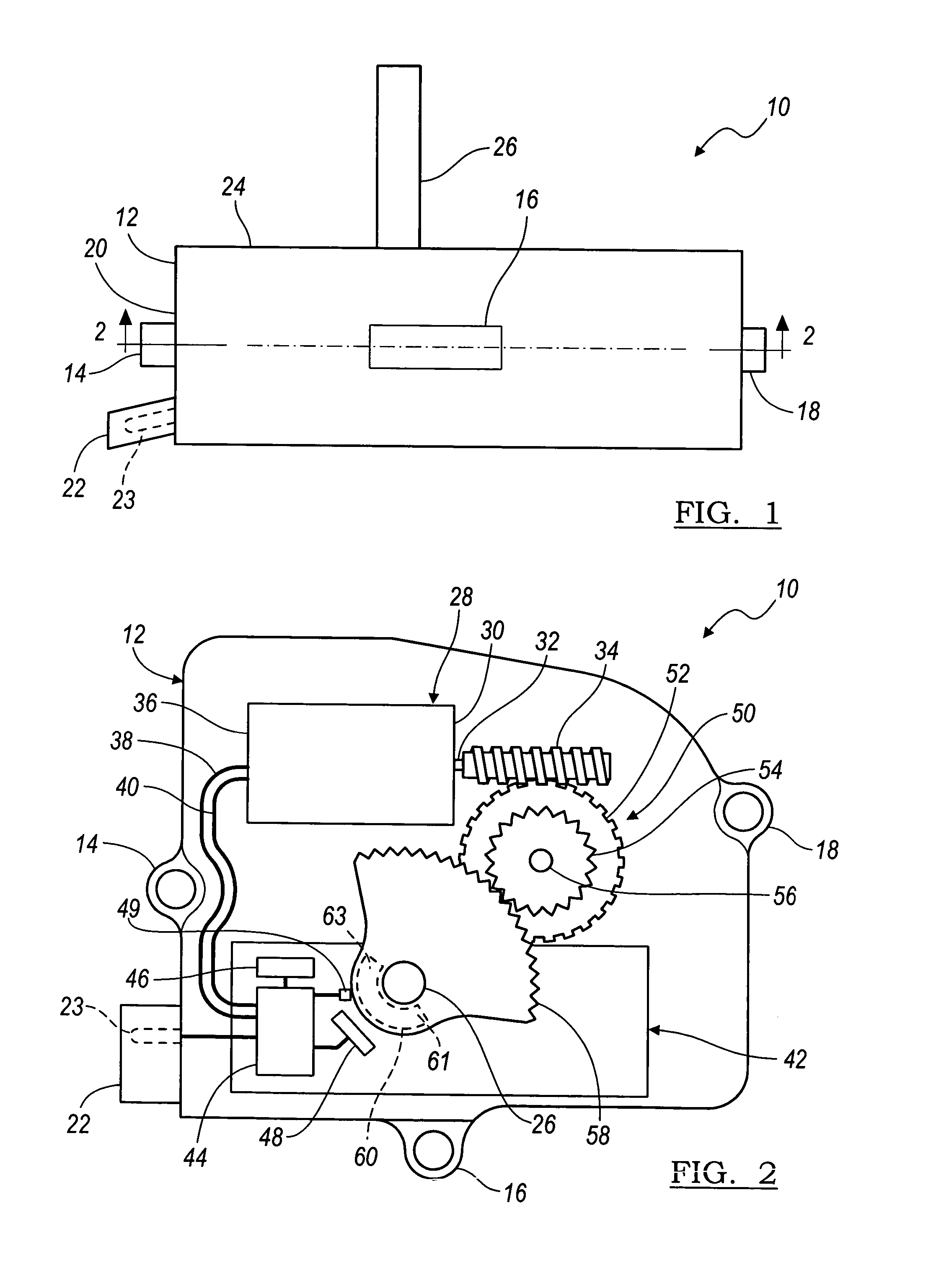

System, method and apparatus for reducing frictional forces and for compensating shape memory alloy-actuated valves and valve systems at high temperatures

ActiveUS7748405B2Temperature control without auxillary powerOperating means/releasing devices for valvesAlloyTemperature Compensator

A valve system including a number of shape memory alloy (“SMA”)-actuated valves for controlling the flow of fluids is disclosed as is a variety of types of SMA-actuated valves and methods of operation. In one embodiment, a valve system includes a housing having a substantially closed cavity as well as a second port for communicating a fluid. Further, the valve system includes a first SMA actuator configured to control the position of the first seal to vary fluid flow through the firs port, and a first temperature compensator for adjusting the position of the seal by an amount proportional to temperature. A second SMA-actuated valve, driven by either a unidirectional or a bidirectional SMA actuator, controls the position of the second seal to vary fluid flow through the second port, and a second temperature compensator for adjusting the position of the second seal by another amount proportional to temperature.

Owner:ALFMEIER PRAZISION BAUGRUPPEN & SYSTLOSUNGEN +1

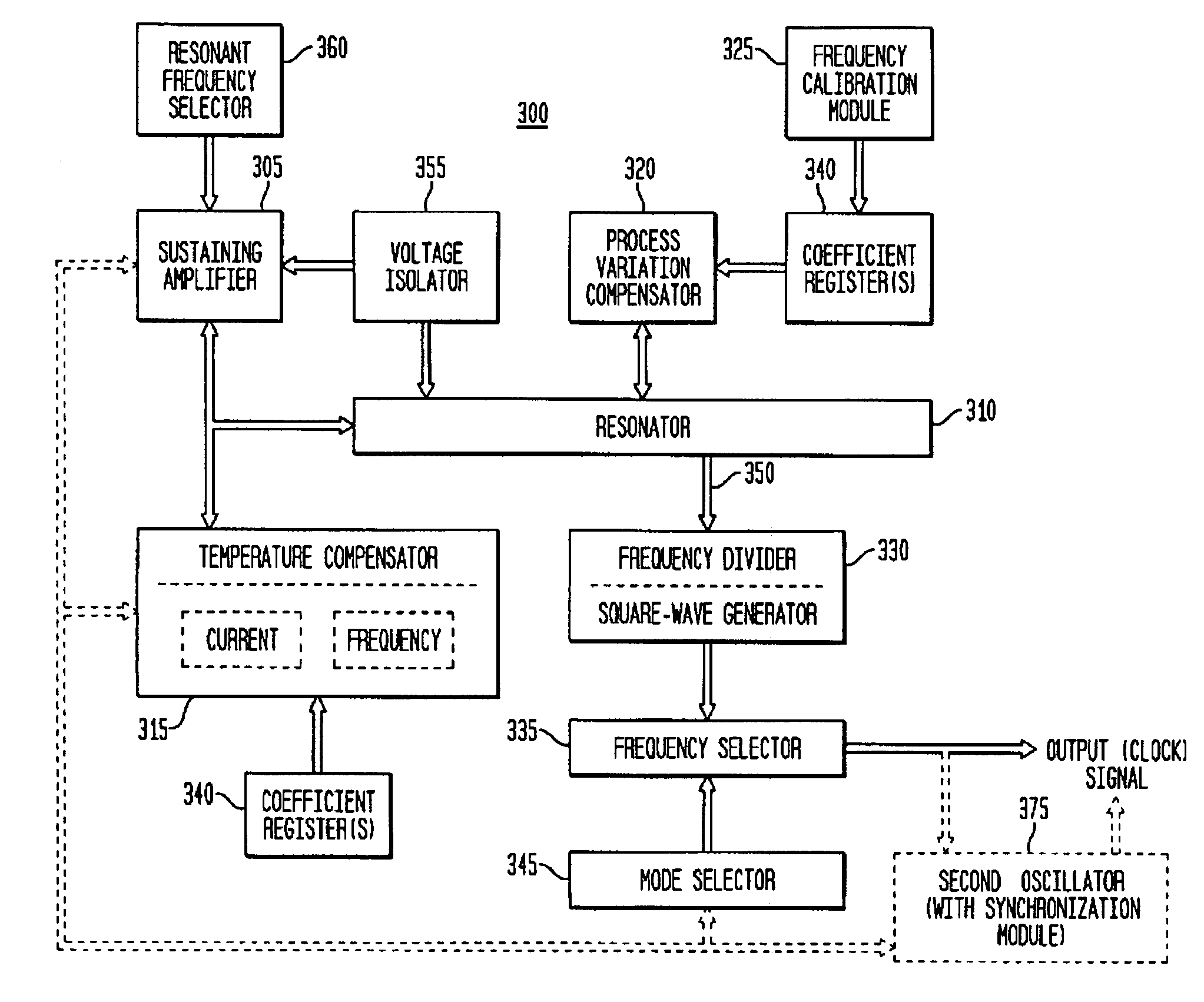

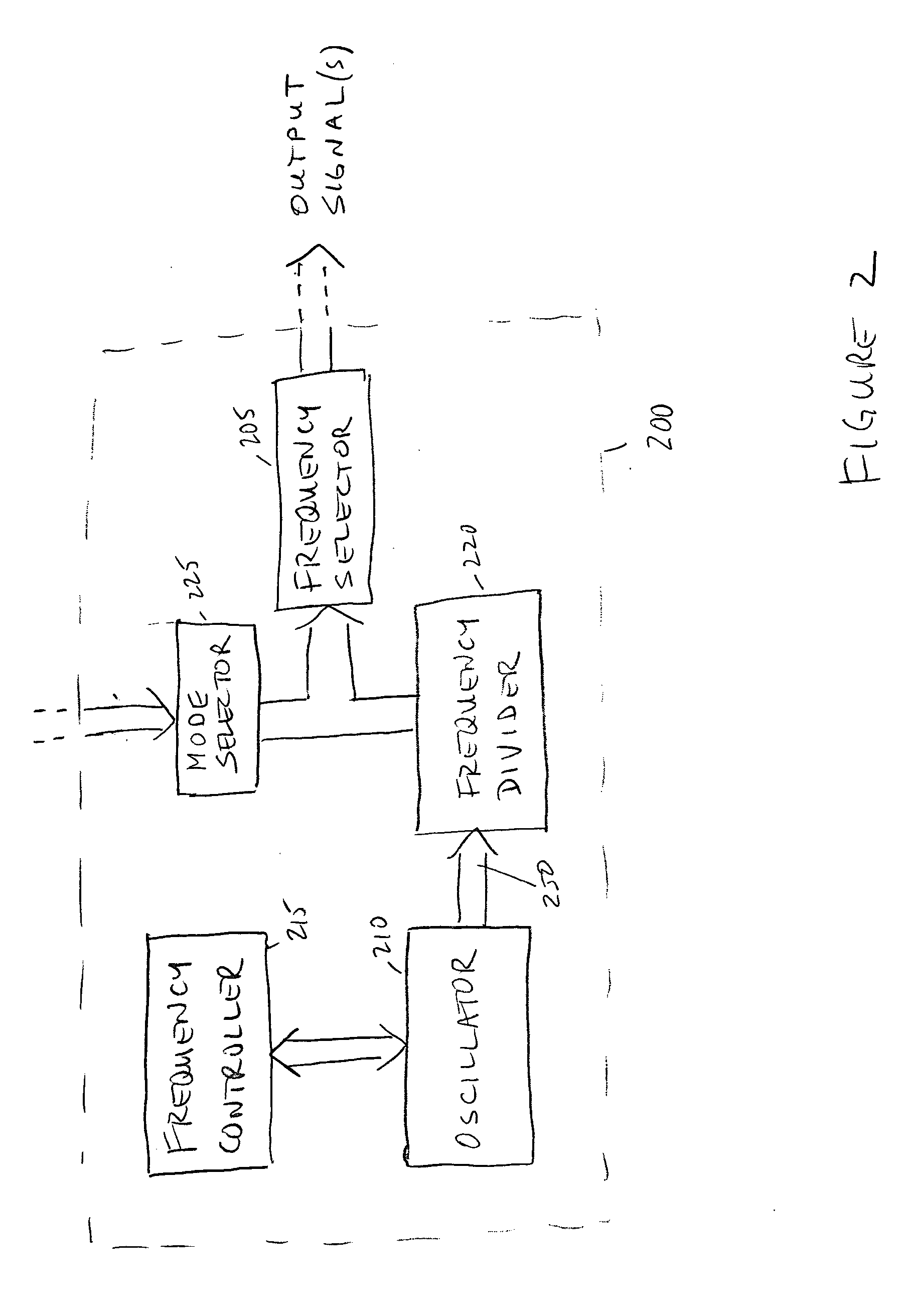

Transconductance and current modulation for resonant frequency control and selection

ActiveUS7227424B2Highly accurate over PVT variationGenerate accuratelyAngle modulation by variable impedenceResonant circuit tuningAudio power amplifierEngineering

In various embodiments, the invention provides a frequency controller and a temperature compensator for frequency control and selection in a clock generator and / or a timing and frequency reference. The various apparatus embodiments include a resonator adapted to provide a first signal having a resonant frequency; an amplifier; a temperature compensator adapted to modify the resonant frequency in response to temperature; and a process variation compensator adapted to modify the resonant frequency in response to fabrication process variation. In addition, the various embodiments may also include a frequency divider adapted to divide the first signal having the resonant frequency into a plurality of second signals having a corresponding plurality of frequencies substantially equal to or lower than the resonant frequency; and a frequency selector adapted to provide an output signal from the plurality of second signals. The output signal may be provided in any of various forms, such as differential or single-ended, and substantially square-wave or sinusoidal.

Owner:INTEGRATED DEVICE TECH INC

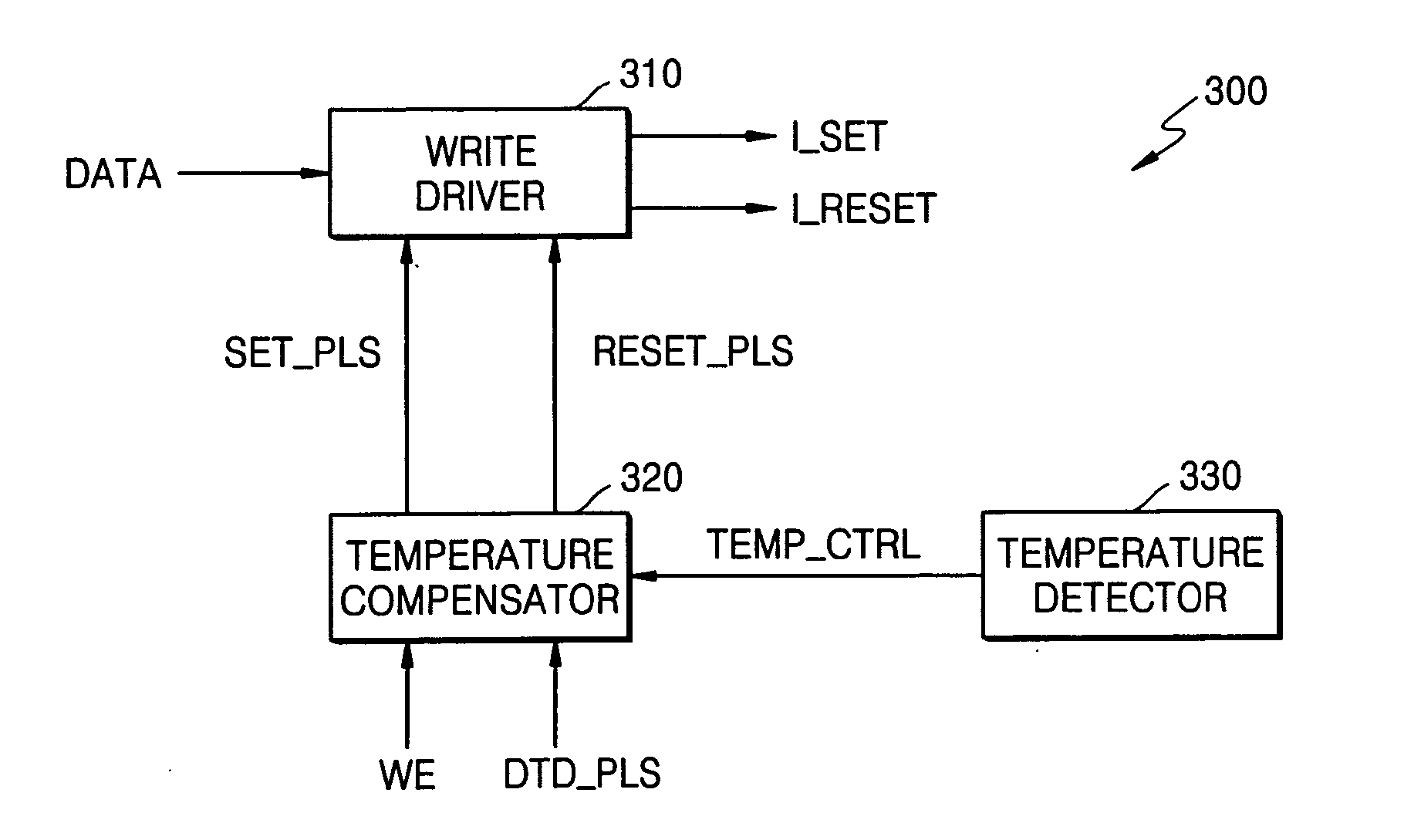

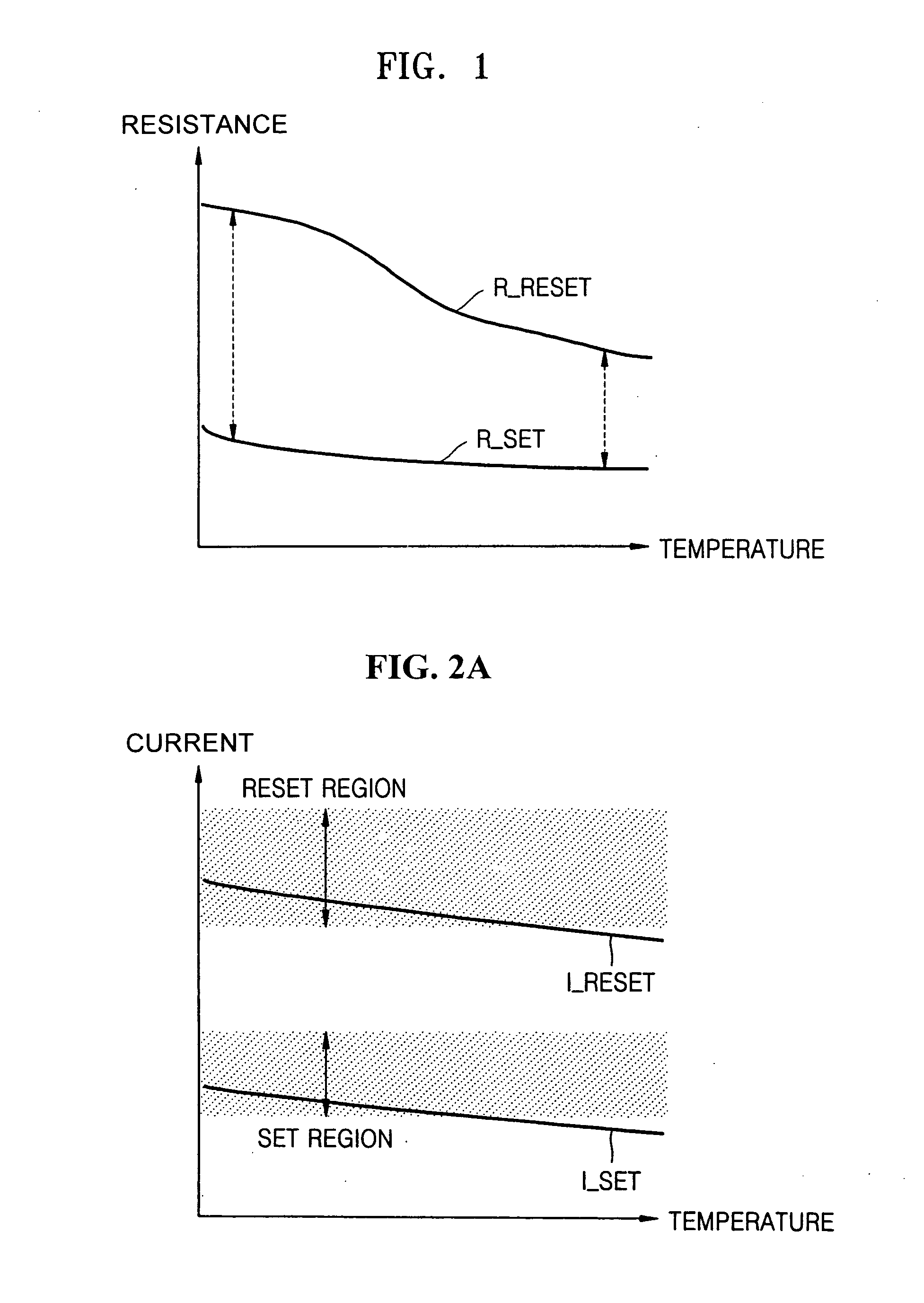

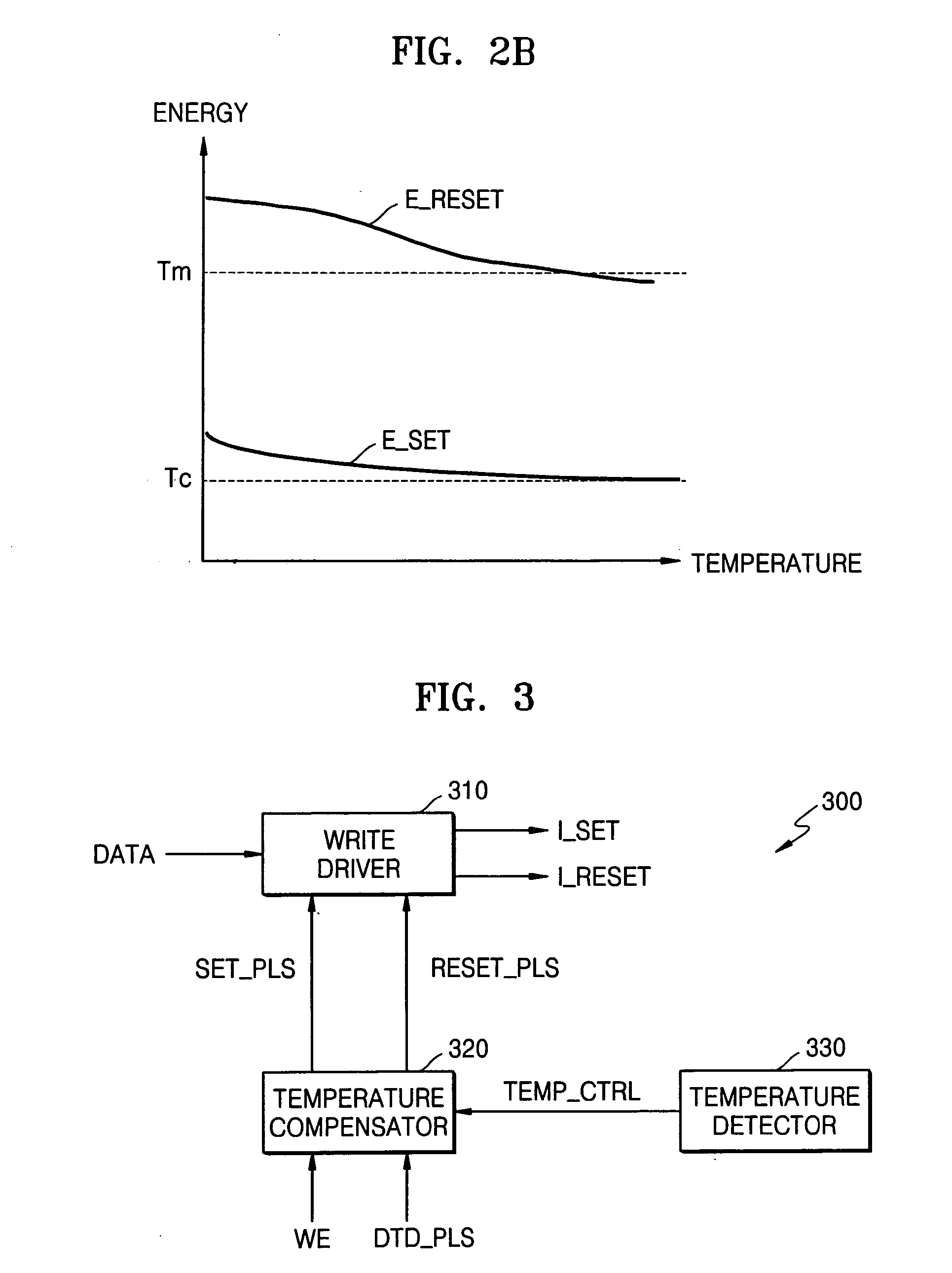

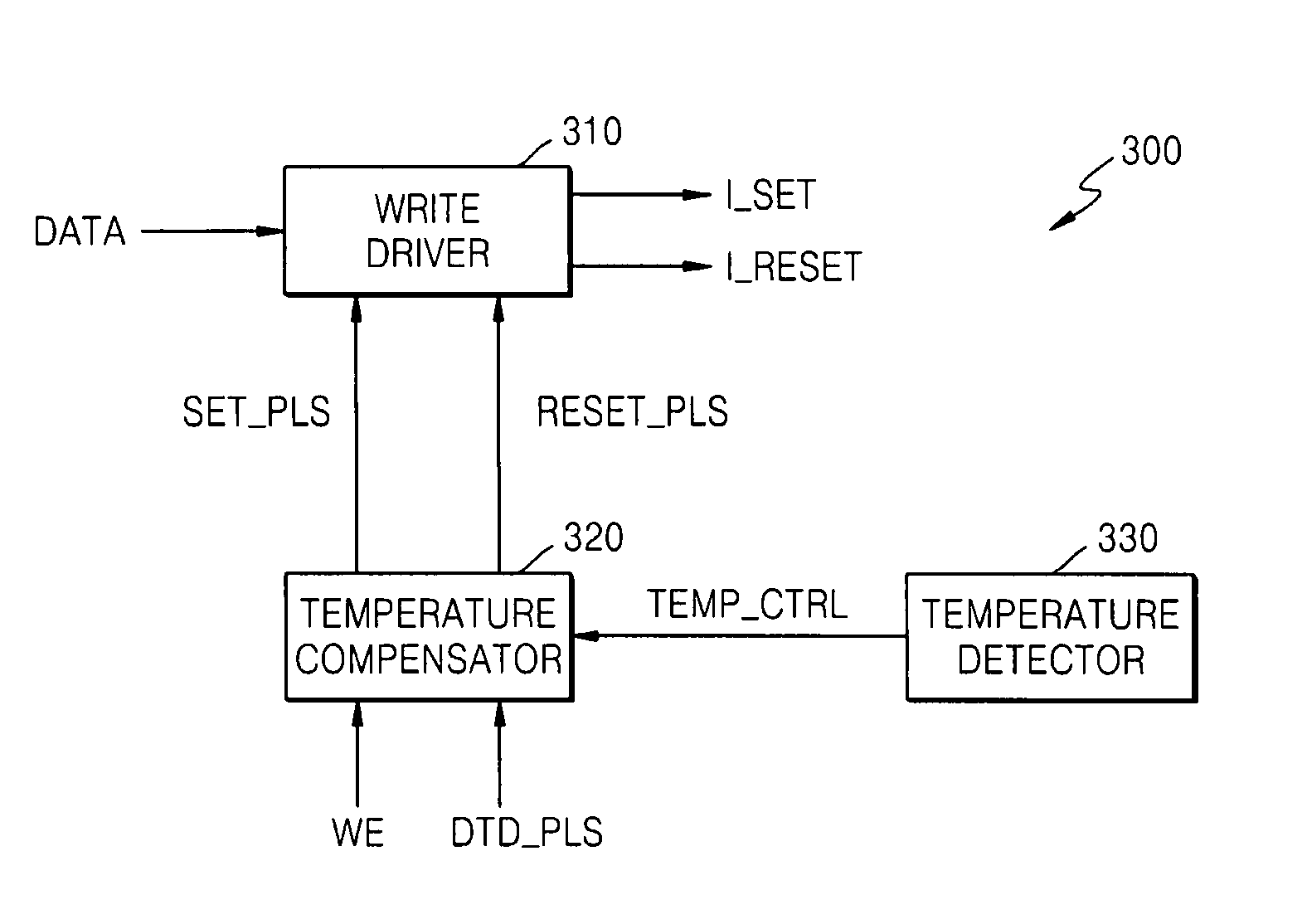

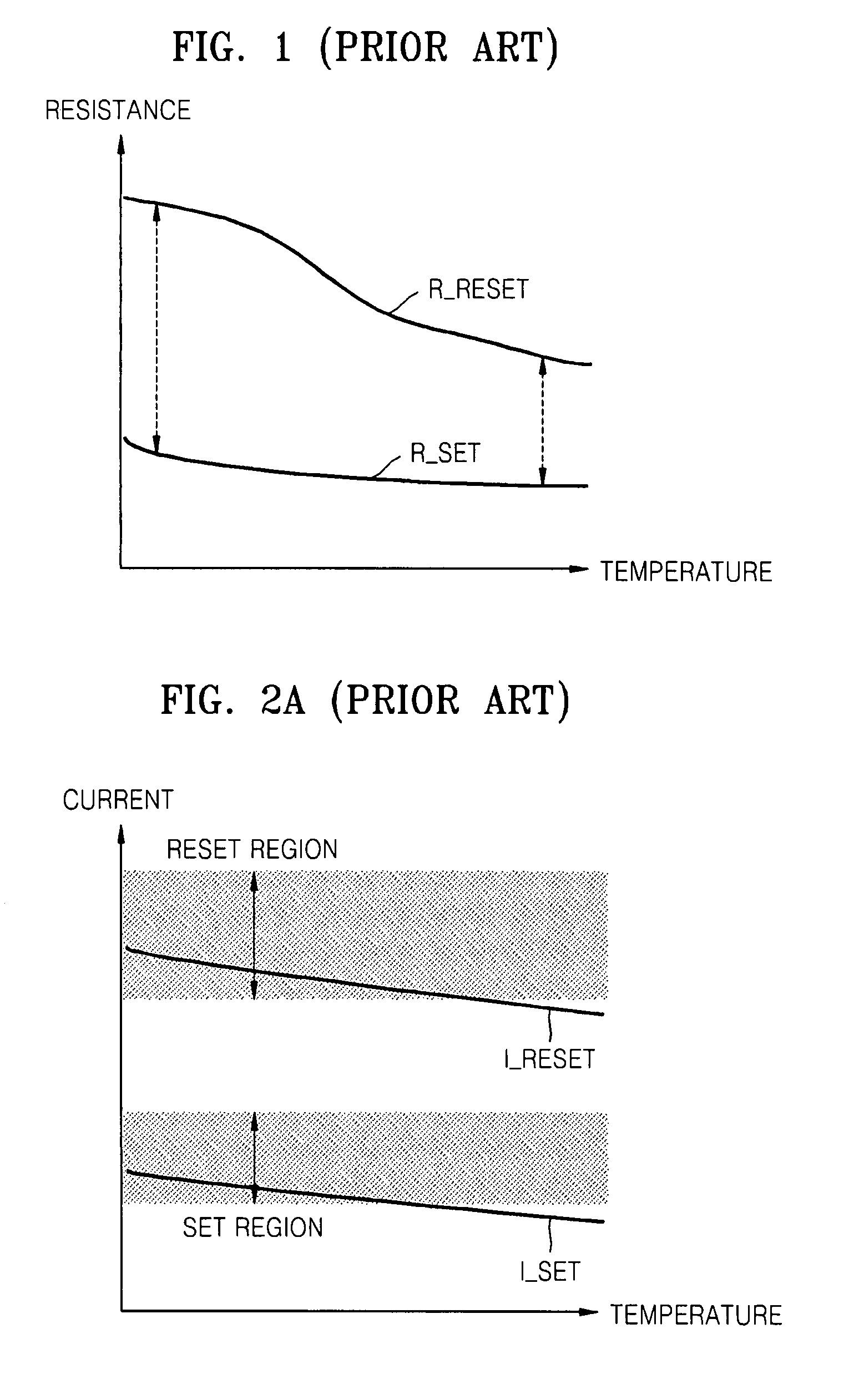

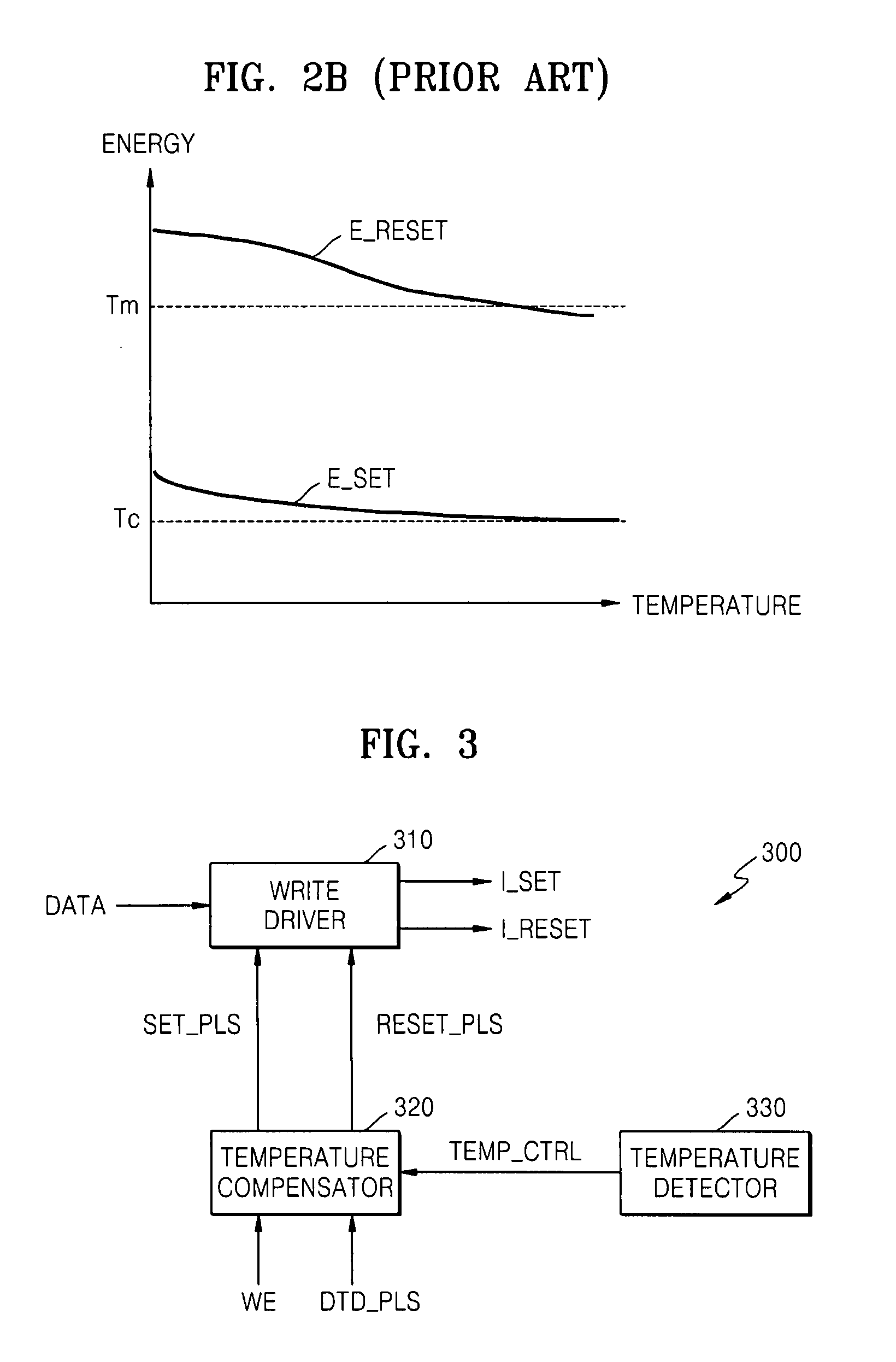

Control of set/reset pulse in response to peripheral temperature in PRAM device

A drive circuit for a PRAM (phase-change random access memory) device includes a write driver that generates a set / reset current in response to a set / reset pulse. In addition, a temperature compensator controls a pulse width of the set / reset pulse in response to a peripheral temperature of the PRAM device. For example, the temperature compensator maintains the pulse width to be substantially constant irrespective of the peripheral temperature. In another example, the temperature compensator decreases the width for higher peripheral temperature.

Owner:SAMSUNG ELECTRONICS CO LTD

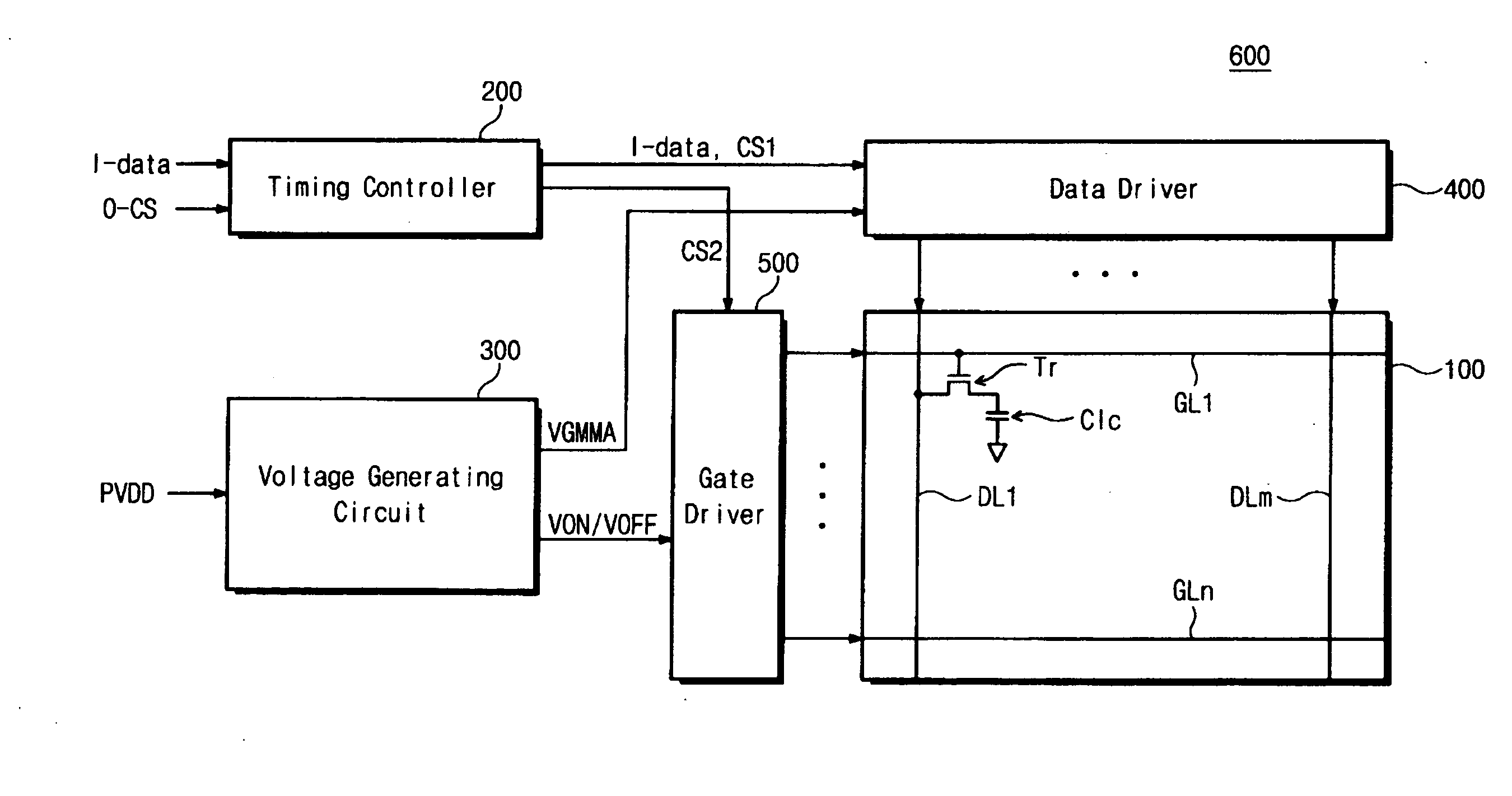

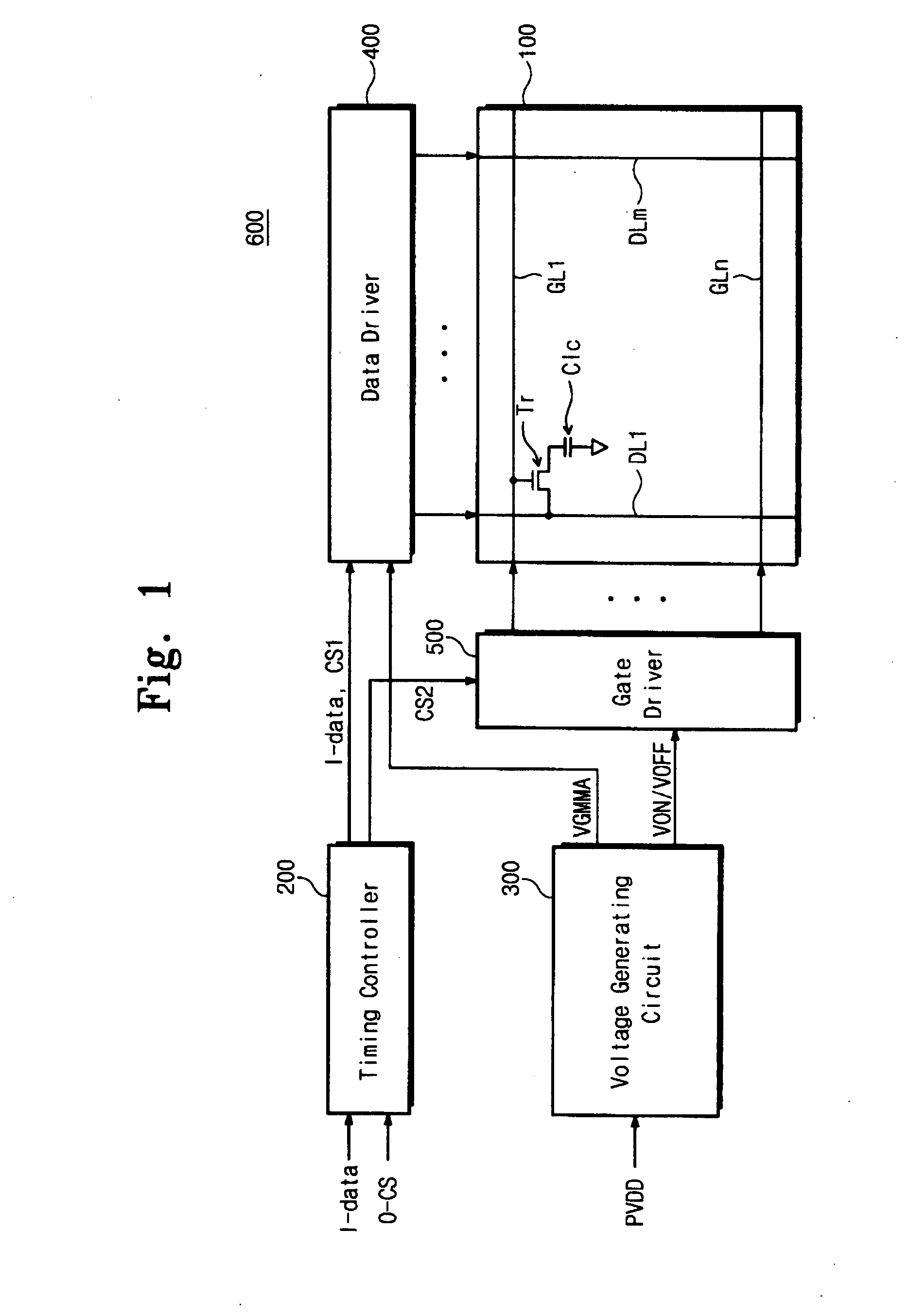

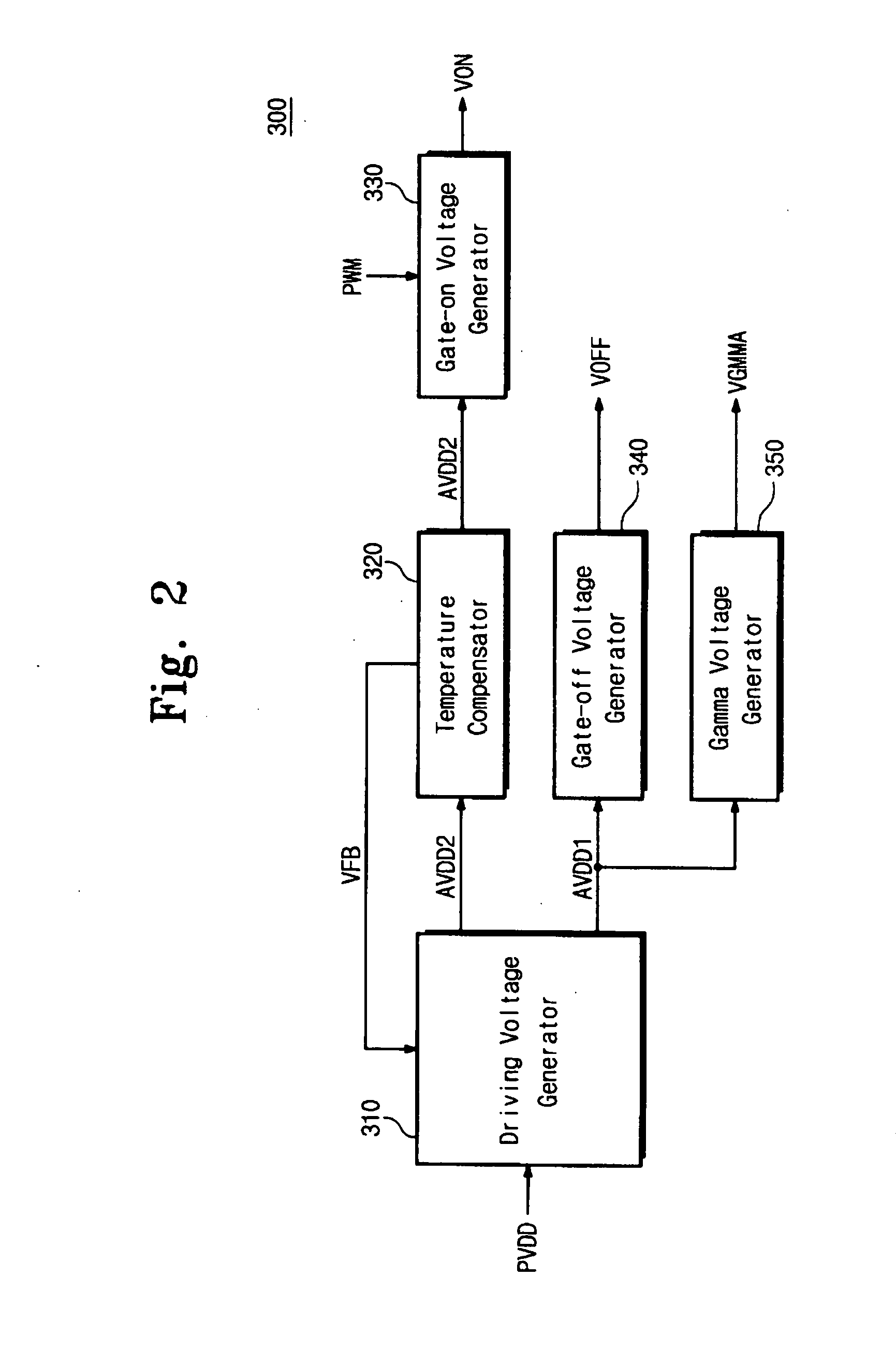

LCD voltage generating circuits

InactiveUS20080062100A1Preventing variation of response speedElectronic switchingCathode-ray tube indicatorsVoltage generatorEngineering

In a voltage generating circuit and a display apparatus, a driving voltage generator receives an input voltage to output a first driving voltage and a second driving voltage that is inversely proportional to a temperature in response to a feedback voltage. A temperature compensator generates the feedback voltage as a function of the temperature and the second driving voltage and applies it to the driving voltage generator. A gate-on voltage generator pumps the second driving voltage to generate a gate-on voltage, and a gamma voltage generator outputs a plurality of gamma voltages, each having a different voltage level that is disposed between the first driving voltage and a ground voltage. The gate-on voltage, which is inversely proportional to the temperature, is applied to the gate driver, and the gamma voltages, which are maintained at constant levels, prevent the response speed of the display apparatus from varying with temperature.

Owner:SAMSUNG DISPLAY CO LTD

System, method and apparatus for reducing frictional forces and for compensating shape memory alloy-actuated valves and valve systems at high temperatures

ActiveUS20070277877A1Little strengthTemperature control without auxillary powerOperating means/releasing devices for valvesTemperature CompensatorClosed cavity

A valve system including a number of shape memory alloy (“SMA”)-actuated valves for controlling the flow of fluids is disclosed as is a variety of types of SMA-actuated valves and methods of operation. In one embodiment, a valve system includes a housing having a substantially closed cavity as well as a second port for communicating a fluid. Further, the valve system includes a first SMA actuator configured to control the position of the first seal to vary fluid flow through the firs port, and a first temperature compensator for adjusting the position of the seal by an amount proportional to temperature. A second SMA-actuated valve, driven by either a unidirectional or a bidirectional SMA actuator, controls the position of the second seal to vary fluid flow through the second port, and a second temperature compensator for adjusting the position of the second seal by another amount proportional to temperature.

Owner:ALFMEIER PRAZISION BAUGRUPPEN & SYSTLOSUNGEN +1

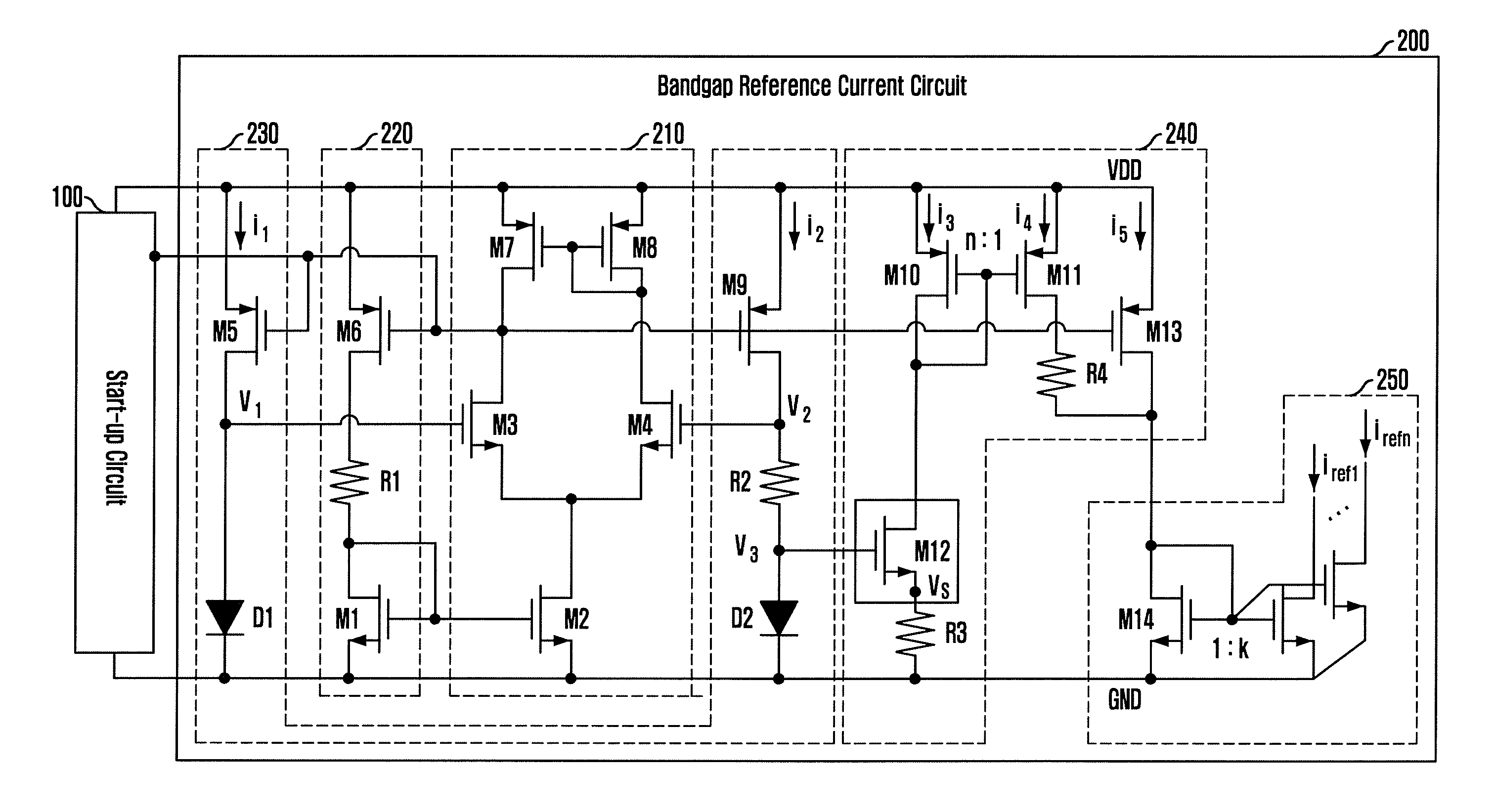

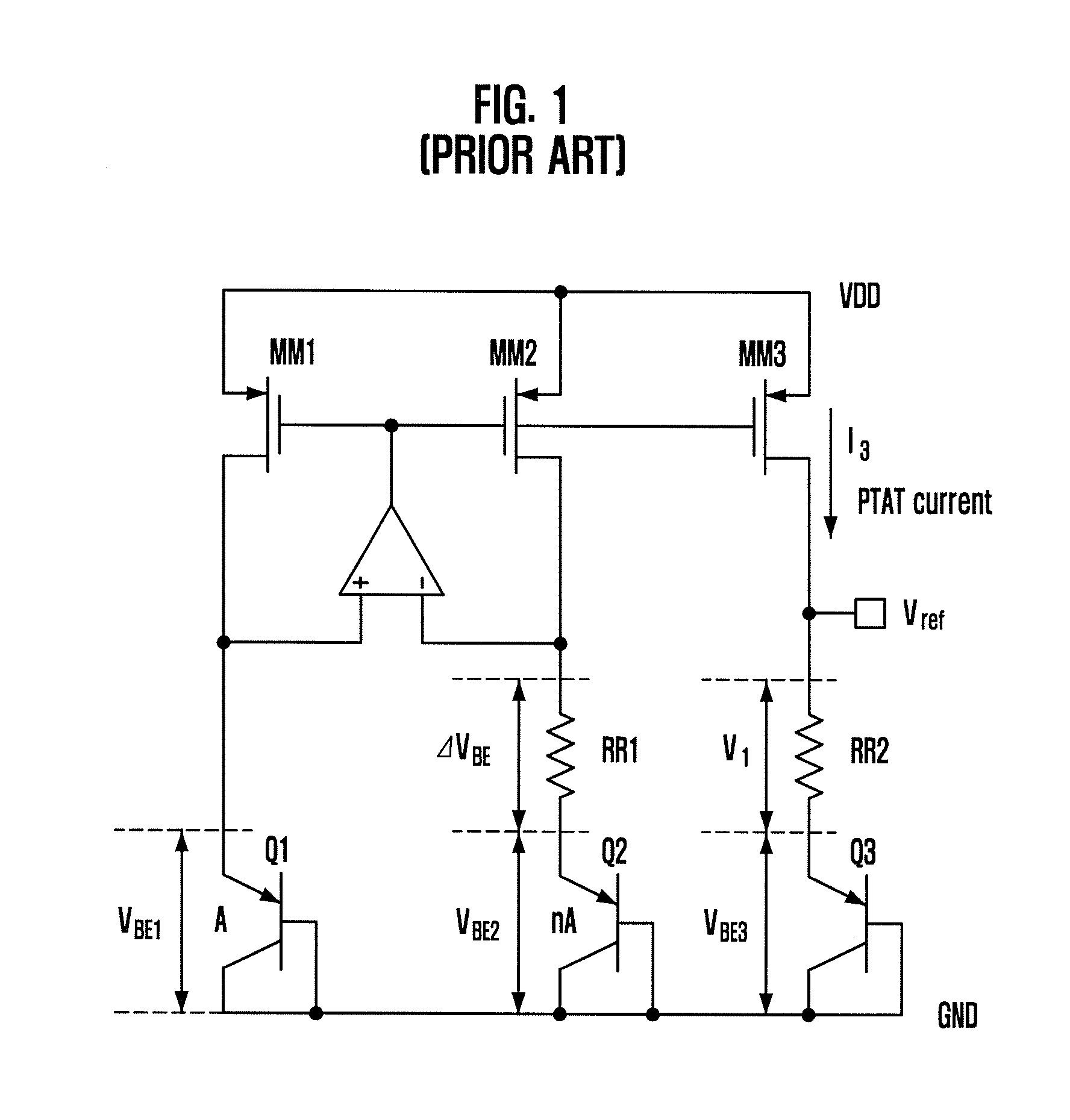

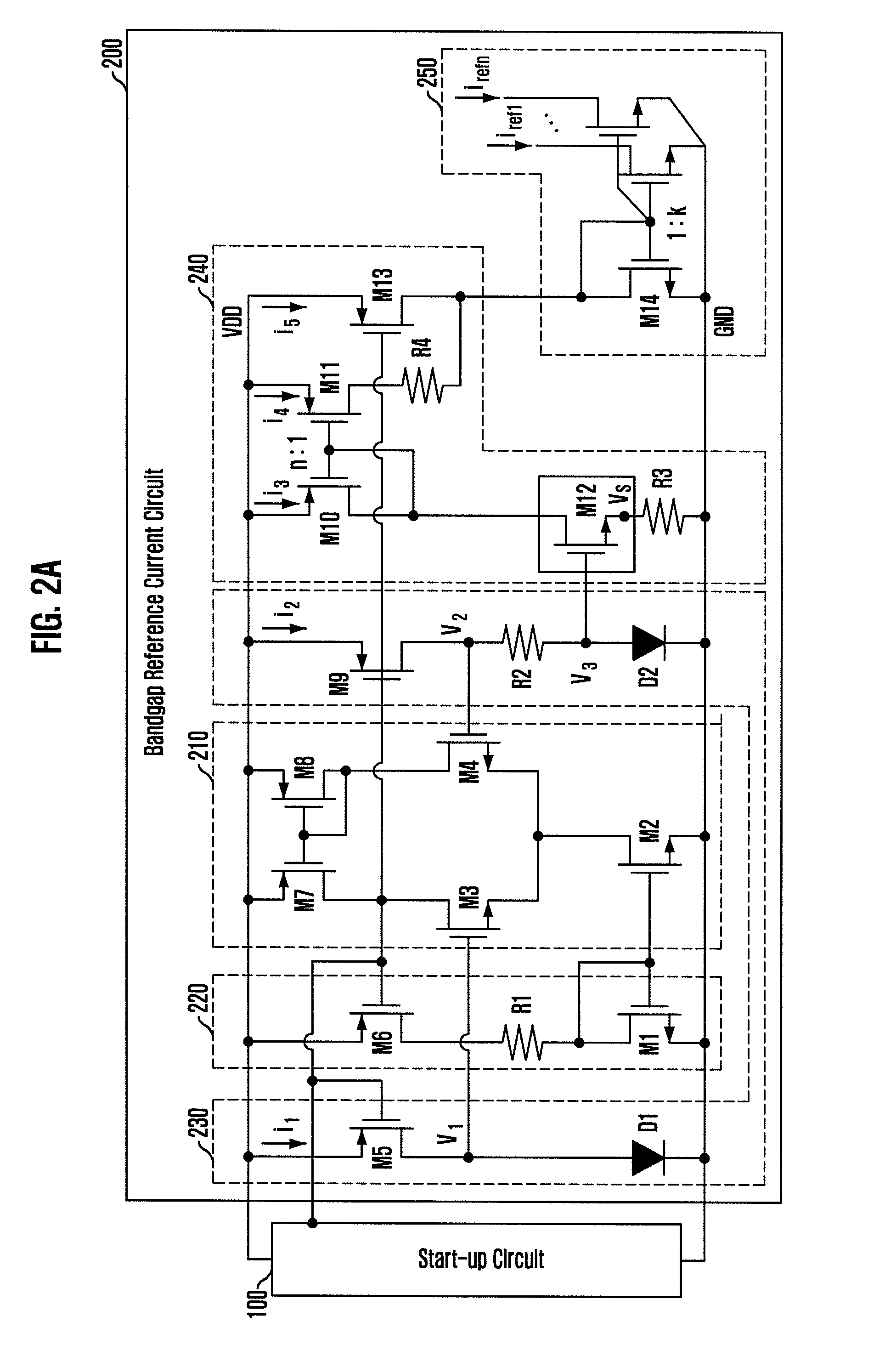

Reference bias generating circuit

ActiveUS20100141344A1Reduce power consumptionAmplifier detailsElectric variable regulationAudio power amplifierNegative temperature

A reference current bias circuit includes a self-bias circuit configured to provide a bias current to an amplifier; a basic bandgap circuit coupled to inputs of the amplifier; a startup circuit configured to support an initial operation of the amplifier; a temperature compensator configured to include a first mirroring unit for mirroring current according to a positive temperature coefficient characteristic from the basic bandgap circuit; and a second mirroring unit for mirroring current according to a negative temperature coefficient characteristic from the basic bandgap circuit, and to provide a reference current by combining the current of the first mirroring unit and the current of the second mirroring unit; and a reference current mirroring unit configured to generate reference current biases based on the reference current from the temperature compensator.

Owner:ELECTRONICS & TELECOMM RES INST

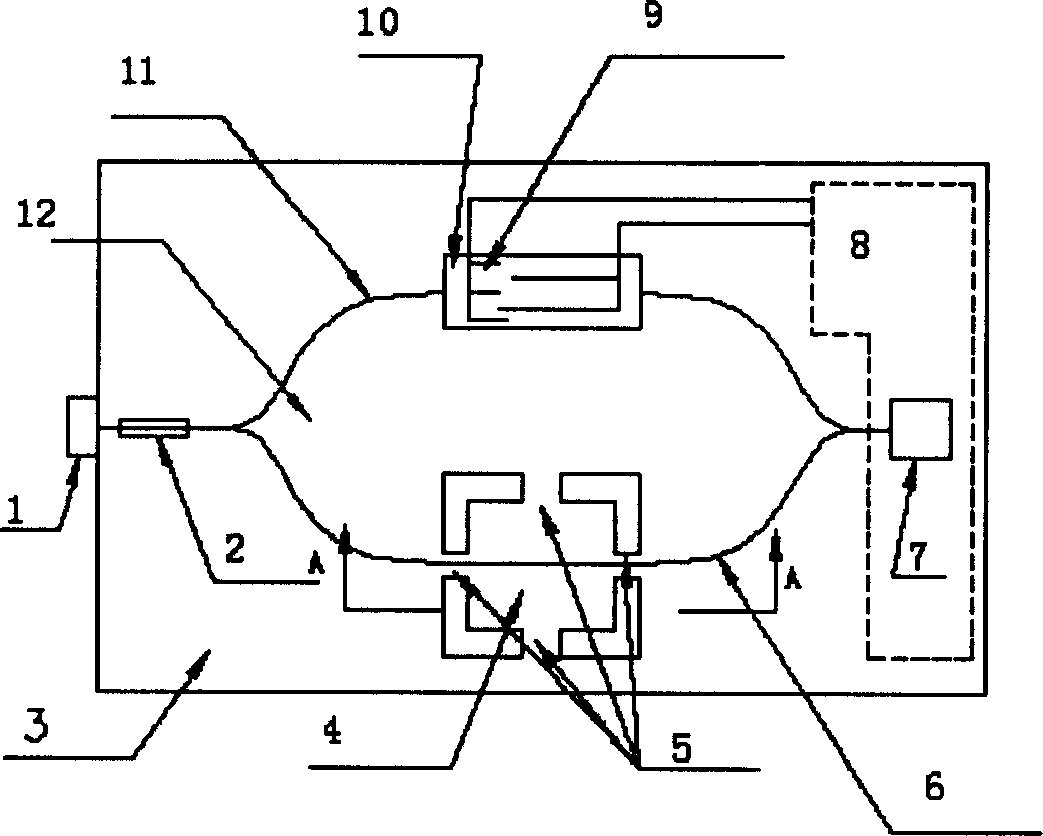

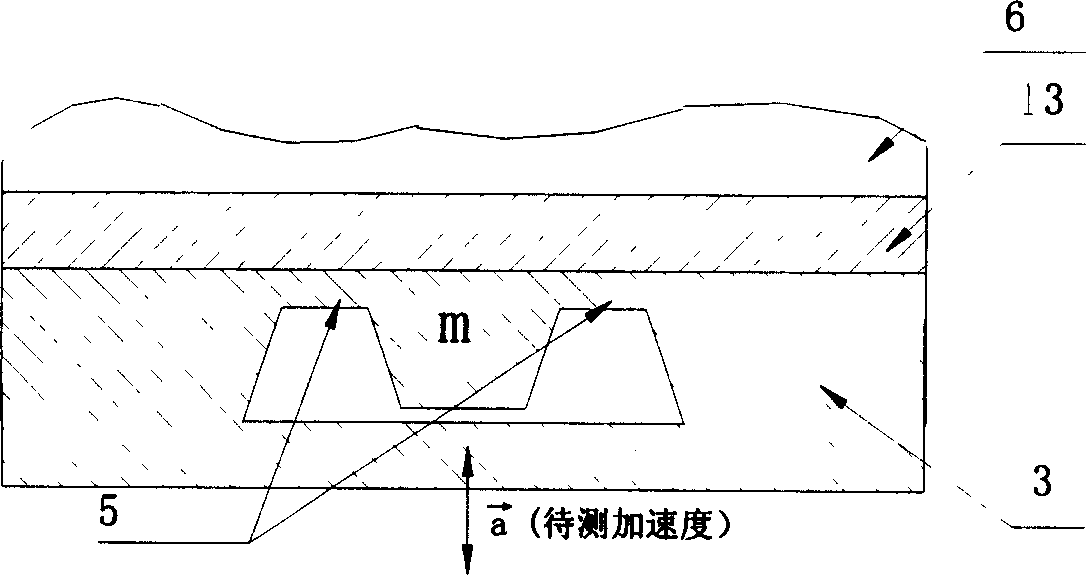

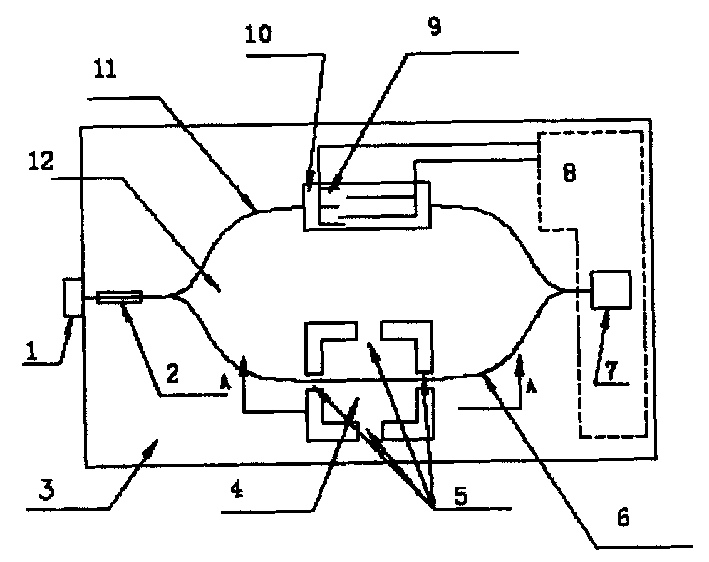

Photoelectronic integrated acceleration geophone

InactiveCN1425926AImprove fidelityLow costSeismic signal receiversSignal processing circuitsPolarizer

The photoelectronic integrated acceleration geophone is one acceleration and seismic wave detector. Inside metal casing, there are photoelectronioc integrated acceleration geophone chip and laser. The chip consists of silicon substrate, buffering silica layer and integrated optical waveguide polarizer, M-Z waveguide interference instrument, interdigital photoacoustic transducer, photoelectronic detector, temperature compensator and demodulator circuit and signal processor circuit; and has simple harmonic vibrator comprising cross beam etched on the silicon substrate and silicon mass block. The present invention features the connection of the input of the M-Z waveguide interference instrument and the laser, the connection of the output and the photoelectronic detector, and the connection of the signal arm with planar waveguide and the photoacoustic transducer.

Owner:TIANJIN UNIV

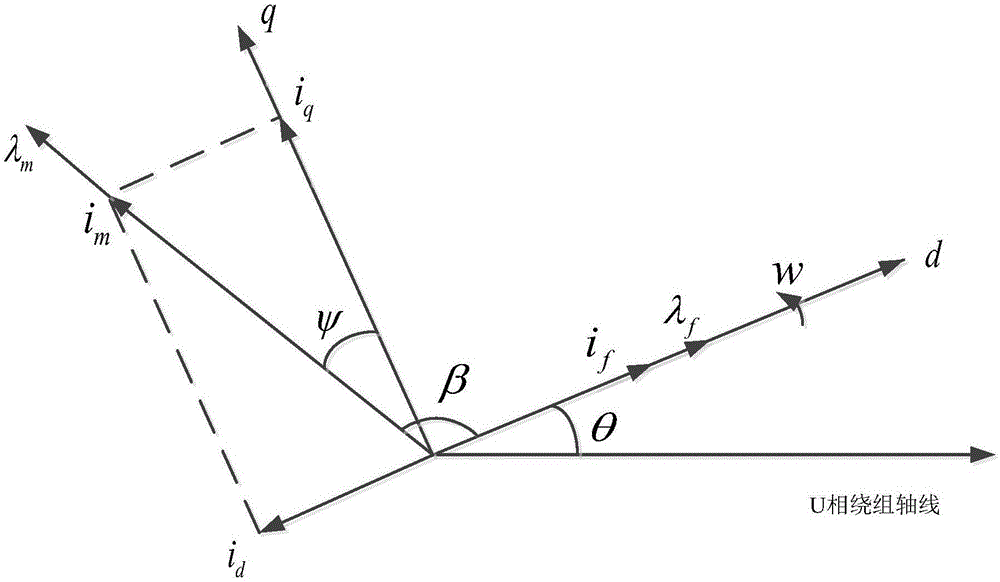

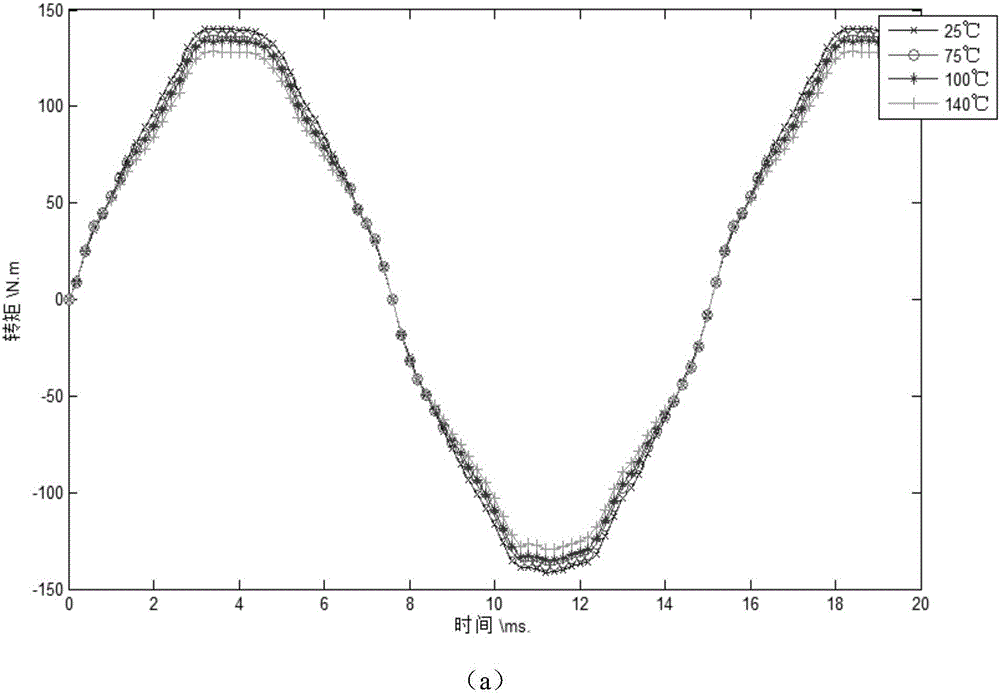

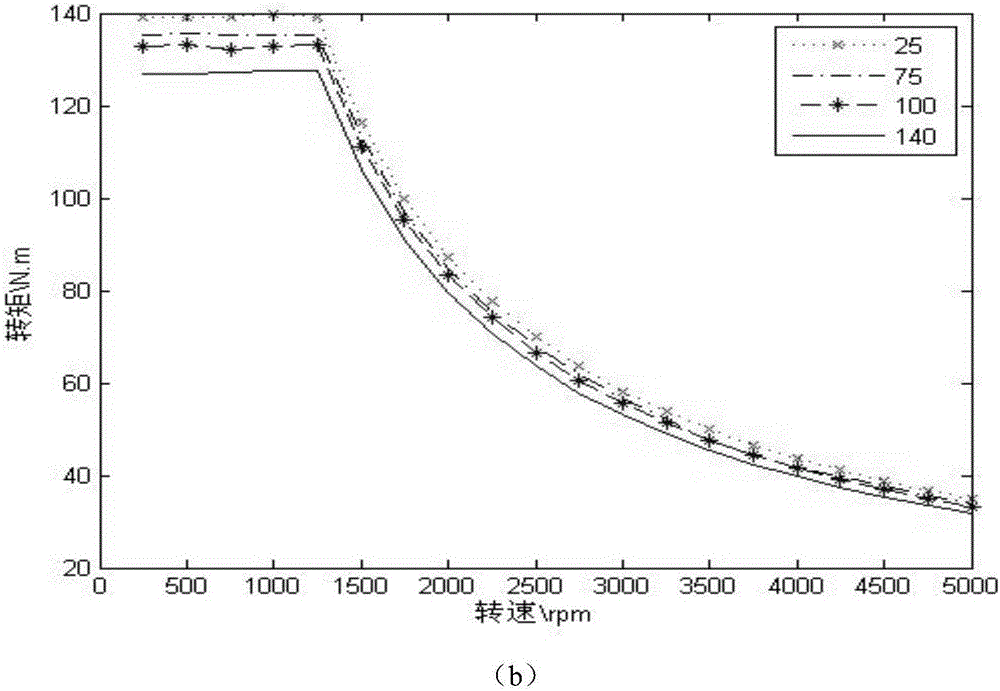

Temperature compensation method of output torque of permanent magnet synchronous motor for vehicle based on neural network

ActiveCN106357184AReduce output torqueSmooth output torqueElectronic commutation motor controlSpeed controllerNon linear couplingPermanent magnet synchronous motor

The invention discloses a temperature compensation method of an output torque of a permanent magnet synchronous motor for a vehicle based on a neural network. The method aims at the influence of temperature on stator resistance and a permanent magnetic flux linkage and comprises the following steps: building a neural network model for describing non-linear coupling action of the temperature on multiple parameters of a vehicle-mounted permanent magnet synchronous motor; and based on the built neural network model, designing a temperature compensator on the output torque, so that the motor can be effectively and continuously controlled and an ideal and smooth output torque is obtained. The method disclosed by the invention has the advantages that a temperature compensation control system is adopted, the controller regulates the control quantity according to different motor temperatures, and then real-time control is carried out on the motor, so that the smooth output torque is obtained, and the operation difficulty of a technician is lowered; and the voltage control quantity does not need to be adjusted according to an efficiency map in real time and can be adjusted in real time according to the continuous change of the temperature, so that the control precision is greatly improved.

Owner:ANHUI UNIVERSITY

Control of set/reset pulse in response to peripheral temperature in PRAM device

A drive circuit for a PRAM (phase-change random access memory) device includes a write driver that generates a set / reset current in response to a set / reset pulse. In addition, a temperature compensator controls a pulse width of the set / reset pulse in response to a peripheral temperature of the PRAM device. For example, the temperature compensator maintains the pulse width to be substantially constant irrespective of the peripheral temperature. In another example, the temperature compensator decreases the width for higher peripheral temperature.

Owner:SAMSUNG ELECTRONICS CO LTD

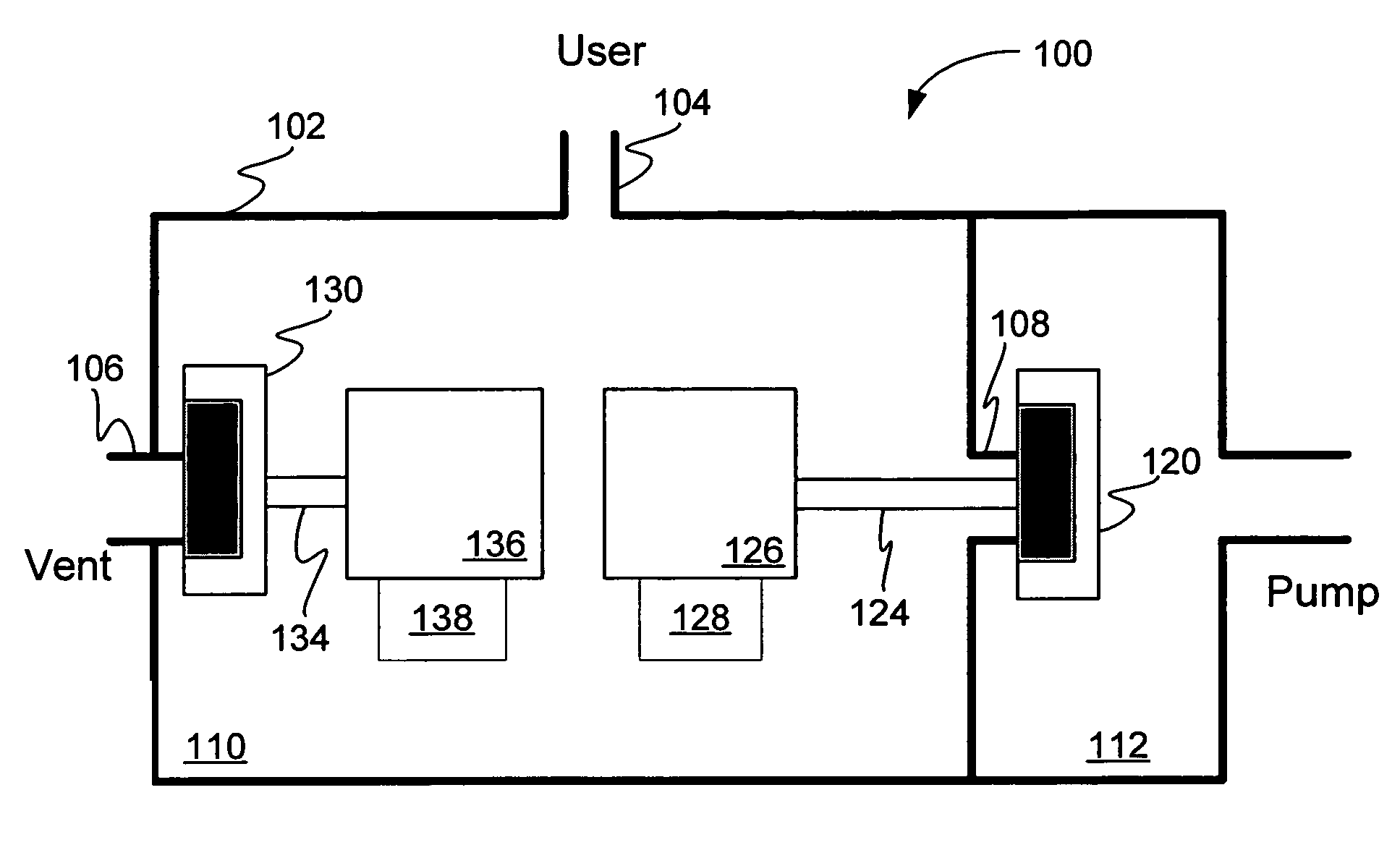

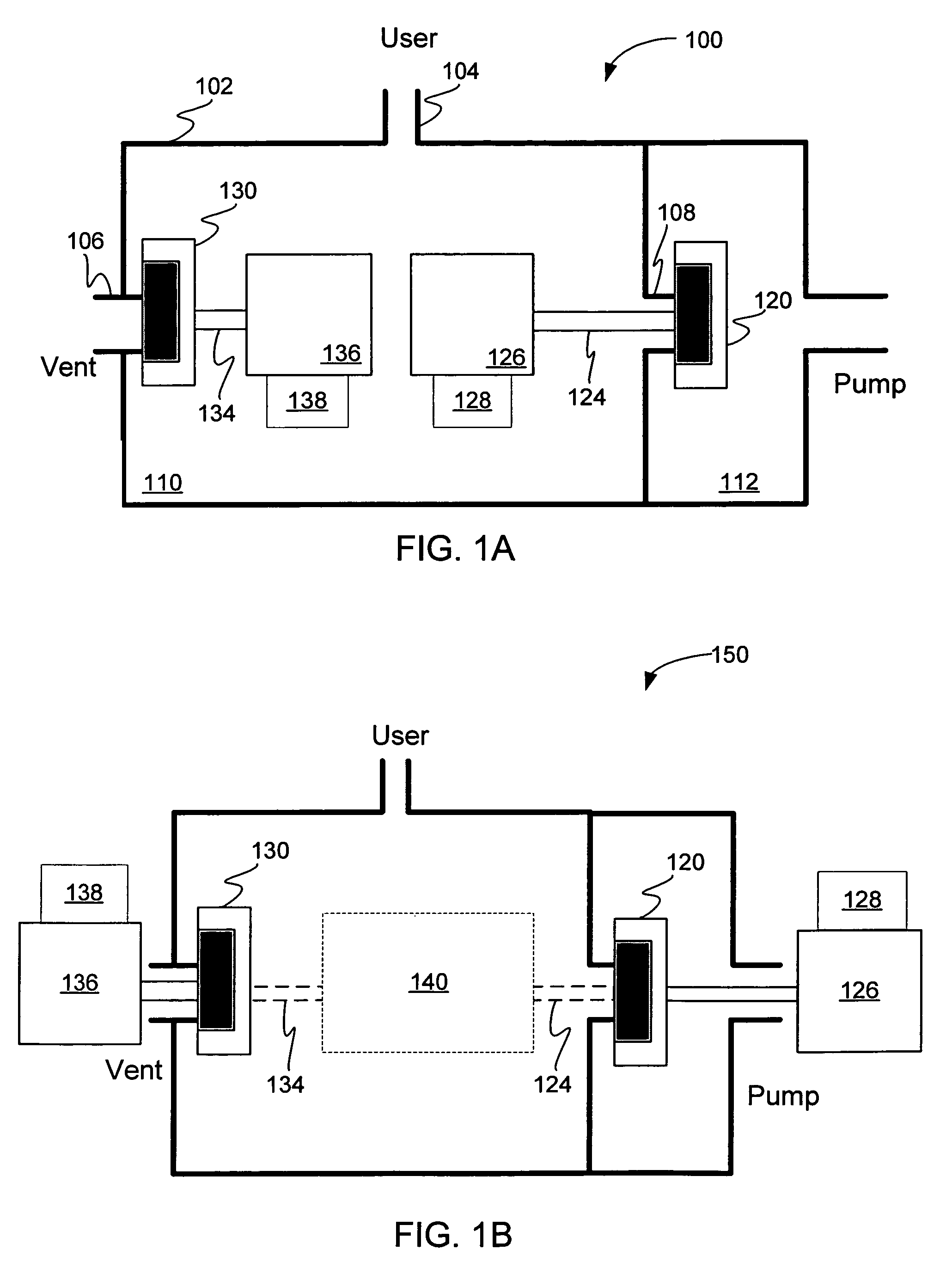

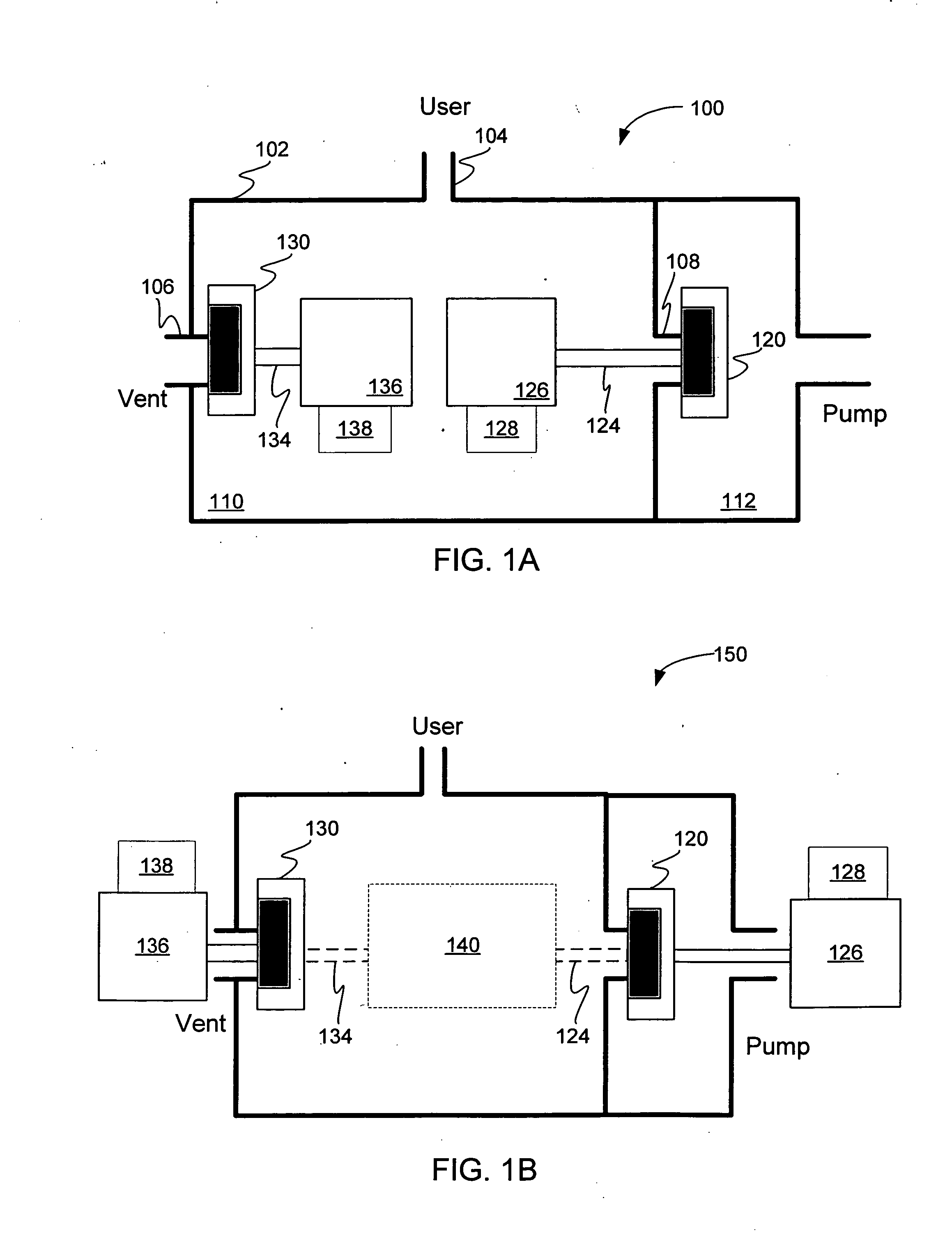

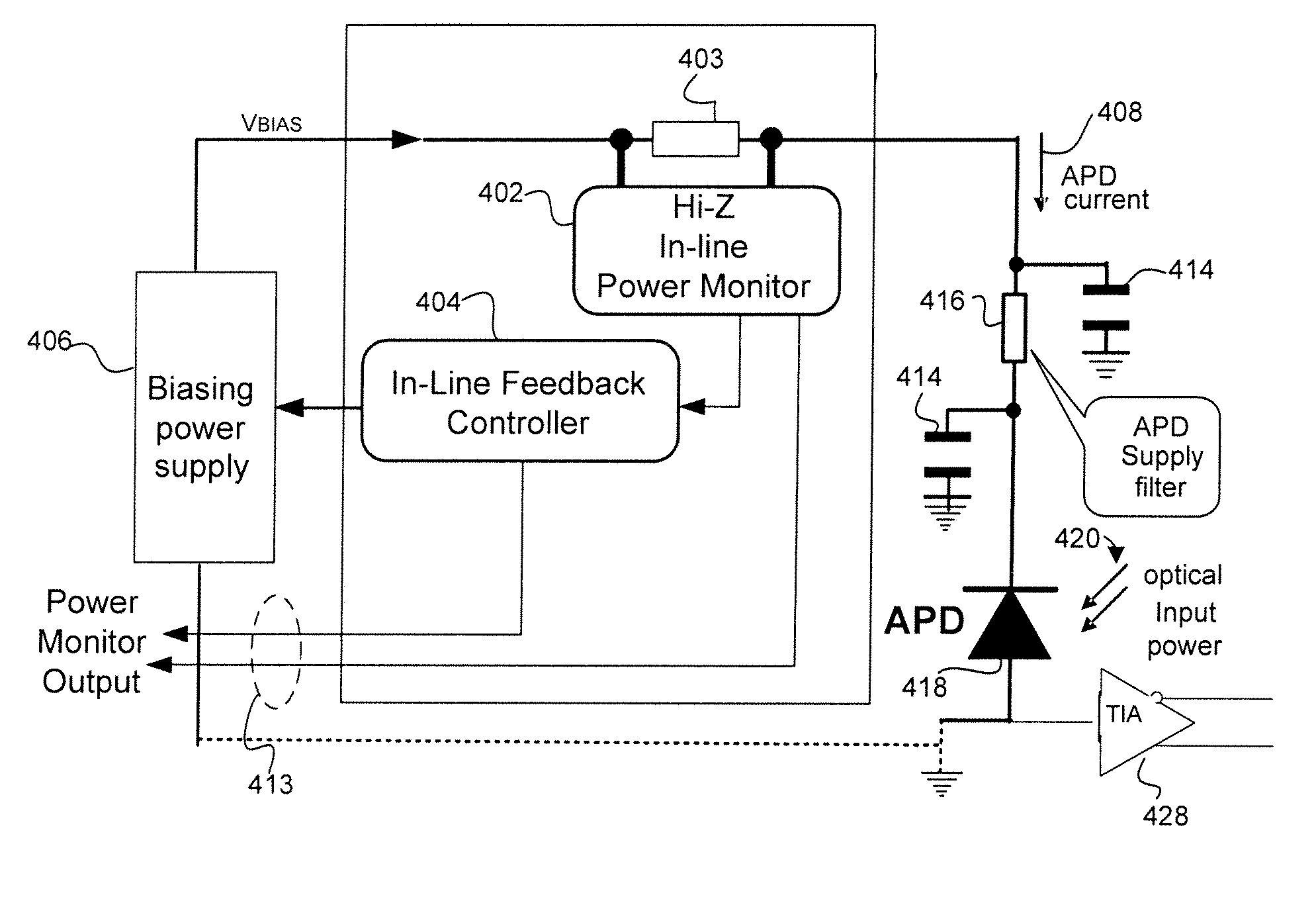

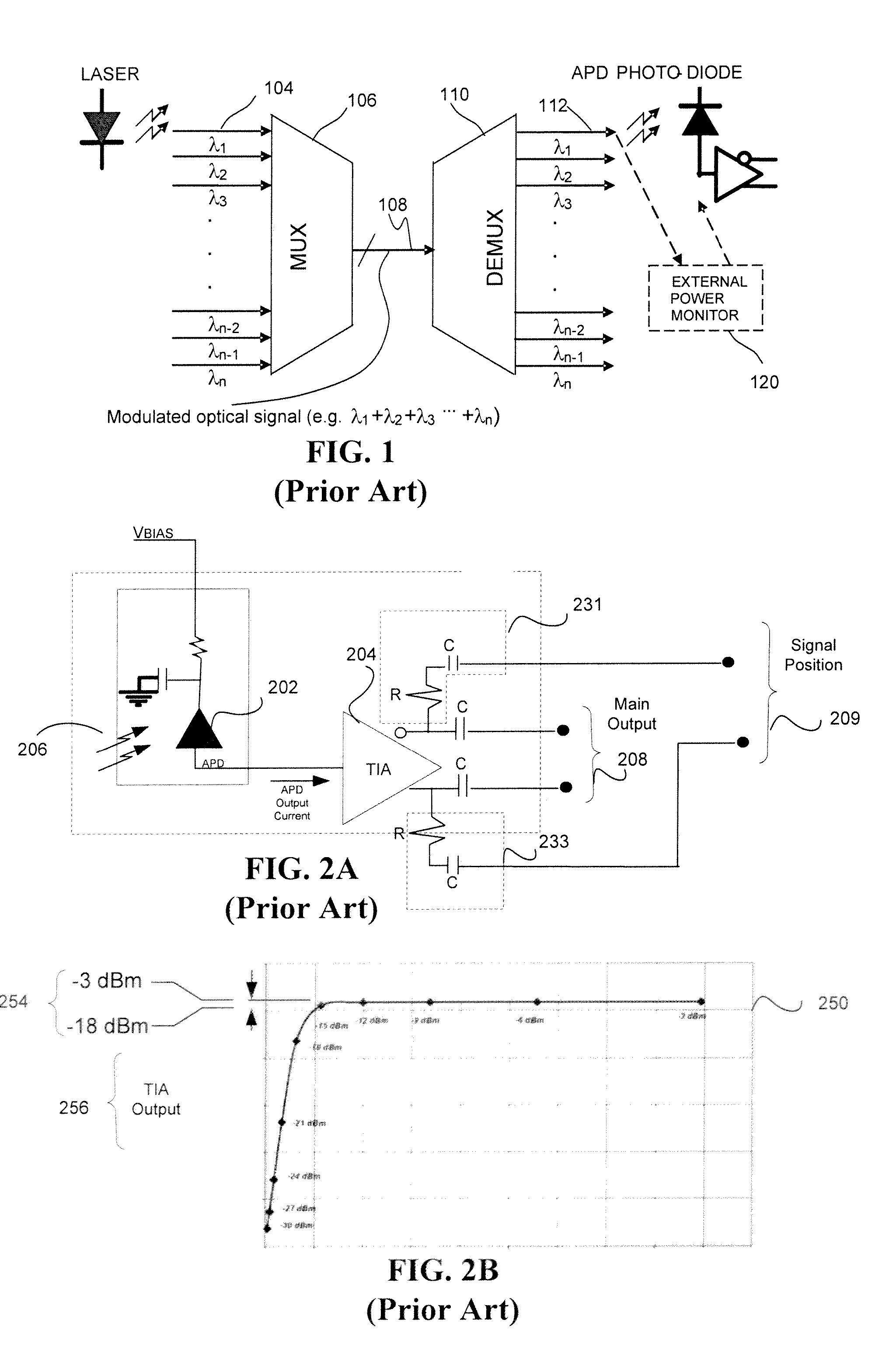

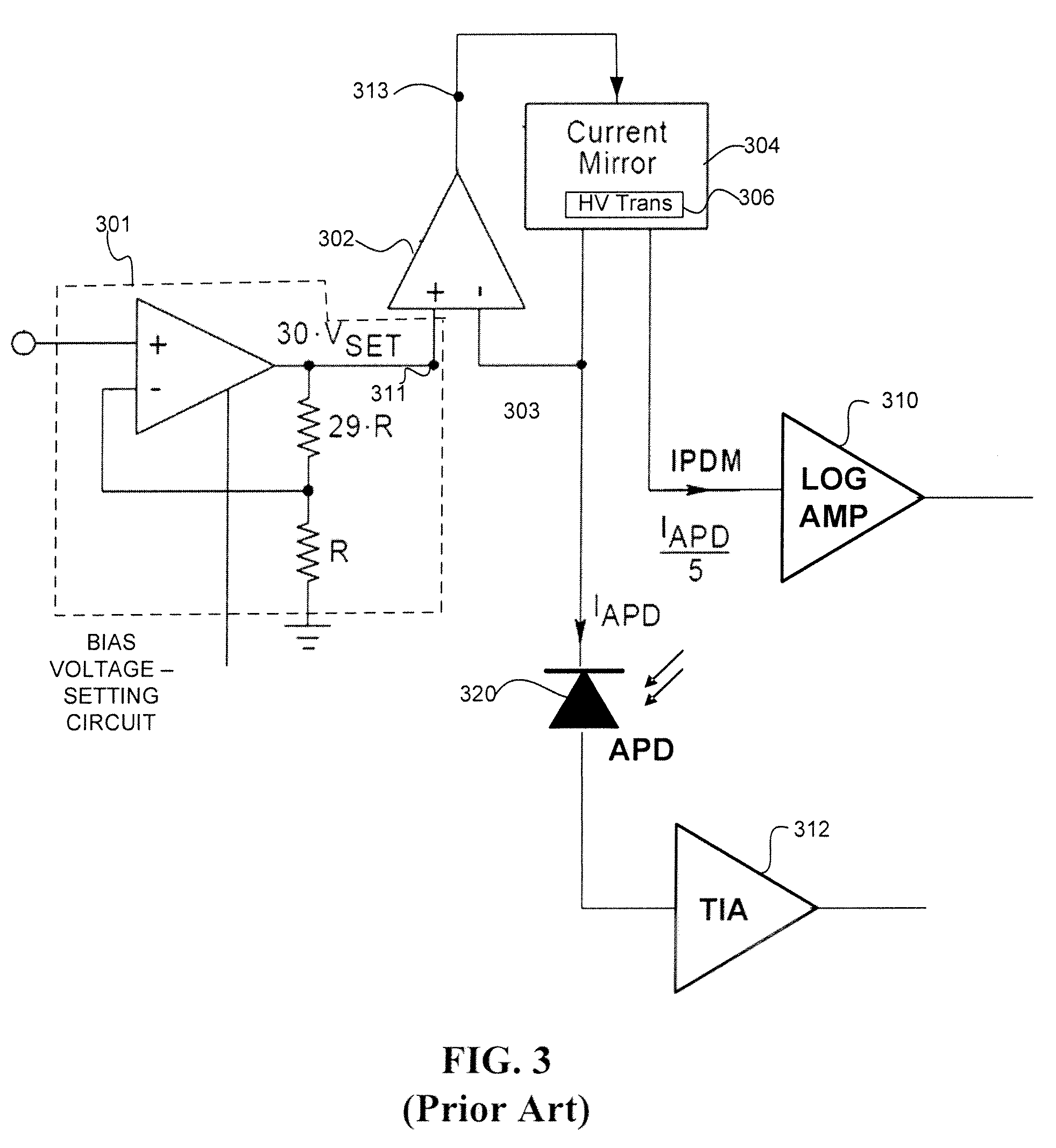

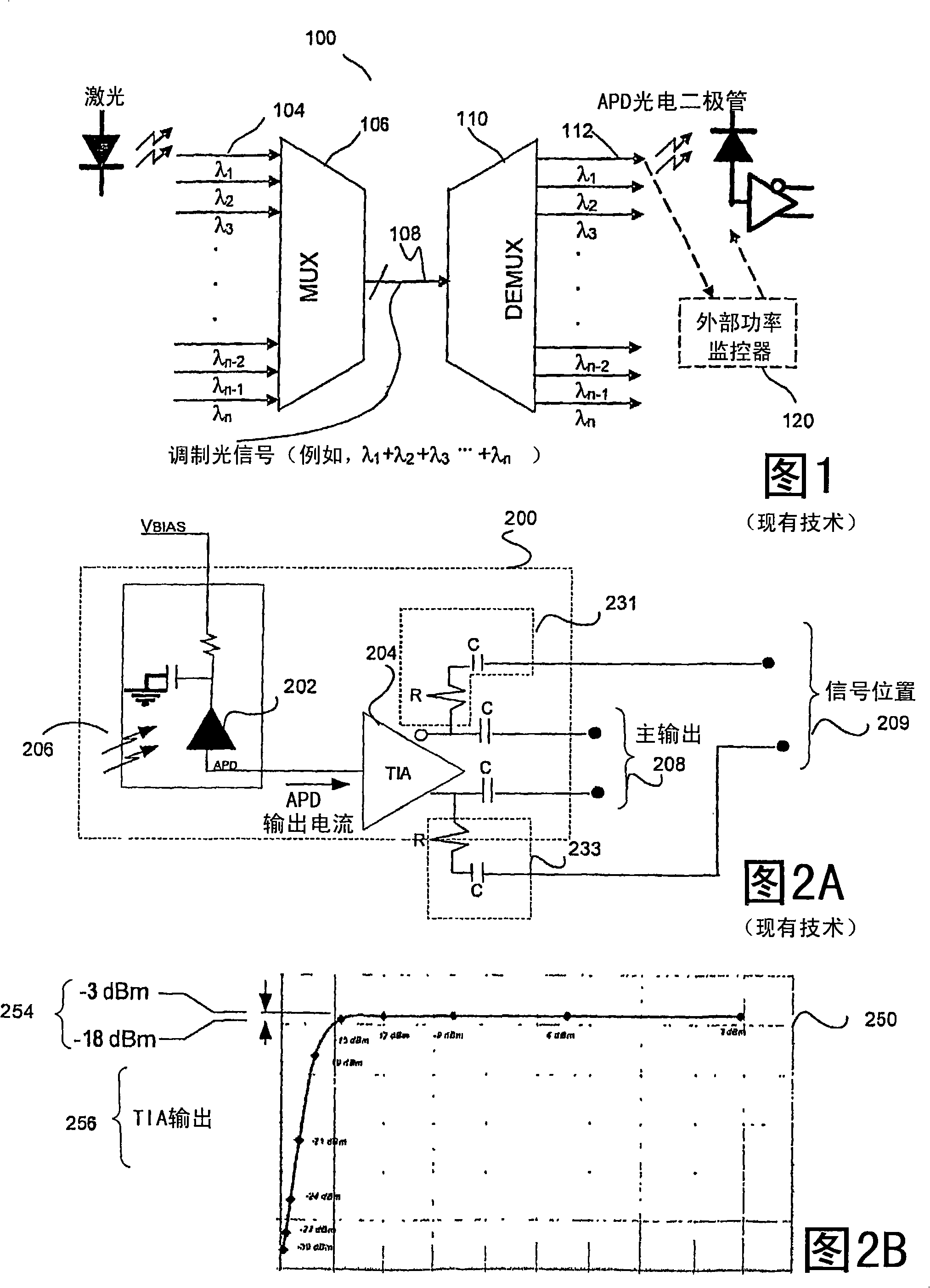

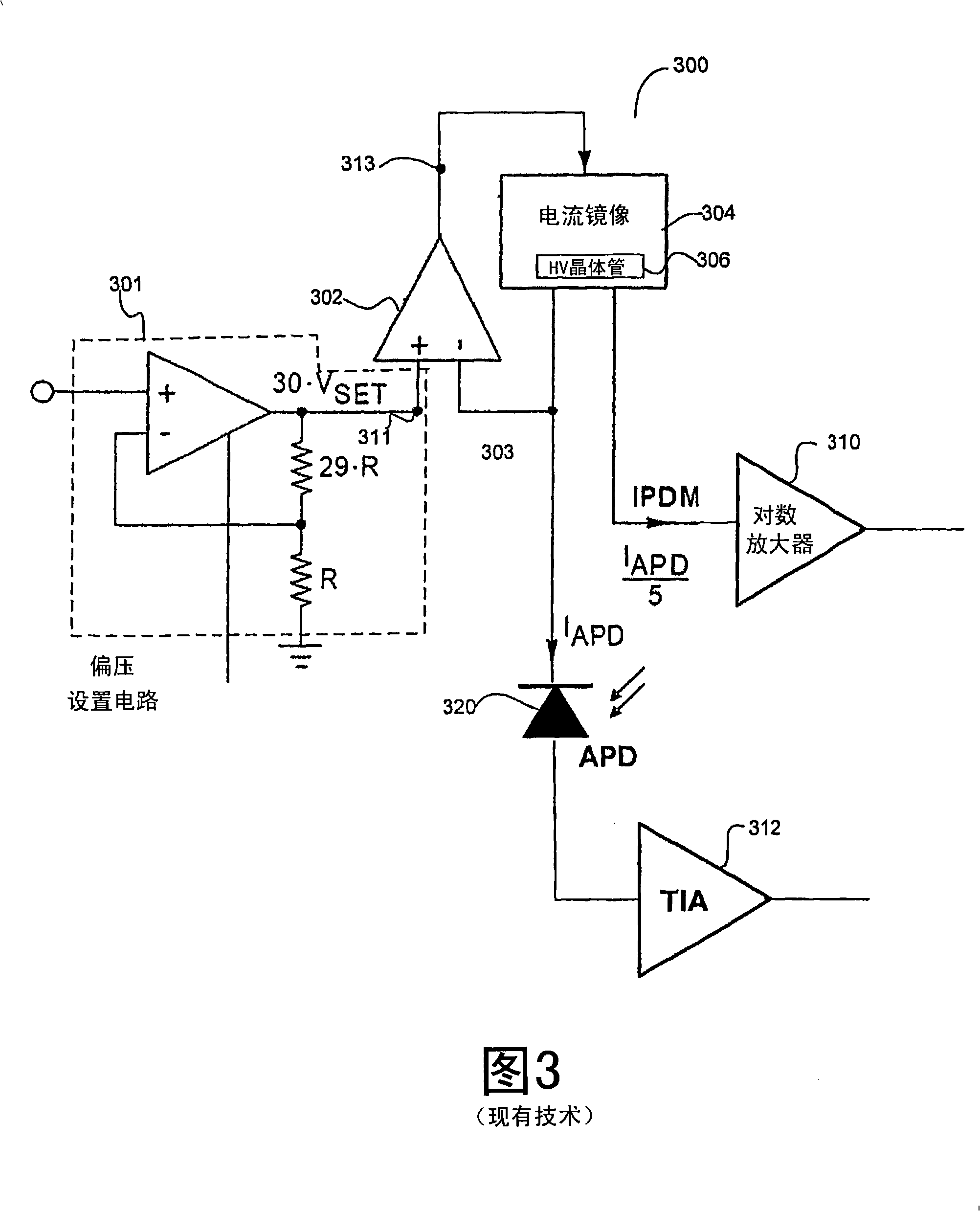

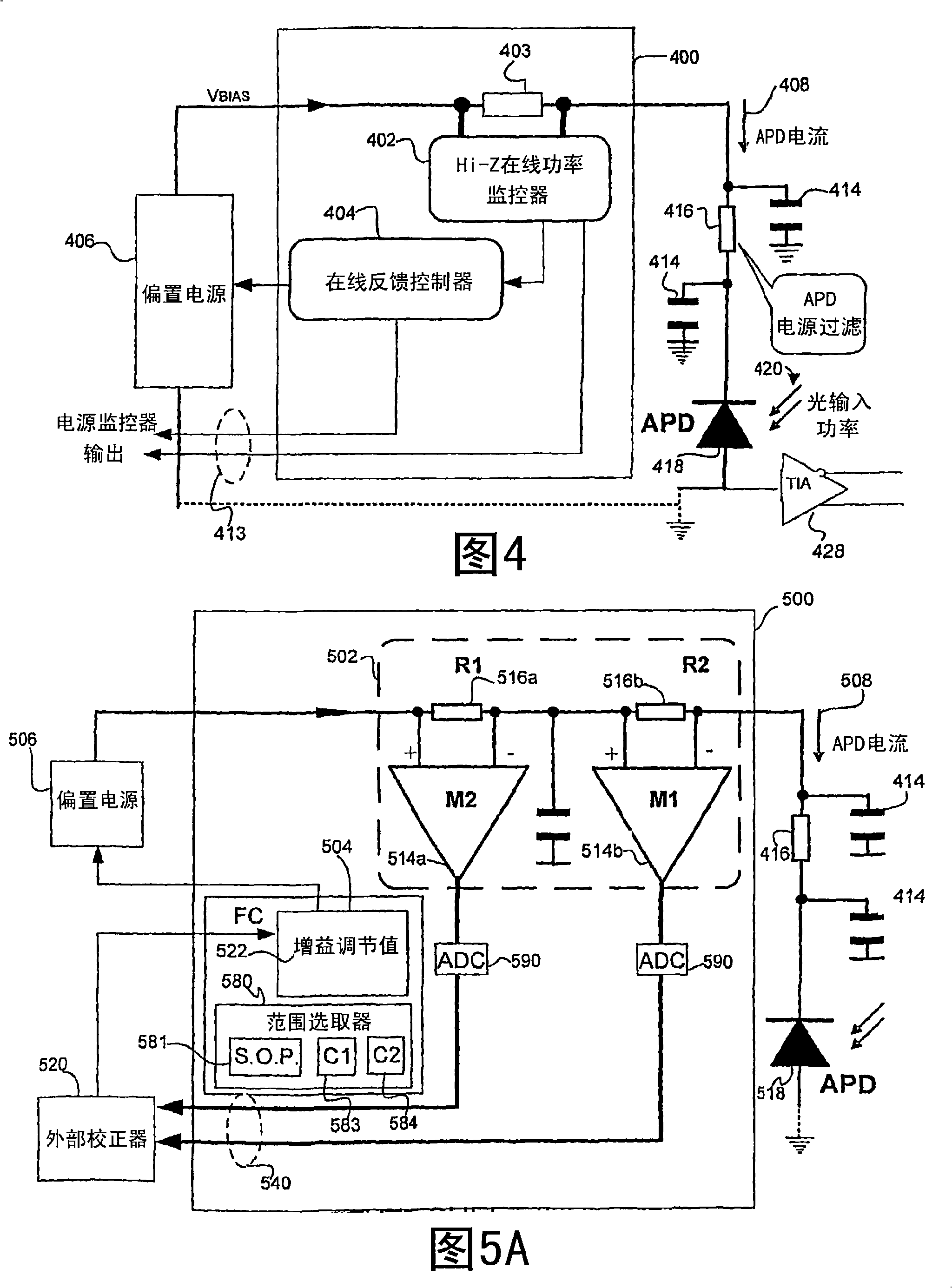

In-situ power monitor having an extended range to stabilize gain of avalanche photodiodes across temperature variations

ActiveUS20070057160A1Uniform gainHigh sensitivityMaterial analysis by optical meansPhotoelectric discharge tubesEngineeringTemperature Compensator

Disclosed are an in-line monitoring apparatus with a temperature compensator, an optical receiver and a method for stabilizing gain of an avalanche photodiode (“APD”) over an extended range of input power values and across temperature variations. The apparatus can include one or more power monitoring stages coupled in parallel to the APD for generating one or more measurement signals in-situ. The apparatus also includes a temperature compensator configured to adjust an operational parameter for the APD as a function of temperature and the measurement signal. The temperature compensator adjusts the bias to maintain a substantially uniform gain across temperature variations to facilitate an increased sensitivity with which to monitor the input power at lower levels than if the temperature compensator did not adjust the bias in response to the temperature. One of the power monitoring stages can be configured to monitor the low-powered optical signals.

Owner:ALLIED TELESIS

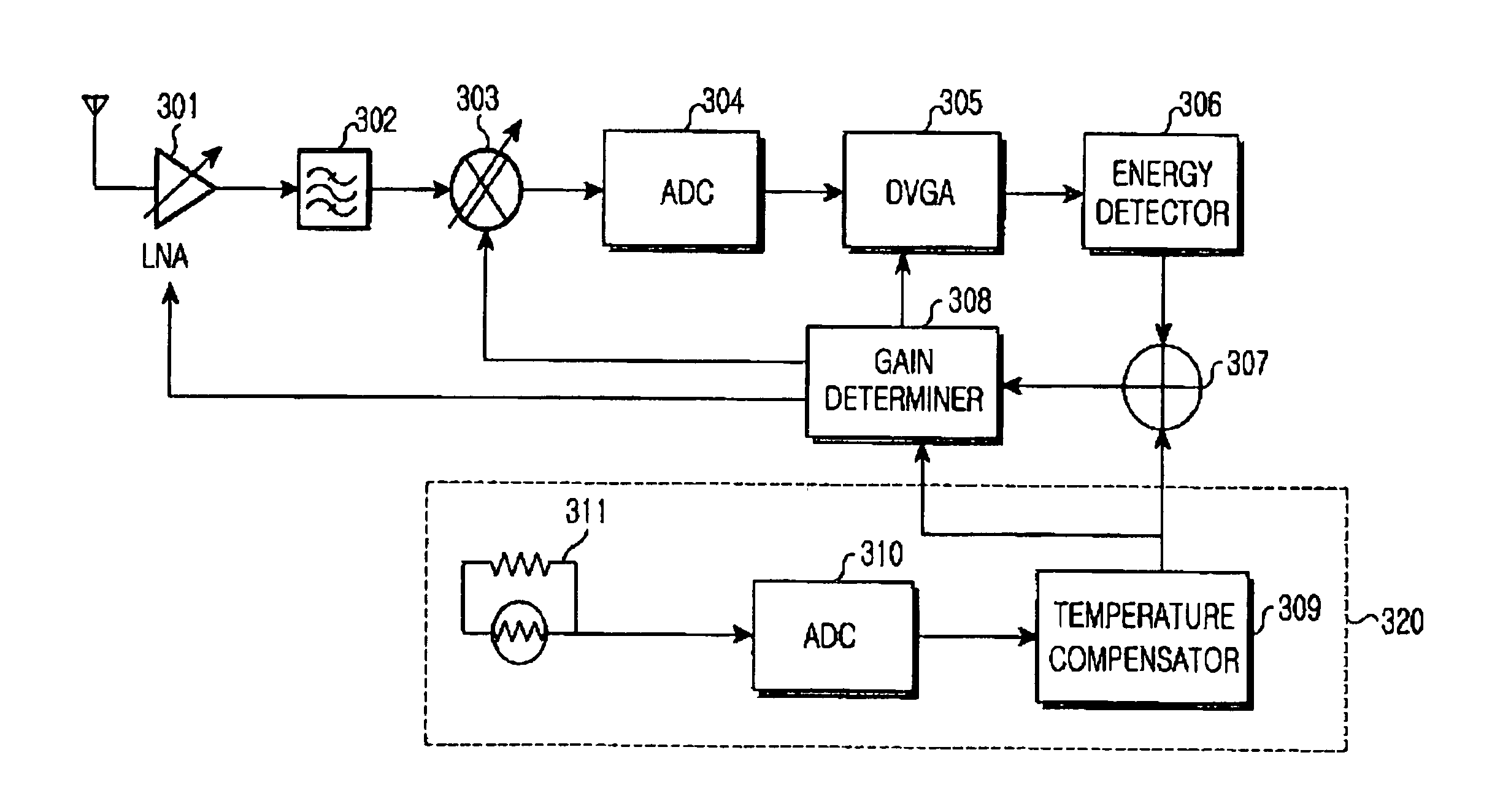

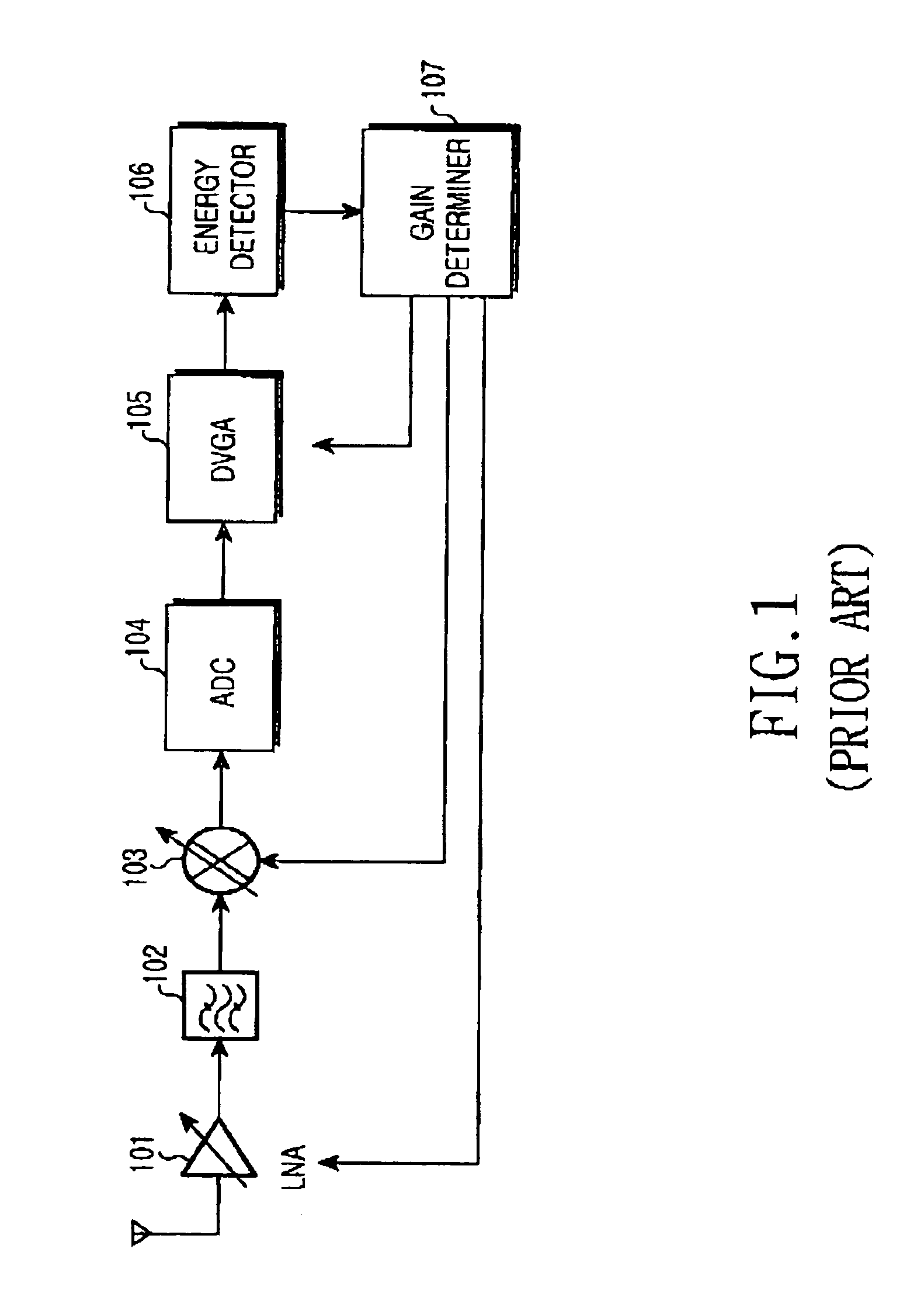

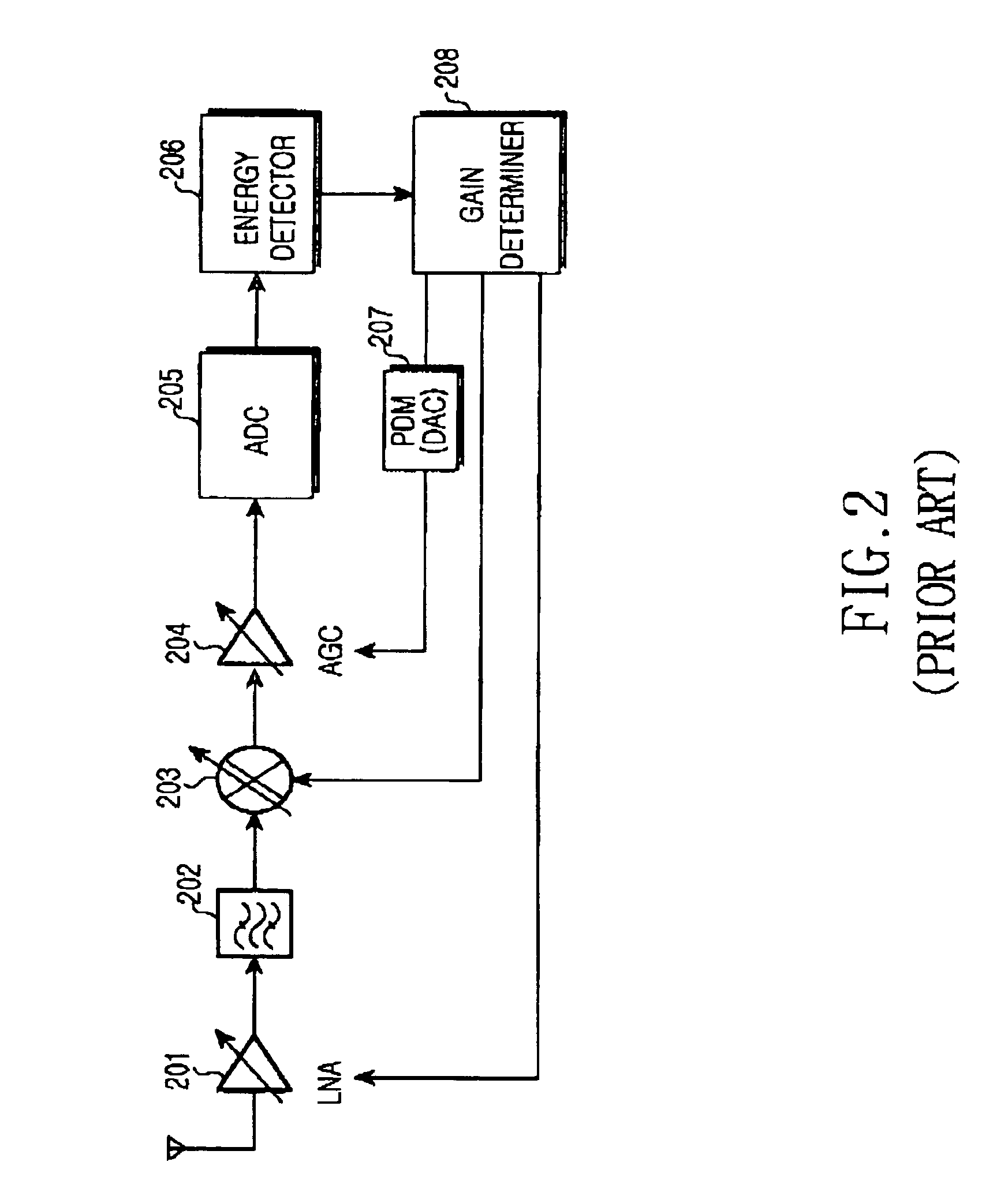

Temperature compensation device for automatic gain control loop

InactiveUS6999012B2Exact strengthElectric signal transmission systemsGain controlSimulation basedTemperature Compensator

A temperature compensation device for an automatic gain control loop in a receiver of a mobile communication terminal is disclosed. The temperature compensation device comprises a thermistor having a resistance varying with temperature to vary its output voltage, an analog / digital converter for converting the output voltage from the thermistor into a digital signal, and a temperature compensator for outputting a temperature compensation value in response to a digital signal based on a specific temperature variation from the analog / digital converter.

Owner:SAMSUNG ELECTRONICS CO LTD

Transconductance and current modulation for resonant frequency control and selection

ActiveUS20050206464A1Highly accurate over PVT variationAccurate frequency generationResonant circuit tuningImpedence networksSquare waveformAudio power amplifier

In various embodiments, the invention provides a frequency controller and a temperature compensator for frequency control and selection in a clock generator and / or a timing and frequency reference. The various apparatus embodiments include a resonator adapted to provide a first signal having a resonant frequency; an amplifier; a temperature compensator adapted to modify the resonant frequency in response to temperature; and a process variation compensator adapted to modify the resonant frequency in response to fabrication process variation. In addition, the various embodiments may also include a frequency divider adapted to divide the first signal having the resonant frequency into a plurality of second signals having a corresponding plurality of frequencies substantially equal to or lower than the resonant frequency; and a frequency selector adapted to provide an output signal from the plurality of second signals. The output signal may be provided in any of various forms, such as differential or single-ended, and substantially square-wave or sinusoidal.

Owner:INTEGRATED DEVICE TECH INC

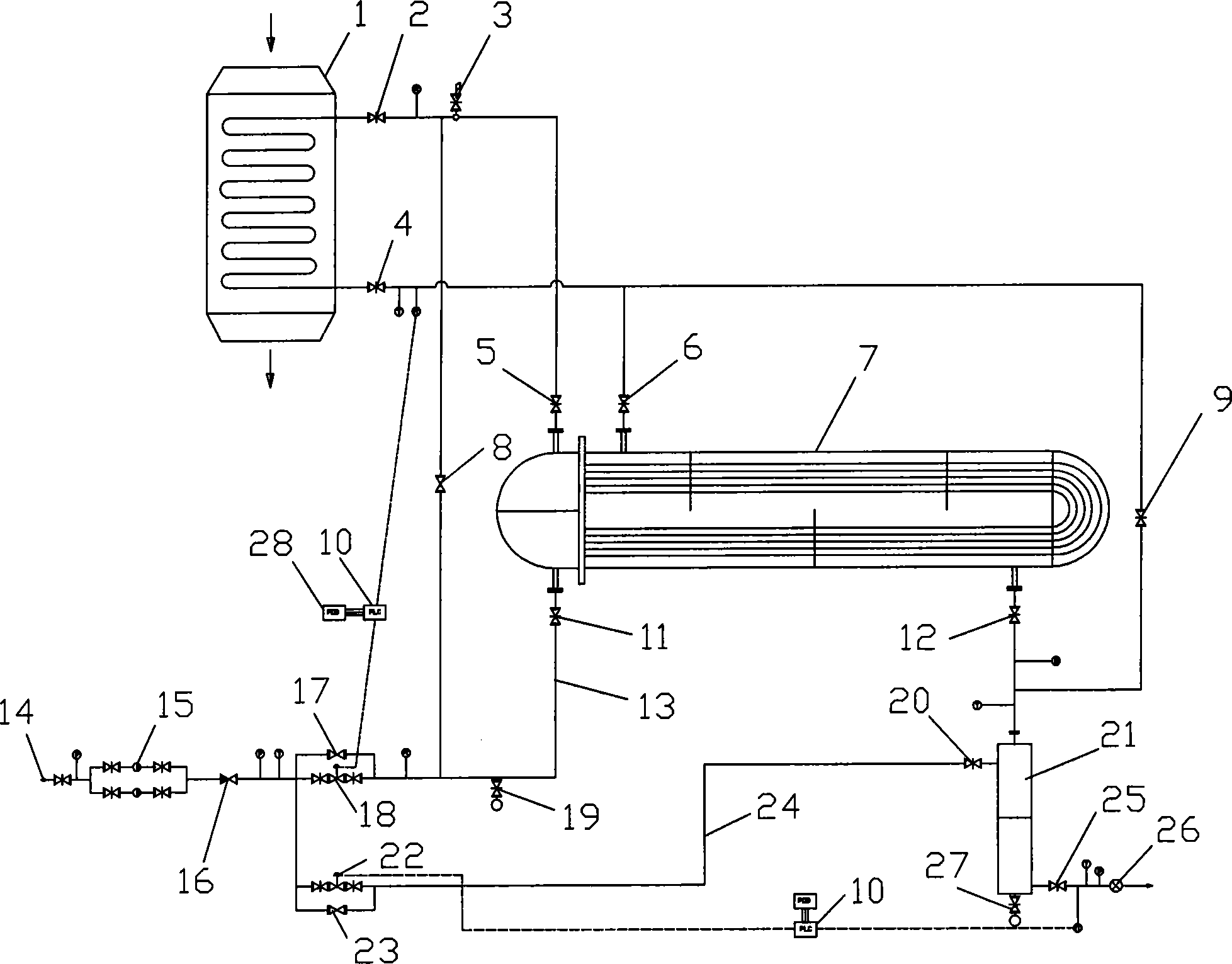

Dew-point corrosion resistant residual heat recovering system

InactiveCN101191700AExtended service lifeEfficient waste heatStationary tubular conduit assembliesWaste heat treatmentFlue gasEngineering

The present invention discloses a dew point corrosion resistant waste head recovery system; a header pipe (14) is connected with a main pneumatic valve (18) and an auxiliary pneumatic valve (22) through the distributary of a booster pump (15); the main pneumatic valve (18) is connected to the heating end inlet of a temperature compensator (7) through a first valve (11); a heating end outlet of the temperature compensator (7) is connected to a heat exchange inlet of a thermotube heat exchanger (1) through a second valve (5) and a third valve (2); a heat exchange outlet of the thermotube heat exchanger (1) is connected with a cooling end inlet of the temperature compensator (7) through a fourth valve (4) and a fifth valve (6); the cooling end outlet of the temperature compensator (7) is connected with a mixer (21) through a seventh valve (12); the auxiliary pneumatic valve (22) is connected with the mixer (21) through an eighth valve (20); an outlet of the mixer (21) is connected with a sixth valve (25). The system has the function of self-temperature compensation of cold fluid and temperature adjustment of the heat exchanger wall, effectively solves the problem of low dew point corrosion of the heat exchanger, prolongs the life-span of the heat exchanger, recovers the waste head of low-temperature flue gas and achieves the effect of energy conservation and emission reduction.

Owner:CENT SOUTH UNIV

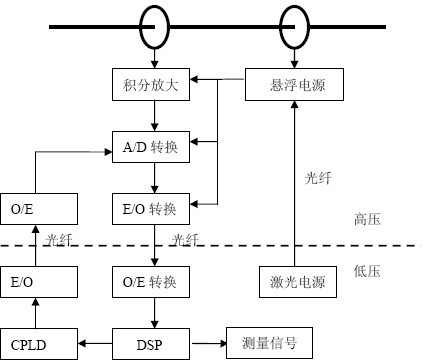

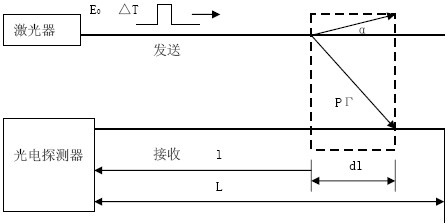

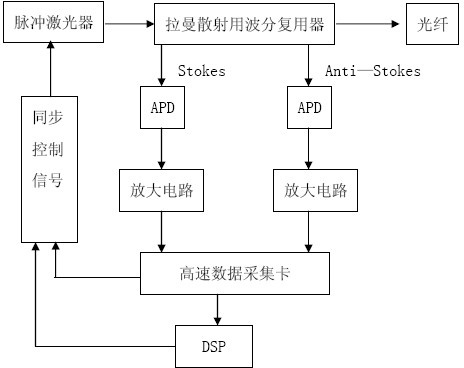

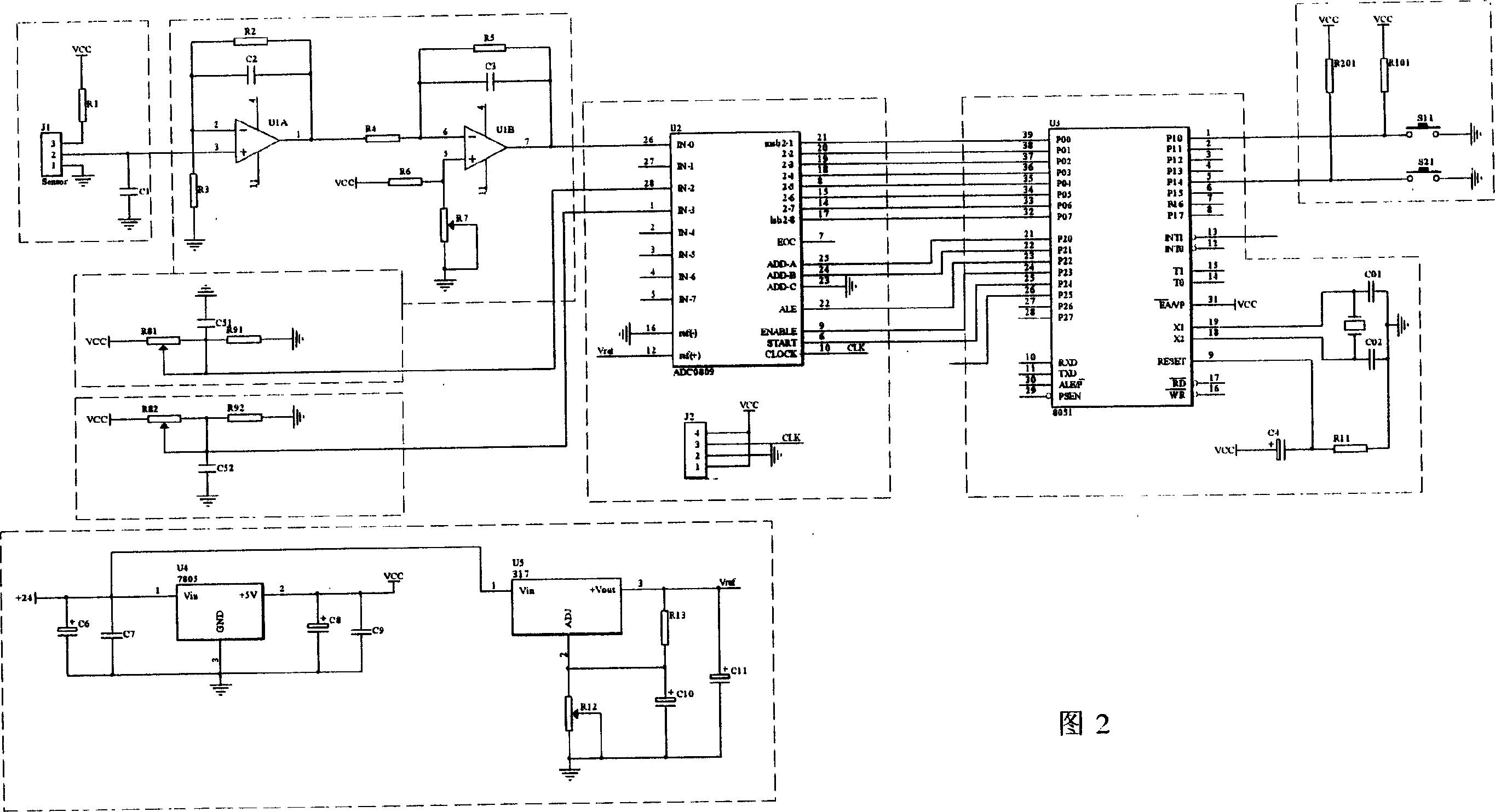

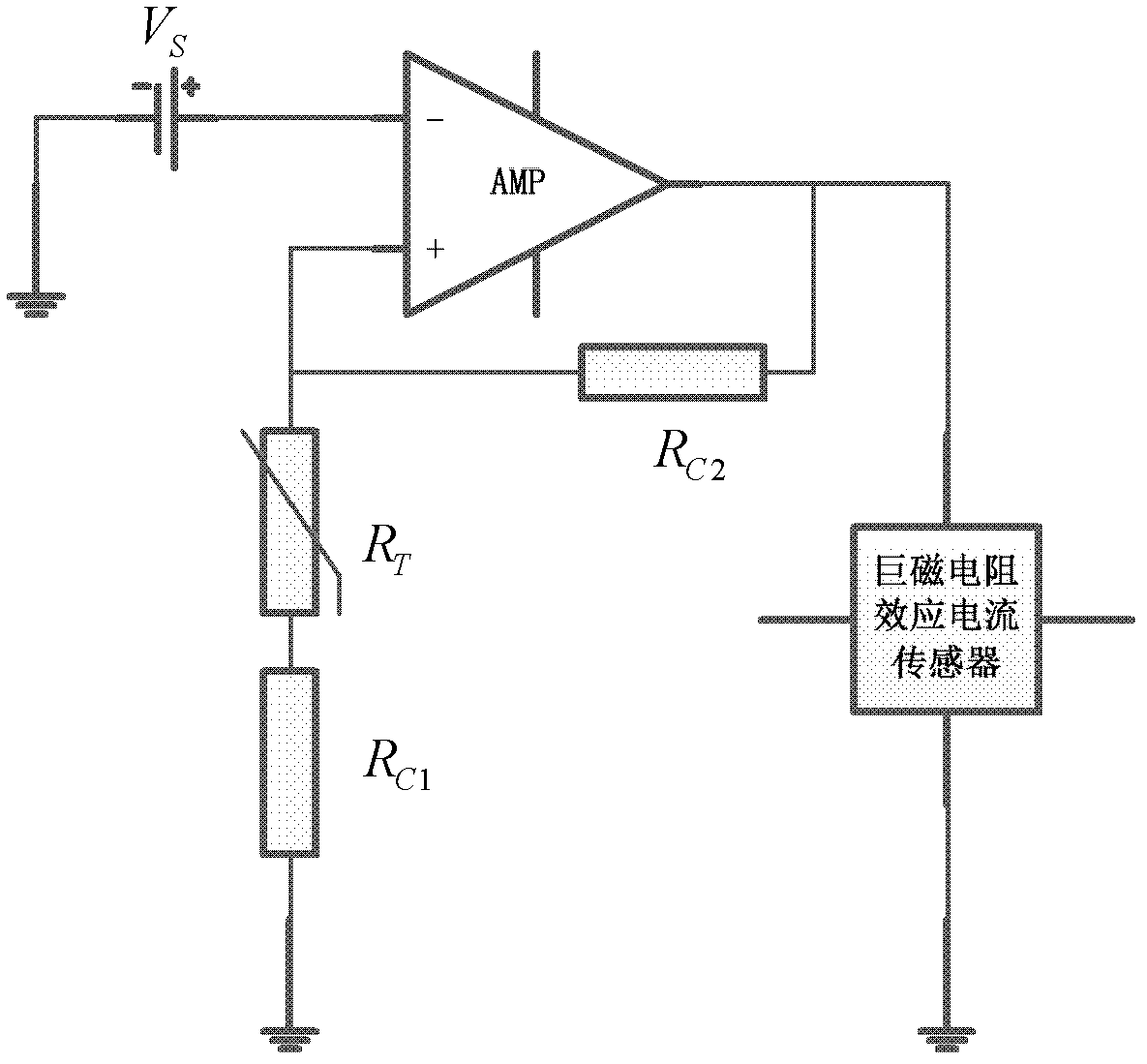

Optical fiber temperature compensator of electronic current transformer

InactiveCN102072980AEfficient measurementCurrent/voltage measurementVoltage/current isolationData acquisitionEngineering

The invention discloses an optical fiber temperature compensator of an electronic current transformer, the current transformer comprises a current measuring coil and an energy obtaining coil which are sleeved on a line to be measured; the current measuring coil is sequentially connected with an integral amplification module, an A / D (analogue / digital) conversion module and a first E / O (electric / optic) conversion module, the first E / O conversion module is connected with a first O / E conversion module through an optical fiber, and the first O / E conversion module is connected with a current operation module which is connected with a synchronous control module; the energy obtaining coil is connected with a suspension power supply, and the suspension power supply is connected with the integral amplification module, the A / D conversion module and the first E / O conversion module; a semiconductor laser is connected with a wavelength division multiplexer, the wavelength division multiplexer is connected with the optical fiber, and interfaces of two backward scattered light channels of the wavelength division multiplexer are respectively connected with a photoelectric converter and an amplification circuit and further connected with a high-speed data acquisition card; and the high-speed data acquisition card is connected with the current operation module. The optical fiber temperature compensator of the electronic current transformer can effectively measure the temperature and perform temperature compensation for the measured current values.

Owner:ZHEJIANG UNIV OF TECH

Monolithic clock generator and timing/frequency reference

ActiveUS20050206462A1Less jitterLoud noiseResonant circuit tuningPulse automatic controlAudio power amplifierPulsed mode

In various embodiments, the invention provides a clock generator and / or a timing and frequency reference, with multiple operating modes, such power conservation, clock, reference, and pulsed modes. The various apparatus embodiments include a resonator adapted to provide a first signal having a resonant frequency; an amplifier; a temperature compensator adapted to modify the resonant frequency in response to temperature; and a process variation compensator adapted to modify the resonant frequency in response to fabrication process variation. In addition, the various embodiments may also include a frequency divider adapted to divide the first signal having the resonant frequency into a plurality of second signals having a corresponding plurality of frequencies substantially equal to or lower than the resonant frequency; and a frequency selector adapted to provide an output signal from the plurality of second signals. The output signal may be provided in any of various forms, such as differential or single-ended, and substantially square-wave or sinusoidal.

Owner:INTEGRATED DEVICE TECH INC

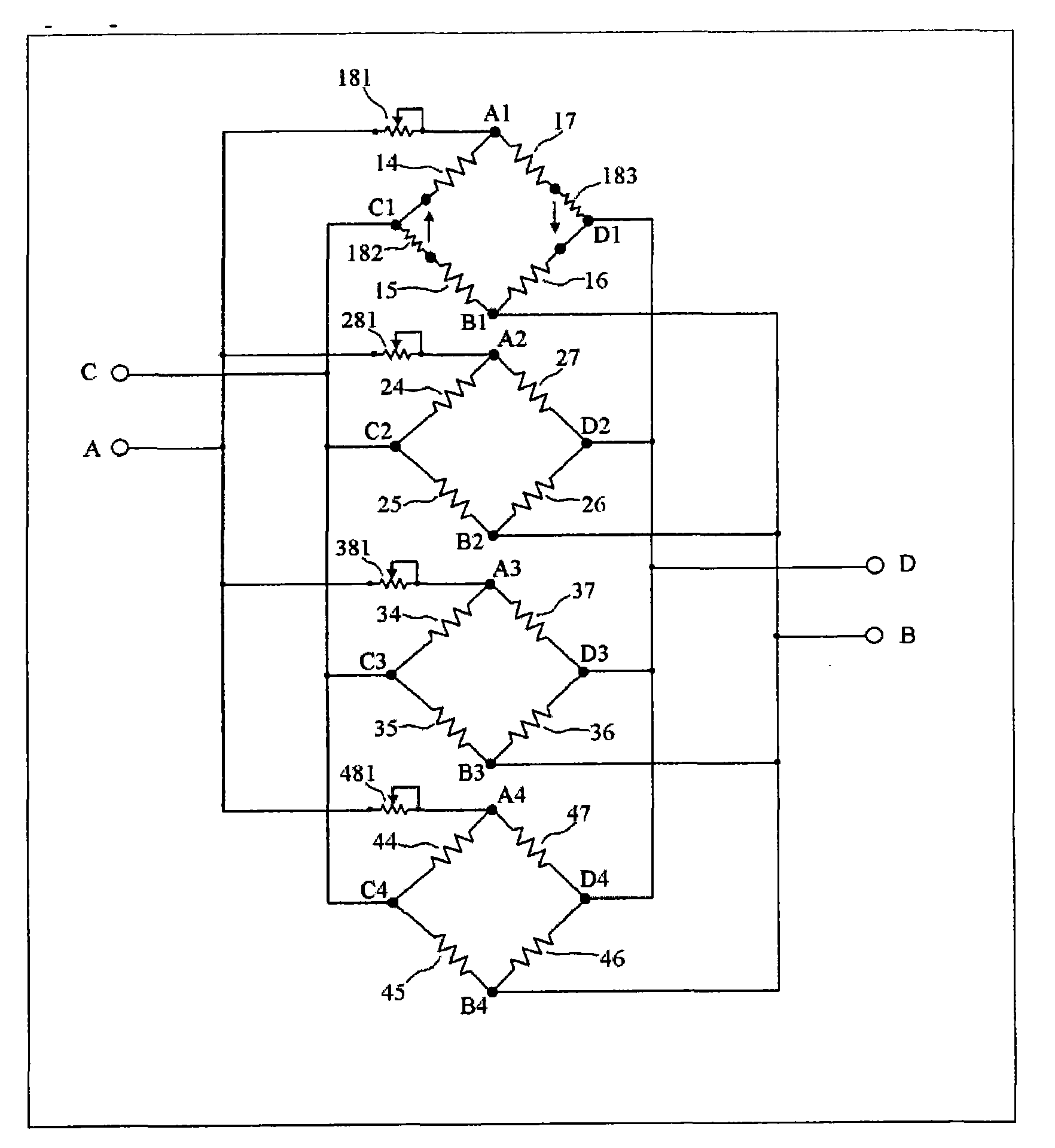

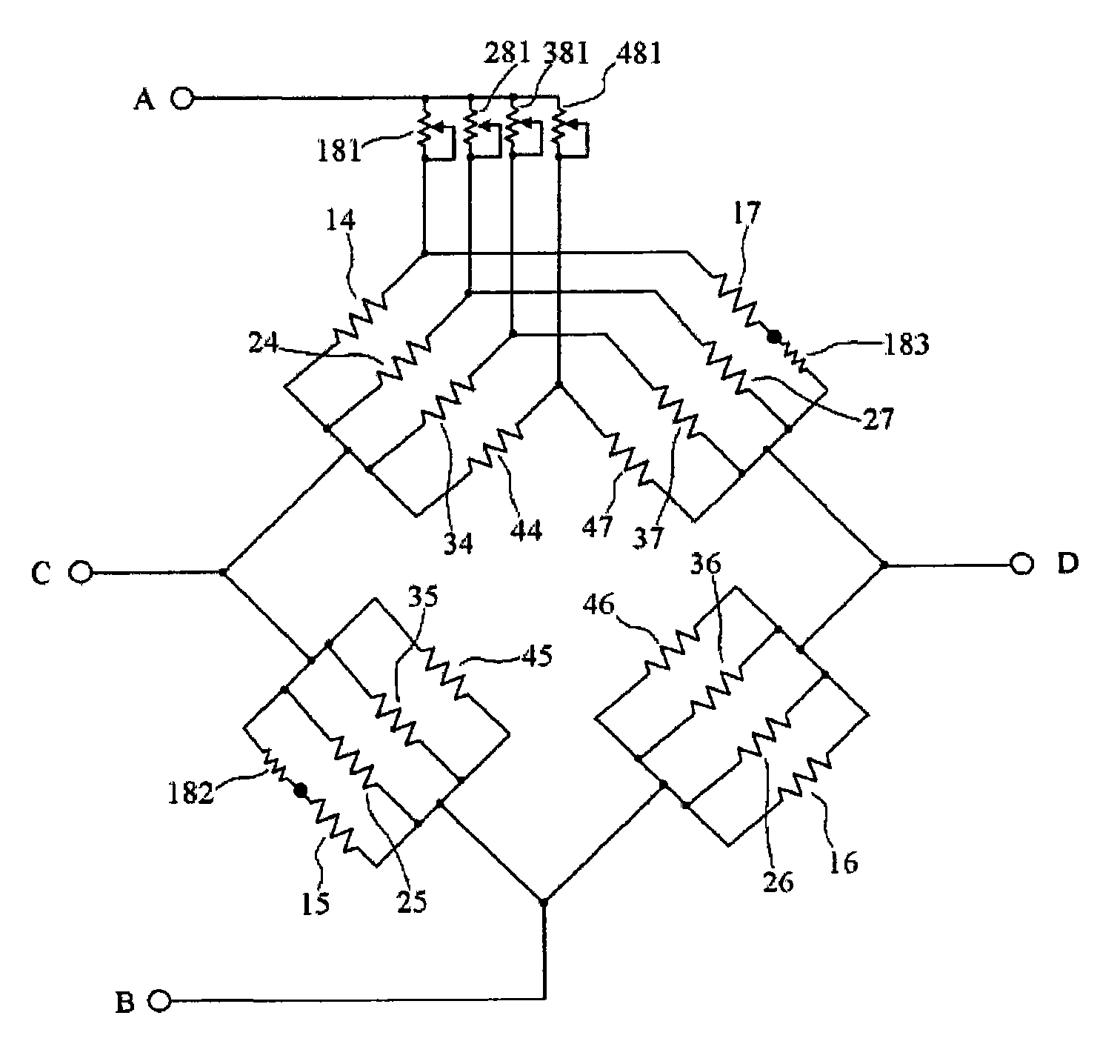

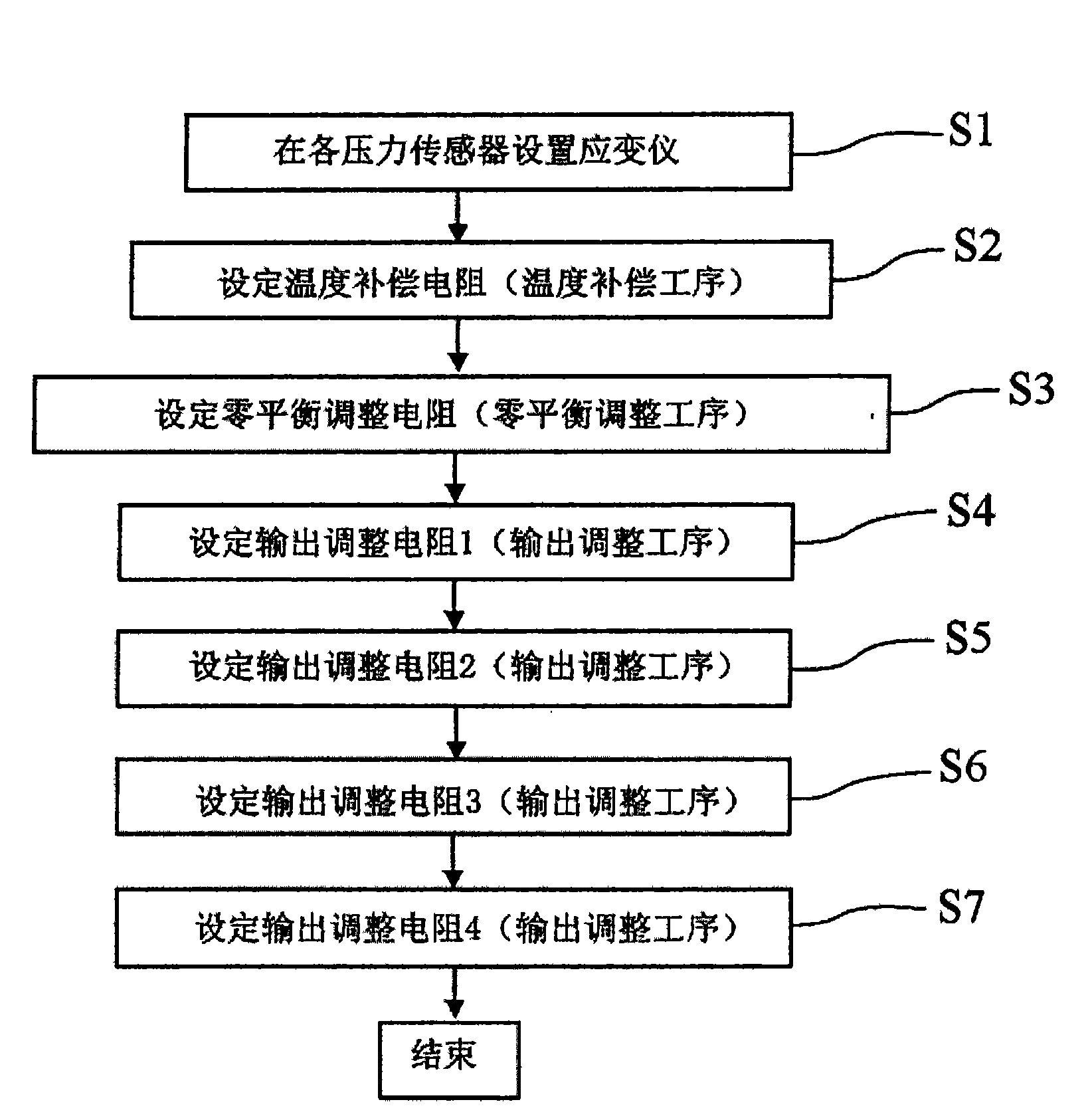

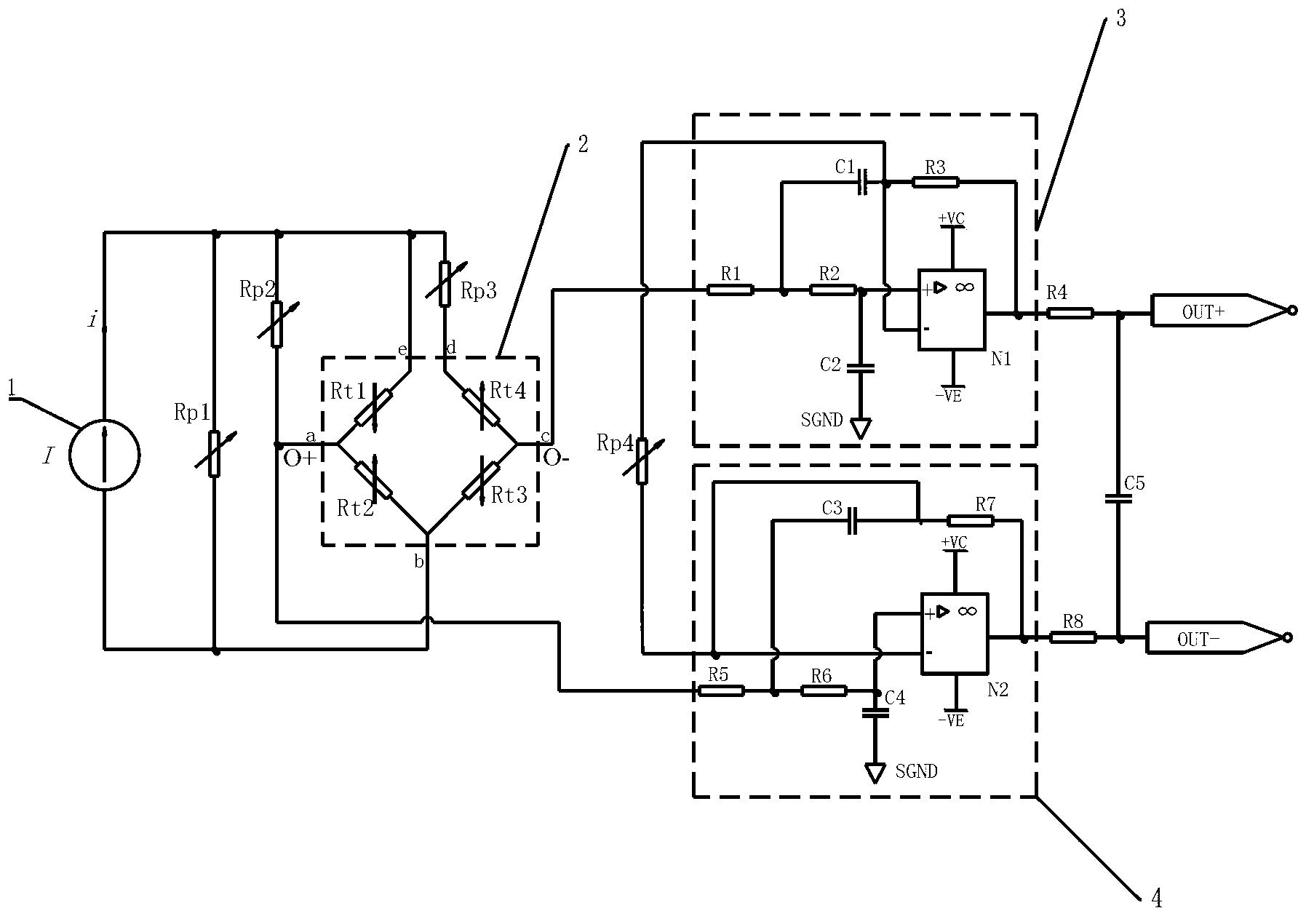

A multi-point type weighing equipment and a manufacturing method for the same

ActiveCN101603849AShorten the timeLow costWeighing apparatus using elastically-deformable membersElectrical resistance and conductanceTemperature Compensator

The invention relates to a multi-point type weighing equipment and a manufacturing method of the same. The time and cost which requires the adjustment of a load cell in case of manufacturing the multi-point type weighing equipment using a plurality of load cells are fully reduced. Four strain gauges comprise a Wheatstone bridge circuit for every load cell, and it has composition that these were connected in parallel. When all the load cells are not loaded, in order to make small the variation of the load cell of the output voltage depending on temperature between CD in case of input voltage being applied between AB as much as possible, temperature compensator (182) which is the first resistance for adjustment is provided in the Wheatstone bridge circuit corresponding to load cell (10). Also, when all the load cells are not loaded, in order to make minimum the absolute value of the output voltage between CD in case of input voltage being applied between AB as much as possible, zero balance adjustment resistance (183), which is the second resistance for adjustment, is also provided in this Wheatstone bridge circuit.

Owner:TANITA CORP

Preparation of zirconium tungstate ceramic body products thereby and optical fiber grating temperature compensator

A process for preparing zirconium tungstate (ZrW2O8) ceramics includes the reacting between the superfine Zr compound and W compound particles and sintering, and features that the powdered monocrystal of ZrW2O8 is used as the crystal seeds in said reaction for simplifying process, shortening period and lowering sinter temp and cost. A modified ZrW2O8 ceramics with regulated thermal expandability is prepared by generating the second phase in the ZrW2O8 ceramics and can be used for the temp compensator of fibre Bragg garting (FBG).

Owner:BROPTICS TECHNOLOGY LTD

Circuit of high-accuracy pressure transmitter

InactiveCN103234689ASimple structureAvoid interactionFluid pressure measurement using ohmic-resistance variationEngineeringTemperature Compensator

The invention belongs to a pressure sensing technique and relates to circuit design of a high-accuracy pressure transmitter. In combination with the transmission characteristics of a piezoresistive SOI (Silicon on Insulator) pressure-sensitive device and a differential amplification circuit at different temperature conditions, the compensation of the temperature error of the output signal of the pressure transmitter is realized through a precision resistor network. Commonly used temperature compensation devices such as thermistors and diodes are not needed to be used in the circuit of the high-accuracy pressure transmitter, the temperature compensation of the pressure transmitter is realized only through four groups of precision fixed resistors and the errors of the pressure transmitter are reduced; and the applicable temperature range of the pressure transmitter which is designed by using the circuit is negative 55 DEG C to 175 DEG C and the output errors within the full temperature range are smaller than plus or minus 0.5% FS. The high-accuracy pressure transmitter has the advantages of small size, light weight, strong interference-resistant capability, stable output and simple and convenient technological process, and is suitable for large-scale production.

Owner:WUHAN AVIATION INSTR

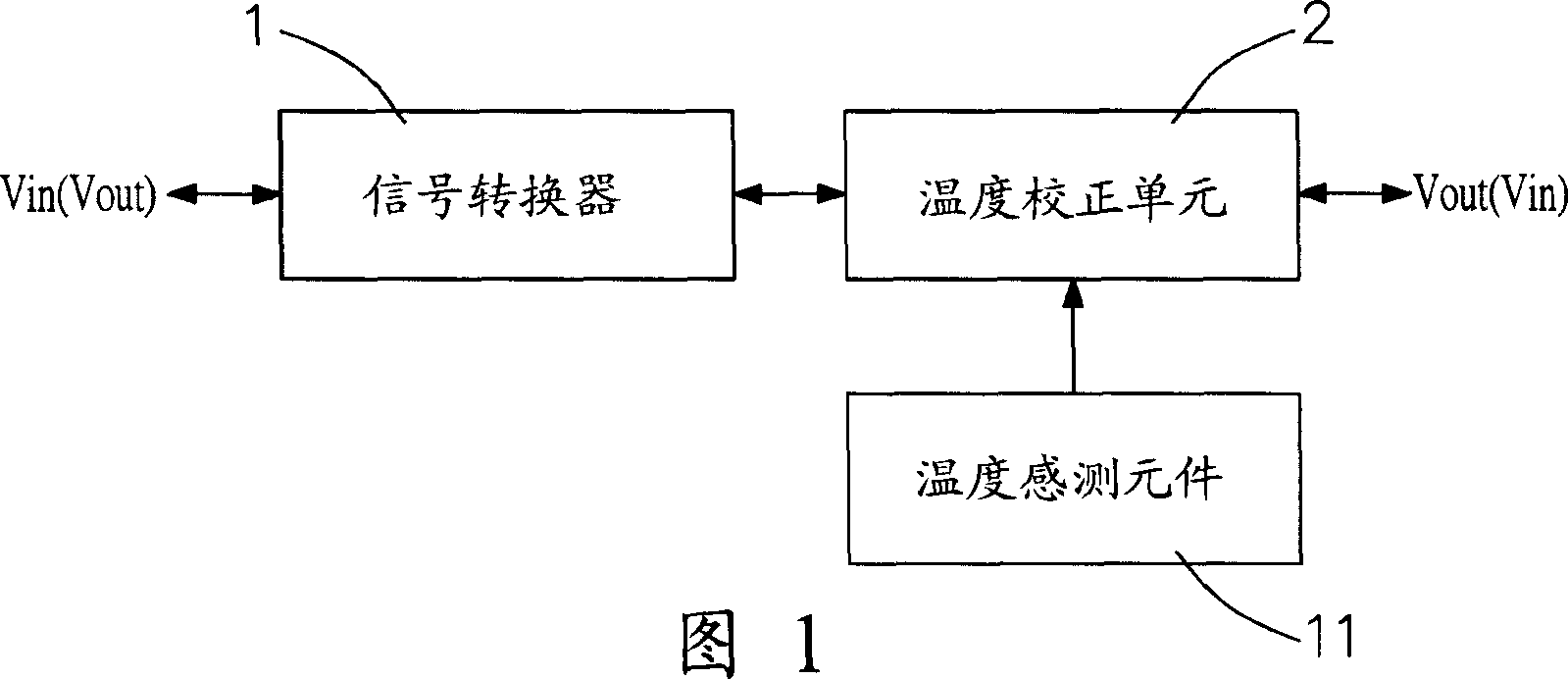

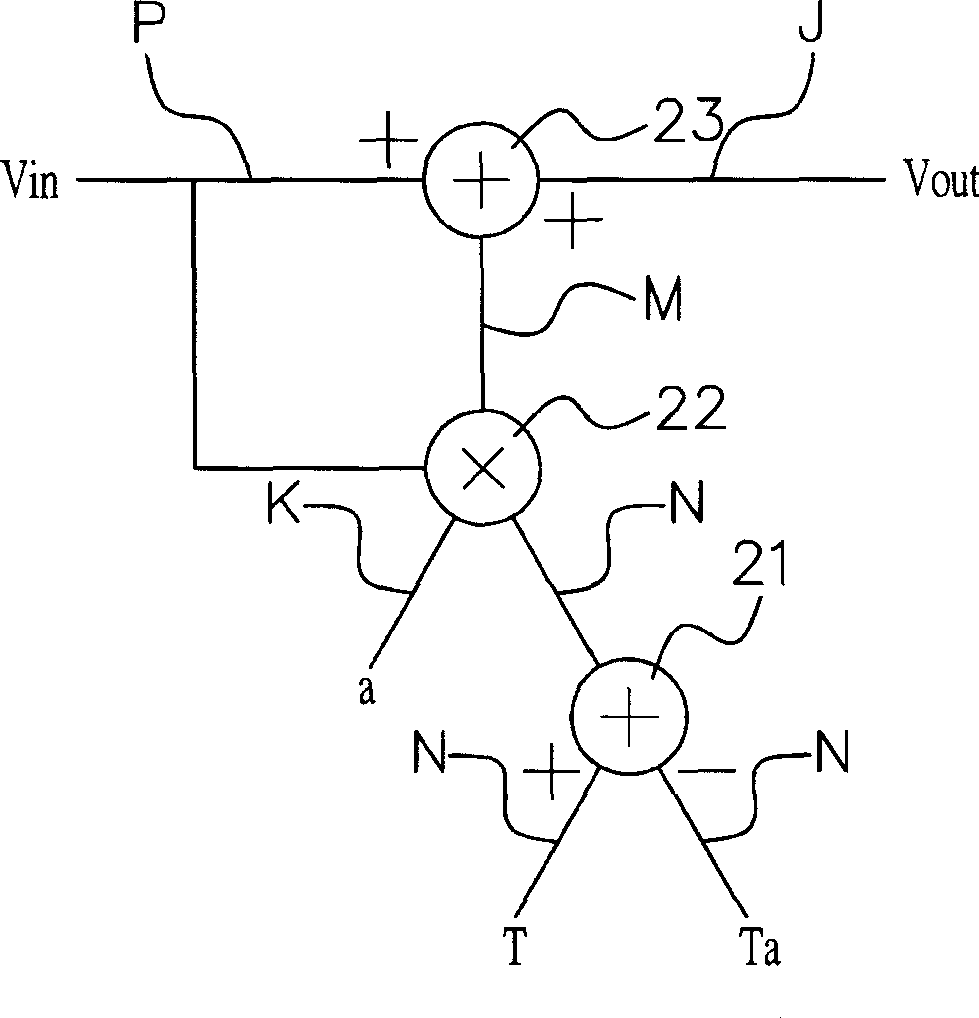

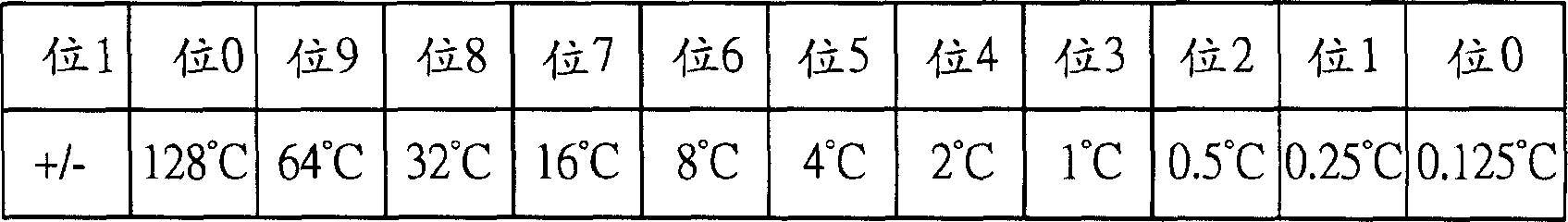

Temp. compensation device of electronic signal

InactiveCN1869615AThermometers using electric/magnetic elementsUsing electrical meansEngineeringVoltage reference

The invention is a temperature compensator for electronic signal, comprising: signal converter, and temperature correction unit coupled with the signal converter to make temperature correction and compensation, where the temperature correction unit comprises a digital circuit composed of first adder, first multiplier and second adder, executing temperature correction and compensation digital calculation according to the measured real-time environmental temperature value, reference temperature, temperature compensation coefficient and input signal and then producing corrected signal output, thus solving the problems of influence and low accuracy caused by temperature drift of reference voltage source of analog compensation technique.

Owner:FORTUNE SEMICON

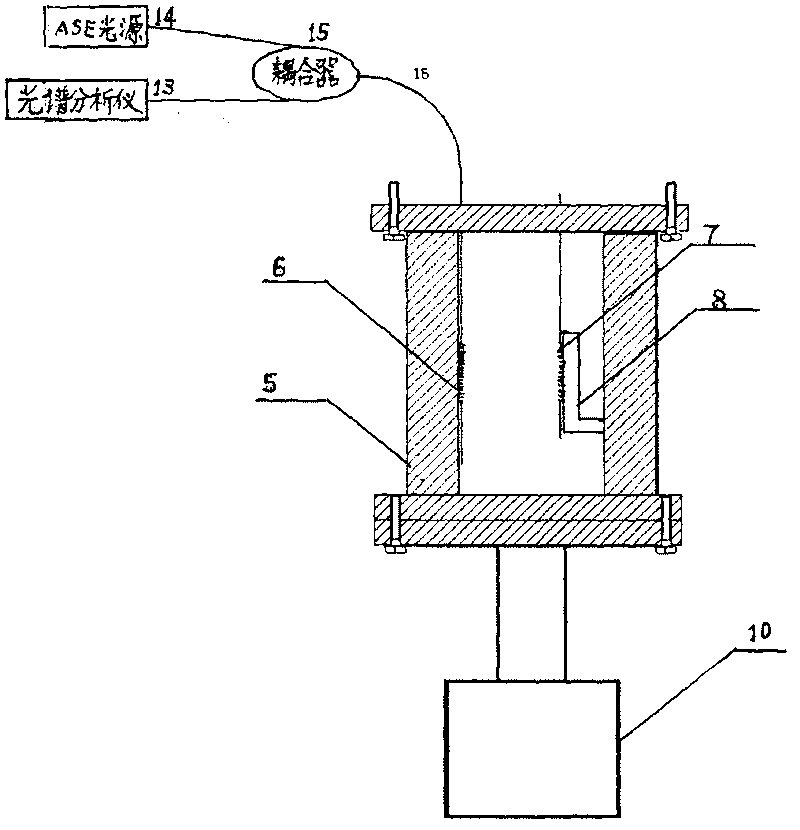

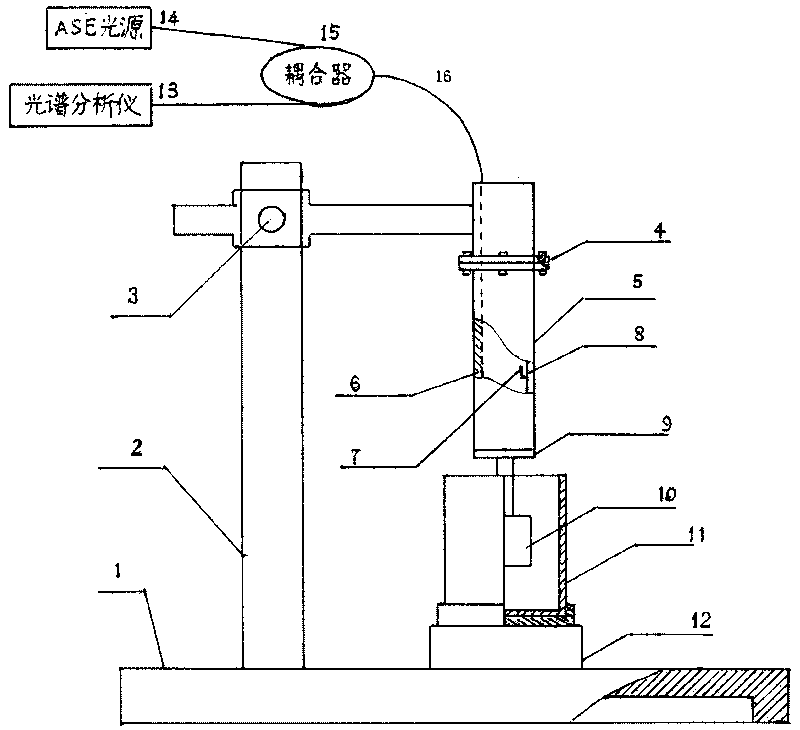

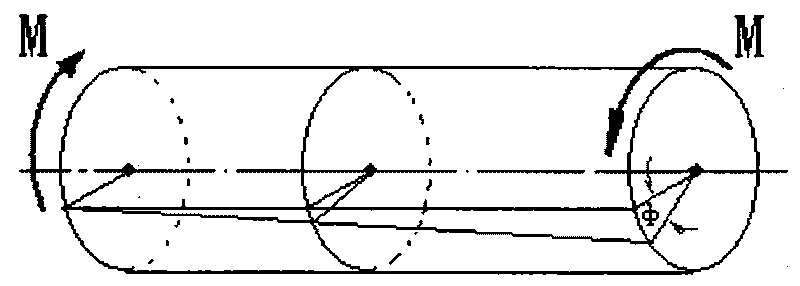

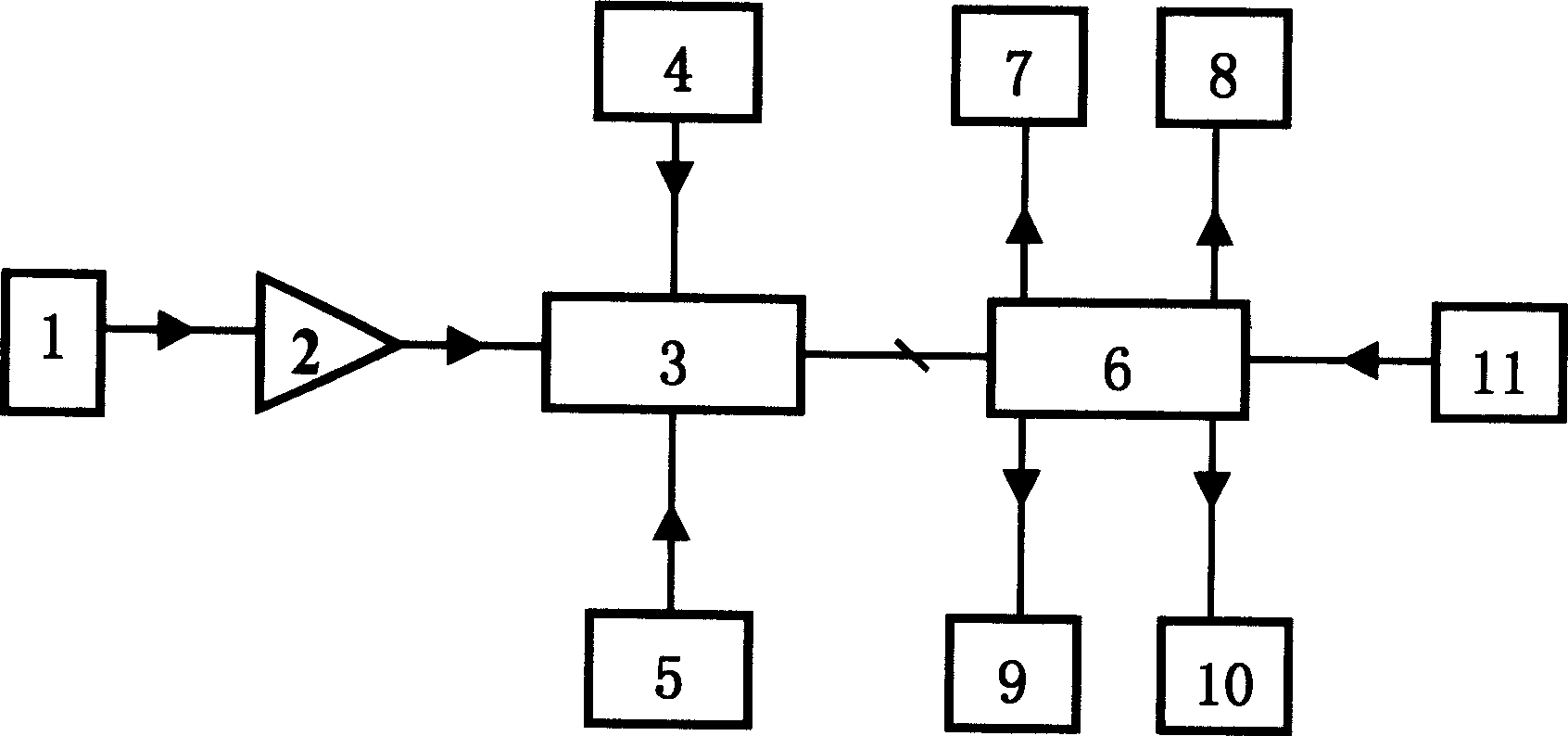

Outward-turning type coaxial cylinder viscometer of hollow cylinder type optical fiber Bragg grating

InactiveCN101692033ASo as not to damageRealize single parameter measurementCladded optical fibreFlow propertiesHollow cylinderTemperature Compensator

The invention provides an outward-turning type coaxial cylinder viscometer of a hollow cylinder type optical fiber Bragg grating, comprising a torsion measurement grating, a temperature compensation grating, an elastic hollow cylinder, an L-shaped temperature compensator, a stator and a viscometer measuring system which is composed of a spectrum analyzer, an ASE light source, a coupler and an optical fiber; the inner wall of the elastic hollow cylinder is pasted with the torsion measurement grating and the L-shaped temperature compensator, a long side of the compensator is pasted with the temperature compensation grating. According to the measured value of torsion and temperature sensitivity difference of the torsion measurement grating and the temperature compensation grating, the compensation of torque measurement disturbed by temperature fluctuation is realized by adopting differential operation, so as to realize accurate measurement of the torque. One end of the optical fiber is respectively connected with the spectrum analyzer and the ASE light source by the coupler, the other end thereof is connected with the optical fiber Bragg grating; wideband laser emitted by the ASE light source enters into the optical fiber Bragg grating, viscosity number is directly read out by wavelength displacement operation through an embedded computer of the analyzer. The sensor is suitable for measuring the viscosity of various fluids.

Owner:KUNMING UNIV OF SCI & TECH

Collision-proof device for opening automobile door

InactiveCN1597397AReduce power consumptionEasy to installPedestrian/occupant safety arrangementFresnel lensEngineering

Owner:秦皇岛秦冠弧度镜有限公司

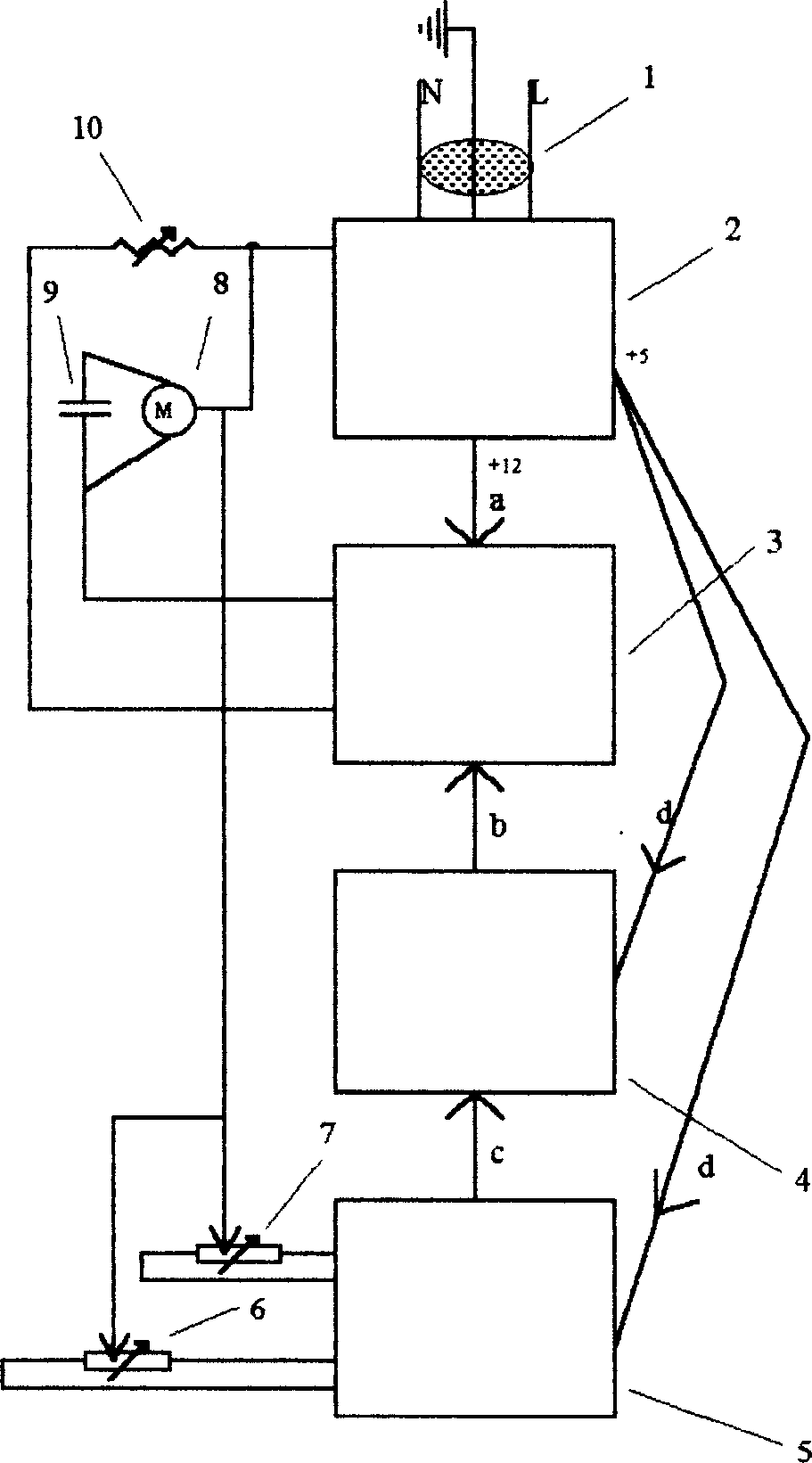

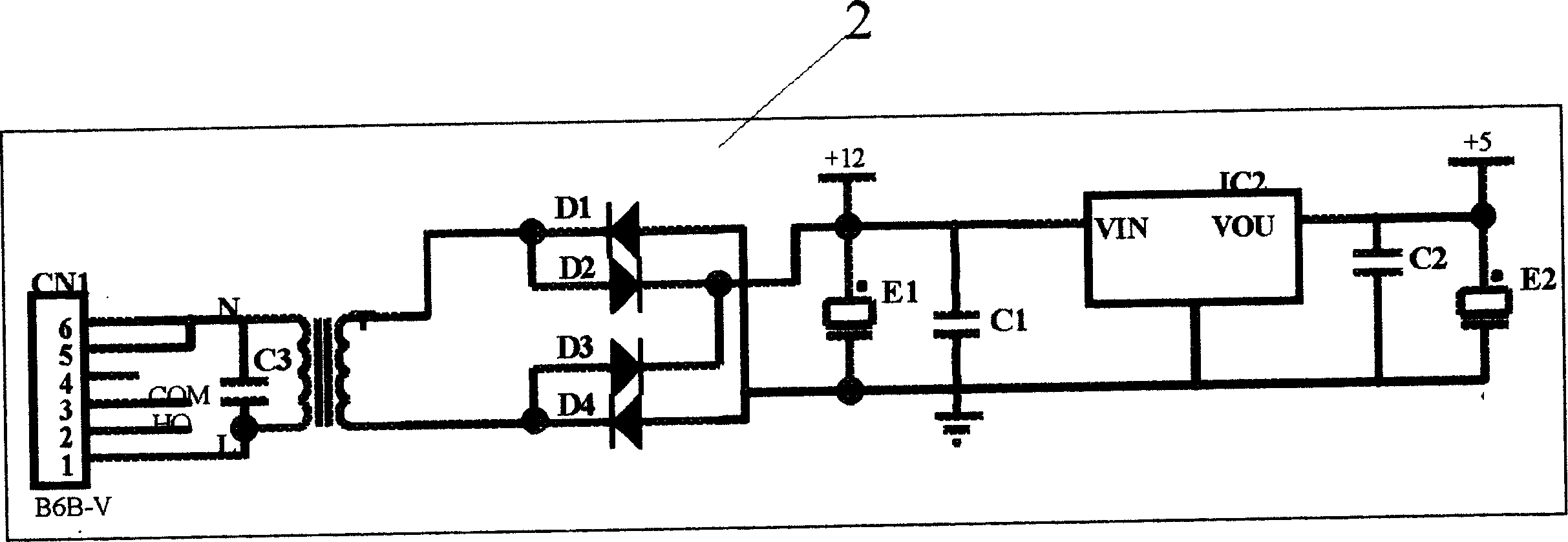

Temperature control equipment in use for full automatic mechanical refrigerator

InactiveCN1601211AFix bugs that run in an unreasonable stateSimple circuit structureLighting and heating apparatusDomestic refrigeratorsElectricityTemperature control

The invention provides a full automatic mechanical electric refrigerator temperature controller, composed of power supply unit, executing unit, control unit, signal input unit, refrigerating chamber temperature sensor and refrigerate-evaporating temperature sensor. Its characteristic: the power supply unit converts the 220v AC electric supply to +12V and +5V DC power supplies, where the +12V power supply supplies the power to the executing unit; the +5V power supply supplies the power to the control unit and signal input unit, is converted to analogue voltage signal through the signal input unit and converted to digital signal through the control unit, and after analyzed and judged by the control unit, transfers to the executing unit to control the stop or delayed switching-on by starter for the compressor and the switching-on and -off of temperature compensator. It has simple structure, and the refrigerator temperature can automatically be regulated according to environmental temperature, remedying the defect that the existing refrigerator works in an unreasonable state because of temperature change.

Owner:TCL家用电器(惠州)有限公司

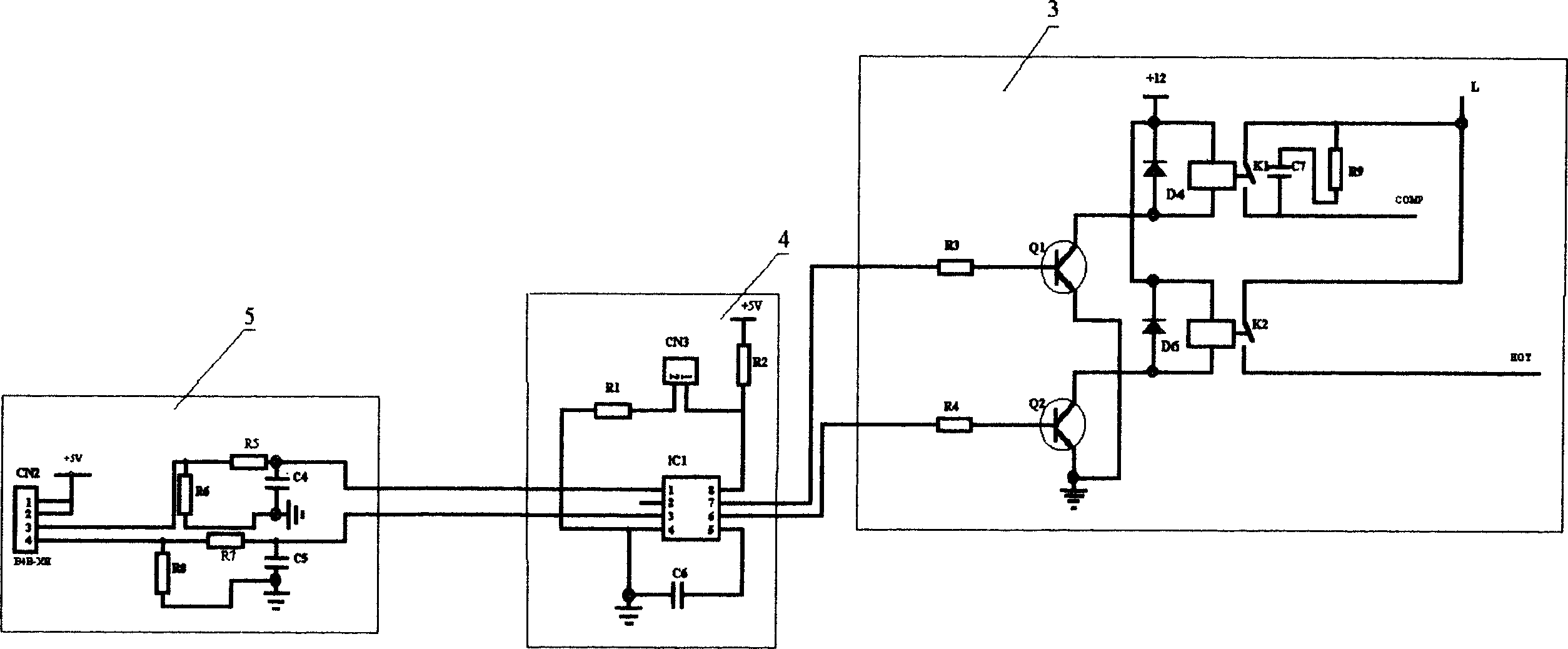

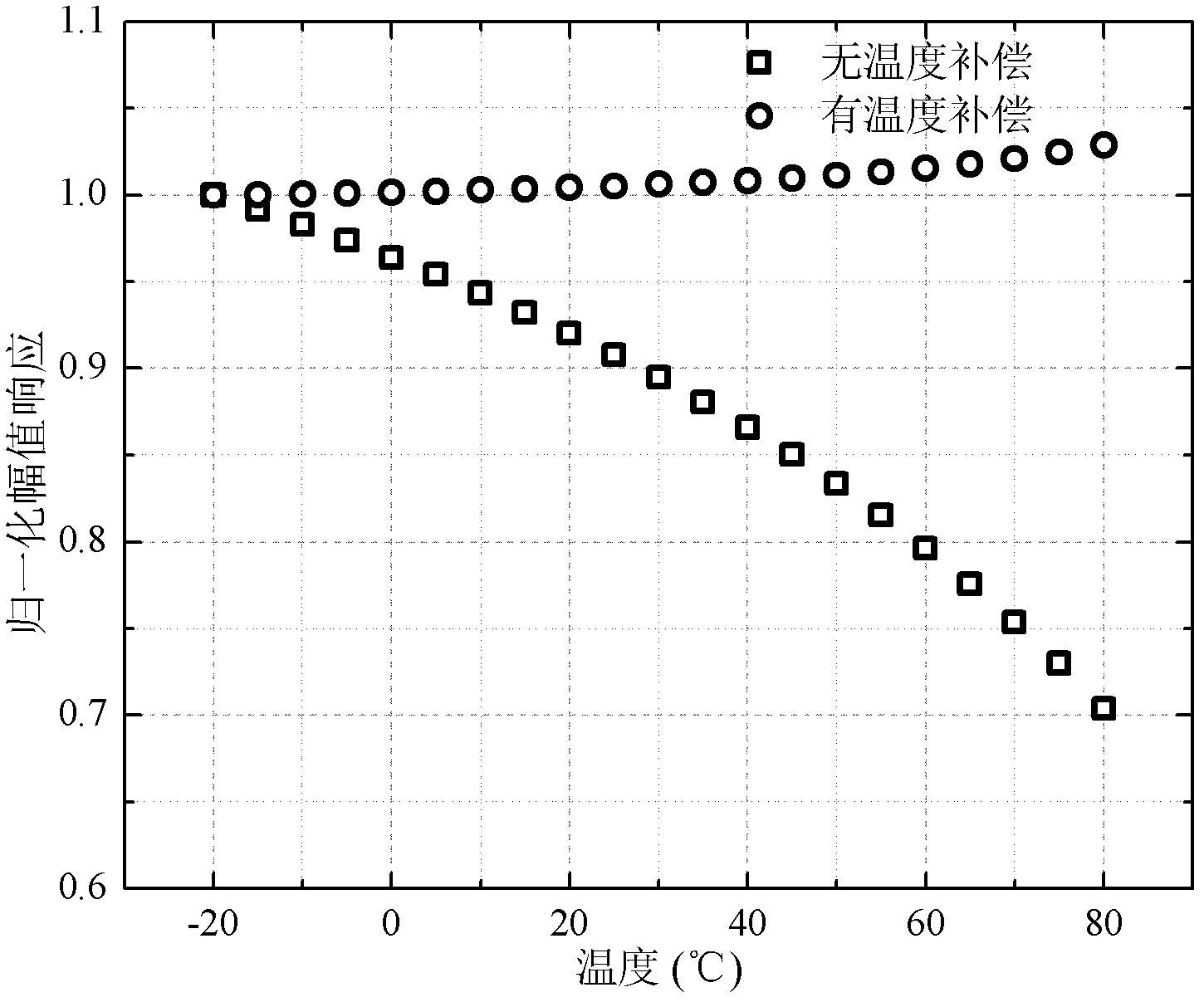

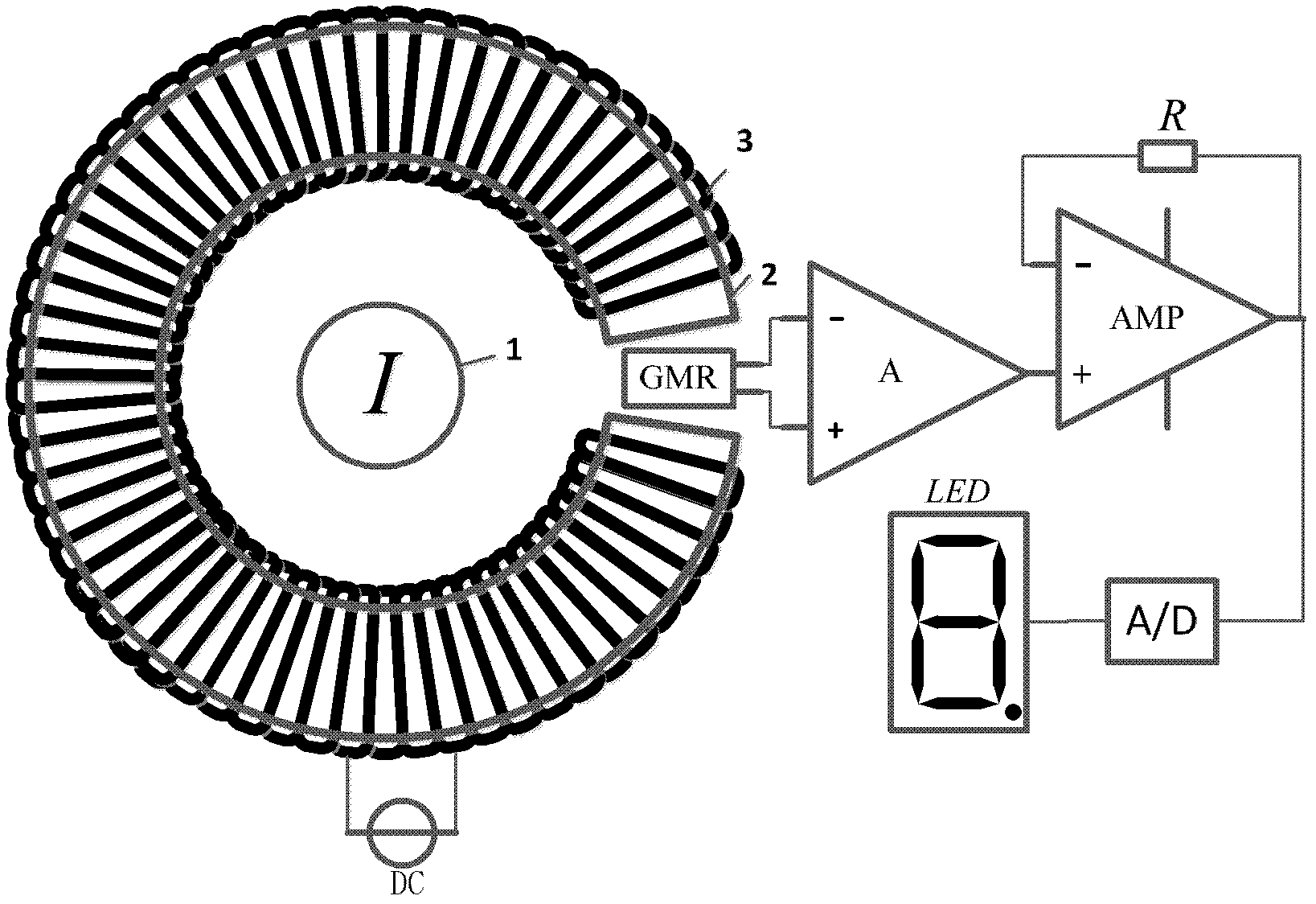

A temperature compensator for giant magnetoresistance effect current sensor

ActiveCN102288815AGood temperature characteristicsHigh measurement accuracyCurrent/voltage measurementCompensation effectElectric power system

The invention relates to a temperature compensator for a giant magneto-resistance effect current sensor, belonging to the technical field of electric power system measurement. A reversed-phase input terminal of an operational amplifier in the temperature compensator is connected with an positive electrode of a direct current voltage source; one terminal of a negative temperature coefficient thermistor is connected in series with one terminal of a first high precision low temperature coefficient resistance; the other terminal of the negative temperature coefficient thermistor is connected withthe in-phase input terminal of the operational amplifier; the other terminal of the first high precision low temperature coefficient resistance is earthed; a second high precision low temperature coefficient resistance is connected in parallel between the in-phase input terminal and output terminal of the operational amplifier; and the output terminal of the operational amplifier is connected with a power supply terminal of the giant magneto-resistance effect current sensor. According to the invention, the temperature compensator p has the advantages of low cost and good stability and the like and is suitable for applying to the temperature compensation of the giant magneto-resistance effect current sensor; the precision of the giant magneto-resistance effect current sensor is greatly increased; moreover, a circuit with a simple structure, low cost and stable performance is used so that the compensation effect is very obvious.

Owner:TSINGHUA UNIV

Hall effect sensor temperature compensator

InactiveUS20060279244A1Motor/generator/converter stoppersSynchronous motors startersActuatorTemperature Compensator

A system and method for compensating the output of an uncompensated Hall Effect sensor used to monitor an output shaft of an actuator. The actuator includes an output shaft, a magnet coupled to the output shaft, a motor for rotating the output shaft between a first position and a second position and an electronic control module having a controller, a diode and an uncompensated Hall Effect sensor.

Owner:FORD GLOBAL TECH LLC

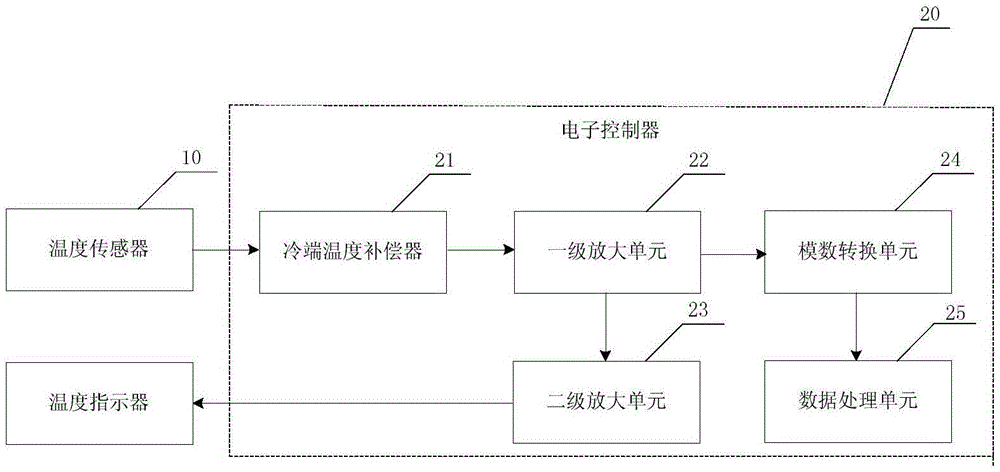

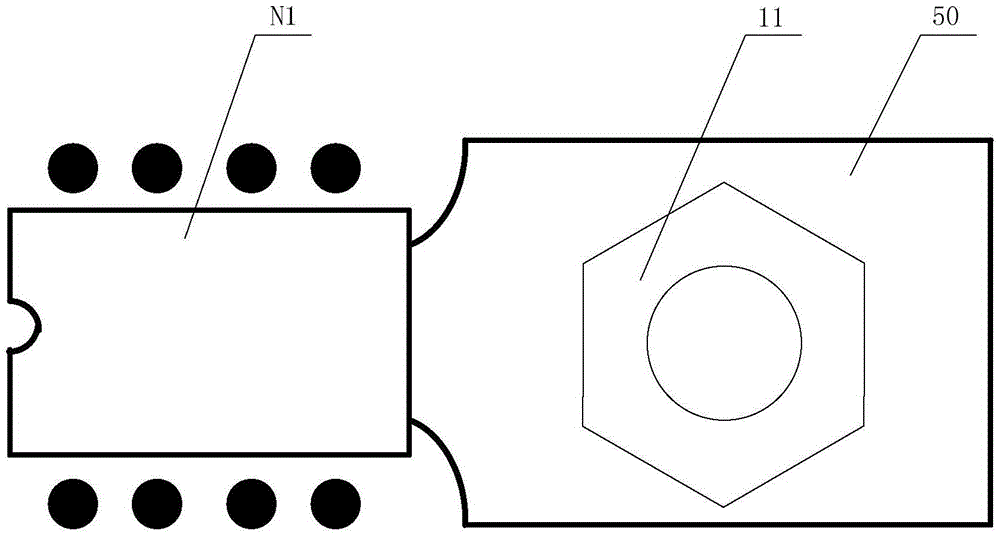

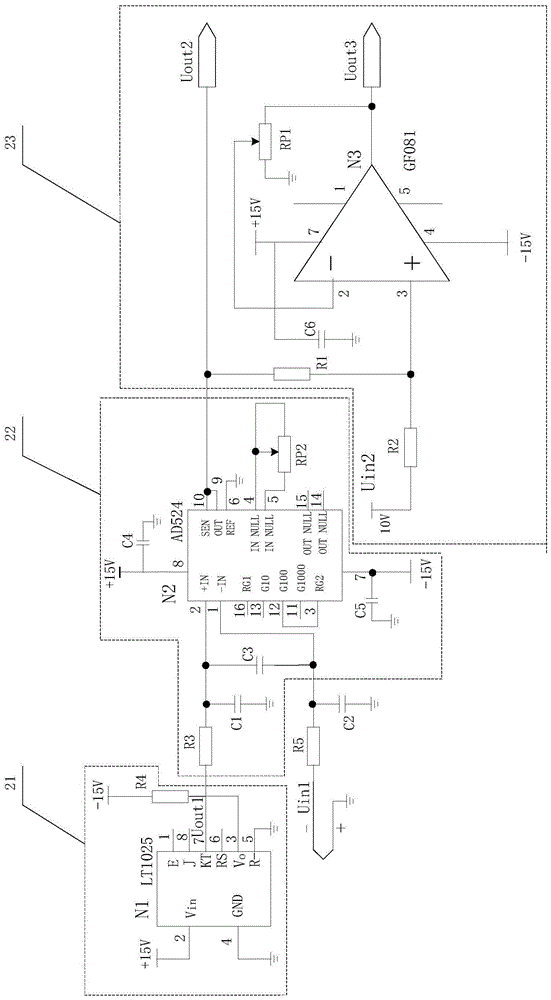

Thermocouple cold junction compensation and temperature measurement circuit and device

ActiveCN105651409AAccurate measurementReliable transmissionThermometers using electric/magnetic elementsUsing electrical meansElectronic controllerReliable transmission

The invention discloses a thermocouple cold junction compensation and temperature measurement circuit and device. The thermocouple cold junction compensation and temperature measurement circuit comprises a temperature sensor and an electronic controller, wherein the temperature sensor is used for acquiring the environmental temperature; the electronic controller comprises a cold junction temperature compensator and a pair of binding posts connected with the cold junction temperature compensator, and the cold junction temperature compensator is connected with the temperature sensor and used for performing temperature compensation on a cold junction of a thermocouple according to the environmental temperature acquired by the temperature sensor; the cold junction temperature compensator is connected with the cold junction of the thermocouple through the pair of binding posts and a group of compensation leads, the materials of the pair of binding posts and the group of compensation leads are the same with that of a thermode of the thermocouple, and the cold junction temperature compensator is mounted close to the pair of binding posts. Precise measurement of the temperature of the cold junction temperature compensator and a pair of binding posts thermocouple is realized through organic integration of the compensation leads and the temperature sensor, meanwhile, longer-distance reliable transmission of mV-level temperature signals in an auxiliary power unit system is guaranteed, and the precision and reliability of the temperature signals are improved.

Owner:CHINA HANGFA SOUTH IND CO LTD

In-situ power monitor having an extended range to stabilize gain of avalanche photodiodes across temperature variations

InactiveCN101258576APrevent tolerancePhotoelectric discharge tubesElectromagnetic transmittersMonitor equipmentTemperature Compensator

Disclosed are an in-line monitoring apparatus with a temperature compensator, an optical receiver and a method for stabilizing gain of an avalanche photodiode (''APD'') over an extended range of input power values and across temperature variations. The apparatus can include one or more power monitoring stages coupled in parallel to the APD for generating one or more measurement signalsin-situ. The apparatus also includes a temperature compensator configured to adjust an operational parameter for the APD as a function of temperature and the measurement signal. The temperature compensator adjusts the bias to maintain a substantially uniform gain across temperature variations to facilitate an increased sensitivity with which to monitor the input power at lower levels than if the temperature compensator did not adjust the bias in response to the temperature. One of the power monitoring stages can be configured to monitor the low-powered optical signals.

Owner:ALED TELESIS

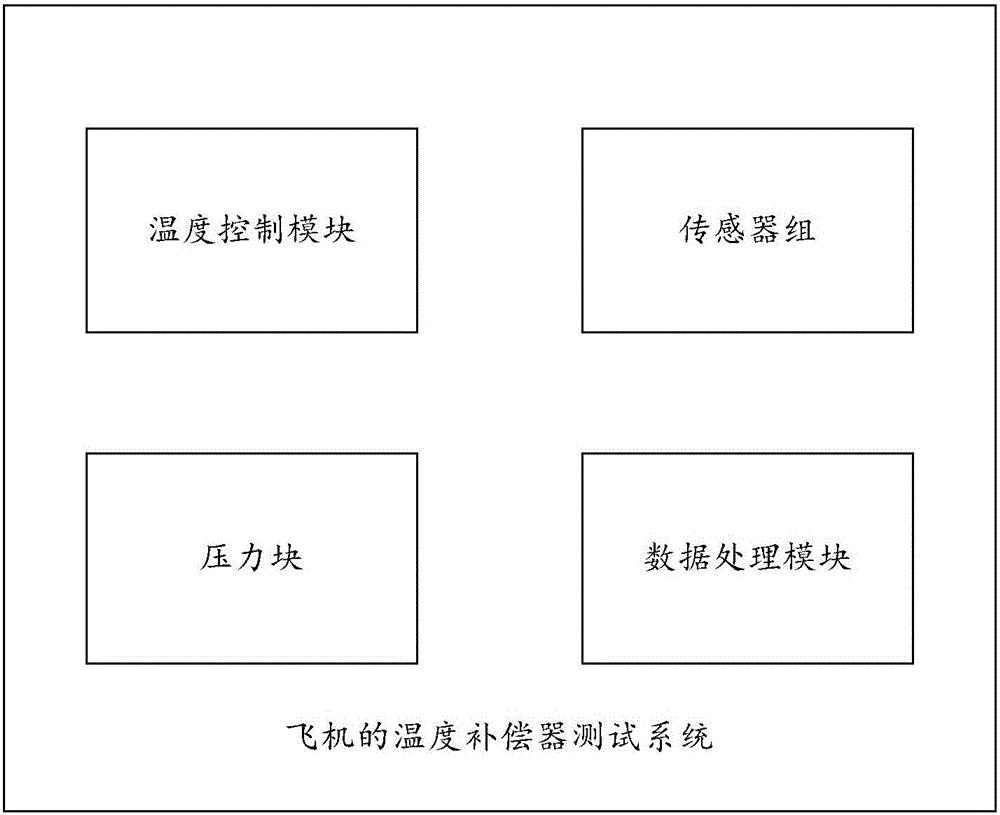

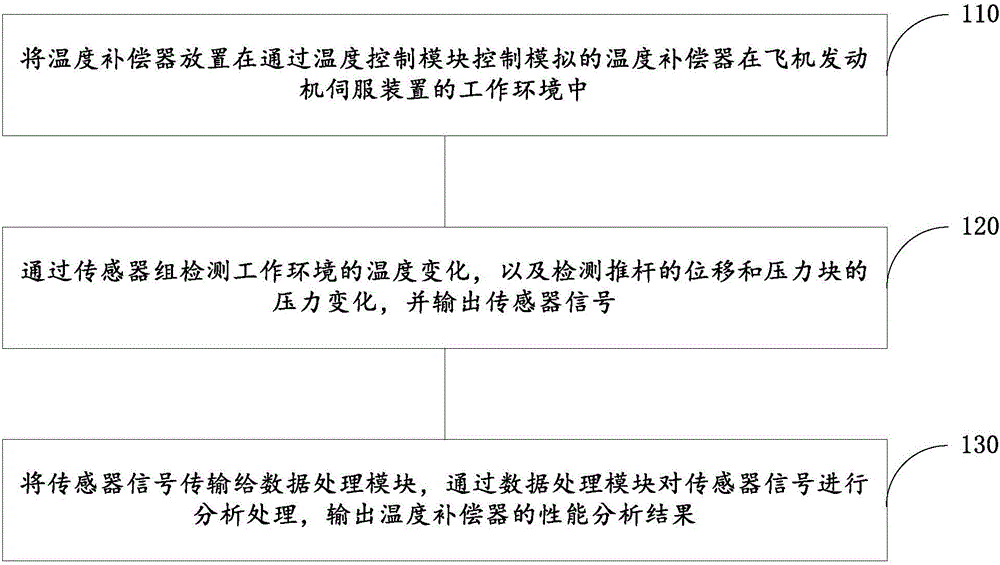

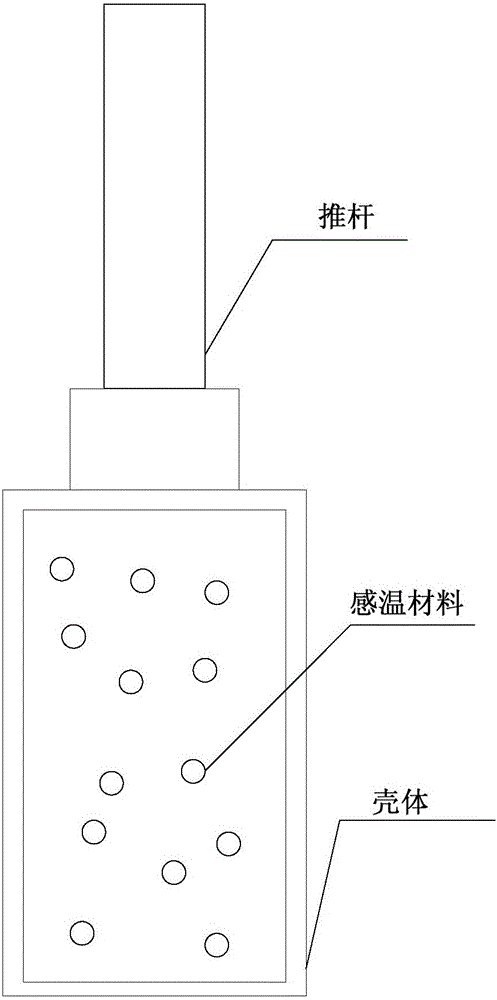

Airplane temperature compensator test system and test method

InactiveCN105716890AEasy to operateImprove detection efficiencyStructural/machines measurementJet aeroplaneTemperature control

The invention provides a temperature compensator testing system and testing method for an aircraft. The temperature compensator includes a push rod, and the system includes a temperature control module, a sensor group, a data processing module and a pressure block, wherein the temperature control module is set to have different temperatures , used to simulate the working environment of the temperature compensator in the aircraft engine servo device; the sensor group is used to detect the temperature change of the working environment, and detect the displacement of the push rod and the pressure change of the pressure block, and output sensor signals; the data processing module Receive the sensor signal, analyze and process the sensor signal, and output the performance analysis result of the temperature compensator. By automatically simulating the working environment of the temperature sensor, using the sensor as a data acquisition device, performance analysis is performed based on the data output by the sensor, and finally a performance analysis structure is obtained to realize automatic detection of the performance of the temperature compensator, with simple operation and high detection efficiency.

Owner:DONGGUAN GUANGXIN INTPROP SERVICES CO LTD

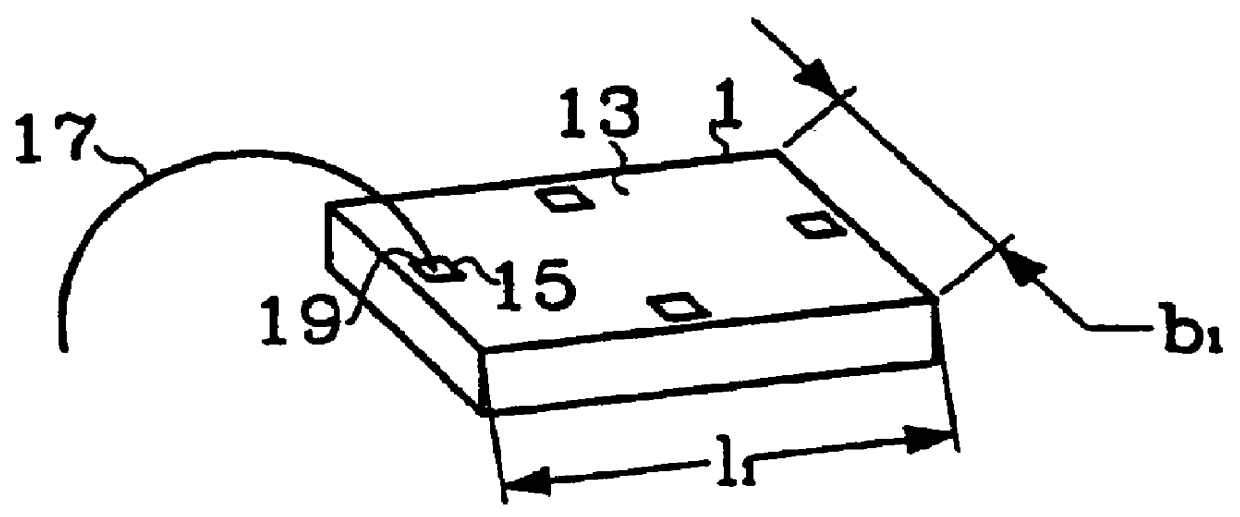

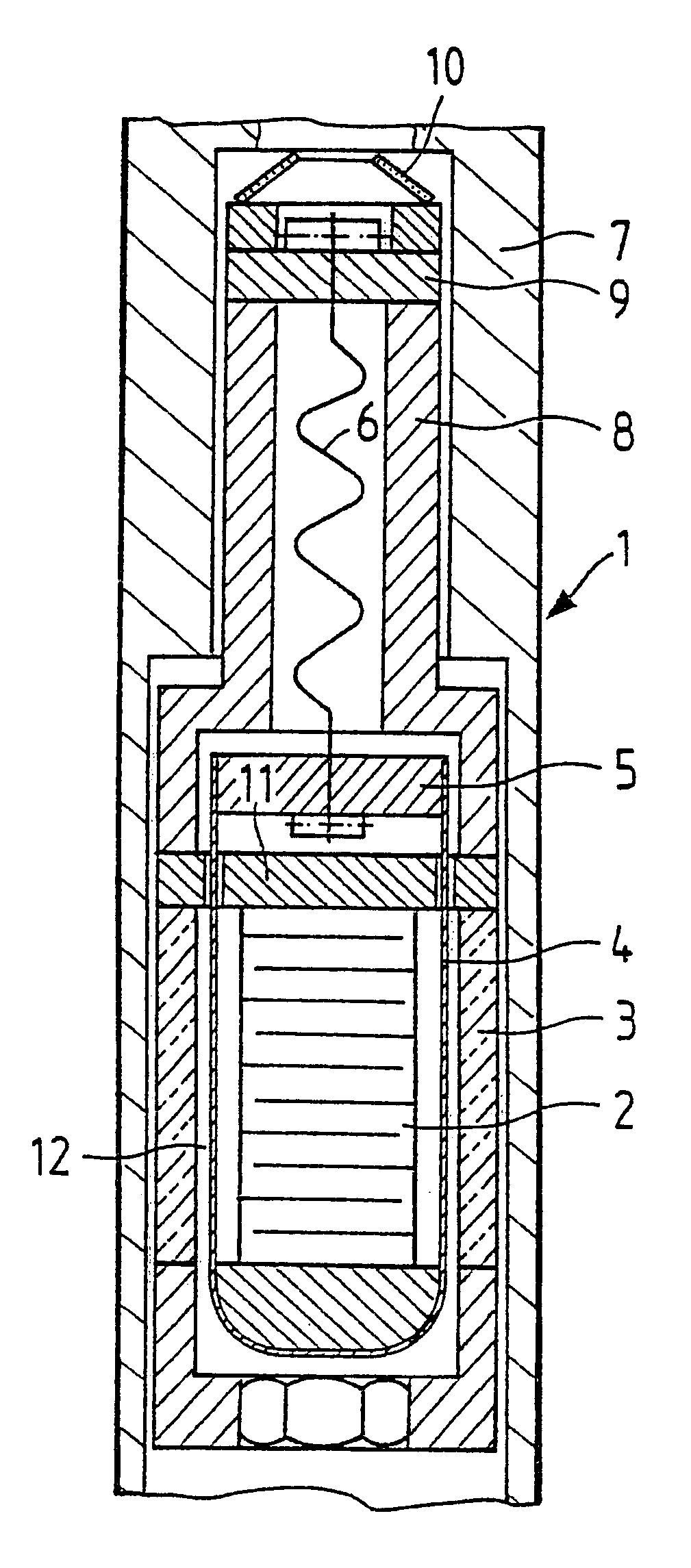

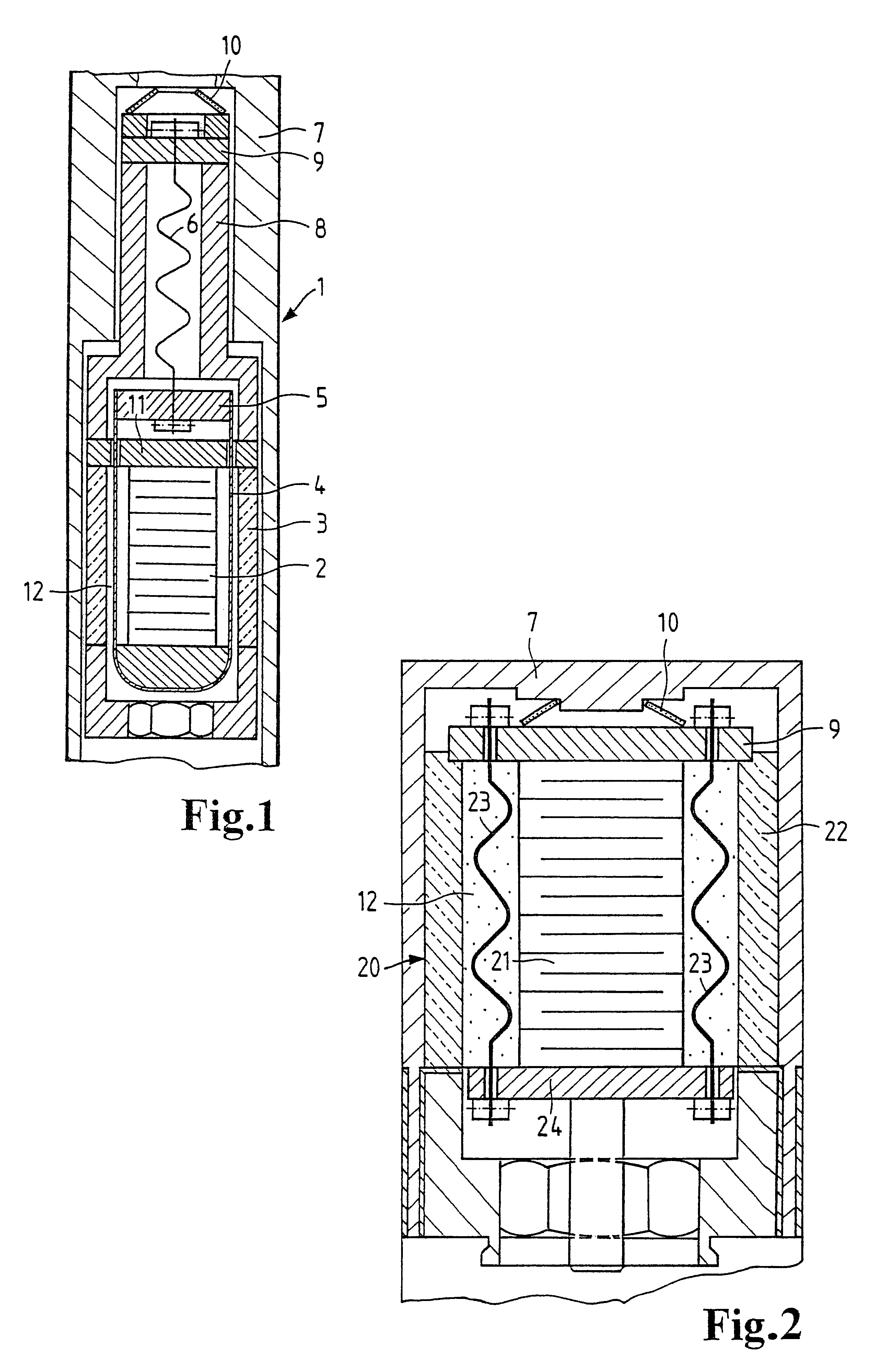

Piezo-actuator comprising a temperature compensator

InactiveUS6633108B1Piezoelectric/electrostriction/magnetostriction machinesFuel injection apparatusMechanical componentsPiezoelectric actuators

A piezoelectric actuator, e.g., for actuating a mechanical component, is proposed, in which a piezoelectric element (<HIL><PDAT>2< / BOLD><PDAT>) for acting on an actuating element (<HIL><PDAT>9< / BOLD><PDAT>) with a pulling or pushing force, and a compensating element (<HIL><PDAT>3; 20< / BOLD><PDAT>) are provided, wherein the piezoelectric element (<HIL><PDAT>2< / BOLD><PDAT>) and the compensating element (<HIL><PDAT>3; 20< / BOLD><PDAT>) basically have the same temperature expansion coefficients. The compensating element (<HIL><PDAT>3; 20< / BOLD><PDAT>) is mechanically coupled to the piezoelectric element (<HIL><PDAT>2< / BOLD><PDAT>) in such a fashion that the temperature-induced expansions of the piezoelectric element (<HIL><PDAT>2< / BOLD><PDAT>) and the compensating element (<HIL><PDAT>3; 20< / BOLD><PDAT>) cancel each other out in the effective direction in such a fashion that the actuating element (<HIL><PDAT>9< / BOLD><PDAT>) remains in its position. A heat transfer compound (<HIL><PDAT>12< / BOLD><PDAT>) is located between the piezoelectric element (<HIL><PDAT>2; 21< / BOLD><PDAT>) and the compensating element (<HIL><PDAT>3; 22< / BOLD><PDAT>).< / PTEXT>

Owner:ROBERT BOSCH GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com