Optical fiber temperature compensator of electronic current transformer

A technology of current transformer and optical fiber temperature, applied in the direction of voltage/current isolation, measuring current/voltage, instruments, etc., can solve the problem that electronic current transformer cannot effectively measure temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be further described below in conjunction with the accompanying drawings.

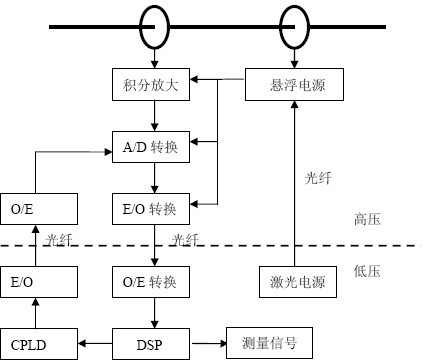

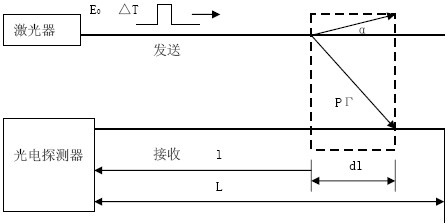

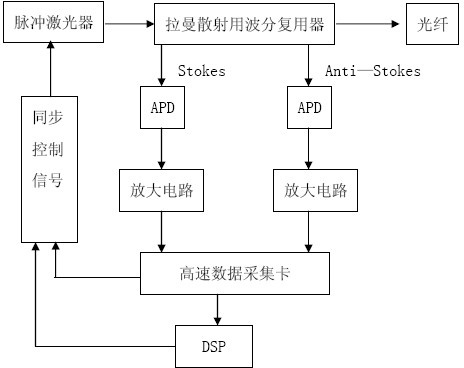

[0062] refer to Figure 1 ~ Figure 4 , an electronic current transformer fiber optic temperature compensator, the current transformer includes a current measurement coil and an energy harvesting coil set on the circuit to be tested, and the current measurement coil is sequentially connected to an integral amplification module and an A / D conversion module and the first E / O conversion module, the first E / O conversion module is connected to the first O / E conversion module through an optical fiber, the first O / E conversion module is connected to the current operation module, and the current operation module is connected synchronously A control module, the synchronization control module is connected to a second E / O conversion module, the second E / O conversion module is connected to a second O / E conversion module through an optical fiber, and the second O / E conversion module...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com