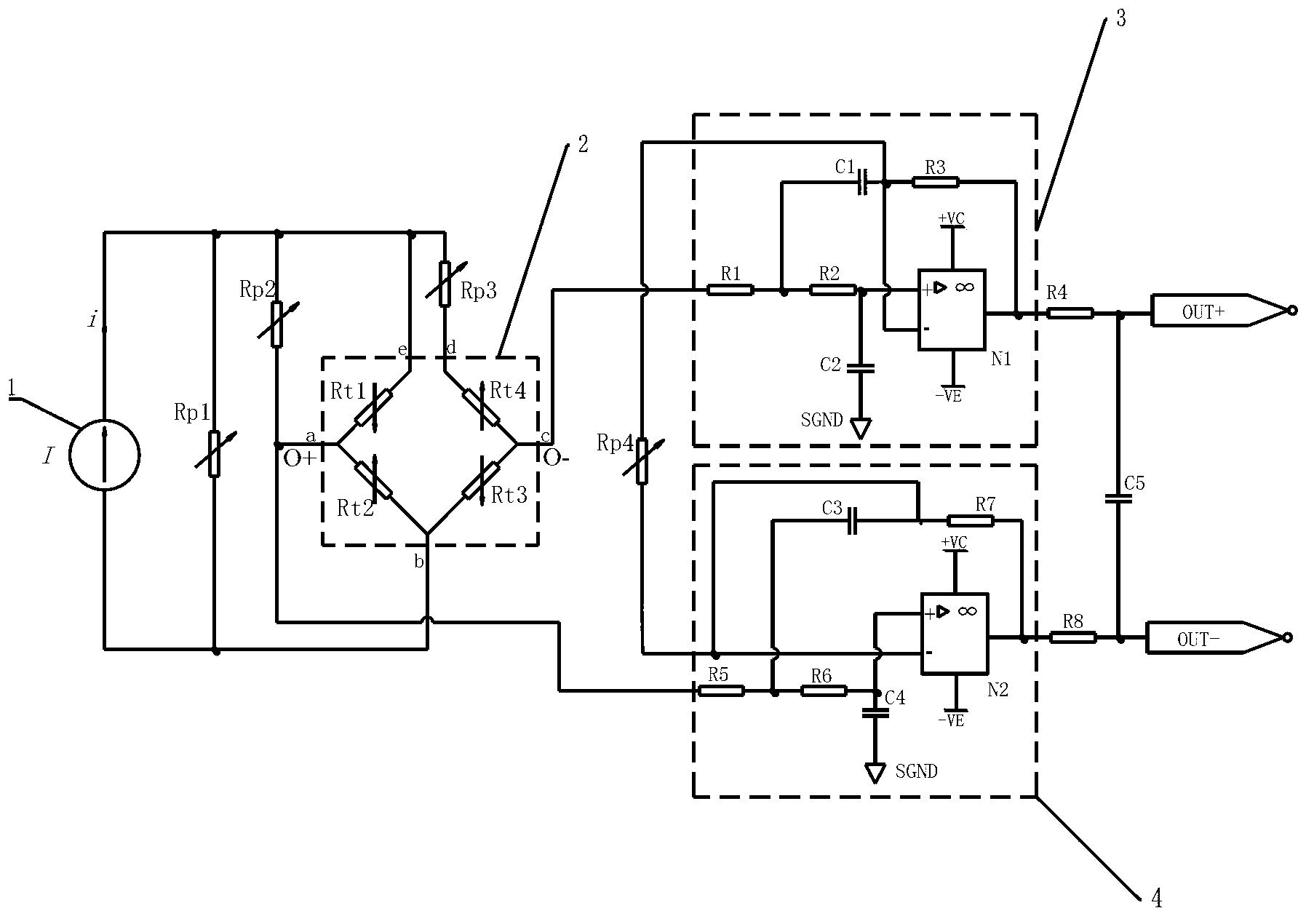

Circuit of high-accuracy pressure transmitter

A transmitter and high-precision technology, which is applied in the direction of fluid pressure measurement by changing the ohmic resistance, can solve the problems of low temperature compensation accuracy of thermistor, difficulty in meeting the requirements of pressure transmitters, and inability to meet the use requirements, etc. Achieve the effect of avoiding repeated debugging, reducing product cost and shortening production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0014] Embodiment: Take R1=R2=R5=R6=78.7kΩ, R3=R7=100kΩ, C1=C2=C3=C4=0.01μF, then the gain H of the second-order low-pass KRC active filter 0LP =1, cut-off frequency ω 0 =592.7Hz, quality factor Q≈0.707.

[0015] The invention combines the temperature transfer characteristics of the SOI pressure sensitive element and the differential amplifier circuit, and uses four groups of precision adjustment resistors to respectively complete the adjustment of the zero output voltage of the pressure transmitter, the adjustment of the full scale output voltage, the temperature compensation of the zero output voltage and the sensitivity Temperature compensation. And according to the characteristics of the differential amplifier circuit, two independent and symmetrical second-order low-pass KRC active filters are designed to filter the differential mode interference signal from the pressure sensitive components and ensure the accuracy of the differential output voltage signal of the pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com