Temperature control equipment in use for full automatic mechanical refrigerator

A technology of a temperature control device and a refrigerator, which is applied to household refrigerators, household refrigeration devices, coolers, etc., can solve problems such as food spoilage and failure to achieve the purpose of preservation, and achieve low cost, simple operation, and simple circuit structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

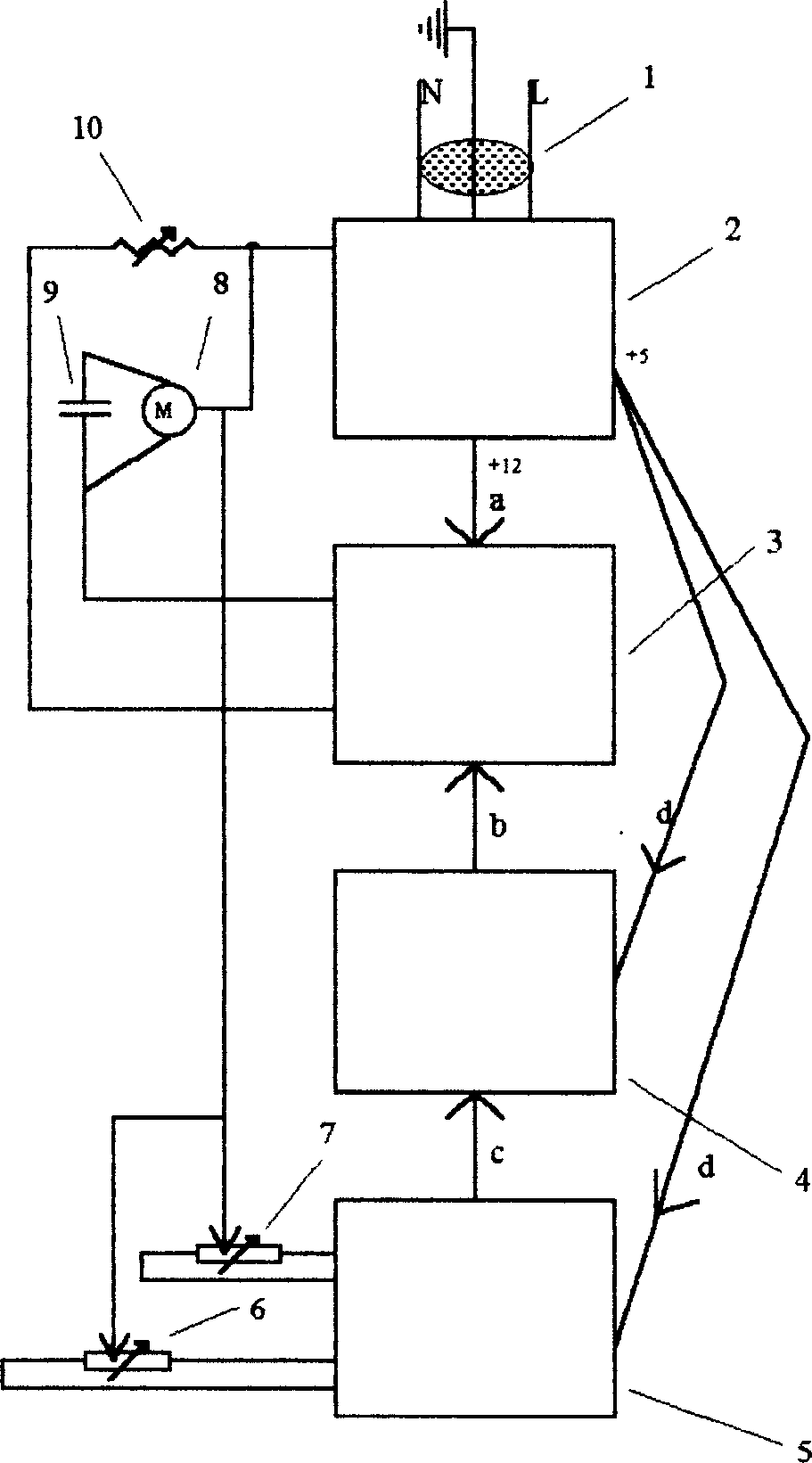

[0011] Such as figure 1 As shown, it consists of power plug 1, power supply unit 2, execution unit 3, control unit 4, signal input unit 5, refrigerating room temperature sensor 6, refrigerating evaporator temperature sensor 7, compressor 8, starter 9, temperature compensator 10 composition.

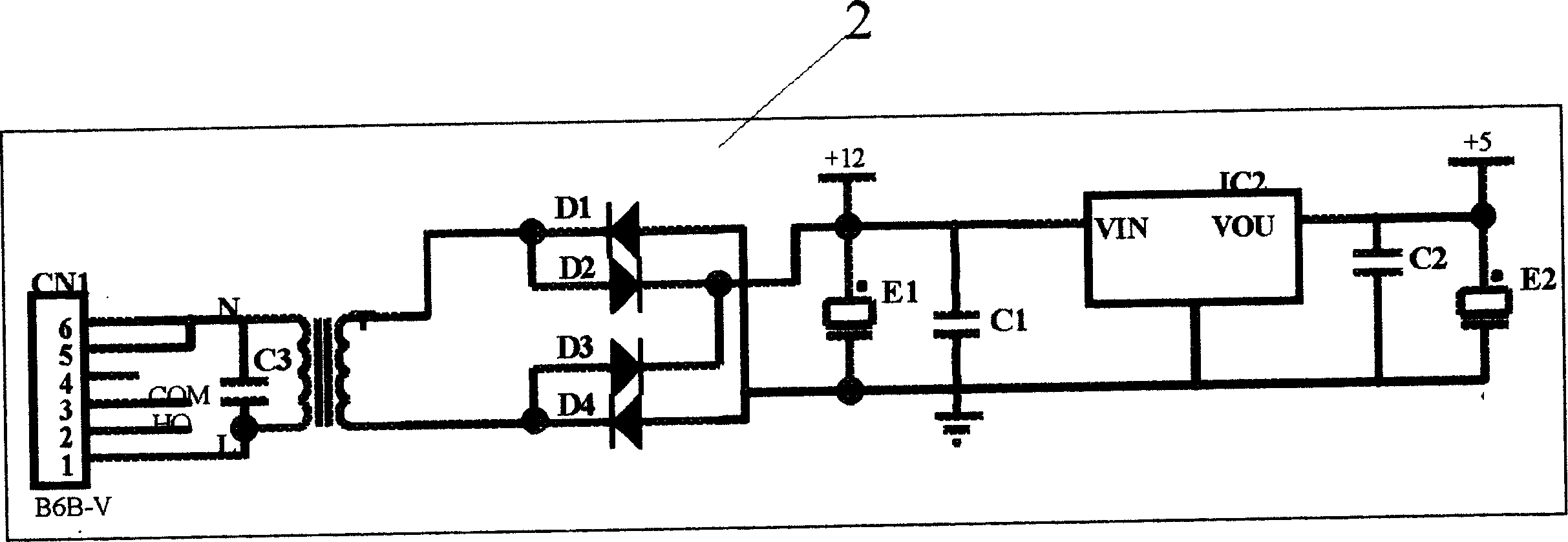

[0012] Such as figure 2 As shown, the circuit diagram of power supply unit 2 is composed of socket CN1, transformer T, diodes D1, D2, D3, D4, electrolytic capacitors E1, E2, ceramic capacitors C1, C2, and C3, AC220V / 50Hz mains power passes through transformer T, and After bridge rectification by diodes D1, D2, D3 and D4 and filtering by E1 and C1, +12V DC power is obtained for the execution unit 3 to work. The 12V DC power is stepped down by regulator IC2 and filtered by capacitors C2 and E2 to become +5V, for the control unit 4 and the signal input unit 5 to work. Among them, the role of the ceramic capacitor C1 is to filter out the clutter interference in the mains. The model of CN1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com