A multi-point type weighing equipment and a manufacturing method for the same

A manufacturing method and multi-point technology, applied to measuring devices, instruments, weighing, etc., can solve problems such as resistance value differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

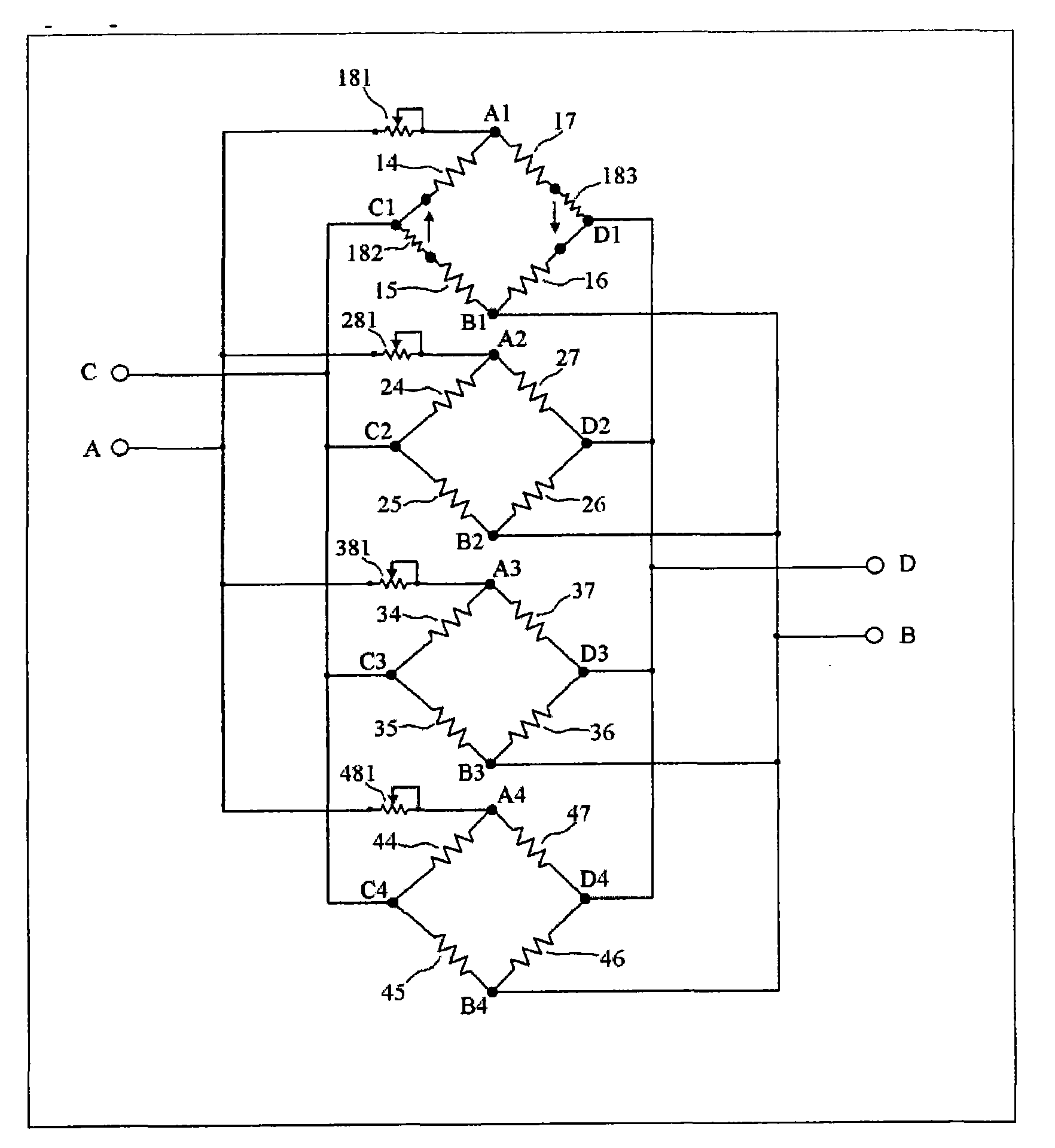

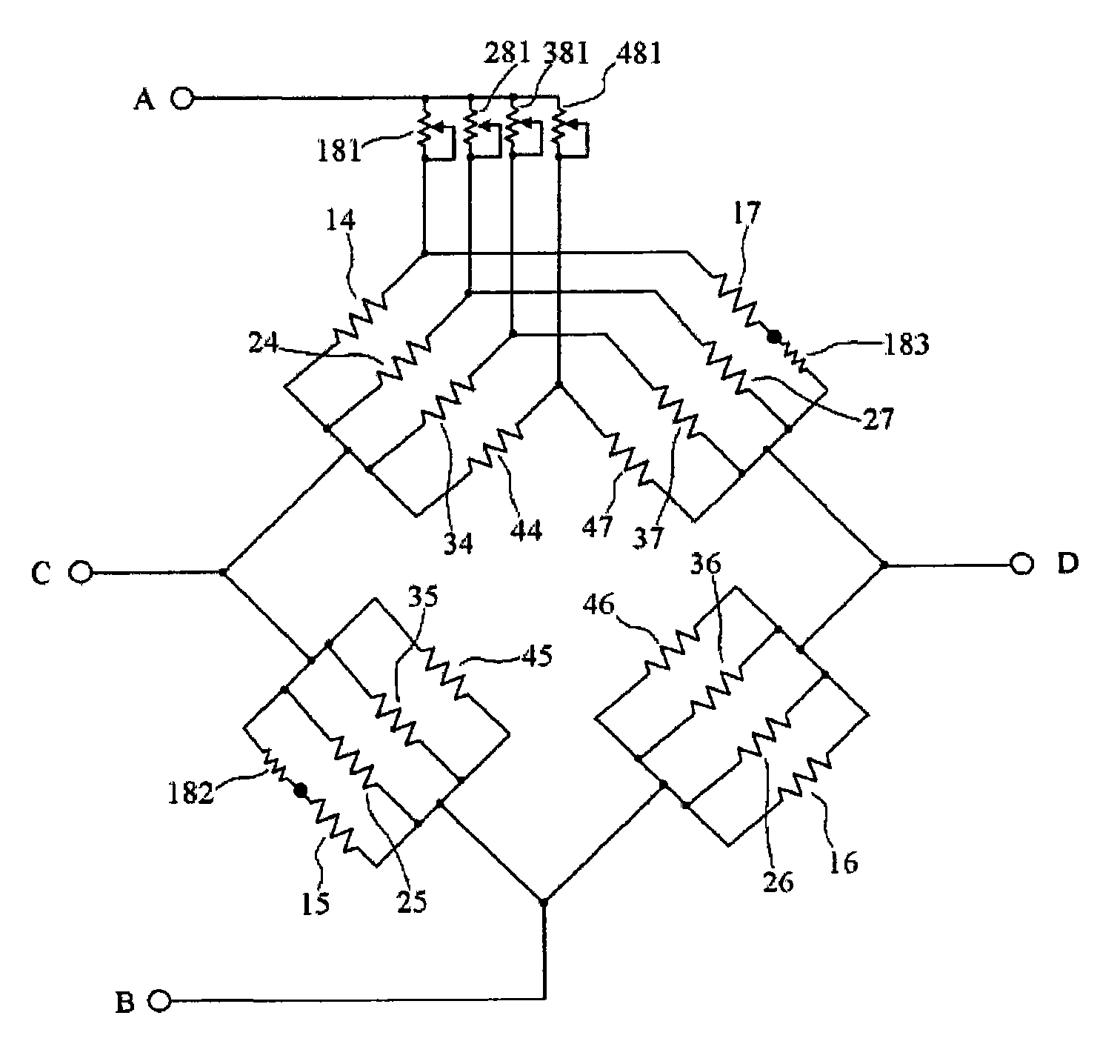

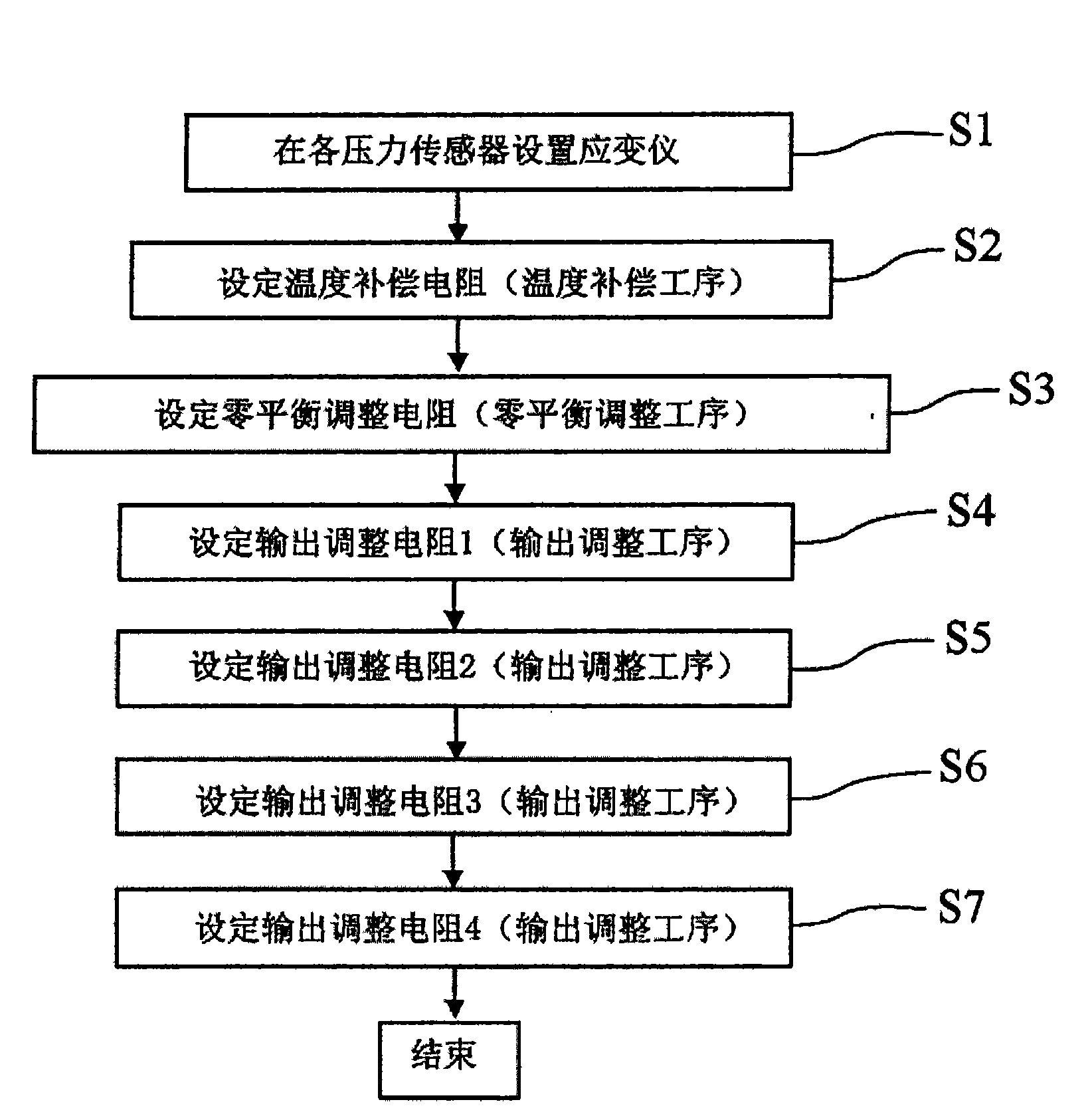

[0044]Hereinafter, a multi-point scale using four pressure sensors 10, 20, 30, 40 will be described as the best mode required for carrying out the present invention. Each pressure sensor has the same specification, and four strain gauges are provided on each pressure sensor. The warping body on each pressure sensor is strained by the load applied to each pressure sensor, and thus the resistance values of the four strain gauges fluctuate. Therefore, if a Wheatstone bridge circuit composed of these four strain gauges (resistors) is formed, the zero balance of the Wheatstone bridge circuit will be unbalanced due to the fluctuation of the resistance value, and an output voltage will be obtained.

[0045] The cross-sectional structure of each pressure sensor and Figure 4 Same as shown. That is to say, each pressure sensor is equipped with a crooked body, a platform, and a base of the same shape, such as Figure 4 As shown, there are 4 strain gauges on each crooked body. Here, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com